Types of cable underfloor heating

The popularity of electrical systems is mainly based on features such as

- ease of installation,

- ease of use,

- durability,

- economic accessibility,

- the ability to quickly adjust the temperature.

In addition, in many cases, the use of similar equipment connected to a heating or hot water supply system is associated with many problems, ranging from the need to dismantle the floor, form a screed, lay pipes and end with the need to obtain a special permit for such an installation (for apartment buildings with central water supply) ...

Therefore, when choosing equipment, the question arises as to which is the best film or cable warm floor. In the first case, it is assumed to use a flexible film, which is an infrared heating element, in which carbon strips are located, interconnected by copper buses to supply the supply voltage.

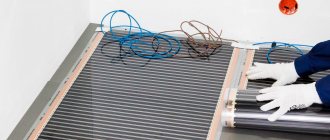

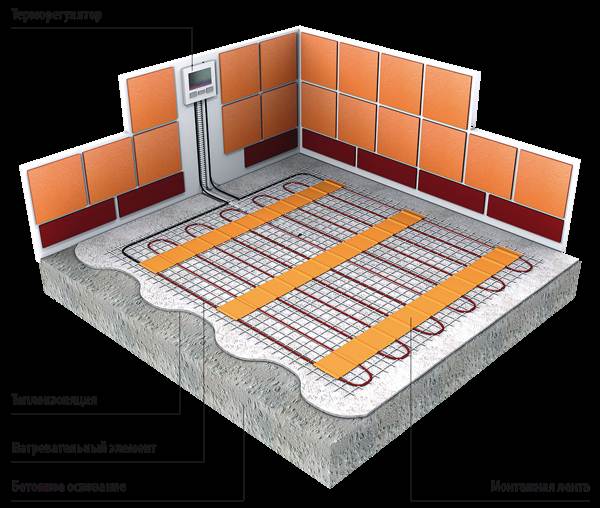

Cable underfloor heating

Its advantage is the ability to avoid the installation of an additional screed and lay the film directly under the floor covering without any difficulties in performing installation work. But at the same time, it is also worth highlighting such features of infrared systems as the need for a perfectly flat surface for laying in order to avoid damage to the film. In addition, the average service life of infrared heating materials is 5-10 years.

film warm floor

If you plan to install a cable underfloor heating, the characteristics of the equipment are determined primarily by the heating power, depending on the area of the room, its purpose

In addition, it is important how exactly the equipment will be used: as the main or additional heating.

electric underfloor heating

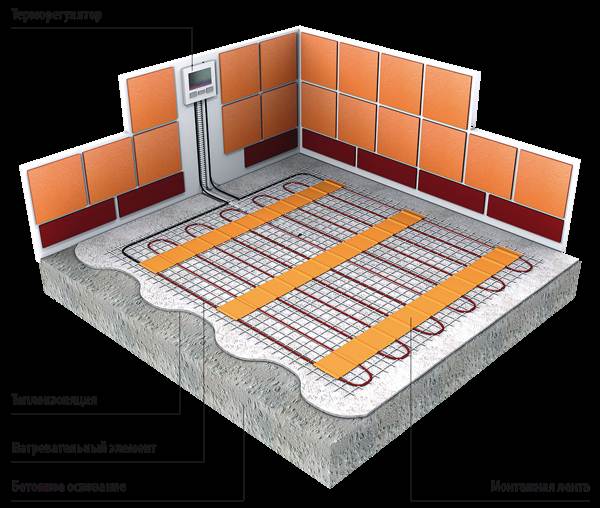

The principle of operation of cable underfloor heating is based on the use of a heating cable (or mat) as a heat source. It fits under the cement-sand screed. Then the flooring is laid. As a result, a solid heating surface is formed, which has a fairly high energy efficiency.

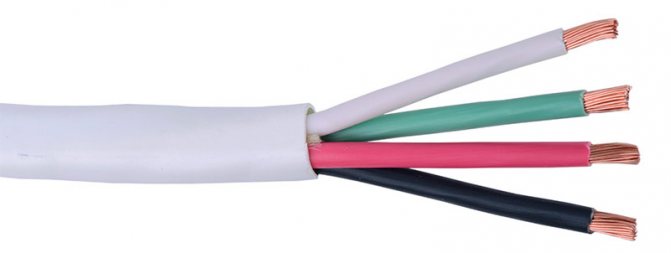

Why double-core underfloor heating is better

Which warm floors to choose - single-core or double-core? Why is double-core underfloor heating better? What kind of underfloor heating is better than two-core or single-core?

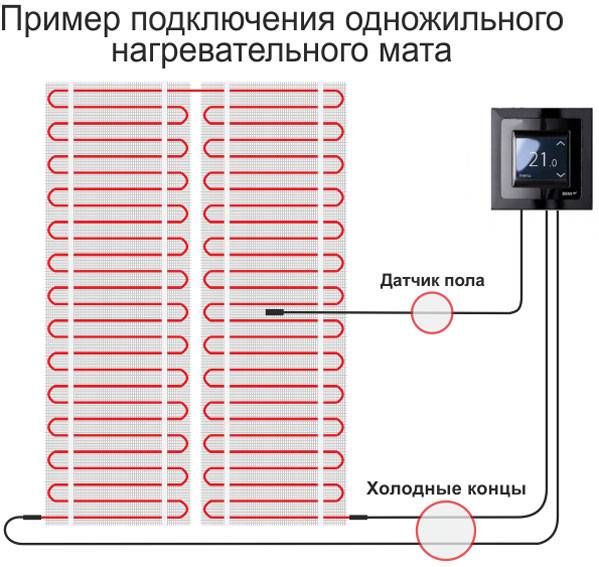

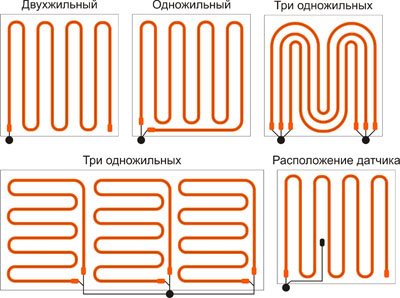

In cable electric underfloor heating, a special electric cable serves as a heating element. When heating mats for tiles Is a thin heating cable fixed with a "snake" on the supporting mesh (you can read what heating mats are here). In the case of heating sections that are installed in the screed layer, this is a length of sufficient thick heating cable. In any case, the type of underfloor heating depends on the design of the heating cable.

