In a private house, the heating system is different from that installed in multi-apartment buildings. It may sound ridiculous, but the systems in private homes are much more complex in design. After all, they can include a warm floor, and radiators with a large number of connections. The heating system is pressurized with air only after final installation. In order to do this work, you need to use special equipment - automatic or manual. If there is one, then there will be no difficulties. But when pumping air or liquid into the system, it is necessary to take into account the fact that the time intervals are stipulated in the standards.

Crimping - what is it?

Pressure testing of the heating system with air in a private house is needed in order to check the tightness of all connections. Once you have done all the installation work, you need to carry out a test and commissioning. But if leaks are found, use of the system is prohibited. Pressure testing is a test of a heating system by injecting air or liquid into it under pressure, which will exceed the working one by about two times.

In private households, you need to carefully check all the contours of radiators, underfloor heating, as well as connections. Be sure to pay due attention to boilers, electric pumps, water heating boilers, if any, in the design of the system. The requirements for crimping will be discussed later in our article.

With the help of pressure testing, you can determine the ability of all elements and materials to withstand high pressure for a long time. In the event that the tests have ended successfully, you can start operating the equipment. If not, then the defects are eliminated and re-diagnosed.

Pressure equipment, pumps for crimping pipes

First of all, the pumps used for pressure testing differ in the design of the discharge mechanism.

On this basis, they are divided into the following groups:

- Reciprocating.

- Rotary vane.

- Membrane.

For crimping systems with a small volume, such as heating circuits in private homes, you can purchase an inexpensive and easy-to-maintain manual crimper.

With the help of such a device, the operator will be able to pump up to 3 liters of working fluid into the pipeline per minute. For a multi-storey building, such an option, of course, will be unacceptable, here you need a pressure operator with an electric or internal combustion engine.

The most popular is a hand-held pressure tester of domestic production UGO-30, designed for a maximum pressure of 30 atm. The volume of the cylinder is 36 cubic meters. cm, handle force - 2 kg. Supplied with a 16 liter tank.

For more serious tasks, two-stage hand pumps UGO-50 (up to 50 atm) and UGI-450 (up to 450 atm) are intended.

Among electrically driven pressure operators, units from the German company Rothenberger are known, for example, the self-priming RP PRO II model, which develops a pressure of 60 atm and a flow rate of 8 l / min. The drive power is 1.6 kW.

Ridgid products such as the 1460-E are also highly regarded. This pressure operator develops pressure up to 40 atm.

When is the crimping done?

All work is carried out strictly in accordance with SNIP-41-01-2003, which clearly indicates when, in what ways, the heating system is pressurized. In the same document, you will find everything about the requirements for ventilation and air conditioning. There are three cases where a test is required:

- Primary pressure testing - performed immediately after the completion of installation work.Diagnostics is performed before the pipes are embedded in the grooves. The underfloor heating system must also be accessible - it must not be poured before crimping. It should be noted that it is allowed to re-diagnose all contours after making the screed and sealing. In this case, you can get rid of the trouble.

- Periodic hydrotesting should be carried out every year before the start of the heating season and immediately after it. The purpose of the test is to pre-prepare the heating system for operation.

- An extraordinary test should be performed after each repair or long equipment downtime. Diagnostics is especially important in cases where water is drained from the system.

In all these cases, pressure testing will be a tool that will allow you to diagnose the system and identify all problem areas in the equipment in advance. Indeed, in the event that a leak appears, heating will not be very effective in the cold season.

Conditions for performing crimping

Test work is correctly performed if all the necessary requirements are met. For example, it is impossible to carry out third-party work on the test object, and testing must be supervised by the shift supervisor.

Pressure testing is carried out only according to the program approved by the chief engineer of the company. It defines: the order of actions of employees and the technological sequence of verification... They also outline safety measures for ongoing and ongoing work performed at adjacent facilities.

There should be no unauthorized people during pressure testing of the heating system, switching on or off the testing devices, only employees who take part in the test remain in place.

When work is carried out in adjacent areas, it is imperative to provide for reliable fencing and disconnection of test equipment.

Inspection of heaters and pipes may only be carried out at operating pressures. When the heating system is pressurized, the certificates are filled out to confirm the tightness.

Work rules

Now let's talk about what the requirements are for the procedure for pressing the heating system with air. All diagnostic work must be carried out in the warm season. It is possible to test heating at subzero temperatures, but only in emergency cases. At the same time, it is necessary to maintain the temperature inside the room above +5 degrees.

