One of the most popular floor coverings is linoleum. The big plus of this material is a huge variety of textures and colors. Not so long ago, insulated samples with a dense base appeared on sale. In this article we will try to figure out what they are, what are their advantages and whether there are any disadvantages.

Insulated linoleum

Linoleum properties

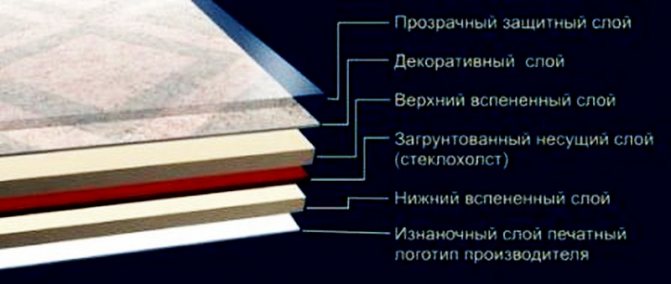

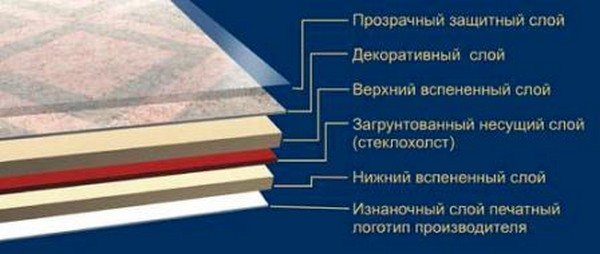

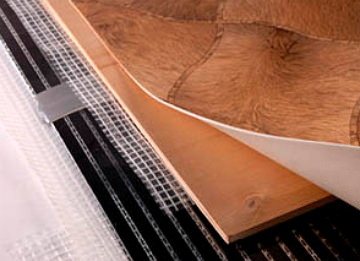

Linoleum with a dense base consists of 5 layers.

- A protective coating that protects against abrasion and mechanical stress.

- Decorative. It looks like a film decorated with an ornament.

- The third layer is polyvinyl chloride. Thanks to him, the coating has a softness and the ability to isolate sounds.

- Fiberglass. It provides strength to the coating.

- Insulation. It is the thickest of all layers. It is he who allows the material to provide thermal insulation.

After it, a finishing layer can be located, which is a film. It may display the manufacturer's brand. But this layer goes separately from linoleum, the base of which consists of felt.

Insulated linoleum consists of five layers

Tips & Tricks

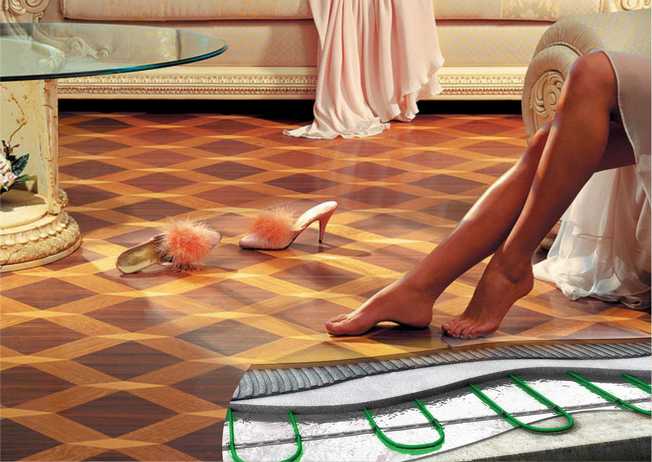

When choosing a heating method, it is extremely important to understand several important nuances. First of all, whether such heating will be primary or additional. When combining linoleum with infrared floor heating, it is allowed only as an additional source of heat. After all, you will not be able to warm up the coating to the required temperature, without damaging the material.

It will also be useful to look at a number of reviews that are left on the forums by those who use a similar heating system. In this way, you can learn from consumers. Well, the most important requirement is compliance with the sequence of installation work. This is the only way you can achieve a positive result.

Types of linoleum

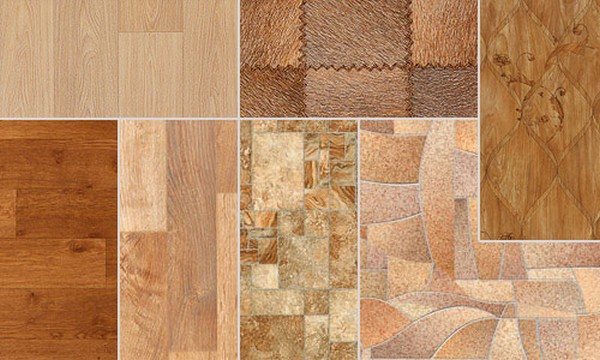

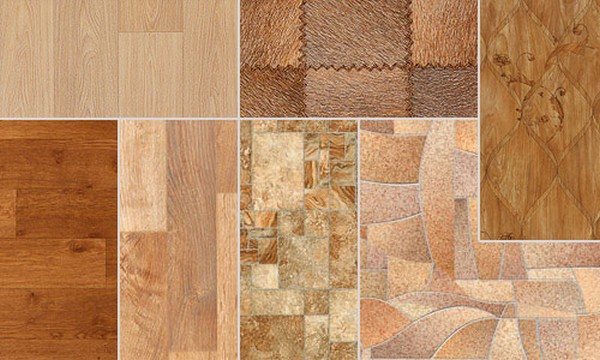

Regardless of its basis, linoleum can be of several varieties.

