Insulating a house with simultaneous cladding (ventilated facade system), everyone is faced with the recommendation to protect the insulation from moisture, wind, steam. Most of the questions about the choice, purpose and use of materials arise here. Without pretending to provide a comprehensive solution to these questions, we will try to answer most of them.

Vapor barrier and waterproofing for siding: when and why you need it

Studying the recommendations of the manufacturers of heaters for the installation of ventilation systems, you can see that most of them recommend the protection of the heater with a vapor barrier from the side of the wall, moisture and wind protection between the heater and the hinged facade.

Many homeowners who insulate a house on their own have a desire to save on expensive films, so it is worth figuring out what vapor barrier, waterproofing, moisture-windproof membranes are, when and how to use these materials.

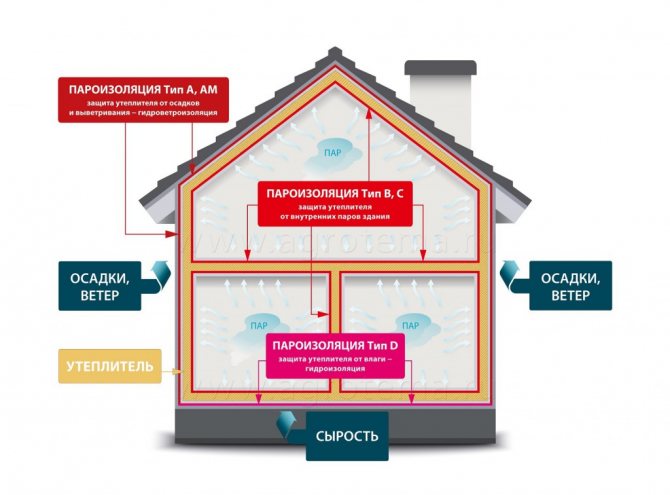

What is vapor barrier

Any design is carried out in accordance with regulatory documents, now it is a joint venture - building rules, each of which has a section "Terms and definitions". From the point of view of building codes, a vapor barrier is a layer of roll or mastic material that prevents water vapor from passing through it.

A lot of vapor barrier materials have been developed for wall insulation, most of them are 2… 3-layer films made of non-woven material or special polyethylene.

ATTENTION! Conventional polyethylene is not suitable for vapor barrier.

What is waterproofing

Waterproofing is building materials (roll, mastic, plaster) that prevent the structure from getting wet under the influence of waste water. These materials are usually used in floors, underground structures, structures in the aquatic environment.

Regarding insulation systems, it is more correct to use the term moisture and wind protection, since the heat insulator should not come into contact with water directly in the insulation system, but rain water or snow can get into the lining gap in strong winds, and therefore the thermal insulation needs protection from water, water vapor and wind.

Diffusion membranes are used as waterproofing in insulation systems, a feature of which is the ability to release water vapor outside, preventing them from penetrating inside. As a rule, these are 3 ... 4-layer films with marking of the location of the sides relative to the insulation (inner and outer layers).

What is a vapor barrier for in general?

Water vapor can be of atmospheric origin or operational. Any building material has vapor permeability, for some it tends to zero (extruded polystyrene foam - 0.013, metals, glass - 0.0) in others it is much higher (wood across the fibers - 0.03, mineral wool - 0.06).

The higher the vapor permeability, the more moisture the material can collect, while its thermal insulation characteristics decrease, it ceases to play the role of insulation. To prevent this from happening, vapor barrier materials are used. The use of a vapor barrier is especially necessary if the wall material has the ability to breathe - that is, to let these water vapor pass through itself.

Types of adhesive tapes for vapor barrier

When choosing a vapor barrier material for the construction of a roofing pie, you need to remember that the adhesive tapes for connecting the panels and the film must be produced by the same manufacturer. Often, when using products of different brands, there is no gluing effect or it lasts for a short time.

The joining of membranes is made with a connecting tape specifically for vapor barrier, because it excludes the formation of capillary moisture in the connection zone:

- laid by a number of panels;

- adjoining elements passing through the roof - chimneys, antennas, communication risers;

- adjoining adjacent building structures, including parapets, panoramic windows, doorways, etc.

The choice of vapor barrier material to protect structures from vapors depends on the conditions of the upcoming operation, which must be taken into account before purchasing. In addition, you need to carefully study the instructions for the device of the vapor barrier so as not to collide directly on the object with the impossibility of installation.

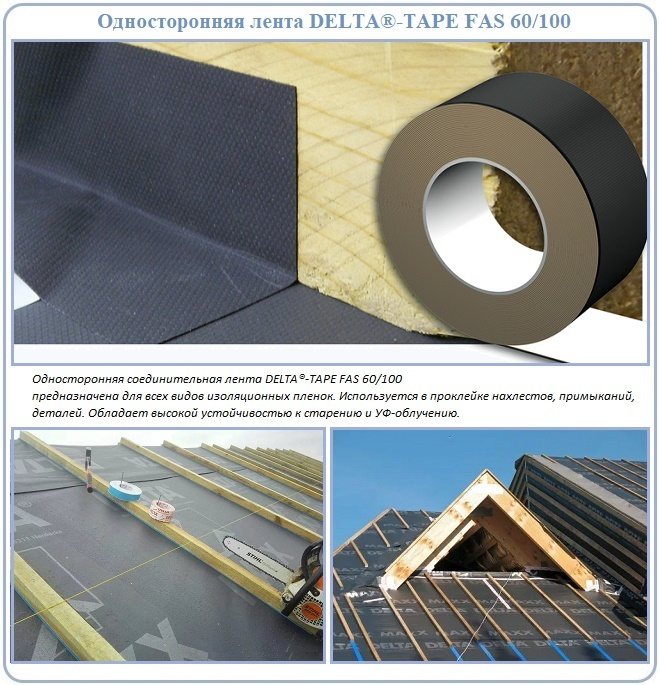

One-sided tape for tight connections

Adhesive tape of this type is used to connect the sheets of vapor barrier material by overlapping the edge over the edge that goes over the already installed adjacent panel.

Single-sided tape with the DELTA® logo and the nomenclature TAPE FAS 60/100 is a 6 cm wide strip with a laminated cardboard backing and an acrylate adhesive on the working side. This tape should not be used for bonding film materials made of chlorinated paraffin wax, it should not be adhered to recyclable boards. It is not suitable for installation in swimming pools and bathrooms.

It is used exclusively for carrying out work inside the equipped attic or other room. Suitable for joining vapor barrier with adjacent smooth metal, wood, plastic surfaces.

In the line of domestic products, the analogue is Izospan SL - adhesive tape designed for hermetic connection of vapor barrier strips.

