A kind of heat insulator

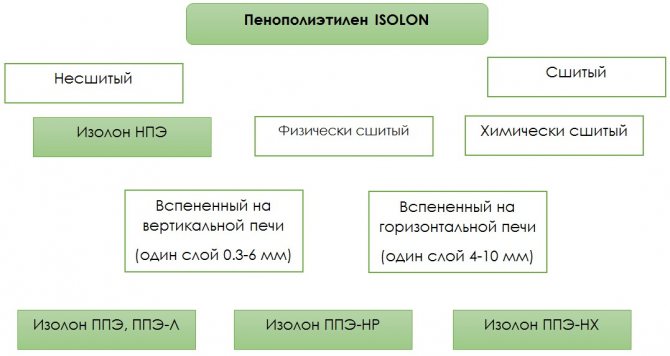

Depending on the manufacturing technology, there are main types of isolon and its varieties.

Insulation can be of two types: stitched and unstitched

... A stitched heat insulator is designated as NPE, an uncrosslinked one is designated as PPE.

Based on the structural features of the filler, the insulation is divided for the following brands:

- PPE-500 and 500L. The basis is polyethylene, cross-linked in a vertical oven

in a physical way. The finished sample has a cross-linked structure. - PPE-500NR. A similar heat insulator, but made in a horizontal oven.

- PPE-500-300. It is produced in a horizontal furnace by foaming the polymer mass with the addition of chemical components.

- 100 and 100L (old name - NPE). Manufactured from extruded polyester.

Depending on the mounting option

, heat insulators are divided into the following types:

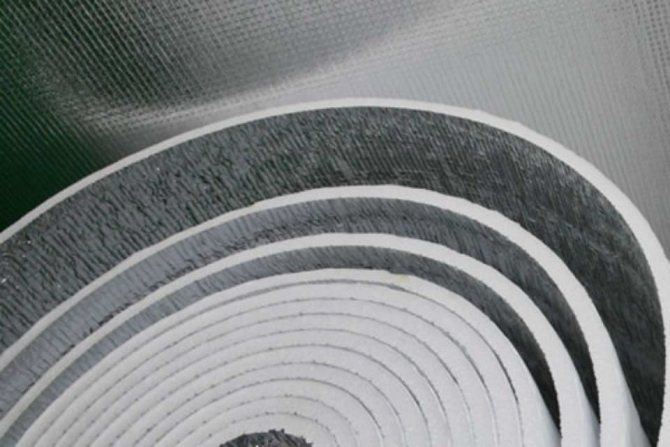

- Rolled. It is produced in rolls, from 50 to 200 meters long, from 0.8 to 1.5 meters wide. The height ranges from 0.2 to 1.0 centimeters.

- Sheet. Produced in slabs. The dimensions of the slabs can be of two types: 1.0x2.0 meters or 1.4x2.0 meters. Isolon is characterized by its thickness, which ranges from 1.5 to 10.0 centimeters.

- Foiled. It can be produced in slabs and rolls. Foiled Izolon can have one or two foil side

... The letter L in the marking means that the foil sides are connected to the insulation by lamination. Available in rolls. Has dimensions: length from 80 to 300 meters, width 1.2 meters. Insulation thickness from 1.0 to 10.0 centimeters. - Tape. An adhesive composition is applied to the surface, protected from drying with a special sticker. Before gluing the insulation, the sticker must be removed and the strip must be pressed in the right place. The adhesive composition can be on one or on both sides of the heat insulator. Available in rolls, 10, 20 or 30 meters long, 1.0 meters wide.

For gluing boards and rolls butt to each other, available special glue.

It can be Quick-Bond, Contact Acrol or Neoprene spray.

Before you start gluing Isolon, you need to familiarize yourself with the recommendations that are indicated on the package with the glue.

Popular isolon manufacturers are Pereslavl-Zalessky "Lit Plant" and Izhevsk Plastics Plant.

Depending on the type and size, its price fluctuates. So, rolled insulation costs from 110 to 500 rubles per square meter. A heat insulator in slabs will cost from 315 to 1015 rubles per square meter.

