Home comfort is largely due to the microclimate that prevails in the house. However, the central heating system does not always allow creating the desired conditions, therefore, often the best solution is a warm floor system, which effectively copes with its task even in severe cold, providing fast and high-quality heating. The room warms up most evenly, in apartments on the ground floors this is a real salvation. In this article, you will learn how to properly connect a water-heated floor to central heating using a plate heat exchanger.

The device of the heat exchanger as an intermediary

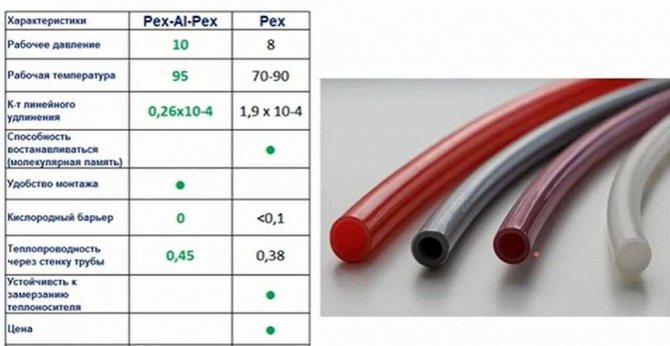

But first, let's take a closer look at exactly how it works. So, heat exchangers of this type are divided into non-separable (brazed) and collapsible, they are made from a variety of materials. Steel and brass are suitable for use under high pressure. Copper versions are used with great success in the beer industry, they are convenient for sharp cooling of beer, there is no high pressure, but a good rate of thermal conductivity is needed, which this non-ferrous metal possesses. Therefore, this heat exchanger is suitable for connecting a hot water floor to central heating.

In general, such heat exchangers have a wide range of applications, they are successfully used in cooling systems, heating, when working with chemicals, together with solar collectors when connected to a boiler and also when connected water underfloor heating to central heating.

What is a heat exchanger for?

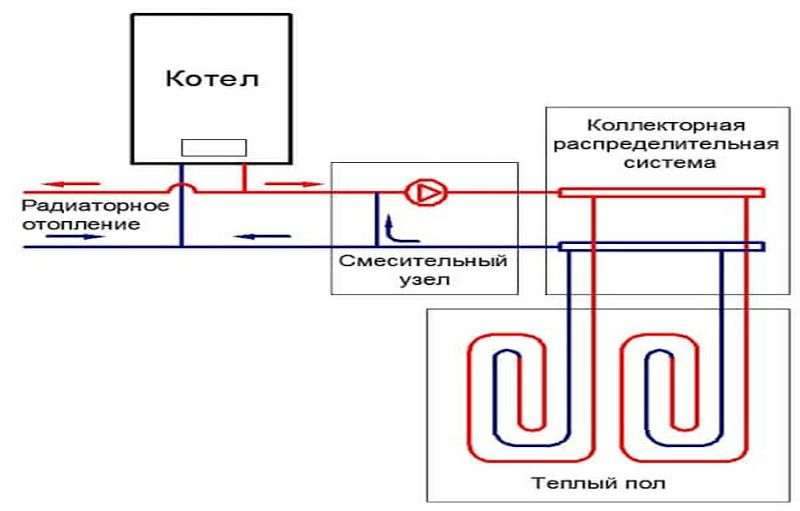

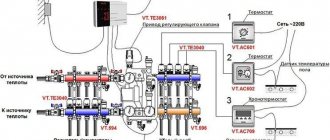

Consider a non-separable plate heat exchanger. There are four outputs on the body, that is, two circuits. The device divides flows according to pressure, temperature, etc., can be used for cooling, however, we need it for heating in order to ensure the correct connection of underfloor heating. This system is connected to one circuit, and a CHP plant to the other. Direct connection of a water underfloor heating to central heating may be associated with the danger of a quick failure of underfloor heating, since high temperatures, strong pressure are characteristic of the heat carrier of a CHP plant, there are also special chemicals and a lot of debris... All these factors clearly will not contribute to the prolongation of the service life of underfloor heating.