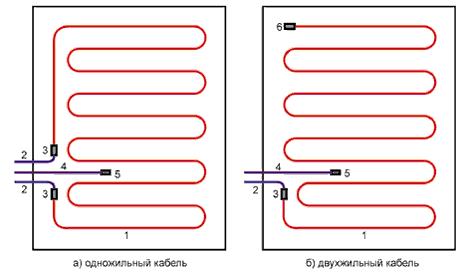

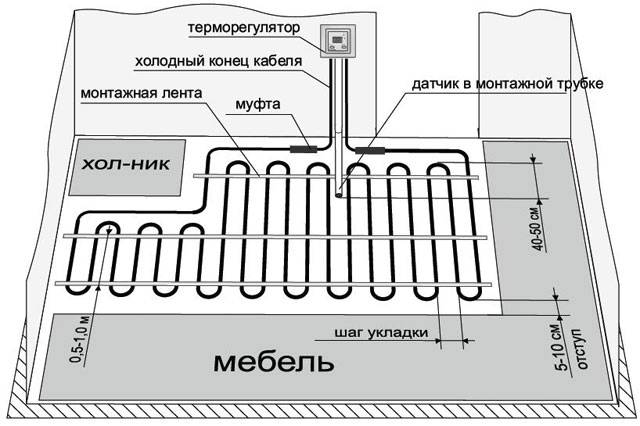

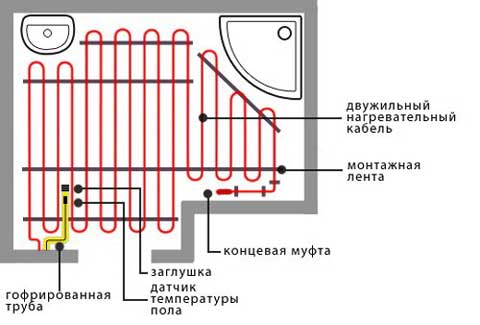

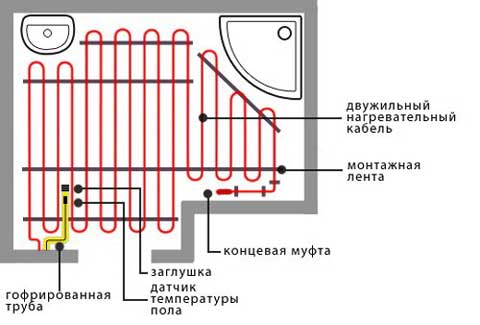

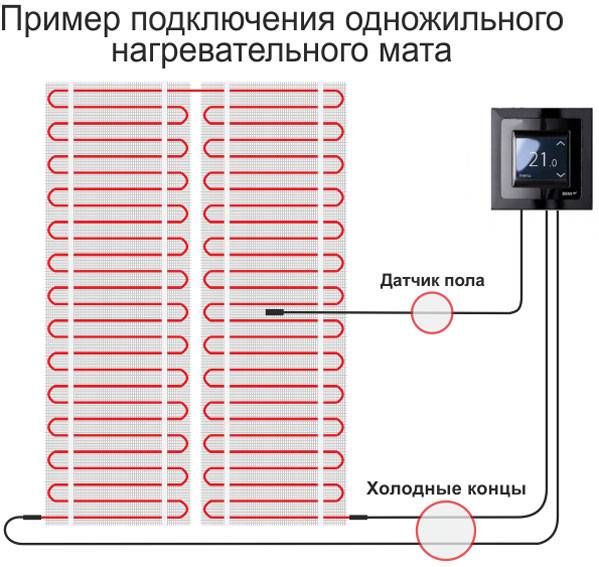

The main differences appear when laying a warm floor. During installation, the supply cable of a single-core mat or section begins to be laid from the thermostat and it will be necessary to return the second end of the single-core cable to it; The two-wire cable requires only one end of the connection to the thermostat. After laying the cable, the second end remains in the place where the laying ended, which in rooms with a complex configuration greatly facilitates installation;

- Heating cable

- Power ("cold") ends - connection to the thermostat

- Clutch

- Corrugated tube

- temperature sensor

- End coupling

The second difference is also explained by the design: due to the two-core design of the cable, the radiated magnetic field in the two-core heat field is compensated. Due to this, the level of magnetic radiation generated by a single-core cable is 0.2 - 0.4 μT, created by a two-core cable - 0.02 - 0.05 μT. Thus, the level of magnetic induction created by a single-core cable is slightly higher than that of a two-core cable. But the most important thing is that both for a single-core cable and for a two-core cable, these levels are orders of magnitude lower than both the permissible levels of magnetic induction in residential premises and the natural geomagnetic background of the Earth, which is 30-60 μT.

General recommendations of manufacturers of underfloor heating are as follows: it is recommended to install a two-core warm floor in rooms where people stay for a long time (bedrooms, children's rooms, etc.), and a single-core warm floor in bathrooms, on balconies, etc.