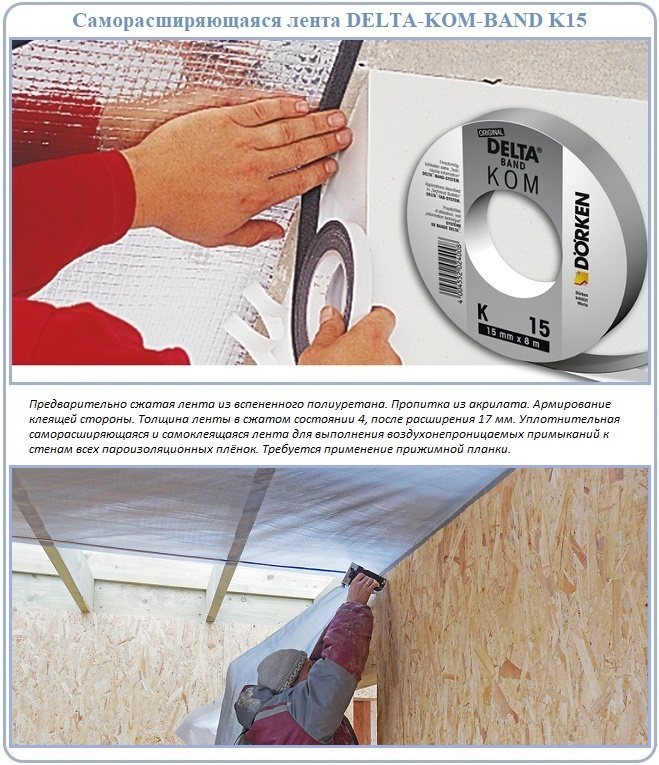

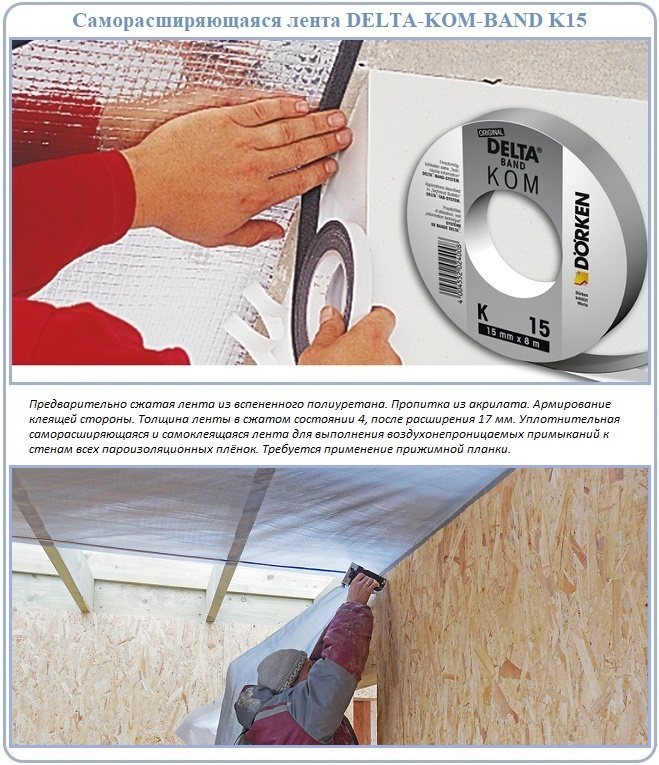

Self-adhesive self-expanding option

In the line of the German company Delta, such products are presented by a tape with the nomenclature name DELTA-KOM-BAND K 15. It is used in the formation of sealed, as well as air-tight junctions to adjacent structures, walls of ventilation shafts, brick chimneys.

In the state offered to the buyer, the tape is compressed, as a result of which the width of the offer is only 4 cm, after straightening the material, the width of the strip reaches 17 cm.It is made of foamed polyurethane, reinforcement is arranged on one side of the tape and an acrylate adhesive is applied.

This type of adhesive tape is suitable for outdoor use because can be used for adhesion to damp and even frosty surfaces. It is first glued to the film, and then pressed against the wall with a rail.