| View | Description |

| Domestic | This type is intended for residential premises in which there is no large-scale congestion of people. Since this is the most economical option, its surface has a rather simple color, which weakly imitates high-quality expensive coatings. Household linoleum is soft enough and can be placed in a room on the ground floor or in a country house. |

| Semi-commercial | This variety is able to withstand increased loads, so it can be used for installation both in residential premises and in offices. If the floor is very cold in the room, then this type of coverage can get rid of such a problem, but provided that there are not many people there. The colors of linoleum are often the same as those of tiles or parquet, but there are also quite interesting patterns or ornaments. |

| Commercial | Commercial insulated linoleum is not often found on sale. It is rarely purchased, since in workrooms where this material is used, people walk in shoes, which allows them to keep their feet warm and without insulated linoleum. |

There are several types of linoleum

There is another, rather original type of linoleum called "homogeneous". This variety has a base of polyvinyl chloride mixed with a variety of dyes.The peculiarity of such linoleum is associated with its structure. Thanks to her, the material, even after being used, does not lose its decorative appearance. This is due to the fact that the material is painted in full thickness and the abrasion of the surface does not affect the pattern in any way. This type of coating can be made on an insulated basis. It is perfect for classrooms in educational institutions.

homogeneous linoleum

Another variety - material incapable of conducting electrostatic stress. It is used for rooms where there is a large accumulation of electrical equipment. The outer layer of the material is an insulator against electric current, since it is not capable of conducting it. However, copper tapes are embedded in it, which are connected to ground. They are necessary to dissipate static electricity collected by the floor.

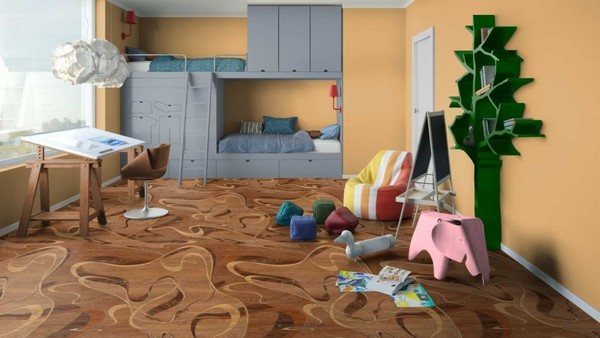

Everything is known, linoleum is a very slippery coating, especially when wet. It is easy to slip on even in socks. In this regard, manufacturers have developed a coating that has an anti-slip effect. This flooring material is ideal for children's rooms. In addition to having a soft base, it will prevent children from slipping on slippery floors.

You can buy linoleum with an antistatic effect, anti-slip, natural - there are a lot of options

Consumers are used to thinking that linoleum is a completely synthesized material. However, thanks to the latest technologies, manufacturers create a natural material with an insulated base on resins of natural origin. Such a coating will be a good solution even for an eco-house, as it is harmless to health and does not cause allergies. However, the prices for such coverage are also not low.

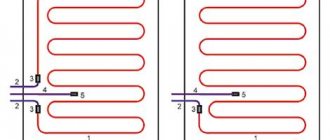

Which is the best IR heating

Making a warm floor for linoleum with your own hands is possible using infrared heating. There are two types of it: film and rod. Which one is the best to stack? Let's consider their features:

- If we talk about the budget option, then this is a film infrared heat-insulated floor. This heating element is best combined with such a coating. Thanks to the installation of a thermostat, you can set the most comfortable temperature, which will allow you not to spoil the linoleum. The heating process is carried out by radiation of an infrared ray.

- As for the IR rod heating, a composite material is used here. Flexible rods are built into thermocouples with busbars. They also radiate infrared heat. In contrast to the film floor, the rod has the advantage of using a self-regulating cable. That is, it regulates the floor heating temperature by itself.

Insulation types

In addition to the top layer, linoleum also differs in the type of insulation used in the manufacture of this floor covering. Various materials can be used for thermal insulation.

Insulated types of linoleum are produced with different parameters. In this case, the dimensions are not only set by the manufacturer's wishes, but also depend on the type of substrate. Each manufacturer produces any type of linoleum with a minimum width of 1.5 meters. Further, the width continues to increase by 50 cm.