The tests can be considered successful if:

- During the diagnostics, you did not find any fogging of the seams, leaks in radiators, pipes, boilers, fittings, and other devices.

- Decrease in pressure for 5 minutes of diagnostics is no more than 0.2 bar.

- In the case of panel heating, the pressure on the pressure gauge did not drop by more than 0.1 bar in 15 minutes.

- A drop of no more than 0.5 bar in 10 minutes is allowed in hot water systems using metal pipes.

- As for plastic pipes, a fall is allowed within half an hour, but not more than 0.6 bar. During the next two hours, the drop should not exceed 0.2 bar.

- If tests are carried out with compressed air of panel and steam heating, the pressure drop in the first 5 minutes by more than 0.1 bar is not allowed.

Diagnostic methods

In total, according to SNIP-41-01-2003, two methods can be distinguished with the help of which it is allowed to carry out tests of the heating system:

- The water test is the main method by which all circuits are tested. In this case, water must be pumped into the lower part of the pipes through the tap. It is allowed to pump liquid both with an automatic and a manual pump-pressure operator. The advantage of this method is that it is very easy to carry out all the work, and the efficiency of detecting leaks at altitude.The fact is that traces of liquid will immediately appear on the pipes.

- Testing with air is not a very effective method as it is difficult to detect leaks. But it is allowed to use this technique at negative temperatures - after all, the air will not freeze. A compressor is used to force air into the system. It is connected with an adapter to the pipeline. In order to find the leak, you need to listen. Once you find an approximate location for the leak, use a soap solution.

Test pressure

According to SNIP 3-05-01-85, which was replaced in 2003, pressure testing must be carried out in accordance with the rules. When carrying out work in apartment buildings, it is necessary that:

- The pressure was more than 1 MPa (this is 10 bar) - for hot water supply systems and heating circuits with heaters.

- At least 10 bar for panel and convector heating systems.

- At least 6 bar for circuits with pressed steel or cast iron radiators.

- The pressure for hot water supply must be higher than the working one and from above another 5 bar (but not more than 10 bar).

If panel heating and heat exchangers are used, the head should not have a pressure greater than the maximum permissible for the devices. In the event that you are conducting an air test in a steam or panel heating, you need to check the pipes that fit the ventilation equipment. The air must have a pressure of 1 bar.

Crimping procedure

This method of checking the heating system involves the implementation of hydraulic tests:

Thus, it is possible to identify leaks, which indicate a depressurization of the network.

Before testing the heating system with plugs, isolate the heating system from the water supply, visually assess the reliability of all connections, and also check the functionality and condition of the shut-off valves.

After that, the expansion tank and the boiler are turned off for flushing radiators, pipelines from various deposits, debris and dust.

During the hydraulic test, the heating system is filled with water, but when performing air tests, this is not done, but simply the compressor is connected to the drain valve. Then the pressure is increased to the required value, and its indicators are monitored with a pressure gauge. If there are no changes, the tightness is good, therefore, the system can be put into operation.

When the pressure begins to decrease beyond the allowable value, means there are defects... It is not difficult to find leaks in a filled system. But in order to identify damage during the air test, a soap solution should be applied to all joints and joints.

An air pressure test takes at least 20 hours, and a hydraulic test takes 1 hour.

Having corrected the identified defects, the procedure is repeated again, and this has to be done until there is good tightness achieved... After carrying out these works, the certificates of pressure testing of heating systems are filled out.

Checking the heating network with air, as a rule, is carried out if it is impossible to fill it with water, or when working at low temperatures, because the liquid can simply freeze.

Test procedure

According to the rules for the technical operation of thermal devices, tests should be carried out in the following sequence:

- The circuit is filled with water using a pressure tester. The temperature of the liquid should be around 45 degrees. The air must be vented through special vents.

- Further, water is pumped with a pressure for at least 10 minutes. During this time, you need to visually inspect all seams, pipe joints, connection of all equipment, fittings.

- After that, the pressure can be brought to maximum pressure and held for 10 minutes.If the pipes are made of polymeric materials, then the tests should be carried out for at least half an hour.

- In the event that the pressure does not change during the tests, then it can be judged that there are no defects at all.

You can complete the tests and start operating the equipment directly.