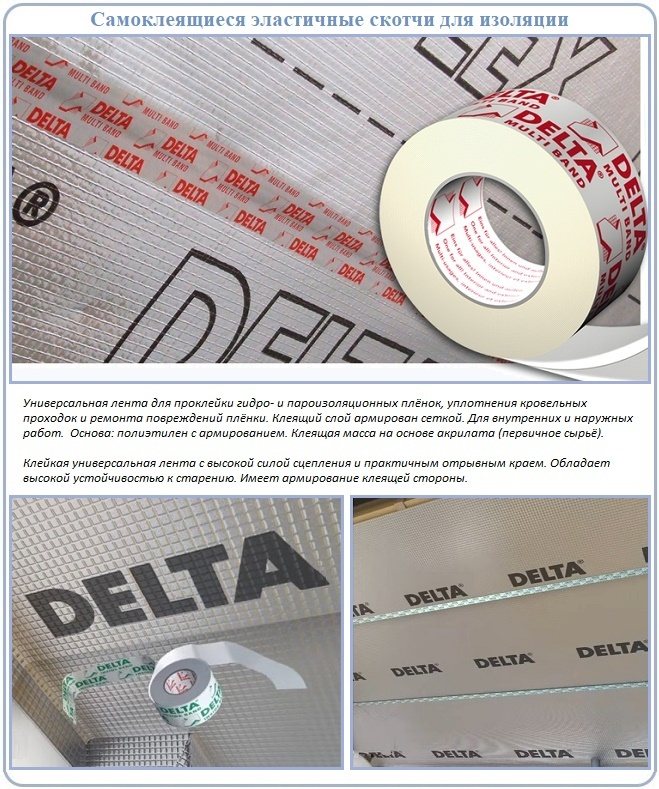

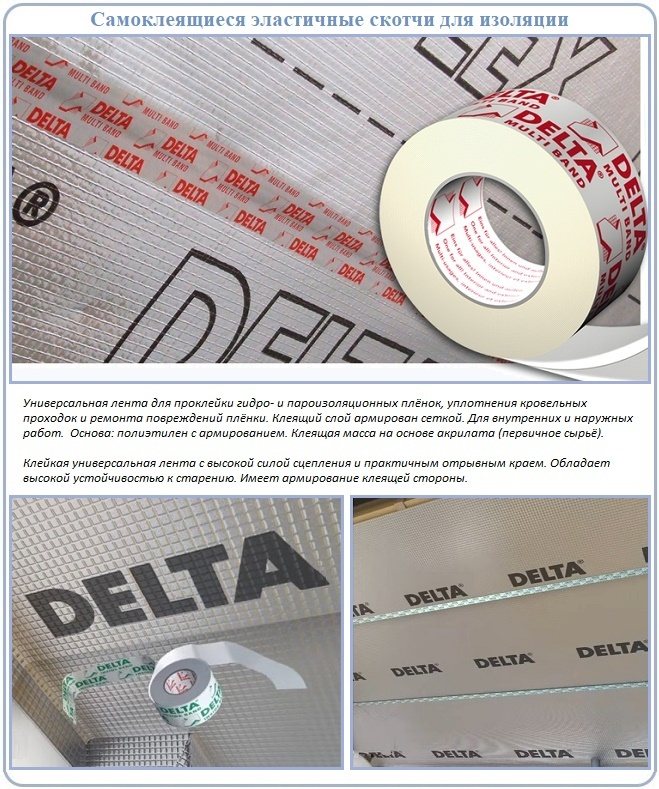

Elastic self-adhesive tapes

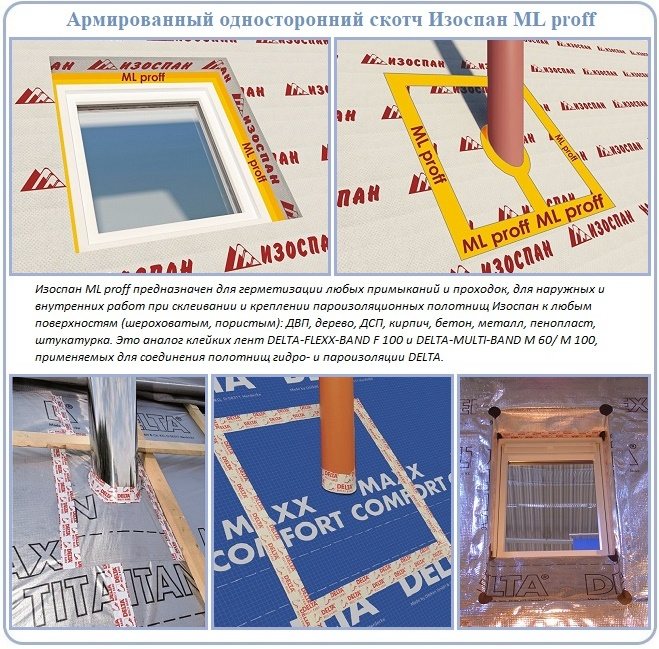

To seal passages through the roof of communication risers, antennas, narrow steel pipes, one-sided bitumen-rubber adhesive tape DELTA-FLEXX-BAND F 100 and DELTA-MULTI-BAND M 60 / M 100 is used.

These are universal adhesive consumables suitable for work both inside and outside the building. They are used in the arrangement of penetrations, compensate for linear movements of building structures relative to each other, allow their movement without loss of tightness of the equipped junction.

Universal adhesive tapes are used to repair damage to all types of insulating films, but are only suitable for gluing to smooth surfaces. Since they are designed for outdoor work, during development they were reported to be resistant to UV and other atmospheric negative.

The Izospan product range includes a one-sided, weather and UV resistant tape with the Izospan ML proff marking.

Double-sided tapes and their application

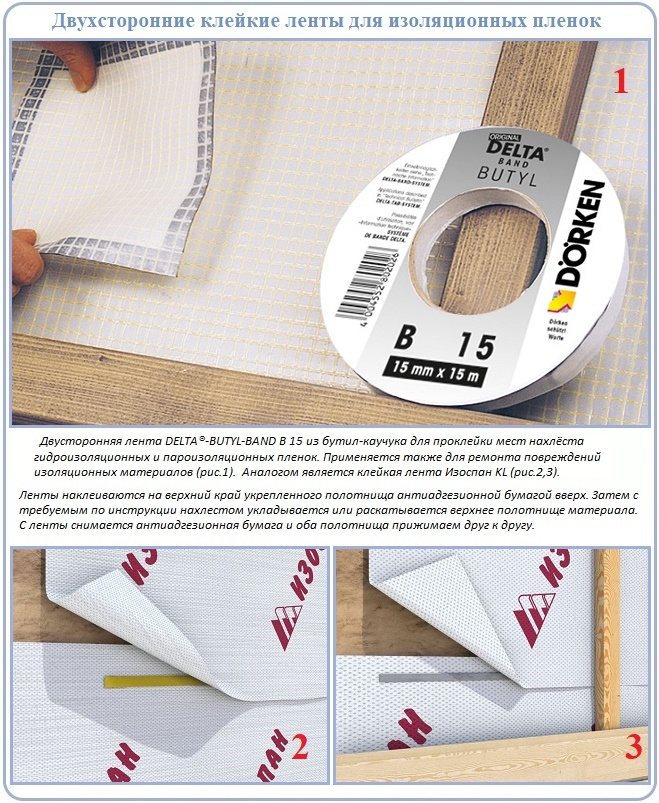

Resistant to atmospheric negative double-sided adhesive tape of German production with the nomenclature name DELTA-BUTYL-BAND B 15 is made of butyl rubber. Tape with two adhesive sides is used to join vapor barrier sheets and to repair defects such as breaks and cuts.

Double-sided adhesive tapes for insulating films are used for both external and internal types of work, suitable for the device of abutments to dormer windows, rafter legs and rigid floorings. When installing abutments to building structures, the installation of clamping strips is required to ensure flawless fixation.

In the line of Russian adhesive tapes, Izospan KL has similar characteristics. This adhesive tape is glued over the rolled vapor barrier strip, retreating from its edge the distance indicated by the manufacturer. First, only the lower anti-adhesive paper is removed, after gluing, the upper one is removed, on which the next vapor barrier is applied.