In conclusion, we can say that a two-core warm floor is considered better because it is more environmentally friendly and easier to install, but it is more expensive and slightly thicker. Single core warm floors (especially heating mats) are thinner and cheaper. So if you need the minimum thickness of the underfloor heating, then the use of single core heating mats will be better and more correct.

In the online store you can purchase single-core and double-core warm floors of different manufacturers from budget to the most expensive.

- Electrical

- About heating household pipes

- About construction heating

- About warm floors

- About electric heaters

How power is calculated

In order not to miscalculate with the power, they first determine whether the warm floor will be the main source of heating or an auxiliary one.

On a note. When performing the calculation under the condition of an auxiliary source, the power of the main heat source should be taken into account.

An approximate calculation for a two-room apartment, where, taking into account the correction coefficients of the heat transfer resistance of surfaces, the total heat consumption is 6 kW.

The logic is as follows:

- to heat 10 square meters of living space, about 1 kW of thermal energy will go;

- with the main heating, heating of the area is covered by 90 percent;

- underfloor heating as an auxiliary heating element needs to be compensated for by 10 percent;

- taking into account 6 kW of total consumption, (10x6) / 100 = 0.6 kW.

This calculation is correct if underfloor heating is installed in all rooms of the apartment.

Sometimes average values are used for calculation.

- for kitchens and residential areas 110-150 watts per 1 square meter;

- for bathrooms 140-150 watts per 1 sq.m.

When choosing which warm floor is better, two-core or single-core, you need to take into account the level of the comfortable temperature. Two-core models heat up most intensively. The temperature level adjustment depends on the heating time of the floor. When there are no special requirements for the microclimate, you can choose single-core modifications.

Determination of power

To determine the power, it is important to decide whether the electric floor heating will be additional or main. To make it easier for you to determine the power of underfloor heating, take as an example a room (of two rooms), for which the total heat energy consumption, taking into account the heat transfer resistance coefficient of surfaces, is 6 kW.

If you are going to calculate the floor heating, which will be used as an additional one, it is important to take into account the power of the main heating.

So, for 10 m2 on average 1 kW of generated heat is required. If it is radiator heating, designed to heat 90% of the area of the room, then underfloor heating will compensate for the missing 10%. So, for 90% of the area, 5.4 kW of energy will be needed, and for the missing 10% - 0.6 kW. But this rule only applies if the warm electric floor is laid over the entire area. However, this is not always possible.Therefore, it is best to build on these values:

- For living quarters and kitchens, 110-150 W / m2 will be required.

- For bath and shower 140-150 W / m2.

Another important factor is temperature comfort. If more heat is required, then it is worth laying a two-core cable. It is also worth paying attention to the settings that are made through the thermostat. You can set a program for a specific heating time. Firstly, this way you will reach the desired temperature, and secondly, the heating system will be economical.

If there are no individual temperature preferences, then it will be enough to purchase a single-core cable.

So, deciding which cable is the best is quite difficult. This will largely depend on the desired room temperature.

Solid and stranded cable

In order to give the wire more flexibility and elasticity, a thread is sometimes braided along with the cores in production. In terms of strength and composition, it is very similar to a nylon thread.

It is clear that each cable has its own purpose, otherwise they would not be different. And there really is a difference. And it is that a single-core wire has more rigidity than a stranded one. This means that you can do twists. That is, you can twist the ends of the wire with pliers, wrap it with insulating tape, and the connection is ready. And no terminals are required. It can also be used in high frequency circuits.

And if a single-core cable has a large cross-section, then it can be very difficult to bend it. The high rigidity of a single-core wire is a property that is taken into account, for example, when installing electrical wiring in an apartment. That is, the use of a single-core wire, first of all, where fixed wiring is required. It is used when it is necessary to supply electricity to outlets, lighting lamps, etc.

In industry, thick single-core conductors can also be used to divert the electricity generated by electric generators into the power grid. For industry, as indicated above, single-core wires are also used, however, provided that their cross-section is much larger.

The great flexibility and elasticity of a stranded wire is a property that is taken into account, for example, in headphones, in extension tees, in car wiring, in household appliances, and so on.

Stranded wires have a higher conductivity than solid wires. If you use special terminals, then the connection of such wires becomes more reliable and has a lower current resistance compared to a single-core conductor.

It is convenient to solder such wires. But there is something confusing about multicore cable when using it. Small veins break off. It is, of course, necessary to point out the disadvantages of both types of cable. Solid wire does not tolerate strong vibration. Any excesses are harmful to him. For stranded wires, there are limitations in their use in high-frequency circuits.

Two-core warm floor

Such designs have a slightly different structure - two heat conductors significantly increase the heating power of the system. Compared to single-core models, these models are more energy-intensive and easier to install. For cables with one conductor, it is necessary to provide an input of 2 ends of the wire for connection to the power supply. In the second case, the circuit closes at the end of the cable - the contacts are simply connected to each other.

Heating cable requirements

If you rely on state standards, then it is important not to forget about the following general requirements for the heating cable:

- If the underfloor heating system is to be used in an apartment, then it must be an additional, not the main, source of heating.

- In wooden houses with a wood base, you need to install such a wire, the power of which will not exceed 2 kW.

- For heating ramps or stairs located outside the room, a wire with a rated power of 4 kW is used.

- To equip one circuit, you must use a continuous piece of cable. It is advisable to mount one circuit in one room if its area does not exceed 25 m2.

- The passage of a wire from one room to another is not allowed. In the transition area, it can simply break.

- To lay the product, you must use only those parts and accessories that are sold with it in the kit.

Installation of underfloor heating cables must be carried out in strict accordance with the manufacturer's instructions.

