Suspended polystyrene foam is one of the most popular insulation materials on the market. The material is distinguished by really good performance. And I want to tell you about its technical characteristics, scope and other features.

The foam board must be marked.

Scope of insulation PSB-S-35

The material has a porous structure, which provides high heat and vapor barrier. Besides, PSB belongs to the category of artificial building materials. It is obtained by foaming plastic, therefore, the insulation is neutral to almost any external environment, it has a long service life

Due to its excellent technical characteristics, PBS S 35 is considered a versatile material with a multifaceted scope. It can be used to perform the following types of work:

- insulation of wall structures, external and internal partitions;

- increasing the sound insulation of premises;

- installation of multilayer thermal insulation panels;

- arrangement of parking lots;

- waterproofing of engineering communications;

- insulation of foundations, fences and loggias;

- thermal insulation of basements and utility rooms;

- arrangement of paths with heating systems.

In principle, expanded polystyrene has practically no restrictions on its use, therefore, it can be equally effectively used in residential and industrial construction.

In addition, the material is easy to process, so it is often used when transporting electronic equipment.

Properties of popular insulation

Like many other types of foam, high-density material has similar qualities, it is necessary to list a number of its advantages.

- It has a low level of thermal conductivity due to the fact that it consists mainly of air, therefore it easily retains heat.

- Resistance to active chemical attack.

- It is not afraid of microorganisms, it is not subject to the processes of decay, mold and the formation of fungus.

- Long service life, with the right choice of insulation and work, can last about 40 years.

- It is environmentally friendly, therefore it is used not only in construction, but also in other industries, for example, the food industry.

- New and modern types of material are practically not subject to combustion processes, therefore it can be classified as fireproof.

- Ease and simplicity in work, which is very important when performing installation work.

- Low cost of insulation.

New and modern polystyrene is no longer so fragile, since its quality has changed for the better over the years of production. He became stronger and more durable, therefore, the attitude towards the material has changed.

Insulation material marking

Like any building material, polystyrene foam has markings that indicate the main properties and characteristics. It looks like this.

| Designation | Decoding |

| PS | First letters. Indicates the type of material. In our case, this is expanded polystyrene |

| B | Production technology. Without pressing method. |

| FROM | Fire safety class. Self-extinguishing material |

| The numbers | Density of material |

Considering PSB S 35, the marking informs about the following features: this expanded polystyrene, made without creating high pressure, does not support combustion. The maximum allowable sheet density varies within 35 kg / m3.

Installation features

Thermal insulation of the walls will be done with high quality, if you take into account a few simple points.First you need to choose the right material. You shouldn't buy styrofoam that is stored outdoors. Styrofoam should be white, without spots or burnt areas. The slab is resilient and soft. Its balls are approximately the same in diameter.

Slabs are mounted on previously prepared surfaces. So, the walls need to be leveled and treated with a primer that will protect against mold (and mildew). For fixing the plates, glue is used. The sheets are laid according to the principle of brickwork, that is, between the three sheets, the seams form the shape of the letter "T". The glue should dry within a few days (depending on the weather).

After the glue is completely dry, the expanded polystyrene is fixed using “umbrellas” (dowels with a very large head). Initially, holes are prepared into which the dowels are inserted. "Umbrellas" are driven inside. Umbrellas-dowels choose plastic ones, as metal ones let the cold through. This stage of work is carried out in order to increase the reliability of the connection between the wall and the foam.

The next step involves gluing a reinforcing mesh. This is done using an adhesive that completely covers the mesh. The mesh is rolled over the entire surface of the wall. Its individual parts are overlapped. Pay special attention to the corners. The glue should completely hide the mesh. After it dries, the wall is sanded with sandpaper. The surface must be flat.

Next, a layer of putty is applied. After it dries, the wall is primed. At this point, the surface is considered ready for topcoating. It can be paints, wallpapers and any other materials.

Expanded polystyrene PSB-S 35 can be considered a universal material that has found its application as a heat and sound insulation layer in the construction of buildings and structures for various purposes. The material is used in regions with different climatic conditions.