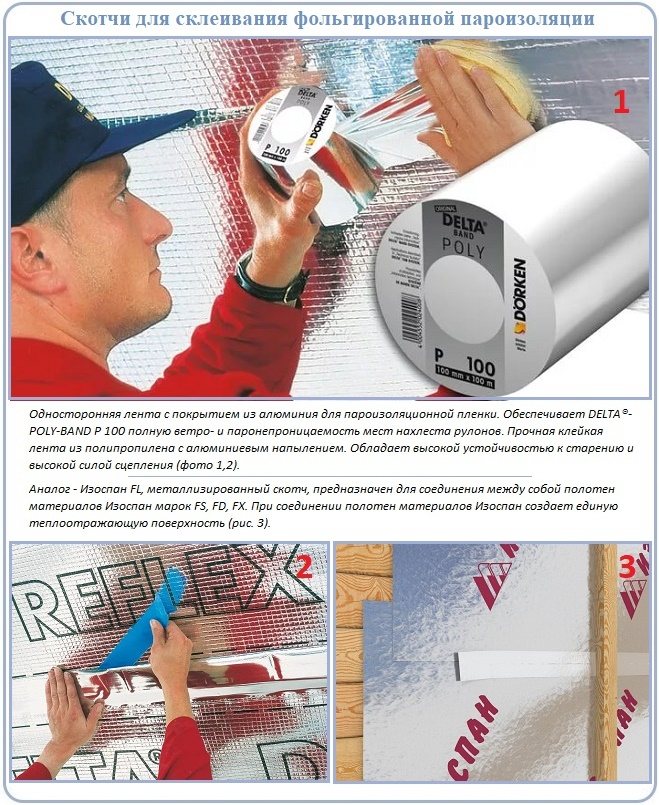

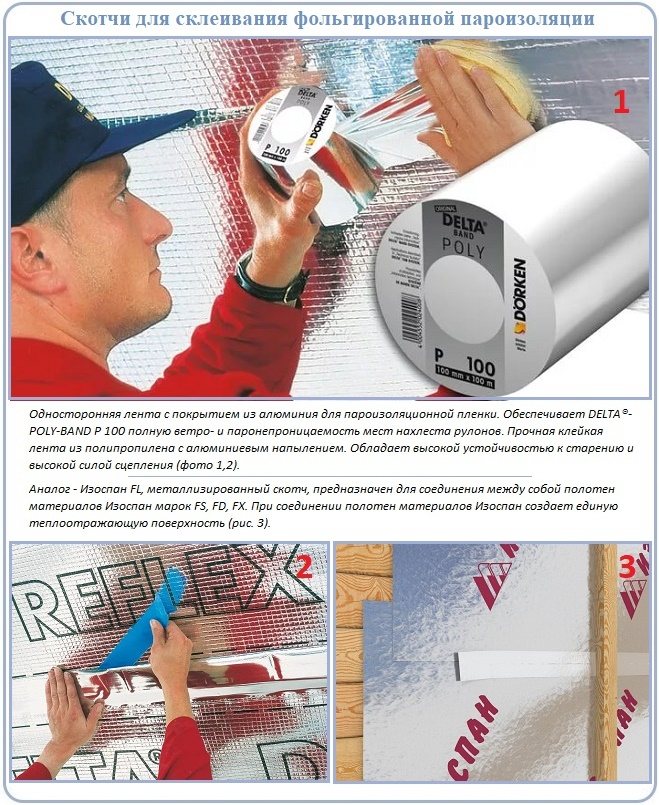

Metallized Vapor Barrier Tapes

In the connection of vapor barrier materials with a metallized side, aluminum coated scotch tapes are used. The product from the German brand of roofing materials is called DELTA-POLY-BAND P 100.

This is a one-sided tape made of polypropylene with metal spraying on the outside. The width of this type of adhesive tape is 10 cm, the ability to bond significantly exceeds the properties of conventional tapes.

In the line of Russian products, Izospan FL Termo is distinguished by equivalent qualities, the specified adhesive tape allows you to create a single heat-reflecting plane like a German product.

Adhesive tapes with a metallized side serve well in rooms with non-standard operating humidity and temperature conditions. They are used to equip steam rooms of Russian baths and Finnish saunas supplying dry steam. The adhesive tapes are laid on dried and degreased vapor barrier sheets.

How can condensation damage your home?

On the example of a wooden log house insulated with mineral wool, the harm from condensation looks like this: vapors pass through the tree. Since the dew point, at which the gaseous vapor turns into a liquid, is in the insulating layer, the vapors in the form of condensate settle and accumulate in the insulation. It gets wet, in winter this moisture freezes.

Instead of warming, the owners receive an ice compress, which prevents the release of vapors, which leads to decay of the walls, deterioration of the microclimate inside the house, and the formation of mold and mildew. In turn, mold and mildew are the cause of many diseases of the human respiratory and immune systems - primarily allergies and asthma. The main task of the vapor barrier layer is to prevent steam from penetrating into the insulation.

Is a vapor barrier needed for a cold roof

From the side of the living quarters, steam constantly rises into the attic and the space under the roofing. This could be steam from cooking, using hot water, or temperature differences between living quarters and the attic.

In the case of a warm roof, there are no questions about the need for vapor barrier on the part of residential premises. If the insulation is saturated with moisture, it will no longer retain heat inside the room. For example, mineral wool loses up to 50% of its heat-shielding properties when the humidity rises by only 5%.

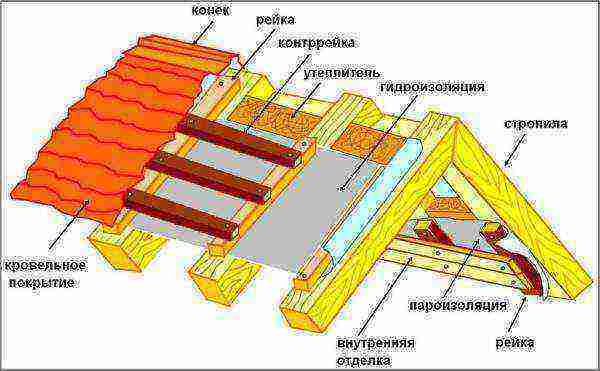

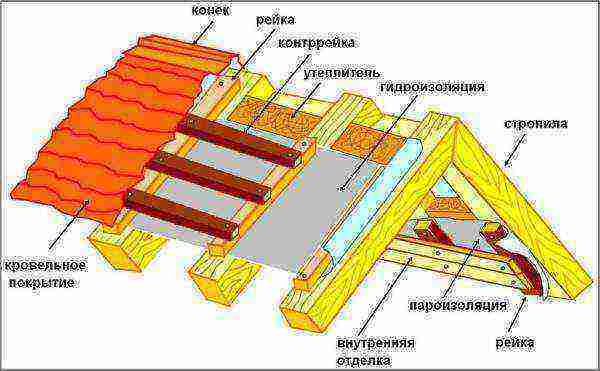

Therefore, when arranging a warm roof, two moisture-proof elements are installed: waterproofing outside and vapor barrier inside the room.

A cold roof has no insulation, which means that double protection is not needed. When constructing such a structure, only one layer of vapor-waterproofing is used. It serves two purposes:

Protects rafters and under-roof space from moisture that can enter through roof gaps.

Protects roof decking from vapors from residential areas. That is, it acts as a vapor barrier ..

When is vapor barrier and waterproofing needed?

Vapor barrier is required in those structures where the vapor permeability of the wall and heat insulator is high. For example, when insulating a panel house with polyurethane foam, vapor barrier is not needed, and a forced ventilation system is required to remove water vapor, so as not to get high humidity in the house, and with it - mold and fungus. A brick house will already require a vapor barrier.

Pure waterproofing for siding is not needed at all. In order to prevent moisture vapor from the atmosphere from getting deep into the heat-insulating layer, a vapor barrier is needed. But in order for the condensate accumulated on it to be taken out, a ventilated gap with a width of at least 40 mm is arranged between the cladding and the insulation.

And here the second enemy of soft cotton insulation acts - the wind. The higher the building, the higher the wind speed in the ventilation gap, the sooner soft slabs and mats will loosen.