Single or double core cable

Is a two-core cable really much safer than a single-core cable in terms of radiation? In fact, both cables are safe: the level of electromagnetic radiation generated by them is much lower than the maximum permissible for human health. But

a two-core cable is safe "squared", since its radiation (0.02-0.05 μT) is an order of magnitude lower than the radiation of a single-core cable (0.2-0.4 μT)

... That is why a two-core cable is recommended for residential premises, especially those where children are regularly and for a long time. Another key difference between these types of cable is ease of installation. When laying a single-core cable, it is necessary to return both its ends to the connection point, and when laying a two-core cable, there is no such difficulty.

Heating cable: some physics

The operating principle of the heating cable is based on the Joule-Lenz law. If physics is not your strong point, or you have studied it for too long, here are the main points. In this case, we have a conductor (heating cable) through which an electric current flows. According to the law, a conductor is necessarily heated under the influence of an electric current. The heating power directly depends on the magnitude of the electric current and the resistance of the conductor. This effect is extremely undesirable for wires and cables of power supply systems, but in the case of a heating cable, on the contrary, it is welcomed and developed.

Brief classification of cables

All modern heating cables are structurally can be divided into 2 types: resistive and self-regulating

... A resistive cable is characterized in that it has a constant output power over its entire length, which depends on the length of the cable, the applied voltage and the resistivity of the material. For the manufacture of cores of such cables, special alloys are used, which are characterized by an insignificant value of the temperature coefficient of electrical resistance. Due to this property, it is possible to produce a cable that, with different heating, has an almost unchanged thermal linear power, i.e. heat generation is constant over the entire length of the cable.

Resistive cables are divided into 3 groups depending on the operating temperature range:

- low temperature - up to 100 ºС; - medium temperature - 100-250 ºС; - high-temperature - 250-1000 ºС.

Cables can also be:

- single-core, - two-core.

Single core resistive cable

Resistive single-core cables are connected to the power supply at both ends. The most budget-friendly version of such a cable has only an insulating layer and an outer protective sheath. A more expensive and safer version implies the presence of a special protective screen that protects a person from electric shock. In addition, the screen is used to reduce the voltage of the electromagnetic field to the permissible sanitary standards.

Two-core resistive cable

Two-core resistive cables are connected to the electrical current source at one end only. At the other end of the cable, there is a sleeve that connects the heating and return conductors.In this heating system, the coupling is one of the most vulnerable elements, therefore, special attention is paid to their development. As a rule, the manufacturing technology of couplings is protected by manufacturers as know-how and is not disclosed. In a two-core resistive cable, two conductors are located in parallel.

Electric current moves along them in opposite directions to each other,

which contributes to the appearance of the effect of mutual compensation of the strength of electromagnetic fields

... That is why a two-core cable is safer during operation for human health.

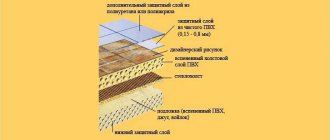

- For the manufacture of heating conductors, which are used in high-resistance cables, nichrome is most often used. Nichrome is an alloy of nickel (55-78%) with chromium (15-23%) with the addition of iron, manganese, aluminum and silicon as alloying additives. For the production of low-resistance cables, either galvanized steel or nickel-plated copper conductors are most often used. - Insulation of two-core cables can be either single-layer or multi-layer. Multilayer insulation provides a higher quality dielectric strength, but such a cable is slightly more expensive. A wide range of materials is used for the production of insulation: polyethylene, fluoropolymer, polyvinyl chloride, etc. - An insulated heating conductor is placed in a special protective screen in the form of a braid made of tinned or nickel-plated wire. A solid metal tube made of aluminum or lead foil can also act as a protective shield. - The final layer of the entire structure is a shell made of high-strength polymers.

As a rule, a two-core resistive cable is supplied for sale with ready-made heating sections. Those. this is a piece of heating cable, completely ready for connection to a power source, with pre-installed couplings at the ends. The length of one section can be from several tens to several hundred meters and is selected in such a way that the applied voltage reaches a complete drop without overheating. At the moment, the market is replete with offers from various manufacturers of resistive cables. The STEM Energy brand offers an optimal price solution for heating cables.

Regardless of the type of cable, during its production, special attention is paid to quality control and product reliability. This is especially true in matters of electrical safety. therefore heating cable for "warm floor" is made, as a rule, with shielding and requires grounding during installation

.

Single core underfloor heating device

The main element of a single-core underfloor heating is a cable with a certain diameter. The core material is nichrome, galvanized, brass or other metal. When power is applied, the resistance heats up the core.

For maximum safety during operation, the system is wrapped with two or four layers of insulators:

- a heat-resistant layer, the material for which is polyvinyl chloride, fluoroplastic, silicone rubber, or cross-linked polyethylene;

- sheath made of foil-clad aluminum and copper mesh, which protect against electromagnetic radiation;

- outer layer of plastic that protects against mechanical damage;

- copper ground, which is connected to the supply cable.

If everything is done correctly, then the heating core will be warmed up by no more than 80 degrees. The insulator can withstand from 100 degrees. Different manufacturers have their own insulation system, so when buying, you can separately ask what material it is made of and in how many layers.

Single core electric floor

Underfloor heating installation schemes.

A single-core wire consists of one metal core covered with an insulating material.The cable material is usually nichrome, brass, galvanized steel or carbon compounds. The cable has strong insulation that can withstand heating up to 100 ° C and can be made of silicone, polyethylene and Teflon. The insulating layer contains a copper or steel screen that protects the heating conductor from damage and serves as a grounding conductor.