The width of the foam-based material is 5 meters. Such parameters are in great demand, as they are convenient for laying in apartments with a standard layout. In this case, it is usually not necessary to resort to joining or gluing the canvases.

The felt material is produced with a maximum width of 3 meters.

Insulated linoleum is felt, on a foam basis, from jute

The natural jute backing is quite brittle, so it will be no more than 2.5 meters wide.

The maximum roll length can be 60 meters, but usually their length does not exceed 15-45 meters. Due to its fragility, natural canvas cannot be longer than 6 meters.

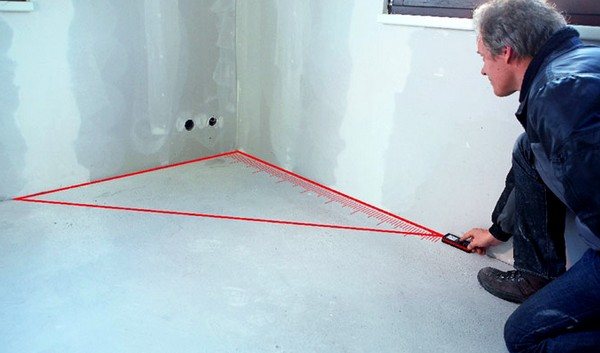

To select the parameters of insulated linoleum for your home, you need to measure the perimeter of the room. Due to the fact that when building a house and repairing the parameters of a regular rectangle are very often violated, it is necessary to carefully measure all four sides.

To the obtained value of the length and width, it is necessary to add another 5 cm each. Thus, you can get the size of the canvas that is suitable for the floor in this room.

Since the width of the linoleum is set in advance and it makes no sense to cut it, you need to choose the optimal size. For example, if for a room 3 * 3.9 m you need a canvas with parameters 3.05 * 3.95 m, this canvas will have to be cut to a minimum. Thus, some of the funds will be saved.

insulated linoleum

It is important to measure the room in advance in order to buy enough material.

Selection criteria

When choosing any type of linoleum, you need to take into account the general classification in order to purchase a coating that is suitable for all criteria. It is worth considering the wear resistance class:

- household - from 21 to 23;

- for public places - from 31 to 43;

- for industrial use - from 41 to 43.

There is a division into such groups:

- F - the smallest thickness, including wear resistance;

- M - low level of wear resistance;

- H - average level of wear resistance;

- T is the most wear-resistant type.

When buying, be sure to pay attention to the wear resistance class of linoleum

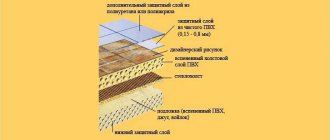

Criteria for choosing a coating on a foamed interlayer

When choosing linoleum on a foam basis, it is necessary to take into account that such a coating is similar in structure to a multilayer cake - this explains its thickness. In order for the coating to fit into the interior, it must be consistent in color and design with the room. To avoid problems with laying the flooring, you can spread it in the room where it will be laid.

This surface is very practical, since even with prolonged use it does not wear off, due to the fact that the pattern passes through the entire structure of the material. This allows it to be used for rooms designed for heavy loads.

Quite popular and inexpensive foam-based linoleum

Choosing linoleum with a natural base

This type of linoleum is good for rooms with low traffic, such as a bedroom. But this natural coating requires selection, taking into account the criteria for use, because mechanical damage is formed on it very quickly. However, this type of linoleum must not be exposed to high humidity, otherwise the natural base will begin to rot.

Natural insulated linoleum does not really "like" high humidity, so it should not be used in the kitchen, in the bathroom

General recommendations for selection

Such a thick floor covering can create a comfortable environment for living indoors, if the choice was made correctly. Of the main conditions, the following can be noted.

- If the level of humidity in the room is increased, then it is better to refuse a two-layer felt or jute coating.

- With increased traffic in the room, the best choice is linoleum on a foam base.

- When purchasing linoleum for several rooms at once, you need to take into account the combination in color and style.

- When connecting separate fragments of the coating, you need to follow the clear joining of the pattern.

- The correct selection of parameters will reduce the number of seams and joints on the flooring.

If the calculations are done correctly in advance, you can avoid a large number of joints. - For each individual room, you need to choose linoleum with suitable wear resistance.For example, for a pantry or a bathroom, a very durable coating is not required.

- For the lower floors of private or apartment buildings, you need to purchase linoleum on a foam base.

- A two-layer surface on a natural surface does not need to be fixed to the floor, because this has a bad effect on the thermal insulation of the material.

- For children it is better to choose jute linoleum - it is very convenient and safe for children.