To prevent this from happening, the outer surface of the heat-insulating material is protected with a moisture-proof film or a more technological material - a special membrane. There are also heaters with a laminated outer surface - protected from weathering by a fabric or film layer in production.

Cold roof. Do you need waterproofing on outbuildings?

First of all, it should be noted that outbuildings differ significantly from residential buildings in both their structure and volume.

The overwhelming majority of developers are trying to save money on the construction of secondary structures, so the issue of waterproofing is more relevant than ever. Before answering the question posed, let's understand the coverage. Today, corrugated board is one of the cheapest materials, so I will talk about buildings covered with it.

Manufacturers from different countries strive to produce such products so that the whole world can start using it. If you are a fan of corrugated board, then today, such material is a sheet of metal with an anti-condensate coating.

In appearance, it practically does not differ from its counterparts. A synthetic compound is applied from the inside, it looks like felt. Due to the large number of pores, this material is able to retain up to 1 liter of water per square meter. After the surface is saturated with moisture, ventilation comes into play and if it is done according to all the rules and regulations, then the drying process will not take much time.

The order of work when insulating a house

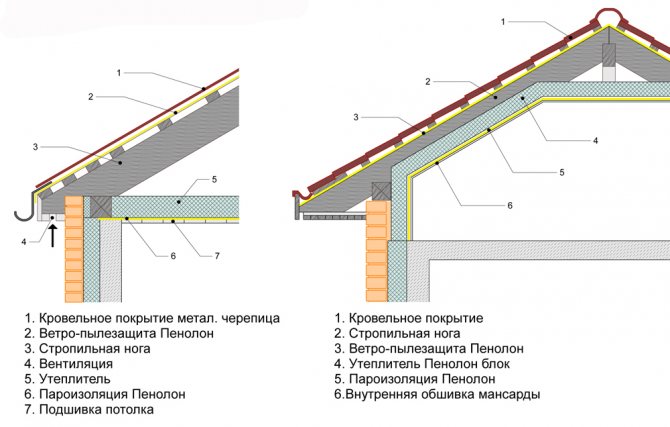

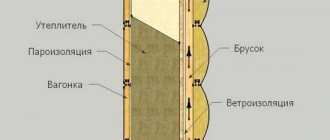

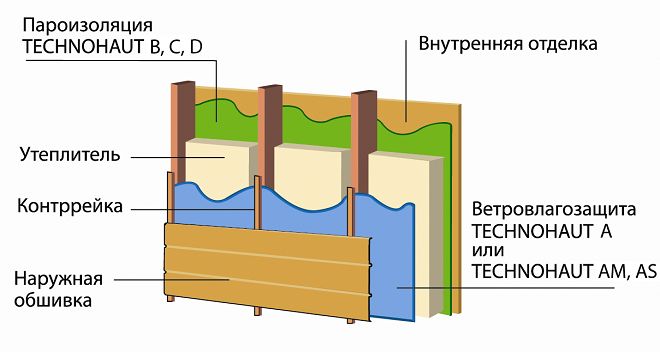

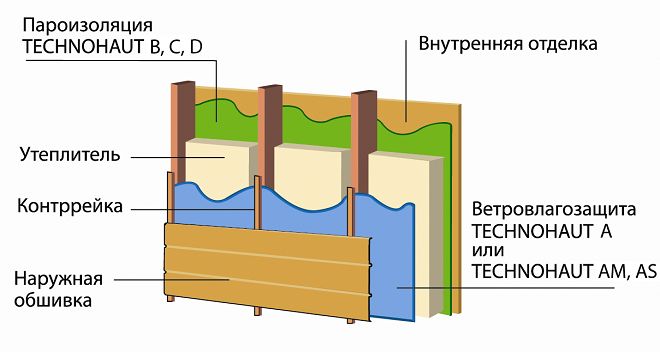

The ventilated facade insulation system looks like this in layers:

- Wall.

- Vapor barrier.

- Insulation.

- Waterproof and windproof membrane.

- Ventilated gap.

- Siding curtain facade.

The curtain wall is attached to a metal frame if the siding is metal or heavy, such as fiber cement or ceramic plinth siding. When insulating wooden log cabins, most often the supporting frame is made of wood.

TIP: On average, the thickness of the insulation is taken to be 100 mm, for the northern regions - more, according to the heat engineering calculation.

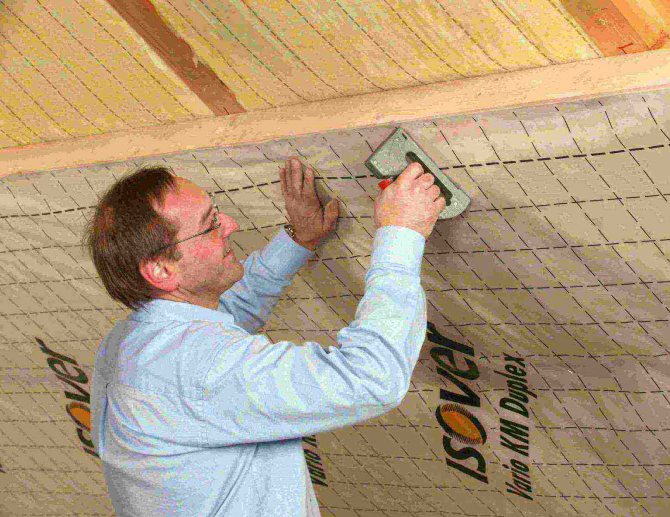

Installation of vapor barrier film on the wall of the house

After preparing the facade - cleaning it from dirt, treating wood, impregnating it with a fire retardant and antiseptic, we attach a vapor barrier strip or membrane.

The vapor barrier is attached to the wall using a construction stapler. The vapor barrier panels are glued together with a vapor-proof double-sided tape with an overlap of 10-15 cm, all edges are glued with tape. The bottom edge of the vapor barrier must lie on the starting (basement) profile.

Installation of insulation over vapor barrier

A frame system made of timber with a thickness equal to the thickness of the insulation layer, 40 mm wide is mounted on nails or dowel screws. The step of the frame racks is equal to the width of the insulation plate minus 5 mm per spacer. The installation of the heat insulator is carried out on disc-shaped dowel screws with a metal core (fungus) at the rate of 5-6 pcs / m2.

Installation of windproofing (wind protection and moisture protection) over the insulation

Fastening of the moisture-windproof membrane is also performed with a stapler to the insulation and the frame racks, with laying the panels with an overlap of 15 cm and fastening with double-sided vapor-proof tape. The lower edge of the membrane is lowered 2 cm below the level of the basement strip to drain the condensate onto the blind area. All edges are also glued with tape.