The whole structure is connected to the network using 2 couplings and 2 ends of the wire, which do not heat up. In this design, the cold wires are connected to the 2nd edges of the heating section. The advantage of such a system is the low cost of the starting material. Due to its design features, a single-core cable is more fragile and can break if laid incorrectly.

Deviations about single core. Solid and stranded wire, what is the difference

Quite often you can hear how they try to compare these two types of cable products and find out which wires are better, stranded or single-core? Let's say right away that such a formulation of the question is generally incorrect and shows the incompetence of the questioner. After all, you can also ask: "Which is better, a shovel or a hammer?"

The choice of the type of conductor in a cable or wire is equally dependent on 1) the location and 2) the operating conditions. Therefore, instead of breaking spears, it is better to "get acquainted" with the candidates for selection, find out their features and differences, and only then decide which one is much better.

What is single core and what is stranded wire

In the truest sense of the word, the expression "single-core and stranded" does not apply to this issue, since the word "cores" refers to the total number of conductors in a cable or wire, and not to the structure of an individual core. It would be correct to say a single-wire or multi-wire core. But, for some reason, the expression "stranded" stuck. For the truthfulness of the information, we will use the correct term, but we will not condemn those who have got into the habit of another option either, it is not our business.

Single-wire wire - having only one core as a conductive element, with a cross-section from the standard row (0.5-1-1.5-2.5-4, etc. mm sq.)

Stranded wire - as a conductive element - it is several conductors intertwined with each other, having a total cross-section in the same standard values. It is allowed to weave a non-conductive thread (usually reminiscent of nylon) into the conductive cores to increase the elasticity of the entire cable.

Features of each of the two types of wires

Both a flexible blade of grass and a rigid tree can withstand a hurricane, so we must understand that the same properties of wires (under certain circumstances and installation requirements) can also become both a disadvantage and an advantage. And, instead of supporting the "best" debate, we will present the full picture, pointing out the characteristics of each type of vein that help in making the right choice in specific situations.

1. Single-wire conductor.

Bottom line: whatever the "home-grown" electricians say, but in most household electrical systems it is more efficient and competent to use wires with single-wire conductors. For most, but not all, consider the other side of the coin.

2. Stranded conductor.

Applications for solid and stranded wires

So a reasonable conclusion suggests itself: each of them is good if it is in its place. The properties indicated above, without dispute and hesitation, show where it is more appropriate to use each type of wire.

Stationary wiring of power cables in houses, apartments and industrial facilities with medium and large cable conductors is preferably carried out with single-wire conductors (if there are no special requirements).On electrified railways, all contact wires have exactly this design, serving reliably and for a long time.

Electrical cables can be divided into single-core and multi-core, they are also called hard and soft, or solid and flexible. Whatever you call them, the former have one core, while the latter have several cores. Single core and many

Two-core or two-core?

Published: 08/22/2009 0:00

A reader called the editorial office and asked how to write correctly: two-core or two-core? Such phrases are quite often found in our speech, but there is no single rule regulating the formation of complex words, the first part of which is the element of two or two, there is no. But the analysis of these words allows us to draw some conclusions. First: the element of two- (the form of a once-existing dual number) is written mainly in the so-called bookish words, in an upbeat speech: a two-headed eagle on the coat of arms of Russia, two-faced Janus, a two-footed cross, a twofold holiday, double-dealing, ambiguity, bilateral agreement , gig, duality. Second: in terms we also use bipartite (dioxide, binomial, bilingualism, diptera, bipartite, bipedal, bipedal, bipartite, bipartite, bidirectional). Third: before vowels (including iotated ones), as a rule, the element two- is written and pronounced. This is done to avoid gaping (that is, the confluence of two vowels, which sometimes makes it difficult to speak): two-address - and not "two-address", where "y" and "a" collide, two-name, two-tiered, two-tiered, double-capacity, two-window. But in terms of this phonetic-orthoepic side, that is, the gaping, is not taken into account, they still have the proximity of vowels: bicarbonate, fluke, bilingual, dioxide. Fourth: in everyday words, the element of two- (two-bucket, two-color, two-hour) prevails, although these words also have book versions (two-bucket, two-color, two-hour) - choose any. But even in book words, an element of two- (two-chamber system, two-stage elections, a two-tee beam) is used, as well as in words of the colloquial style - an element of two- (two-headed, ambiguous, two-edged). Fifth: words with an element of two - win in the historical race. For example, before it was: if "agreement", then "bilateral". And now the option "bilateral agreement" is allowed. Well, how to answer the reader's question? We write "two-core" if we mean someone with two cores. Immediately I remember the great film "The Marriage of Balzaminov", where the illiterate heroine says: "And they say there are two-core horses" ... And we write "two-core" - if this word is synonymous with the word "strong": a two-core person is a strong person. See you! (Author's phone: 562-10-80).

Article author: YANKINA Olga Release: № 169 (26546)

Add "Republic of Tatarstan" to your favorite sources on Yandex.News Subscribe to the channel "Republic of Tatarstan" in Yandex.Zen

Add a comment

Click here to cancel reply.

You may also be interested in

25.05.2020Not everyone was lucky with the "gos"Vice-rector for educational activities Dmitry Tayursky spoke about the nuances of the upcoming examination tests for KFU students ... 3960 |

21.05.2020The exam will begin on June 29The Unified State Exam in Russia will start on June 29 this year. This was stated by the President of the country Vladimir Putin, speaking at a meeting on the situation in the field of education in the context of a pandemic ... 4360 |

21.05.2020How to pass exams remotelyA live broadcast on the organization of distance exams for students will be held at Kazan Federal University on May 22…. 4950 |

20.05.2020A new reading of the term DNAOn the basis of the Yelabuga Institute KFU will open a center for children's additional education…. 6050 |

18.05.2020Login through the portalKazan Federal University will conduct the admission campaign in 2020 completely in a distance format, including for foreign students…. 8370 |

Two core electric floor

A two-core cable is slightly different from a single-core cable in its design. In such a cable, 2 wires isolated from each other (cold and heating) run in parallel under the outer sheath. These wires are attached to one side of the heating section.