For children, it is better to choose natural linoleum, for example, jute or felt

Installation of a water floor under linoleum

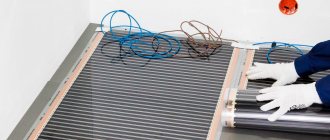

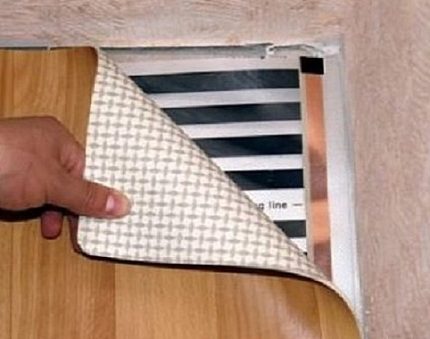

The infrared film is glued with tape to the base

For each type of underfloor heating, its own installation technology is applied. It is carried out on the basis of a compiled project and calculations.

The water pipes are laid in such a way that there are no joints along one circuit that cause leaks. The best option for fastening are foam blocks with grooves for the line. The products are glued to the floor in accordance with the project. After that, the tubes are placed in the grooves, and their ends are connected to the manifold.

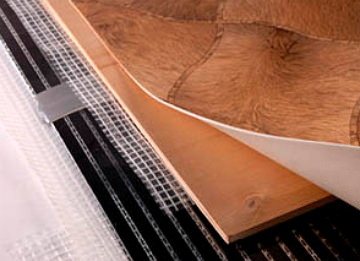

It is advisable to screw the heating cables to a metal mesh fixed to the base plate. The advantage of this solution is that the mesh will serve as a frame for the future screed, adding strength to it.

Mats are fixed with glue or construction tape. So that the plane does not budge, it is advisable to impregnate it with a liquid mortar. After that, you can make a screed or lay linoleum.

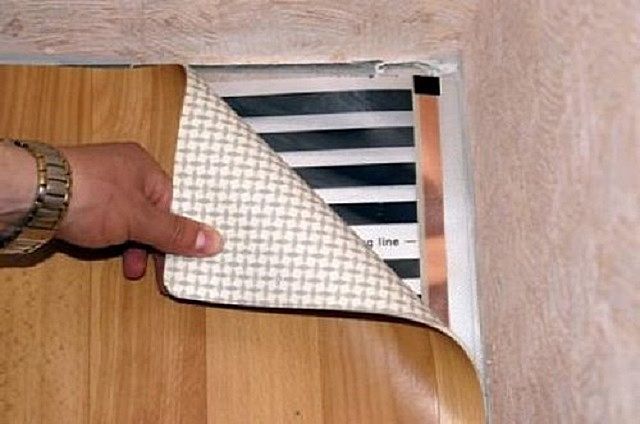

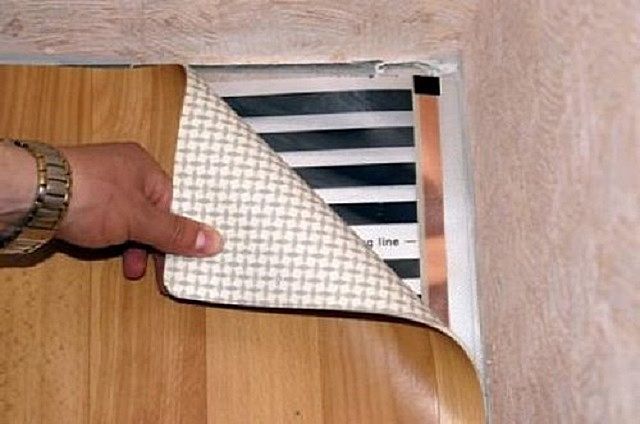

The IR film is glued to the base with tape. Metal fasteners are not used as there is a risk of breaking the electrical circuit.

The system is checked for operability, after which the linoleum is laid.

The principle of installing underfloor heating under linoleum is reduced to several successive stages. You can do all the work with your own hands and without the involvement of specialists:

- First of all, the preparation of the base is carried out. You need to make sure that it is perfectly even. Among other things, the floor surface must be completely free of construction debris and dust. It is very good if you have a construction vacuum cleaner. They can be trained well. If the rough coating has obvious irregularities, then it is necessary to fill the screed. For this, you can use self-leveling mixtures.

- When everything is ready, the waterproofing layer is laid. Ordinary polyethylene can be used as waterproofing.

- A roll of thermal insulation is rolled out on top of the waterproofing. It is connected to each other with scotch tape.

- The next step is the installation of the infrared heating floor. The mats are laid out over the entire area of the heated surface. Please note that cutting the heating foil can only be done in the indicated places. In this case, the cut is necessarily insulated with bitumen insulation.

- The film is connected using special clamps. They are mounted on copper strips. The film is connected in parallel.

- When laying the film, it is unacceptable to overlap it. When doing this, make sure that the copper busbars are pointing upwards.

- The wire from the film is directed to the thermostat. The thermostat connection is carried out according to the scheme indicated on the reverse side of the thermostat.

- A temperature sensor is placed directly next to the heating element. Its installation must be carried out in a special corrugation. Due to this, if it fails, the sensor will be easy to change.