What is roll foil insulation

Foiled isolon PPE deserves special attention. It is produced by manufacturers in various densities and thicknesses in the form of strips, sheets, rolls. With the application of a special layer of glue, self-adhesive foil isolon is extremely easy to use. Non-self-adhesive isolon can be bought, as a rule, in rolls.

To understand the advantages of foil insulation and find out its basic properties, you must first remember what kind of material it is. Then it will be possible to deal with all its nuances and specifics of operation. Judging by the term "folgoizolon", we can say that this is the same isolon, which has a metallized layer - ordinary foil.

This material is made from expanded polypropylene or from polyethylene raw materials. For this reason, there are two modifications of this insulation on the market, which are abbreviated as NPE and PPE.However, their main indicators practically do not differ, so we will not consider these products separately, but we will talk about insulation in general terms.

Industrial companies offer four main material modifications, based on the applied area:

- Izolon A - we can say the standard version, with a one-sided foil layer with a thickness of 3 to 10 mm.

- Izolon B is two-layer, that is, the foil is applied on both sides of the expanded polypropylene, the design is more durable, but, accordingly, more expensive.

- Izolon S - self-adhesive foil isolon, has a consistently high demand in the device for vibration and noise isolation of a car. Insulation and sound insulation of a car with isolon is considered not a bad way, especially in combination with various mastics. Working with such material does not require complex skills, and any adult man can do it.

- Isolon ALP isolon foil self-adhesive, additionally has a layer of polyethylene film up to 3 mm, this material becomes extremely durable, it can often be found when installing warm water floors.

We suggest that you familiarize yourself with the Dimensions of the shelves in the bath - All about the bath

It is a combined material for insulation of walls, floors and ceilings, consisting of several layers:

- Insulation made from familiar materials.

- A layer of foil.

The material is rolled, therefore it has a relatively small sheet thickness. How does heat preservation occur?

- A thin working layer delays the penetration of cold air from the outside;

- The foil reflects the heated air into the room.

Characteristics

Depending on the type of heat insulator, its specifications

may vary slightly. But they remain within the limits of the indicators indicated in the table.

| Parameter | unit of measurement | The quantity |

| Density of the sheet | kg / cubic meter | 25-40 |

| Water absorption | % | Up to 1 |

| Compression strength | MPa | 0.2-0.3 |

| Operating temperature | ° C | -70 to +90 |

| Heat reflection | % | 98 |

| Thermal conductivity | W / mS | 0,031-0,037 |

| Vapor permeability | mg / mhPa | 0,001 |

| Sound attenuation | % | 50-70 |

| Heat capacity | kj | 1.90-1.95 |

| Flammability group | G2, G3, G4 | |

| Toxicity group | T3 |

Isoplen is a paper-based isolon

Isoplen is a polyvinyl chloride finishing and insulation material made on a paper base. On sale, it can be monochromatic and colored, containing a wide variety of colors. It is also divided into a product with a smooth and embossed surface, which in turn can be glossy or matte. The material is produced in the form of rolls, which have a length of 10, 12 and 18 meters. Their width varies between 50, 60 and 75 cm. The thickness is 0.3 mm.

Isoplen is used mainly for wall decoration for rooms where there is a normal temperature and humidity environment and acceptable operating conditions for it.

Isoplen is usually glued to flat concrete, painted or plastered wood, or other surfaces.

It is customary to use as an adhesive:

- Bustilat;

- Decon;

- Humilax;

- PVA.

During operation, it is allowed to wash isoplen with water, with the addition of a synthetic detergent or soap.

Advantages and disadvantages

The thermal insulation properties of a thermal insulator are complemented by many of its advantages. The main ones are:

- Low thermal conductivity. With a high level of heat retention, it is not recommended to use ordinary isolon as an independent insulation. With high efficiency you can use Isolon foil

. - Good sound absorption. Its sound-reducing characteristics allow it to be used as a sound insulator capable of damping a sound wave.