So, the heat exchanger allows you to create at home an autonomous floor heating system with uncontaminated water and optimal pressure. On one side of the plate comes dirty water from a CHP plant with high pressure, and on the other - clean water from our autonomous system with low pressure. Such a plate provides a clear sealed separation, high-quality heat transfer, mixing of streams is completely excluded. The number of such thin plates determines the power characteristics of the heat exchanger.

Selection of a heat exchanger for connecting a CHP

In order to choose the right heat exchanger for connecting a water-heated floor to central heating, you need to determine the degree of contamination of the coolant in order to understand how much water needs to be purified. If the plaque is small, then a coarse filter that retains chips and scale is quite enough. Such a filter can be cleaned with special means if after some time it becomes dirty and requires cleaning.

Each heat exchanger must have information about the type of product, the manufacturer, the maximum and test pressure, the maximum operating temperature, the mounting location diagram, the designation of the circuits is mandatory,which can be located both diagonally and vertically. A special arrow shows the direction of installation of the product, that is, in which exact position it should be installed. It is important to understand how the coolant flows out. The circulation itself is carried out by the so-called circulation pump.

On the diagram in the passport, you can usually find how to properly carry out the installation. For example, one of the options is to press the product to the wall with a fixing tape or console and, using a special corner, screw it on. Filters are mandatory, at least a coarse filter is required.

Installing a heated floor without using a mixing unit

The need to install the pump completely disappears if you purchase and install a boiler with a built-in pump. The main advantage of such a boiler is a well-chosen equipment. This means that you should not choose a boiler for any characteristics, it is enough to determine the required power.

The described installation methods take place, but it is better to purchase all the elements once, connect the warm water floor system correctly and not worry that the money spent on arranging such a floor will be wasted.

Heat exchanger installation

Installation is most often carried out vertically. Connection diameter, dimensions and power of connection of a water-heated floor to central heating may be different in different devices. I would like to pay special attention to the connection diameters. It is better to take power with a margin, because this parameter does not correspond to the size, the difference can be only a few centimeters. This increases the inertia of heat removal. This is especially true in cases where the temperature from the CHP is not too high, for example, if it is no more than seventy degrees.

After the underfloor heating distributor is installed, a pump with a three-way valve is assembled on it. Next, the electric boiler is installed (for off-season use), including the necessary attachments. That is, first, the supply of the heat exchanger from the boiler is connected, then the tees are cut in, the distributor with the valve is connected, thermometers are placed and an expansion tank is installed in the most convenient place, for example, you can do this under the sink. It is necessary to carry out installation in such a way that easy access to all equipment is provided.

Watch a detailed video on how to connect a hot water floor to central heating through a heat exchanger:

If the circuit was mounted incorrectly, then the consequences can be negative, therefore, mistakes should not be made in any case. It is better to entrust this work to experienced professionals who are aware of all possible nuances.

Non-standard water heat-insulated floor.

Hello everyone reading this post! In it, I decided to express my thoughts about all sorts of non-standard options for the execution of a water-heated floor. Here I will state my opinion, it is not necessarily correct, but it certainly is. I myself am engaged in the sale of equipment for ECP (abbreviated water heat-insulated floor), and not its installation. Therefore, I know better the theoretical side of this matter, and not the practical one. My opponents will be multiple folk craftsmen who "have done this a hundred times and everything works." It, of course, can work, but the whole question is whether it works correctly or not. And here all sorts of questions begin to the craftsmen, to which they cannot clearly answer and go on to shout. Well, okay, let's not talk about sad things. Let's get to the point.

Warm floor without mixing unit.

Many people have a question: "Why do we need a mixing unit?" It can also be called an autonomous circulation group or a mixing unit. A separate article has been written about this tricky device and I recommend it to read. So, can you do without it?