- As for the connection of the thermostat to the electrical network, then it is best to draw a separate line to the electrical panel and install an individual RCD.

Before laying the finishing flooring material, it is necessary to carry out a test run of the warm floor. To do this, turn on the heating for 20 minutes. You need to make sure that all areas of the floor are heated.Also make sure that all connections to the films are properly insulated with bitumen insulation. If you find any malfunctions, then be sure to eliminate them. Failure to do so may result in a short circuit.

We offer you to familiarize yourself with Making a hot smoked smokehouse with your own hands

If everything is working properly, then you can start laying linoleum. Please note that PVC linoleum or some other of its kind is a relatively soft coating. It is very easy to pierce it with a sharp object, heel, etc. Therefore, before laying it, be sure to put plywood or other sheet material on the floor. Before that, lay the polyethylene film on top, which will exclude accidental damage to the heating element.

Advice! It is recommended to stick the infrared film to the base with tape. This will keep the heating circuit in place when installing the topcoat.

So, having laid plywood or other sheet material, you can start laying linoleum on the floor. The process of laying linoleum on a warm floor is no different from simple laying. Spread it all over the floor and leave it on the floor for about a day. During this time, he will acquire the required room temperature and straighten out. Then its flooring is carried out.

Before starting work, it is necessary to prepare the base for laying linoleum so that over time all irregularities (bumps or small stones) do not appear on the surface of the linoleum. Therefore, the base is carefully leveled and swept. Manufacturers recommend keeping the flooring material in a warm room for 24 hours after purchase so that it warms up to room temperature. With the theory sorted out, now you can start laying linoleum.

Installation scheme for infrared film underfloor heating

The presence of a ready-made solid base suggests that you can start laying linoleum. The material is laid on the floor, covering its entire area. Along the perimeter, linoleum must be fixed with baseboards. If the floor is covered with several sheets of linoleum, then they must be glued together with adhesive tape and attached to the floor.

Laying linoleum

For fixing, many builders use a special adhesive, but if it was not at hand, then you can use adhesive tape. When installing linoleum made on a felt basis, it is recommended to use "Gumilax", and when laying natural linoleum - "Bustilat".

The easiest and cheapest way to mask (seal) the seams

warm floors Caleo

There are several types of linoleum in construction supermarkets, and not all of them are suitable for laying on a heating surface. Here are 5 categories that you will come across in a large number and variety of designs:

- vinyl (PVC);

- glyphthalic (fabric-based);

- nitrocellulose;

- rubber;

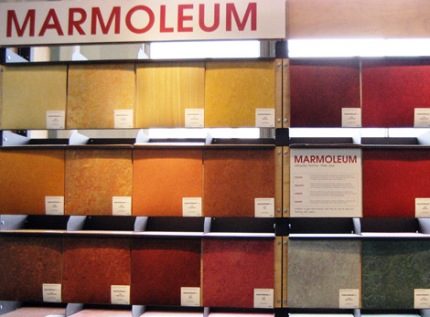

- marmoleum (natural).

Glyphthal (or alkyd) has excellent thermal insulation properties, however, despite the strong fabric base, it deforms over time with regular heating.

Nitrocellulose material perfectly repels moisture and is highly durable, but it is sensitive to high temperatures and can ignite.

A two-layer rail made of rubber, bitumen or synthetic rubber also does not tolerate heat. Thus, either natural marmoleum or vinyl canvas is suitable for installing a warm floor.

Marmoleum is considered the safest material, as it consists of natural components: pine resin, cork particles, linseed oil, natural dyes, lime.When heated, it retains its original shape and size, does not emit substances harmful to health. The surface does not fade for a long time, the colors are preserved, the borders of the picture remain clear.

Marmoleum is recommended to be laid in houses where small children and allergy sufferers live. The only condition for use: do not raise the floor temperature above 27-28 ° C (no more than 60 W / m²)

A more economical option is vinyl PVC linoleum. Durable and wear-resistant commercial types from 34 to 43 classes, intended for use in public premises and in production, will last longer.

Coatings with a heat-insulating layer will not work as they will impede the passage of heat.

The best option for installation is homogeneous vinyl linoleum or synthetic material on a thin fabric base. The only inconvenience is the unpleasant odor when heated, but after a few weeks it usually disappears.

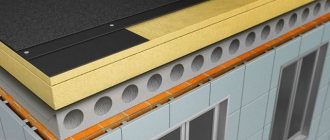

Before starting the installation, it is necessary to completely clean and prepare the rough screed. The screed should not have height differences. When you carry out the alignment, if necessary, you should start installing a layer of thermal insulation that will prevent heat loss.

Most often, expanded polystyrene (polystyrene) is used as a heat-insulating material. After you have installed the thermal insulation layer, you need to cover it with a polyethylene film. Damper tapes are mounted on all areas. After that, a mesh of reinforcement is installed.