There are no differences in quality and service life of 2 compared heating elements. However, the two-core floor has a plug at each end of the section that connects and reinforces them. 2 other parts are similarly connected using a sleeve and cold ends of the wire.

The two-core cable floor is easier to install, since it already has a ready-made end for connecting to the mains. And the end of the single-core cable after laying must be returned to the connection point (looped back).

The main criteria that influence the choice are: the type and size of the room in which such a structure will be mounted and the thickness of the screed. Experts recommend using a single-core system in small and warm rooms, and a two-core floor for potentially cold, damp and spacious rooms. In apartments, cottages and private houses for the installation of underfloor heating, as a rule, a two-core underfloor heating is used. And in public, office and non-residential premises, it would be more expedient to use a single-core cable, since almost any conductor with an electric current generates electromagnetic radiation, which is unsafe for both people and animals. In a single-wire cable, current flows in one direction, creating harmful electromagnetic radiation.

A two-core cable has 2 wires with mutually directed electromagnetic fields that neutralize each other. In terms of quality and service life, both systems have no differences.

It should also be borne in mind that when using such a cable heating structure, the floor height will rise by 5-10 cm. The electric cable heating system is universal and suitable for many types of coatings (linoleum, tiles, carpet, laminate, natural stone). It helps evenly and correctly distribute warm air throughout the room thanks to the regulator. Modern developments and technologies make it possible to maximally screen the heating conductors of the cable. Today, underfloor heating is an environmentally friendly, economical, practical and very convenient solution for insulating your home.

Electric option

When using the electric option of underfloor heating, there is no need to install additional equipment. Such a floor is a simple and quite effective solution for any room.

What elements does it consist of

Underfloor heating components.

Consider which components are used to assemble the electrical system of the heated floor:

- the heating element is the main component of the system, a conductor with a sufficiently high resistance, it heats up from the passing electric current;

- the underfloor heating temperature sensor is used to monitor the operation of the cable;

- thermostat - an electronic device for the possibility of automatic control of the floor heating process;

- mounting tape, used to secure the heating element;

- thermal insulation is designed to reduce heat loss and reduce energy consumption.

Important. No mounting tape is required when installing heating mats. In the mats, the cable is already fixed to the mesh, which means that these floors are easier to assemble with your own hands. Mats are used under the minimum floor screed of an apartment or house or tile adhesive, and the heating cable under the screed at least three to five centimeters.

Heat source

The figure shows the structure of two types of heating cables.

The cable is the main element of the warm floor of an apartment or house, which actually serves as a source of heat. Resistive cable is used in floor heating systems. It has constant resistance. The heat is evenly distributed along its entire length.

Like all other electrical appliances, the heating element creates an electromagnetic field. The question immediately arises as to whether it can be used in a residential area? Let's try to figure it out.

There are two different types of resistive cable:

- single-core, with one conductive core;

- two-core, with two current-carrying conductors.

They differ in that in a two-core structure, the electromagnetic fields from the two cores cancel each other out. This is the difference between a single-core warm floor and a two-core one.

Right choice

Diagram of a heated floor device with a two-core heating element.

In order not to be mistaken with the choice of the option, it is necessary to understand for what purpose which cable is used.

Single-core can be used for the device:

- heated floors in utility rooms where a person is not located for a long time;

- for heating garages and utility blocks;

- for the device of the anti-icing system;

- for heating external steps;

- for heating industrial sites.

Advice. In Europe, according to the norms, it is forbidden to arrange a single-core warm floor in rooms where people are for a long time. So far, this is only at the level of councils. It is believed that electromagnetic radiation from such a floor is significantly lower than permissible standards. But those who care about the health of their loved ones will choose a two-core warm floor, as the safest for a person.

Two-core shielded heating system for installation under tiles in tile adhesive.

The plus of a two-core heating system lies in the simplicity of its installation compared to a single-core one, in which the other end must be returned to the connection point during installation.

Two-core systems do not have such a need, they have a second end ready for connection. The clear instructions from the manufacturer, attached to each set of the electric floor, allows for competent installation in accordance with all the rules.

The advantage of a single-core system is, undoubtedly, its price, which is much lower than that of a two-core system. Inexperienced consumers often choose this option for a heated floor without thinking why it is cheaper. It happens that the family has a limited budget and people decide that they will do with this option.

Floor coverings also impose certain restrictions on the choice. For example, it makes no sense to arrange a heated layer under a coating that has a thick rubberized base.

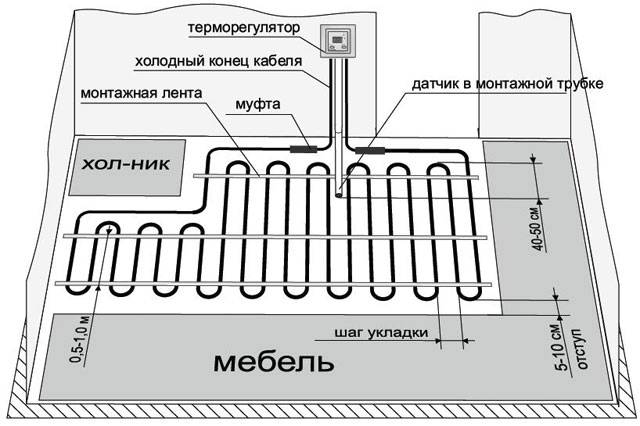

How to install underfloor heating

Before starting the installation, it is necessary to make a "warm floor" project. It indicates the power of the equipment. The data is calculated according to the norm: for heating 10 m2, 1 kW of energy is required. If a two-core underfloor heating is additional heating, only 10% of the room should be heated for full effect, then, accordingly, the indicator will be different, 10 W per 10 m2.