Installation of slabs over windproofing

A beam with a section of 40x40 mm is mounted to form a ventilated gap. If, according to the manufacturer's instructions, a step less (30 cm) is required for fastening the siding than for the frame racks (60–0.5 cm), a horizontal frame is preliminarily built, on top of which the racks for installing siding with a given pitch are attached.

Installation of siding may differ depending on the manufacturer, type of siding, direction of the planks. When selling material, official dealers and large networks of building materials always issue proprietary instructions for installing a specific type of material.

Features of the choice of material for vapor barrier

Let's think about which vapor barrier to choose for the roof, so that its efficiency is at the proper level and the cost is affordable. The building materials market offers a large assortment of special films for mansard and cold roofs used for the construction of a vapor barrier layer.

In order to make the right decision as to whether you need a vapor barrier for corrugated board, you need to have information on a number of factors:

- cost;

- efficiency of use;

- expediency.

Before purchasing materials for profile flooring, you need to deal with the financial side of construction. If price is the determining factor, then economical products are chosen.

In terms of efficiency, vapor barrier films differ in performance and should be familiarized with in advance.

When choosing a material, the characteristics of a particular room are taken into account. For a heated building, foil film will be the best purchase, but for a cold roof made of corrugated board, an inexpensive glassine will be enough. When a roof is being erected on a structure that is rarely visited, a vapor barrier made of polypropylene or ordinary plastic wrap will be required.

The procedure for installing slabs with laying vapor barrier, insulation and waterproofing

Installation of the insulation system always begins with the preparation of the facade - cleaning, dismantling protruding communications and ebb tides, repairing damaged areas.

- A vapor barrier film is spread over the prepared surface, at the same time fixing it with brackets to the wall, gluing the joints of the panels and edges with tape.

- The supporting frame is being built.

- Between the racks of the frame, a heat-insulating plate is laid and fastened with dowel screws.

- The diffusion membrane is spread, fixed with a stapler, seams and edges are glued with double-sided tape.

- A counter-rail is mounted for fastening the siding panels.

- Carry out the installation of the curtain wall.

- Installation of siding is carried out from the bottom up, starting from the corner, connecting and, basement strips and framing of window and door openings. The siding panels are inserted into the grooves of the left panel and snapped onto the bottom panel connector strip. Lastly, the finishing panel is attached under the soffit of the cornice.

Vapor barrier products for the roof

To lay a layer of vapor barrier under the corrugated board or other roof covering, films are used.

The following most popular types are presented on the construction market:

- Polyethylene film... This inexpensive household material has long been used as a vapor barrier. It traps steam from living quarters. Polyethylene is cheaper than membranes and reinforced films. It has a big drawback - insufficient strength, since it can be easily damaged during installation. To make the insulation reliable, the film is laid out in two layers. It is attached with a special stapler to the inner crate, observing a step of 1.0-1.5 meters. In case of damage to the material, a patch must be made. For this, the puncture site is sealed with construction tape. You should also fix the joints.

- Reinforced polyethylene... It is inexpensive but of good quality. It is made from several layers of polyethylene and reinforced with a polypropylene mesh for strength. Despite its low weight, such a film is strong enough and it is more difficult to damage it during the fastening process. Due to the reinforcement, the material is more rigid. The film is fixed with a special tape. The choice of this material can be called the optimal combination of affordable price and good quality.

- Glassine... It has been used to create a vapor barrier for a long time. It is a reliable protection against moisture, is durable, has a long service life, but, unfortunately, it is heavy. Despite its cheapness, glassine is not recommended for use in residential premises. In case of heating, the material begins to emit an unpleasant odor, and after laying the corrugated board, its temperature rises frequently. For the above reason, glassine is used when the answer to the question of whether waterproofing is needed under the cold roof decking of a non-residential attic is positive. It is convenient to use for laying waterproofing on top of the lathing.

- Polypropylene film... It is a durable material for vapor barrier laid under profiled sheets. It is produced similarly to a polyethylene multilayer film, but it has a relief layer. Condensation accumulates on films with a smooth surface, then it collects into drops and they fall from time to time to the floor. A film with a rough surface is produced on the basis of cellulose and viscose. It is capable of absorbing moisture and this feature prevents the formation of drops. Further, provided that the humidity of the air decreases, the collected condensate evaporates. Mount the film with an anti-condensation surface to the room. For the correct execution of installation work, you must study the instructions from the manufacturer of the product. This type of film is one of the best options for a vapor barrier under a profiled sheet.

- Foil... At its core, it is a type of polyethylene or polypropylene product. She has not only a reinforcing mesh, but also a thin layer of aluminum that reflects infrared rays and helps to keep warm. As a result of using foil-clad film, heat loss is reduced by more than 10%. The cost of such an insulator is higher compared to other types of vapor barrier materials, but its installation saves on heating costs. It is also necessary to know which side to fix the vapor barrier correctly. Lay the foil film with an aluminum coating towards the room. A gap of about 5 centimeters should be left between it and the wall decoration. There should also be a small gap to the insulation. To fix the film, self-adhesive tape is used, and the joints are covered with aluminum tape, and then the vapor barrier layer is airtight.

Methods for laying waterproofing material

There are two ways to mount films for vapor-waterproofing on the facade:

- Roll out the roll horizontally from the base of the house while securing the stapler with staples. The next layer of the film is overlapped.

- With a low building height, the film is easier to fix vertically. Both methods guarantee protection of thermal insulation from moisture when gluing all joints with specialized double-sided tape.