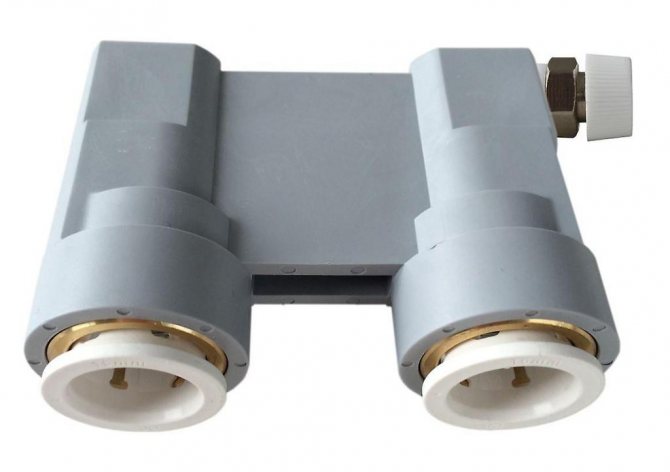

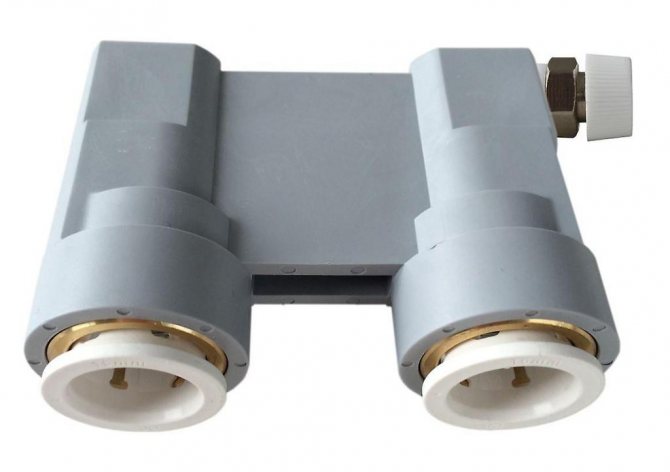

Manual pressure pump

The so-called manual pressure tester allows you to accurately identify damaged areas in heating and other engineering systems. With the help of this equipment, hermetic containers, vacuum devices, and gas pipelines are checked. According to their design features, hand pumps for crimping the heating system are divided into:

- piston;

- membrane;

- lamellar and rotary.

Each of these types has its own strengths and weaknesses. The hand-operated pipeline crimping machine includes a pressure gauge, durable high pressure hoses, filters, fuses and a reservoir. The cost of the specified equipment will depend on its capacity and other technical characteristics. During the tests, the pump pumps water or oil with mineral additives into the circuit

Important! When choosing a device, pay attention to the maximum allowable pressure, as well as the period of time during which the device can withstand the applied load. The power of a hydraulic pipe press is considered to be of secondary importance.

What test tool is needed?

Now let's talk about what kind of crimping equipment is used during the work. To perform hydraulic tests, you need to use a special design of pumps (they are called pressure operators). You can find two modifications - electric and manual.

Hand pumps are a rectangular cuvette, water is poured into it, which is then pumped into the heating system. A plunger-type pump is placed on its side, with a handle on top of it. It is with its help that the pump plunger is set in motion. There are pressure gauges on the body, with their help the pressure of the liquid pumped into the system is monitored. One shut-off valve allows water to be cut off after pumping into the pipes is complete. The second valve allows the liquid to be drained from the tank.

Plunger pumps work in exactly the same way as simple piston pumps that are used to inflate bicycle or car tubes. But there is also a difference - in the design of the plunger pump there is a cylindrical steel piston, which moves in the housing with a minimum clearance. It is with the help of this that it turns out to pump liquid into the heating system with a pressure of up to 60 bar.

The main disadvantage of manual mechanisms is that it takes a long time to carry out crimping work. Moreover, the test time depends on the length of the heating circuits. Sometimes it takes several hours to fill it completely. Imagine how much energy you will spend to pull the handle.

It is with the aim of reducing costs and automating the process that electric pumps are used by specialists. They work according to the same principle as manual ones, only muscle strength is replaced by an electric drive. The good thing about automatic systems is that you can set the desired level of injection pressure. As soon as it is reached, all equipment is turned off.

Automatic devices can pump liquid at a pressure of 40-100 bar. But there are also industrial designs that are capable of creating pressures up to 1000 bar.

Please note that the Ministry of Energy establishes requirements according to which it is necessary to use pressure gauges for control only of the spring type, their accuracy class must be 1.5. The circumference of the body must be more than 160 mm.The scale must be designed to measure the pressure, the value of which is not less than 4/3 of the minimum, the graduation is less than 0.1 bar.