Advantages and disadvantages

The popularity of expanded polystyrene is explained by its cost and ease of use, but these are far from the only advantages. The main advantages can be expressed as follows:

- No chemically active substances are used in the manufacture, therefore PSB belongs to the category of environmentally friendly products.

- After installation, it increases the vapor permeability, which prevents the development of wall mold and mildew.

- The material is easily processed: the sheet can be cut with an ordinary stationery knife. therefore PSB can be used to insulate buildings with complex geometry.

- The cellular structure helps to reduce the weight of the sheet, so one person can easily cope with the installation.

- It is neutral to any external influences, does not react with other types of building materials.

- After installation, expanded polystyrene does not rot, even with prolonged contact with a humid environment. The sheets do not collapse, which completely eliminates the subsidence of the insulation.

- Long service life: PSB does not lose its original properties within 30 years from the date of manufacture.

- Does not support combustion: the flame does not spread over the sheet, it dies out, melting the edges.

Of course, there were some drawbacks.

By the way, the three detected defects in thermal insulation are unable to cover the main advantages. Significant disadvantages are:

- Loses properties in direct contact with solvents and bitumen.

- Attracts rodents.

- When it melts, harmful substances are released into the atmosphere that pose a threat to human health.

Knowing these nuances, you can better understand the scope of application. PSB and avoid possible misunderstandings.

Despite its excellent resistance to bacteriological effects, expanded polystyrene can become a medium for the development of fungi. This shows up as green or black spots of mildew.

Benefits and important limitations of use

One person can mount the foam, since the material is lightweight

The positive properties of the material are due to the composition and structure of the foam.

In construction, the following are important:

- low weight;

- shape and size stability with temperature fluctuations;

- ease of installation and production of sheets of the required sizes;

- versatility of use;

- long service life;

- resistance to decay and mold, not susceptible to infestation by parasites;

- lack of reaction to a slightly alkaline medium (cement);

- incombustibility;

- low thermal conductivity - 5 cm of foam retain heat in about the same way as 70 cm of brickwork or 30 cm of a wooden bar;

- environmental safety - in the composition of finished boards, the styrene content is about 0.02%, which is released only after heating the foam above 80 ° C;

- windproof.

Disadvantages are caused by:

- low stability when exposed to substances with an acidic reaction;

- destruction from sunlight;

- susceptibility to colonization by rodents.

Polystyrene grades PSB and PPS should be used strictly according to the intended purpose and technology, in this case, the durability of the insulation is ensured.

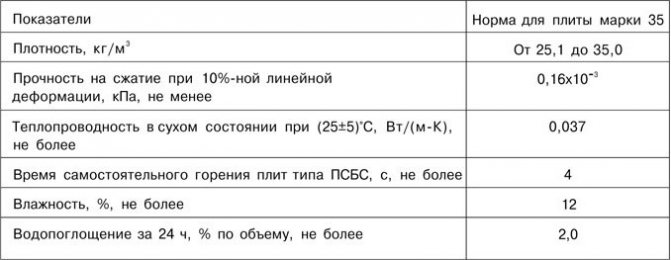

Technical characteristics of polystyrene foam board

PSB S 35 has the following performance characteristics.

| Indicator | Value |

| Density | 25-35 kg / m3 |

| Linear compression resistance | 0.14 MPa |

| Flexural strength | 0.2 MPa |

| Thermal conductivity | 0.038 W (mK) |

| Water absorption per day | 2 % of the total volume |

| Burning time | no more than 4 s when exposed to open fire |

Interesting technical characteristics include the hypoallergenicity of the material. Thanks to this feature PSB S 35 can be used to insulate children's rooms; during work, there is no need to use personal protective equipment. Against the background of a related penoplex, this is an indisputable plus.

Description THERMIT XPS 35

The production technology involves mixing general purpose polystyrene granules with granules of dye and modifying additives. The process takes place at elevated temperature and pressure with the introduction of a blowing agent and subsequent extrusion from the extruder.