Next, you need to lay the pipes of the heating system on the reinforcement mesh. This can be done if you use clamps, thanks to them fixation occurs. Then it is necessary to carry out a tightness test under operating influence. If the test is successful, then the water should remain inside the pipes. The final stage of the installation is the pouring of the finishing screed and the laying of the floor covering, in this case linoleum.

First, the cleaning and preparation of the rough screed is also carried out. After these procedures, a film is laid, which will reflect heat. Next, the strip of the film heating system is installed, they are stacked from the top of the heat insulator. Fixation occurs with scotch tape.

Then it is necessary to install the temperature controller. From the regulator, cables are routed to the strips, which are then connected to the copper connector. This is done thanks to specially designed clips. Next, the mats need to be covered with polyethylene film. Then sheets of plywood or other material are stacked. At the end, linoleum is laid on them.

Compliance with all factors will help you lay linoleum for any type of heating system. Warm floors will help you enjoy the comfort and coziness in your room. You can be content with such heating. You will also admire the floor.

We offer you to familiarize yourself with the Russian white goat breed description

Features of laying felt linoleum

The pile coating needs special attention. It is worth noting that the selection of linoleum is not an easy task, because it will be used for a long time. Linoleum has a structure consisting of two cavities: they will determine the properties of linoleum and its performance.

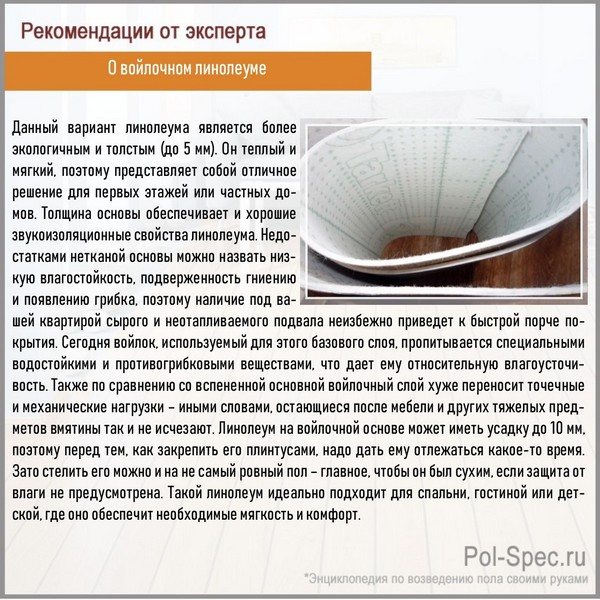

About felt linoleum

Felt linoleum will be appreciated by people who prefer convenience, coziness and warmth. It is resilient, soft and easy to lay.

However, only a dry room is suitable for the operation of such material, otherwise moisture will destroy the coating from the inside and make it unusable. But if the flooring is subjected to heavy loads, it is likely that the surface with a fleecy surface will not be able to withstand it. Thus, before purchasing linoleum, you need to take into account all the features of the room in which it is planned to be laid.

It is better not to use felt linoleum in rooms with high traffic.

Laying linoleum will not be a problem if you take a responsible approach to this task and take into account the recommendations of specialists.

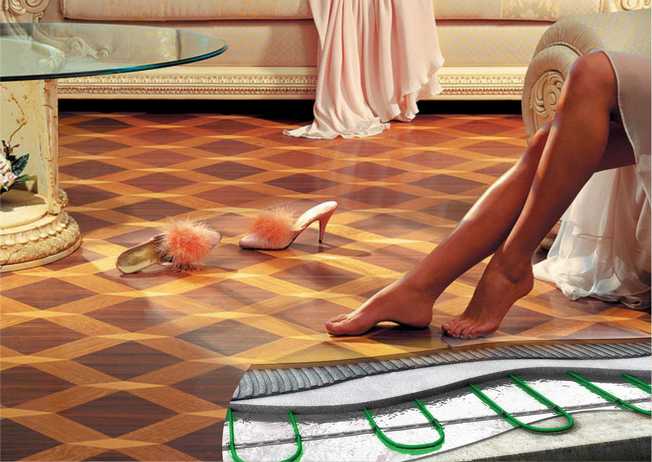

Choosing a warm floor for linoleum

This choice must also be approached responsibly. There are three types in total:

- A water heat-insulated floor is a system consisting of pipes, where the main source of heat is water. Nothing but water. This type is rarely used in apartments, because central heating is most often used there. In order to carry out the arrangement of water floors, there must be a screed between the pipes and the floor covering. This condition is not suitable if the room has low ceilings. However, this design can become an alternative to central heating.