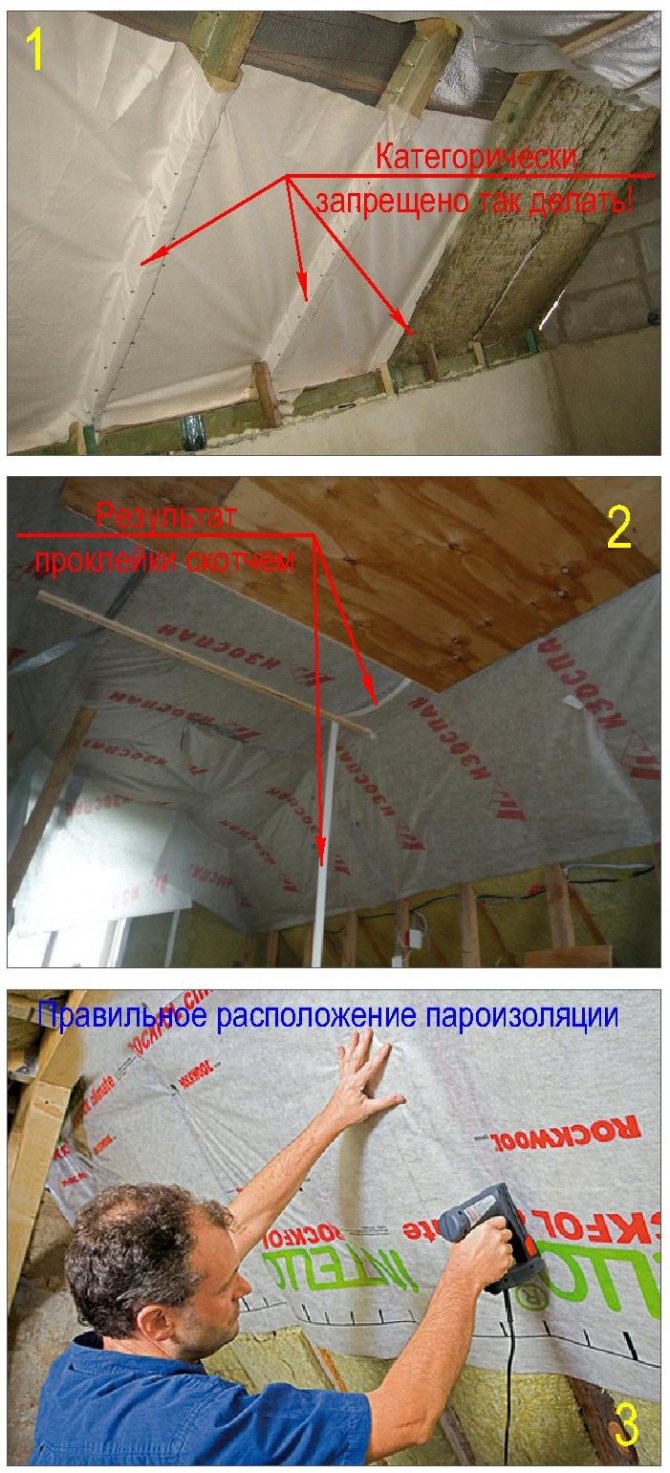

Which side to lay the vapor barrier under the metal tile

Which side to install the vapor barrier? The desired side is easy to discern by touch. The smooth side of the membrane should face the insulation. Rough side - inside the room.

Important! If you put the membrane on the contrary, it will not protect the insulation and rafters from moisture.

In addition, leading manufacturers repeatedly print their logo on the side that should be visible after installation. If you see the logo in a mirror image, the membrane is not mounted correctly.

Construction tape for vapor barrier

Vapor barrier tape is a bonding tape that will help ensure the vapor or water tightness of coatings or where certain parts fit together. If you use ordinary scotch tape, this will lead to its soon peeling off, and moisture will freely enter the heat-insulating layer.

Vapor barrier tape is divided into several types:

- Connecting tape made of aluminum. The thickness is on average thirty micrometers. This type does an excellent job with the task, but it is not suitable for all types of vapor barrier. The width of the aluminum tape is approximately ten centimeters;

- Reinforced tape. This construction connecting tape differs from the previous one in great strength, the width is about the same;

- Polypropylene construction tape. The main advantage of the material is its low cost in the construction market. However, this adhesive tape is rarely used when gluing vapor barrier sheets, since it has low strength;

- Universal reinforced adhesive tape. The basis of this type of tape is fabric. And the base of the glue is rubber. To ensure vapor impermeability, it is used very rarely. The width of the tape is five centimeters;

- Butyl rubber connecting tape. The type has excellent adhesion to the surface and adheres well to the vapor barrier layer.

Regular stationery tape is not suitable for bonding vapor barrier sheets. Literally after a short period of time (one or two days) everything will come off.

When buying a special construction tape, you should consider the following characteristics:

- this material must be highly resistant to ultraviolet rays;

- scotch tape should practically not absorb moisture;

- the ability to withstand temperatures up to 90 degrees Celsius;

- construction tape must have excellent adhesion to wood and metal surfaces (adhesion);

- the service life is fifteen years.

It is not recommended to purchase connecting tape from an unknown company at the construction market or store. The material from which scotch tape can be made is capable of releasing toxins, which can harm the human body. And also there is no quality guarantee.

The vapor barrier should be glued first with double-sided tape, and then the second layer with one-sided.

When working with special tape, you must follow a certain algorithm of actions:

- first you need to clean the surface from dust and other dirt, and then dry it;

- the lowest layer of vapor barrier is installed on the coating, it is glued with a special connecting tape along the entire length and width;

- then we get rid of the film from the top of the tape;

- at the end, the second layer is installed, it must be pressed tightly and glued.

Vapor barrier film with foil

This is one of the types of previous films. But, the material not only has an additional reinforcing layer, but is also equipped with an aluminum layer that reflects heat.What does it do? This layer reflects infrared rays, preventing them from leaving the house. This creates a kind of "thermos effect". Foil film is intended for baths and greenhouses, but they began to use it as a vapor barrier for roofs made of corrugated board and other materials. It is highly efficient, reducing heat loss through the roof by 10-15%. This allows you to significantly save energy, which is spent on heating. For example, the use of Izospan for corrugated board increases the room temperature by only 2˚, while the costs are the same.

Note! The reflective effect is possible only in air, therefore, when mounting the film with foil, it is important to make a gap of 4–5 cm.

Pros:

- light weight;

- high strength and reliability;

- durability;

- low vapor permeability;

- not harmful to humans;

- reflects infrared radiation, keeping warm.

Minuses:

- high price.

Foil film is one of the best, but for quality, as they say, you have to pay. If you have a sufficient amount of funds, then it is better to make a vapor barrier under the corrugated board on the roof from it. All the same, which choice to make is up to you.

- Types of roofs of private houses

- How to properly cover the roof with slate

- How to cover the roof with corrugated board with your own hands

- Roofing cake device for corrugated board

Roofing plays a key role in protecting your home from rainfall and other adverse effects. A number of materials are used to retain heat and maintain a comfortable microclimate. Together they make up the roofing cake. So that the heated air does not leave the room during the cold season, heat-insulating materials are used under the corrugated board. Vapor barrier will allow maintaining a low degree of thermal conductivity.

How to properly glue the vapor barrier?

Let's consider the process of gluing a vapor barrier using the example of working with Delta adhesives and tapes:

1. Surface preparation. Before starting installation work with tapes and delta adhesives, the surface of the base should be cleaned of dust and dried. If the surface of the base is not strong enough, it must first be primed. On highly absorbent and dusty substrates, apply several coats of primer and allow to dry.

2. Bonding the joints of the vapor barrier using pasty glue. The composition is applied in a uniform layer in the form of a solid rope on one of the surfaces to be glued and the film is glued immediately. This should be done evenly and without tension on the glue strand. Strong pressure on the adhesive mass should not be exerted in order to avoid the release of the composition from under the seam. Provide adequate ventilation.

3. Bonding of vapor barrier joints using one-sided adhesive tapes. For reliable adhesion of the joints of the vapor barrier film using Delta adhesive tape, it is recommended to iron the surfaces of the films evenly using a special pressure roller on a flat hard surface.