THERMIT has a uniform, closed porous structure, with a cell size of 0.1–0.2 mm, low thermal conductivity and high strength characteristics. THERMIT boards can be produced with two types of edge processing: smooth N-edge and L-shaped edge (with a thickness of over 20 mm)

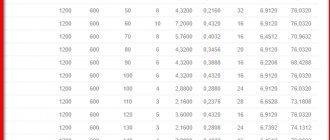

Size range

Expanded polystyrene is produced according to the requirements GOST, therefore, the sheets have standard sizes regardless of the manufacturer. therefore PSB S 35, always present on the market, has the following sheet sizes:

- Length - from 900 to 5000 mm.

- Width - from 500 to 1300 mm.

- Thickness - from 20 to 500 mm.

During production, some deviations from the established norm are allowed. In particular, the linear aspect ratio is 50 mm, thickness: up to 10 mm... Such products are not considered a defect and are allowed to be sold through retail and wholesale trade networks.

Most manufacturers are engaged in the manufacture of products according to individual customer sizes.

Working with material

When performing the bulk of thermal insulation works, polystyrene foam plates PSB S-15 and PSB S-25 are used, which have an optimal thickness of 5 to 10 cm. If the building is insulated during the construction phase, the material is laid under the facing layer of structures. Exterior surface cladding allows you to save valuable internal space when insulating an already finished structure.

Expanded polystyrene is applied to previously prepared, even and primed surfaces. The gaps formed between the slabs are blown out with construction foam. To fix the material, it is advisable to use special adhesives, mastics, cement mortars.

During the installation of expanded polystyrene, the adhesive base is evenly applied to the coatings with a spatula. Further, the sheets of material are sequentially applied to the surfaces and aligned according to the pre-prepared beacons. To securely fix the boards after drying, it is recommended to fix them with plastic dowels.

TOP-5 trusted manufacturers

When choosing any building material, including insulation, you need to take a responsible approach to the choice of the manufacturer. In this case, you can avoid buying counterfeit products of dubious quality.

If speak about PSB S 35, its main suppliers in Russia are the following enterprises:

- Volgograd-Penoplast... Today, it is one of the leading suppliers of expanded polystyrene in the southern region of the country. The production lines are automatic, they operate on equipment from Germany.

The company is considered young, but dynamically developing, therefore values its reputation, meets clients halfway in resolving any controversial issues. The business card of the enterprise: precise geometry of sheets, the lowest possible cost of production. - "RosPenoplast"... The company is located in the Lyubertsy district of the Moscow region. The manufacturer supplies the market with a wide range of PSB varying degrees of density.

The company takes a responsible approach to the choice of raw materials, which allows maintaining the quality of products at a fairly high level. Production facilities are in line with international class ISO 9001, all products are subject to mandatory certification.

- "StroyPlast"... The production facilities of the enterprise are located in the Krasnoyarsk Territory. The manufacturing process is carried out on the equipment of a German company KURTZ, the line works in automatic mode.

The company is well known in the market over 11 years, carefully monitors all production cycles, always adheres to the price-quality ratio.

- "MosStroy 31"... One of the leading manufacturers in the central region, which owns more than 25% of the expanded polystyrene market. The company uses advanced technologies, the production cycle is carried out on equipment from leading world brands.

The product range includes PSB of varying degrees of density, in demand in all branches of construction.

- LLC "ET-Plast"... Samara enterprise working in this production area since 2002... The technological cycle is carried out on a fully automated line using Italian equipment HIRSCH.

All products are subject to mandatory certification, are resistant to any external influences, and meet environmental safety requirements.

The listed enterprises strictly adhere to the norms GOSTwhich helps to bring high quality products to the market. In addition, manufacturers adhere to a reasonable pricing policy, which attracts the attention of a wide range of buyers.

The use of polystyrene foam 35 allows:

- Effectively prevent heat loss through roofs, basements and basements.

- To simplify the process of installation of thermal insulation, to optimize the cost of work on the insulation of buildings and structures.

- Ensure thermal comfort and environmental safety of people who live and work in insulated buildings.

- Increase the usable area of the interior (by reducing the thickness of the insulation while maintaining the required thermal insulation indicators).

- Reduce the cost of purchasing heating equipment and paying for heat supply services.

- Create an effective and durable thermal insulation system.