- Resistant to chemical and antiseptic agents. Izolon has a composition that resists corrosion and decay.

It is not affected by mold and fungal diseases.Withstands contact with antiseptics and many chemical compounds. - High fire resistance. The heat insulator belongs to the class of moderately flammable and moderately flammable materials. The insulation burns strongly or not depends on the strength of the fire effect. But the material ignites very badly and cannot be a source of fire. In case of fire, it emits a lot poisonous smoke.

- Environmental Safety. The heat insulator is made of environmentally friendly materials. Does not emit substances harmful to humans and the environment.

- Considerable strength. The heat insulator can break under mechanical stress or puncture, but has good compressive strength. To avoid accidental rupture of the surface, it is sufficient to install decorative cladding.

- Low vapor permeability. The heat insulator has technical characteristics that do not allow air to pass through. If it is necessary to equip a room with high humidity with material, it is necessary to consider the installation of a ventilation system.

Lack of hygroscopicity. Due to its water-repellent properties, the material will be used as a waterproofing agent. When installing a roof, the material may protrude insulation and waterproofing

at the same time.- Ease of use. The material is flexible and elastic, has a low weight. It can be easily cut with a construction knife or scissors and installed by yourself.

- Long period of operation. After installation, the material can serve about 90 years old.

- Reusable. The heat insulator can be dismantled and installed in a different place. At the same time, the isolon retains its properties and characteristics, and the material restores its shape after the termination of mechanical efforts.

- Significant savings. When using the material for thermal insulation of the room, saving on heat loss is 35-40%

.

Along with numerous positive qualities, there are some cons

... They are as follows:

- Do not apply wallpaper or plaster to the insulation.

- The aluminum coating can easily break with minor mechanical stress.

- The heat insulator has high cost

.

Production stages

Isolone production process is divided into three main stages:

- Mixing. One container combines polyethylene in granules, a foaming agent and "crosslinking" agents, that is, substances that irreversibly transform polymer molecules.

- Extrusion. The polymer mass is heated and melted. In parallel with this, future isolon sheets are being formed.

- Foaming. The sheets are sent to the oven on a conveyor net. Under the influence of high temperature, the foaming agent is activated, and many pores are formed in the structure of the material.

In the production of foil-clad isolon, at the last stage, a thin aluminum foil is glued to the foamed polyethylene layer by lamination.

Foil isolon in a roll

Scope of use

The heat insulator has found application in many industries and agriculture. It is mainly used in the construction of buildings and structures. It is applied to perform following works:

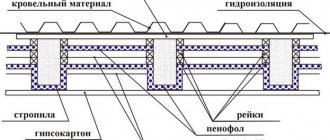

- Thermal insulation of concrete and cement floors, walls, roofs, floors.

- Equipment for foundations, basements and underground premises.

- Thermal insulation of secondary, ancillary, residential and non-residential

premises. - Equipment for trunk and communication pipelines.

- Compensating, shock-resistant lining of sports equipment and surfaces.

- Soundproof lining on all types of buildings and structures.

- Steam and thermal protection of buildings with high air humidity.

- Insulation of ventilation shafts, gas and water pipelines, other engineering systems.

- Protection of household appliances and refrigeration equipment, vehicles of all types.

- Heat, steam and moisture protection of commercial and warehouse buildings.

- Manufacturing of special clothes and shoes.

Insulation tools and materials

Carrying out work on the insulation of the building requires a certain material and tools.

The list of materials includes:

- Izolon.

- Mineral wool.

- Plywood sheets.

- Drywall sheets.

- Flooring.

- Metallized tape and glue.

- Wooden bars.

- Ceiling suspensions.

From tools

to complete the work you will need:

- A hammer.

- Screwdriver or screwdrivers.

- Construction knife.

- Construction stapler.

- Galvanized nails and screws.

- Measuring tool.