- Electric underfloor heating, the main component of such floors is a heating wire. The installation of this element is also carried out in a cement screed. An electric floor has a much simpler structure than the previous type of heating system. Also, this type has a distinctive feature, during heating, the area heats up evenly - this is especially important for linoleum. However, an electric floor may not be suitable for a given floor covering because it heats up in a short amount of time. Because of this, linoleum can easily collapse. According to the opinion of professionals, this material is not suitable for electric floors.

- Film or infrared heat-insulated floor, in the presence of this design there is a thin layer, as well as heating strips. As soon as you connect the structure to electricity, it will heat the surface evenly and not quickly. This eliminates the likelihood of product deformation during sudden temperature changes. The maximum power of the film system is 400 W / m2. For linoleum, the maximum power is suitable, which is 150 W / m2. Don't worry, this is enough power to reach 30 degrees Celsius. The initial characteristics of the material are retained.

Let's separately consider the installation of a water floor under linoleum.

Many people, on the eve of the renovation, are wondering - which warm floor is better for linoleum? There is no single answer to this question that would be absolutely correct. But if you study the features of each type of underfloor heating, then the choice can be made independently. The determining factors include the purchase budget as well as the architectural features of the home. There are three main types of underfloor heating, which differ in the operation of the system, cost and other criteria.

Types of warm floors

Infrared

The essence of this system is slow and gradual heating. The power of the infrared floor is quite enough to heat the surface of linoleum or other flooring up to 27 ° C. When using an infrared underfloor heating system, the likelihood of sudden temperature jumps is practically zero.

Infrared floor heating

Infrared film floor

Electric

An electric cable acts as a heating element, which is laid in a cement screed. At the same time, the floor heats up evenly. If the temperature is not controlled, the floor will heat up very quickly and the floor covering will undergo deformation.

Electric underfloor heating

Water

Another type of underfloor heating system, which consists of numerous pipes. The role of the coolant is played by water. The system is extremely rarely used in apartments, due to the need to perform a screed between the system and the floor covering. In urban apartments, as a rule, the ceilings are low, so the additional screed will significantly reduce the space.

Water heat-insulated floor

Connecting a water underfloor heating

Let's say a few more words about choosing linoleum for an infrared warm floor.First of all, there should be absolutely no harmful substances in the composition of this coating. Therefore, it is best to purchase natural linoleum, which is based on exclusively natural ingredients. According to a number of reviews, some types of linoleum do not withstand constant exposure to temperature. Because of this, the coating may wrinkle, as well as the formation of accordions that will no longer straighten out. This is due to several factors.

For example, when laying linoleum on a rod infrared floor, the temperature level will be automatically adjusted. You will not need to worry about adjustments. With regard to film heating, then it is necessary to set restrictions. For this purpose, a thermostat must be installed. So, it is unacceptable to heat linoleum more than 30 degrees Celsius.

Advice! As practice shows, it is best to warm up linoleum to a temperature of 27 degrees Celsius. This temperature will be sufficient to achieve the most comfortable operating temperature for the coating.

Plus, the flooring itself must be heat-resistant. For this, it should not be too thin or thick. Its thickness should be medium. Ideally, use a commercial grade that is equipped with a protective coating.

As mentioned at the beginning of this article, when choosing, be sure to pay attention to the designations from the manufacturer. The label must have a sign that allows linoleum to be heated. Only in this case it will last a long time and, plus everything, will not have a negative effect on health.

Floor preparation

First you need to remove the old coating and evaluate the subfloor. If it is of inadequate quality, you need to eliminate various defects, irregularities.

Then you need to roll out the substrate, which acts as a transition layer. The best option is a jute base, it is the safest.

First, remove the old flooring, then lay the substrate under the linoleum

To increase the strength of the floor, it is covered with plywood sheets.

If the floor surface is wooden, it is worth providing waterproofing. This can be done by placing a film, then cover it with fiberboard sheets, then prime them and cover with another layer of film.

Professionals do not recommend placing chipboard sheets under linoleum, since this is a fragile material that can deform.

Bonding linoleum joints - analysis of methods

When buying linoleum, you should pay attention to its width. It is good if it matches the width of the room. In this case, it will be possible to lay linoleum without connecting the joining points. Thus, the base will acquire an optimal level of sound and heat insulation, as well as tightness.

In a situation where linoleum has already been purchased, but its width does not correspond to the width of the room, then the seams will need to be glued. This technology is suitable for both foam-based linoleum and warm varieties.

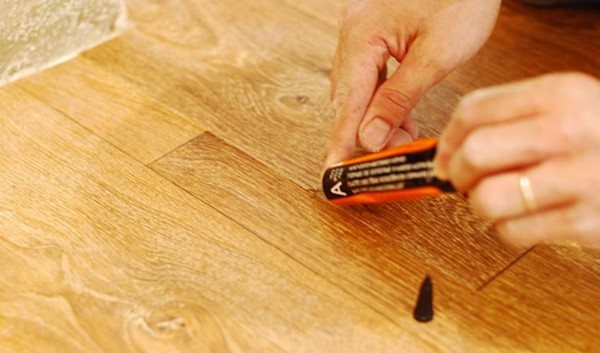

Welding of joints can be done in two ways: hot or cold. The latter can be done using a tube of glue containing tetrahydrofuran, plasticizers and chlorine.

cold welding for linoleum

Linoleum joints can be joined by cold or hot welding

The hot method involves the use of a hair dryer and wire, which must melt under the influence of high temperature. The resulting liquid mixture must fill the joints in order to obtain a tight and impermeable connection. This method is the best, but it requires special equipment and skills to work with them.