Heating system testing equipment

Most often, a pressure tester is used to perform a hydraulic check. It is connected to the circuit to regulate the pressure in the pipes.

A huge number of local heating networks in private buildings does not need high pressure, so a manual pressure operator will be enough. In other cases, it is better to use an electric pump.

Hand-held heating systems testing devices develop a force of up to 60 bar and more. Moreover, this is enough to check the integrity of the system even in a five-story building.

The main advantages of hand pumps:

- Reasonable cost, which makes them affordable for many consumers;

- Light weight and dimensions of hand presses. Such devices are convenient to use not only for personal purposes, but also for professional use;

- Long service life without failures and breakdowns. The device is so simple that there is nothing to break in it;

- Suitable for medium and small heating equipment.

Branched and large circuits in large areas, multi-storey buildings and industrial facilities are checked only with electrical devices. They are capable of pumping water under very high pressure, which is unattainable for manual devices. Equip them with a self-priming pump.

Electric pumps develop a force of up to 500 bar. These units, as a rule, are built into the line or connected to any hole. Basically, the hose is connected to the tap, through which the pipe was filled with a coolant.

Performing a heating pressure test is a very complex technological procedure. That is why you should not do it yourself, it is better to use the services of professional teams.

(2 votes, average: 5 out of 5)

Brief excerpts from regulatory documents, rules and SNiP for heating pressure testing.

Analyzing the statistics of the questions you ask and realizing that many questions about the pressure testing of the heating system for the majority of our audience remain incomprehensible to you, we decided to make a selection from the necessary points and the Pressure Testing Rules approved by the Ministry of Fuel and Energy of the Russian Federation and SNiP.

All SNiP and rules contain information on more than 100 pages, which is sometimes difficult to understand, therefore, in order to facilitate the task for you, so that you can look at, and, if necessary, refer to the necessary paragraph of a specific regulatory document, we have processed the applicable regulatory documents and in a brief form posted on the site. Explanations to the Rules and SNiP can be found in the article: "Norms and rules for pressure testing the heating system"

Varieties of testing and pressure testing the system

As we were able to find out, if the tightness of the heating system is violated, heat transfer is significantly reduced. And the most important thing is that the working fluid is lost and it has to be constantly added. The norms that we talked about above must be taken into account when servicing heating systems by utilities and government organizations. As for private houses, it is not at all necessary to adhere to, for example, SNIP 3-05-01-85.

Pressure testing should be carried out after the work is handed over to the customer. The tests must be carried out prior to commissioning. Further tests are recommended to be repeated every 5 years. When pressure testing the heating system with air, what pressure should be maintained? As with the liquid method, the working pressure must be doubled.

To carry out diagnostics, you do not need to have special knowledge and skills, so anyone can do it.There is no point in purchasing an electric or manual unit, since the most primitive will cost you at least $ 100. If you wish, you can rent a device, in big cities this opportunity is often provided by individuals or companies.

In the event that you do not want to take risks and conduct tests on your own, you can hire specialists. Upon completion of the procedure, they will give you an act of crimping the heating system, which will indicate how and under what conditions the work was carried out. But the cost of the services of such specialists is quite high - you will have to pay about 2,000 rubles for each hour.

Air and water pressure testing - what is it?

The essence of pressure testing consists in filling a certain system with a closed volume - a pipeline, container, machine or mechanism - or its isolated section with an environment whose pressure is 2 - 3 times higher than the operating one and almost corresponds to the maximum permissible value (the value of the test pressure for each particular case is set by the appropriate norms).

If the object withstands this test, it is considered serviceable.

Otherwise, the places where the system has leaked are identified and repaired.

To create the required pressure, either a special pump for crimping pipelines, the so-called pressure tester, or a standard one, for example, a circulation pump in a centralized heating system, is used.

Water is usually used as a working medium, but if, for one reason or another, its entry outside the tested system is unacceptable, pressure testing is carried out with air. In this case, the leaks are more difficult to locate.

Pressure testing is a fairly serious event and should be carried out by a specially trained employee who has passed certification. For utilities and industrial enterprises, this rule is mandatory.

Upon completion of the procedure, the Act of hydro-pneumatic testing of the system (pressure testing of the pipeline) is signed, indicating the date, pressure value, holding time and other information.

For private housing, the decision is in the hands of the homeowner. Many undertake crimping on their own, but it is better, nevertheless, to entrust this work to a professional.