Insulation of the floor with isolon

Floor insulation can be done in two ways. Let's consider both options. The first method involves the presence of a second insulation and waterproofing agent. It is of higher quality, but the cost of such a floor will be somewhat more expensive. The first option provides performance of the following works:

- The sub floor must be cleaned of dust and dirt, covered with a waterproofing film. The strips of the film are laid with an overlap with one strip overlapping another by 8-10 cm. The joining place of the strips is closed construction tape.

- Using corners and dowels, it is necessary to install the bars on the floor. It is recommended to make the bars with a height equal to the thickness of the mineral wool slab. The distance between the blocks should be 3-5 cm less than the width of the rock wool slab. In this case, the mineral wool slab will fit snugly against the walls of the bar and cover the entire laying area.

- On top of the blocks with mineral wool, it is necessary to lay insulation isolon. The seams of the heat insulator are glued with metallized tape. Laying should be done with the foil side inside the room.

The heat from the room will be reflected from the foil and the thermal conductivity of the laid isolon will be minimal. It is recommended to fasten the insulation to the rails with galvanized nails. - A row of rails must be installed on top, perpendicular to the bottom row. The slats should be between 3-5 cm in height. This will create the necessary ventilation space under the floor. The installation spacing of the slats is recommended from 40 to 60 cm, depending on the width of the floorboard.

- Plywood sheets are laid on the slats. Fastening is carried out to the rails using galvanized nails or screws.

- The floor covering is laid on top of the plywood. It can be a board, laminate, parquet.

The second method does not require a second insulation and waterproofing agent. It includes the following works:

- Wooden floor covering is necessary clean from dust and dirt

. - Lay the material in one layer over the entire floor area. The seams of the heat insulator are glued with metallized tape. Laying should be done with the foil side inside the room.

- Lay plywood sheets on the insulation. Fastening of sheets is carried out through the insulation to the floor using galvanized nails or self-tapping screws.

- The floor covering is laid on top of the plywood.

Installation features

PPE is often used along with other types of thermal insulation, for example, with mineral wool. If you are interested in whether it is possible to insulate the floor with an isolon, then the answer is yes. This is a versatile material that is used for interior and exterior wall decoration, and it is also laid on the floor, ceilings, and attic.

Insulation of the floor with isolon is carried out according to the scheme:

- A rough base is being prepared: the old coating is dismantled, the floor is leveled.

- Considering that izolon is characterized by increased waterproofing properties, with internal insulation there is no need to lay an additional layer of moisture protection. However, according to the rules, the waterproofing is still laid on the rough base before installing the insulation.

- From above, the isolon is covered with plastic wrap or membrane material. This is necessary because the insulation does not absorb moisture.If there is no waterproofing under the linoleum, the liquid can negatively affect the finishing materials.

- Izolon is not installed on the walls, however, it is still recommended to protect the lower sections of the supporting structures. For this, a waterproofing film is laid, and it should go onto all vertical surfaces.

- If isolon is used as a heater, then a special tape is prepared to fix it. The coating must ensure the tightness of the heat-insulating “pie”.

When using polyethylene foam, installation is greatly simplified. We must not forget that the foil-clad isolon must be correctly laid: the reflective layer is placed on the side where it is necessary to reduce the rate of heat outflow.

Insulation of walls with isolon

Thermal insulation of walls is carried out according to the same options and according to the same principle as floor insulation.

So that the sheets of material do not fall and do not create discomfort in work, their laying is carried out according to the principle from the bottom up. For fastening mineral wool, on the rails are installed ceiling hangers

... They are sold in a hardware store and hold the mineral filler well. If desired, you can use special glue. The preliminary fastening of the isolon can be carried out using

construction stapler.

Note!

For finishing and decorative work, plywood sheets can be replaced with drywall sheets.

Areas of use

Sound-insulating sealing layer between building structures and guiding profiles of plasterboard partitions. Before installation, the soundproofing tape is applied with the self-adhesive side to the guide profile.

According to the profile width, the sound insulation tape is offered in four versions:

UD 27 width 30 mm

UW 50 / CW 50 width 50 mm

W 50 / CW 75 width 70 mm

UW 100 / CW 100 width 90 mm