The cable is connected to electricity. The passport for the equipment must indicate from what voltage it works. If the home wiring does not provide for the use of high-power appliances, then it is recommended to make new wiring in the house. Some systems operate from 230 V. How is cable heating installed?

- The room provides for a place on the wall for installing a thermostat and an automatic device. A recess is made on the surface of the wall, which is equipped with a plastic box. It will contain electrical wires and a heating system control unit.

- The base must be leveled before laying the cable. A concrete screed is made, equipped with heat-insulating material. A damper tape is reinforced around the perimeter of the room. It retains heat in the room, compensates for the expansion of heating elements at the time of heating.

- If the room is located on 2 or more floors, the thickness of the insulation can be 2-3 cm. It is recommended to use a material with a reflective surface.

- Mats are placed on the marked area, to which the cable is fixed. The upper part of the mat is covered with a protective film. All elements of the system are connected in turn.

- If it is necessary to lay a separate cable, then metal tapes are installed on the thermal insulation for fastening. The sections are laid with a certain step. It is calculated by the formula: S premises / L cable length.

- The ends of the wires must be insulated. To do this, use a shrink film.

- A temperature sensor is placed on the surface of the heated area. The distance from the wall to the sensor is 60 cm.

- The sensor and all wire outputs are connected to the network.

- Testing the system.

- A screed with a depth of at least 20 mm is laid on the floor.

Two-core warm floor

The "warm floor" system has been used for many years. She has proven herself well both in country cottages and in city apartments. It is not difficult to install cable heating. It is necessary to calculate the electricity costs associated with heating the home. The cable is used as additional heating in the children's room, in the bathroom, in the bathroom.

What are the differences between cable and wire

The same conductors of electricity can be called a cable, wire or cord. At the same time, in truth, both buyers and some sellers do not particularly bother with the correctness of the wording.

Wire - base

By definition, a wire is one or more live conductors that connect two sections of an electrical circuit. The veins can be single or multi-wire, bare or insulated and differ in other characteristics. There is also a separate category of protected wires, which are easy to confuse with a cable, due to the presence of an outer sheath - each core has its own insulation, and all together from the outside is additionally closed with a cambric made of polymers or similar materials.

Bare wires are practically not used in domestic conditions - they are more often used to transmit electricity through overhead lines and in other places where a person does not get into without a permit.

Insulated wires themselves are poorly used in everyday life - they are more used inside various electrical equipment or in the electric network of an electric vehicle.

Cable - prefabricated

In structure, the cable is similar to a protected wire - it is one or more current-carrying conductors, each of which is in its own insulation, plus one more insulating and protective outer layer made of polymers, plastic or rubber.

The main difference between a cable and a wire must be sought inside - if the latter's outer sheath is just a tube, then the cable additionally fills the space between the current-carrying conductors - threads, tapes or coated composition. This prevents the cores from sticking together, which may move slightly relative to each other when the cable is bent, which simplifies its installation and further maintenance.

Additionally, armored cables stand out - they have several layers of outer insulation, between which there is protection against mechanical damage in the form of braiding or intertwined metal tapes.

Cord - flexibility

The main use of electrical cords is to connect household electrical appliances to the network. They must have increased flexibility and resistance to repeated bending, therefore, copper stranded conductors with a total cross section of up to 4 mm² are used in the cords.

To avoid excessive consumption of copper in the manufacture of devices, the cross-section of the cords is selected depending on the power of the connected devices.For small electrical appliances, such as an electric shaver, it will be 0.35 mm², TVs need only 0.5 mm², and devices with an electric motor - from 0.75 mm².

There are no strict standards for the length of the cords, but most often they are 1, 1.5, 2, 3.5, 4 and 6 meters. Often, electrical appliances are equipped with cords with non-separable (disposable) plugs, and for some devices, reinforcement is woven under the outer insulation to increase mechanical strength. If you have to change the electrical cord on a device with heating elements: an iron, a boiler, a kettle or an electric stove - it must be borne in mind that the insulation must be with increased temperature resistance.

As a result - the main differences

An independent and separate unit is the wire - bare or insulated. Several insulated wires, collected in a bundle and twisted together, this is also a wire, but stranded. If there is additional insulation on top of a stranded wire, then this is a protected wire.

If there are additional elements between the cores of the protected wire: reinforcing threads, coating, or part of the outer sheath is "recessed" between the wires, then this is already a cable. A flexible wire or cable made to connect to a network of electrical appliances is called a cord.

How is the installation

The next step after choosing the power is to determine the model of the warm floor.

Two types of products with a fundamental difference in installation:

- integral mats with fixed heating elements;

- cable, which are mounted with the desired pitch.

How to choose? In standard configuration rooms, you can safely mount mats. They can be either single-core or double-core cables. The second type will provide faster heating of rooms. The larger the conductor diameter, the higher the temperature level will rise when the equipment is turned on at maximum.

The specificity of the installation of a single-core system provides for the obligatory circuit closure. Both ends of the cable must be connected to a power source. When the areas are large, it is convenient to lay with a "snake", so this condition is difficult to comply with. But for a small room it is quite suitable. Moreover, the price of single-core systems is low.

In a two-core underfloor heating system, the circuits are closed according to a different system. At the ends, two wires are connected. The thermostat is also powered when both cores of the heating elements are connected. The models are more complex and therefore more expensive. At the same time, they allow solving the problem of warming large areas.