The mixing unit changes the temperature of the heating medium in combined heating systems. In particular, if you use radiators and underfloor heating in the heating system, then it will be problematic to do without it. Water with a temperature of 90 degrees must come to the radiator in order for it to give the passport number of watts, and for a warm floor, a coolant temperature is required not higher than 50 degrees, subject to normal insulation. Even if you connect the ECP to the "return" of the radiators (this is possible in a two-pipe system), the temperature of the coolant there will be higher than necessary. There will be an unpleasant "hot" floor effect. You have to walk on it in slippers or cover it with carpets, which negates all the comfort.

If you want to reduce the boiler "inlet" temperature to 60 degrees or less, then you will find that your room has become much cooler than it was before. Indeed, after all, the heat that they had to give off was taken away from the radiators. And water-heated floors cannot compensate for the heat losses of the premises. Thus, it is possible not to use the autonomous circulation group, but then the hot water floor must be the main heating, or a separate boiler must work on the underfloor heating. In the latter case, all savings on the purchase of a mixing unit will be reduced to zero. Okay, let's take a closer look at the issue of using the ECP as the main heating system.

Underfloor heating as the main heating system.

Many people do not like to see radiators on the walls and they want to make heating with ECP everywhere. I will say right away that, in principle, this is possible, but there are several important points that should not be forgotten. Let's list them:

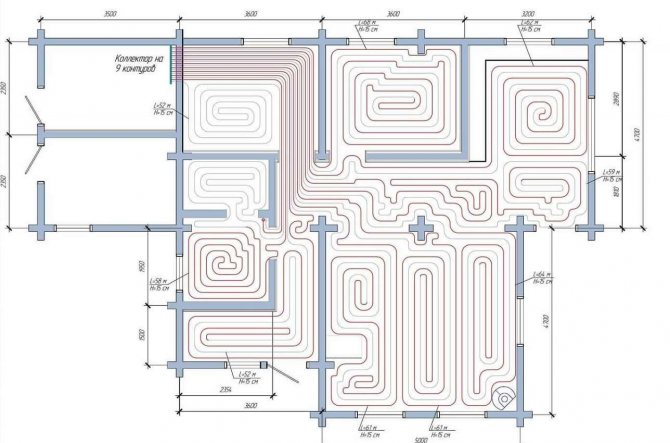

- Good thermal insulation of the house - the heat loss of the house should be small. This is due to the fact that from one square meter of ECP you can "get" a maximum of 75 - 80 watts. Heat losses from one square meter of area should not exceed this figure.

- Warm floors should be everywhere - when using ECPs as the main heating, you will have to lay them in all residential and non-residential premises. This can greatly increase the cost of the heating system.

- It is necessary to select floor coverings suitable for ECP - not every floor covering is suitable for warm floors. The ideal option here would be tiles, but there are few people who want to lay out all the floors in the house with tiles. It's expensive, and the house immediately looks like a hospital or morgue. Popular laminate and parquet flooring is not all suitable for such heating; such a coating will be a heat insulator, which reduces the heat transfer of the ECP.

- Warm floors do not cut off the flow of air from the windows - radiators and convectors are hung under the windows to cut off the flow of cold air from them. In the absence of heating devices under the windows, it can be unpleasant to pull from them with cold.

- It is necessary to minimize the amount of furniture - furniture covers the floor surface and thereby reduces the heat transfer of the surface. In addition, all available furniture should be on legs. This is necessary for air convection.

In addition, due to the large inertia of the system, you will not be able to quickly raise the room temperature. Heating the floor will take from several hours to several days. The time depends on the temperature of the heating medium, the thickness of the screed and the quality of the thermal insulation under the floor. In general, using only ECP has its drawbacks compared to using a standard combined heating system "radiators + ECP". If you are ready to put up with them, then you are welcome! Let's consider another option for saving on underfloor heating - refusal to use standard collectors.

Warm floor without a collector.