Especially carefully you should glue the vapor barrier on the windows: when pasting the corners and edges of window openings, make sure that the Delta Multi Band is always glued from the bend line outward.

VIDEO INSTRUCTION

Please note: if the tape is first glued to the side surfaces, and then the corner joints are glued, then tension may appear in the tape, which will eventually lead to the material peeling off.

In our today's article, we will talk about protecting insulation from steam penetration. To be absolutely precise, we will try to figure out the best way to glue the vapor barrier. What means are there for this, and how are they used in this or that case. We asked an expert in insulation issues to help understand all the nuances and intricacies of the issue.

Editor:

Good afternoon, Specialist! Many words have been said about the thermal insulation of living quarters, attics, balconies, attics. We have clarified the situations in relation to the need to use a vapor barrier material in certain cases. But how to properly connect the vapor barrier sheets, how to seal the joints - these questions were left behind. Let's help readers figure it out.

Specialist:

Gluing sheets of vapor barrier material is a fairly simple process. But, at the same time, he is also very responsible. There are several types of adhesive tapes, and first of all, let's define the basic requirements that they all must meet:

- High adhesion of the adhesive layer - the canvas must be reliably, "tightly" glued both to the insulated structures and to the surface of the vapor barrier sheets;

- Should not deteriorate or change its properties under the influence of ultraviolet radiation;

- Should not absorb moisture;

- The operating temperature range should be up to 90 degrees Celsius;

- The service life of the adhesive tape cannot be less than the service life of the steam insulation itself - which is an average of 15 years.

Editor:

Our readers asked the question: "Is it possible to use ordinary stationery tape to connect the joints?"

Specialist:

My answer is definitely no. For all its stickiness and moisture resistance, it literally lags behind after a few days. Here are the connecting materials that will cope with the functions assigned to them:

- Aluminum tape. It is a ten centimeter wide roll of special aluminum foil with an adhesive layer. Perhaps this is the most versatile connector, but it also copes with gluing far from all types of vapor barrier.

- Reinforced tape. In fact, this is the same aluminum connector, but with increased strength.

- Polypropylene adhesive tape is perhaps the most affordable connector. But it has the lowest strength, which leads to its infrequent use.

- Reinforced adhesive universal adhesive tape. A five-centimeter-wide skein of scotch tape is reinforced with a fabric layer, and at the base of the adhesive composition is rubber resin.

- Butyl rubber connecting tape. High adhesion and reliable adhesion are the main advantages of this connector.

Editor:

As far as can be judged by the characteristics of adhesive tapes, each of them is good in its own way and the area of its application is determined by the characteristics of the premises, structures and types of surfaces that we glue?

Expert:

Quite right. In addition, I want to draw your attention to the fact that even the strongest adhesive composition will not cope with its task if the surfaces to be insulated are not properly prepared.

I strongly advise you not to rely on the Russian "maybe", but to approach the issue of choosing an adhesive tape for vapor barrier with all responsibility, because the reliability and durability of the insulation of the entire building or your room separately depends on such a seemingly trifle. The joint opened due to the peeled off tape will become a channel for moisture to penetrate into the insulation fiber. Deterioration of thermal insulation, dampness, fungus ... Saving on trifles, we risk losing the battle for heat conservation.

Features of installing a waterproofing film

Here are the main points that you need to pay attention to:

- It is unacceptable to install the film so that, during its operation, moisture from the upper part falls on the insulating layer of insulation.

- It is important to properly handle the junction of the penetrating elements, be it chimneys, antennas, ventilation ducts and more. For this, trapezoidal cuts are provided at certain points. The valve of the upper and lower position is fixed to the horizontal component of the crate with a sealed tape, or to a penetrating element.The lateral elements are retracted to the upper point and fixed to the penetrating component in a similar way.

- In the case of roof windows, follow the manufacturer's instructions for quality installation of adjoining materials.

- Roofs with sloped ridges and hipped roofs require laying the film relative to the longitudinal axis of the corresponding element.

- Horizontal strips on the pitched roof are mounted externally with overlapping.

Scotch selection criteria

Remember that stationery tape is definitely not suitable for bonding vapor barrier films. It is not designed to firmly bond to rough surfaces, so it falls off after a few hours. Even if it seems that it stuck reliably, keep in mind that the manufacturer did not count on using his tape in frosty conditions.

When choosing mounting tape, pay attention to the following factors:

- if you plan to use it outdoors, then the tape must withstand ultraviolet radiation and precipitation;

- the level of water absorption should not exceed 0.2%;

- it is important that the working temperature coincides with the climatic zone;

- choose tape for specific jobs, either for sealing the film or for bonding to hard surfaces;

- minimum service life 10 years.

Taking into account all the recommendations described, you can choose the best option for bonding the vapor barrier. Give preference to well-known brands, as they have proven their reliability in practice.

The installation of a vapor barrier is mandatory when building a living space. The film serves to protect the insulation from the vaporous liquid that emanates from the room into the inside of the roof of the house. A vapor barrier membrane prevents condensate from entering (the transition of a substance from a vapor state to a liquid) into the living room.

If the vapor barrier is installed on the wrong side, the house will accumulate too much vapor. The penetration of moisture under the roof will not be controlled. The insulation will absorb a large amount of water over time and lose its thermal insulation characteristics, and gradually the wall or ceiling coverings will be destroyed. This article will consider the issue of gluing vapor barrier sheets.

Since the seams of the vapor barrier layer are sealed with the help of a special construction tape, this material will be discussed. The general rules and nuances of establishing a vapor barrier will also be considered.

Vapor barrier of a floor in a wooden house

Hydro and vapor barrier are needed for insulated floors due to the action of two factors:

- moisture from the basement or basement passing through the ground;

- steam from the premises.

When insulating the floor, the waterproofing is first laid in the space between the logs on the rough floor. Film strips are placed with an overlap and glued with special tape.

Plates or rolls of insulation with a thickness of 15 cm are placed in the cells of the frame, and then covered with a vapor barrier film. Overlap and gluing of the joints are also necessary here.

Boards with a thickness of 30 cm and with a step of 40-60 cm are placed across the log. They are fastened with self-tapping screws or other suitable fasteners. Due to them, a ventilation gap is created between the floor and the vapor barrier.

Across the lathing, a tongue-and-groove floorboard of 25-30 mm or edged floorboard of 40-50 mm is tightly laid and fastened. A finishing floor covering is arranged on top.

Insulation of the floor of the first floor

The use of a vapor barrier for the floor is effective only in conjunction with a breathable insulation. Styrofoam and similar materials are not suitable here. It is advisable to use mineral wool with a density of 37-57 kg / m3, since there is no load on it in the floor structure.