Advice. The level of electricity consumption by underfloor heating is directly proportional to its power. In this regard, it is necessary to correctly calculate the load on the wiring. If there is a discrepancy, the wiring must be replaced.

If the room has a complex configuration, then a two-core warm floor will solve the problem, since there is no need to return the cable back to the thermostat. The equipment installation process will take about 4-5 hours, no more.

It is believed that both variants of underfloor heating are harmless to humans. However, a two-core cable for a warm floor creates an electromagnetic field 300 times less than the norm, a single-core cable - 60 times. For this reason, in large kitchens and living rooms, where people stay longer than in other rooms, it is more expedient to use two-core cables. Single-core - in bathrooms, corridors and loggias.

When laying the equipment, you should take into account how much heat energy will go into the subfloor. So, for example, in apartments and houses on the second floors and above, there is no need to build powerful thermal insulation, a foil layer is enough. But above basements or on cold floors in households, the surface must be thoroughly insulated, otherwise some of the heat will go "nowhere". With the loss of heat, kilowatts of electricity go away. Therefore, it is better not to save on a heat insulator for the floor.

Some misconceptions about the warm field

The most common misconception is that many people think that the effect of a warm floor will be felt 10-15 minutes after it is turned on.This is not the case, the floor will only get warm after a few hours, because first you need to warm up the concrete slab. Even if a floating screed with thermal insulation is arranged, 3-4 hours should pass for warming up to 30-40 degrees. Therefore, if you are planning an electric heated floor in the bathroom, be aware: to feel a comfortable temperature under your feet, you need to turn on the warm floor in advance, 3-4 hours in advance. In general, underfloor heating is not relevant for short start-ups; it will be useful when turned on for long hours.

Due to the need to "warm up", there are many myths about energy consumption. In fact, energy consumption is not difficult to calculate. To do this, the total floor power in kilowatts must be multiplied by the number of working hours.

Example:

Underfloor heating in the corridor, installed in a place where they take off their shoes and leave shoes, an area of about 2 m2, a cable length of 24 m, a power of 440 watts. In kilowatts, 440 W is 0.44 kW, multiplied by 24 hours: 0.44 * 24 = 10.56 - ten and a half kilowatt / hours will consume this floor during continuous operation for one day.

It is worth adding that there are "smart" thermostats on sale that can turn on the warm floor a few hours before your arrival. Naturally, for this you must first program the thermostat.

Installation methods

The heating cable must ultimately be closed on all sides with mortar / tile adhesive, this can be achieved in three ways:

Fill

... The most correct way in my opinion. It consists in pouring a mini-tie 1-2 cm over the mounted cable. The resulting screed will be suitable for any floor covering. To implement this option, when pouring the main screed, a couple of centimeters of height should be provided, in places where there will be a warm floor. For work, mixtures are used that allow pouring such thin layers. If initially the screed is poured into one level and raising the floor level is unacceptable, then this method is not suitable.

Glue layer

... When tiles are laid, and everything else, it is permissible to raise the level of the subfloor by 1-2 cm (do not forget, the tiles themselves will add at least 1 cm), the tiles are placed on top of the cable on a thick layer of glue. This option should be considered last, because there will be a significant drop at the border of the warm zone.

Gutting

... The most difficult and dreary way, however, when raising the level of the screed is unacceptable - the most correct. First, you need to mark the lines where the heating cable will go. It is also necessary to take into account the groove for the corrugation with a temperature sensor and a coupling with a cold connecting cable. After marking, you need to attach some kind of thread / rope to the lines to check the length of the groove. You need to be sure that the entire cable will fit into the future strobe, otherwise you need to change the markup.

After strobing, the dust is thoroughly removed and the surface is primed. The wire is laid in the groove, the depth of the groove should allow 3-5 mm of grouting solution to be applied over the cable.

The thermal sensor in the corrugation is also mounted in the groove, the corrugation must be muffled from the end (wrap with electrical tape). The end of the corrugation should be located between the heating veins, not far from the edge of the heating zone (but not at the edge). The optimal distance of the temperature sensor is 30-50 cm from the edge, deep into the warm area.

When the wire is laid, the grooves are sealed with tile glue, or a mixture of self-leveling floor. If you plan to lay linoleum, it will not be superfluous to apply a finishing layer of 1-2 mm of self-leveling floor.

The floors should be checked or used no earlier than a month after the completion of all wet processes with the floor (pouring, laying tiles). Turning on earlier will not damage the cable itself, but may cause the solution / glue to crack.

Conclusion

- The heating cable is recommended for underfloor heating. The most preferred application is a direct heating system or "thin floor" system.

- Among the variety of heating cables, it is best to use a two-core resistive cable in terms of price-quality ratio.

- The choice of the right cable with the required power density, its length and laying pitch are obtained as a result of calculations.

- It is unacceptable to change the length of the resistive cable section (except for the zone cable).

Which wire is better in terms of parameters single-core or stranded

stupid question cross-section and separation of channels or phases

For what purpose? For stationary electrical wiring, single core is better, as it is more resistant to corrosion. A stranded wire has a more developed surface, therefore, the oxidation area is larger. And the price of stranded wire is higher.

but depending on why ... If a cord for equipment, a portable extension cord, etc., is naturally multi-core with its much greater resistance to multiple bends and twists .. A single-core such "liberties" simply cannot bear, breaking off somewhere at 5-7 sharp bends , but on the other hand, when the wire is stationary (for example, in a cable channel or on brackets on the wall, etc.), it better retains its shape and does not sag, and a lower cost also matters ...

Strange electricians surround you. VVG 3X2.5 and PPVS 3X2.5 is it a single-core wire or not?