Tests in apartment buildings

In apartment buildings, air pressure testing of the heating system can also be carried out. We will now consider the necessary conditions for the work. In the event that you find water leaks, they need to be repaired. But often, without high pressure in the system, it is quite difficult to find thin cracks in the seams. In apartment buildings, it is necessary to carry out pressure testing of both individual apartments and all highways.

You need to complete the preparation:

- Inspect all locking fittings. If the valves are made of cast iron, then be sure to replace the glands on them. Replace gaskets on flange connections. All bolts that have lost their original appearance must also be replaced. Be sure to install new pressure gauges, it is recommended to send the old ones for verification in order to decide whether they can be further used for measurements.

- Visually inspect all pipes and fittings to identify even minor defects and damage. If you find problem areas, you need to quickly repair them.

- Check the condition of the thermal insulation material on the highways laid in the basement and between floors.

After preparation, you can proceed to directly pressure testing:

- Fill the entire circuit with water of low hardness (to prevent limescale build-up). It is better to pump it into the system, of course, with an electric pump. Pressure - 6-10 bar. In a container with liquid, you need to lower the hoses - drain and supply. Next, connect the pump to the heating network and turn on the pressure operator. It is necessary to set the pressure in advance.

- Timed half an hour - during this period, the pressure should remain almost at the same level.In the event that the pressure does not drop, the test can be considered completed. You can fill the system with working fluid and start active operation.

- If the pressure drops, then there are defects in the heating system. The procedure for pressure testing the heating system with air is about the same, but you will have to use a soapy solution - without it, it is difficult to find a leak. As soon as you find defects, you can proceed with the evacuation of the system and repair. After that, you carry out a repeated diagnosis of the entire heating.

The inlet assembly is carried out in a similar way - the pressure in this case should be about 10 bar.

Preparatory measures for pressure testing

[sticky-ad id = 13532]

Before starting work on performing crimping, you must perform the following steps:

- The tested pipeline system is inspected for obvious defects (missing elements, rusted areas, etc.). The revealed violations are eliminated. If the system is filled with any substance that cannot be used for testing, such as a heating medium in the heating system, it must be drained.

- Further, according to the rules, the pipeline is flushed. This operation will remove scale, rust, organic and inorganic deposits from pipes. Flushing can be done in various ways, some of which require a compressor. According to the rules, upon completion of this procedure, the quality of its implementation should be checked by cutting a 0.5 m long section at an arbitrary place in the pipeline and assessing the condition of its inner surface.

- The preparatory stage ends with the installation of a check valve and a pressure gauge, if these are not part of the injection device. A check valve is required to keep the process fluid in the system.

When pressure testing the heating systems of apartment buildings, the preparation of the heating unit is carried out separately from the entire system and after it. This is due to the fact that this unit is being tested with a higher pressure value.

Testing in private homes

It is worth noting that in autonomous heating systems, which are used in private houses, the pressure is usually no more than 2 bar. Therefore, in order to carry out the tests, it is necessary to pump liquid into the system at a pressure of 3.5-4 bar. It is allowed to use both the air method of pressure testing and the hydraulic one.

The sequence of the test work:

- First, drain the coolant and pump pressurized water into the heating circuit. It is imperative to add additives that are used when flushing the system. The circuit is filled with water through the branch pipe located in the lower part.

- The filters must be thoroughly cleaned before flushing. It is recommended to flush at least once a year.

- Next, drain the flushing fluid and fill the system with clean fluid. You can skip this step if you allow the flushing fluid to cool to 45 degrees. After that, it is necessary to pump in more water with the help of a pressure testing device in order to bring its pressure to 4 bar.

- If you are using a manual pressure tester, fill the tank with liquid, then connect it to the drain pipe of the heating system. Next, you need to open the taps and pump water. This is done simply - you need to raise and lower the handle of the device. As soon as the required pressure is reached, close all valves.

- Leave the entire system filled for about half an hour and monitor the pressure carefully. In the event that a drop of less than 0.2 bar occurs over a period of 30 minutes, it can be said that there are no leaks. If the pressure drop is too large, then it is necessary to find and eliminate defects.

Remember that it is imperative to observe the permissible pressure standards when performing pressure testing. It should also be noted that there is a high probability of leaks inside the walls.In this case, you will need a heat radiation meter. Only he is able to detect the presence of hot liquid leaks in the walls or under the floor.

Some may ask the question: "What pressure should be maintained when pressing the heating system with air?" Air is not a liquid, therefore, it is allowed to inject about 2 bar into a system whose length is no more than 10 meters. But it all depends on the specific heating system, its length and volume. If it is relatively small, then the test pressure can be reduced.