Underfloor heating collectors cost a lot of money and for this reason many people try to avoid buying them.Home-made ones made of polypropylene tees or, at best, from collectors with shut-off valves, which are designed for distributing a radiant heating system, come to replace the standard collectors. They look like this:

Homemade polypropylene manifold.

Manifold with shut-off valves.

Their main difference from standard ones is the absence of flow meters. Many self-taught people tell me that they did everything 100 times without them and everything works. But at the same time, they do not specify that it is impossible to achieve the same temperature in the circuits. This effect appears due to the fact that water as an electric current tends to follow the path of least resistance, which means that through shorter circuits the flow rate of the coolant will be greater than through longer ones. Flow meters are just needed to see through which circuit the flow rate is greater. The flow through the circuits is balanced by balancing valves, which are located on the return manifold. Balancing circuits without flow meters is almost impossible! ECP is an inertial system and you will receive a response from the valve rotation at least in a few hours. At the same time, flow meters are very expensive for all separately. In my opinion, this was done on purpose in order to force the consumer to buy collectors, and not spare parts for them. Now let's look at another non-standard ECP.

Warm floor without screed.

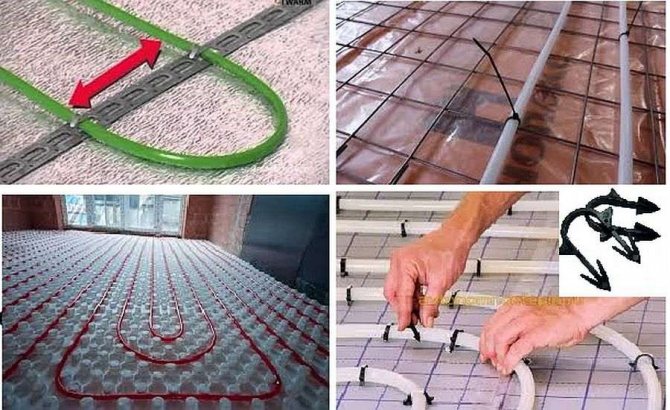

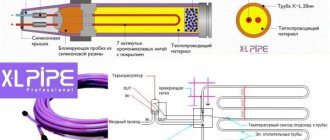

The owners of two or more storey buildings with wooden beams are most often interested in this option of HTP. On a wooden floor, a screed is not poured due to the large load on the structure, and then the question arises of how to implement a water-heated floor without a screed. There are two options here:

- Laying an electric underfloor heating - most often, film TP is laid under the laminate, and for bathrooms you can use mats that are laid in a layer of tile glue.

- Leveling ECP system - here the pipe is laid between the logs, which are stuffed onto the subfloor. To improve surface heating, special reflective metal plates are used. Most often, thick aluminum foil is used for this. It looks like this:

If you save money and do not use reflective plates, then the "zebra" effect will appear. That is, some areas of the floor will be warmer than others. Laying pipe loops in this way is, of course, more difficult. We will have to cut grooves in the boards into which the pipe will fit, but I do not know of another version of the ECP for wooden floors. The heat transfer of such floors will be slightly worse than that of concrete. It will already be problematic to use them for main heating. In addition, they will have less inertia, that is, the switched off ECP will cool faster than the concrete one, but it will also heat up faster. You can watch the following video for a better understanding of the process:

Results of the article.

I recommend everyone who is going to use any non-standard solutions for water heated floors to think carefully about the possible consequences of mistakes. It is very likely that a system made by a craftsman will not work correctly or lead to faster wear of the equipment. For example, if you connect the ECP to the return flow of the radiators, then this not only complicates the circulation of the coolant in the system, but also leads to the fact that too cooled coolant will enter the boiler. This can damage the boiler heat exchanger. This is especially important to consider if your boiler has a cast iron heat exchanger. Other consequences are also possible, which cannot be calculated in advance. My advice to you is to use the circuits recommended by the manufacturers. You will pay more, but they will definitely work as they should. That's all for now! I look forward to your questions in the comments!

znayteplo.ru