The gluing procedure must be performed very carefully so that the melted glue does not drip onto the linoleum.

Before buying linoleum from the seller, you need to get information on how to connect it.Many types of household coatings cannot be hot glued because soft coatings are not suitable for high temperatures.

Experts recommend using cold welding for living quarters.

To perform cold welding, you will need a ruler, masking tape, a tube with welding, a knife with a sharp blade. Let's describe the sequence of actions.

| Sequencing | Description |

| Linoleum is laid joint to joint. In this case, you need to ensure that the connection of the canvases is very tight and the drawing coincides. After this, the joints are connected using masking tape. With good gluing, the seam should be in the center of the tape. Then an incision is made through the tape at the joint. |

| Read the instructions carefully before applying the mixture. After opening the tube, a special needle is placed on it, which is placed in the incision. Then the joints are filled with welding along the entire length of the seam. |

| The gluing process must be carried out very carefully. If the welding gets on an uncovered canvas, then it will be difficult to remove it without damaging the surface. After 10 or 15 minutes, the masking tape can be removed. The weld will dry completely only after 2-3 hours. |

The hot method is more complicated. To complete it, you will need to purchase a welding gun with a special attachment. Instead of glue, in this case, instead of glue, you will need a special wire, which has a similar composition with linoleum.

When performing work, in addition to equipment, you will need a knife with a sharp blade and a vacuum cleaner in order to collect the debris.

hairdryer for welding

| Sequencing | Description |

| When the quality of the joining and registration of the pattern has been assessed, it will be possible to trim the seam for a chamfer. For this, both a construction knife and a curved knife designed for docking are suitable. After that, you will need to collect all the trash. The joints of the canvases must be thoroughly cleaned with a vacuum cleaner. |

| For work, a building hair dryer is heated to a temperature of 350 or 400 degrees. Then a nozzle is put on it and a wire is inserted. The first wire burn is carried out. |

| After that, you can start gluing the seams. Filling the joints with the composition is carried out along the entire length. |

| When the seam dries, its remnants are cut off with a knife. For this, special blades are sold. First, the most protruding part of the welding is cut, and after that the final trimming is performed at the same level with the felt surface. |

Linoleum from different manufacturers: Tarkett brand material

If you are interested in the described material, then you can pay attention to the insulated linoleum "Tarkett", which has been manufactured for over 120 years. During this time, the company has established itself as a manufacturer of durable and safe floor solutions. Today Tarkett is the number one brand in Russia, this title distinguishes it among analog flooring manufacturers. This linoleum is insulated, the price of which starts from 196 rubles. per square meter, ready to serve for more than 10 years with proper installation. It belongs to the KM5 fire safety class.

Famous manufacturers

Insulated linoleum from several companies is sold in the markets of our country. Let's list the most popular ones.

Tarkett

This manufacturer is a leader among the companies involved in the creation of flooring. He has been producing a wide variety of floor surfaces since the early 20th century. In terms of quality, the product meets not only domestic sanitary standards, but also European ones. The company manufactures both felt-based and foam-based products. In addition, all material has a high fire safety class.

Linoleum Tarkett

IVC

This manufacturer manufactures its products in Belgium. His product has excellent characteristics and unique design, so a room with such a floor looks very chic.Thermal insulation is provided in this case by felt. Therefore, the surface will not only be soft and warm, but it will also be possible to move on it barefoot.

Linoleum IVC

Forbo

This company specializes in the production of eco-linoleum. Her products contain about 97% natural ingredients. One of the company's lines creates a cork-based coating. It not only perfectly prevents heat loss, but also blocks sounds. Other lines are used for thermal insulation jute.

Forbo linoleum

"Komitex Lin Parma"

The specialization of this company is to create economy class household coverage. Felt acts as a heater in this case. Such linoleum is well suited for temporary housing or summer cottages. Its cost allows it.

Linoleum Comitex Lin Parma

Why is it worth choosing an insulated coating

Popularity among consumers and first positions in the market of this floor covering are provided by performance characteristics, ease of installation and general availability. As a rule, the question of using this type of flooring arises when there is a need to insulate the floors with high quality, quickly and not so expensively. This material can be laid on any surface made of concrete or wood, but it is recommended to comply with certain requirements for the base.

Warm linoleum is divided into two types, one of them is made on a warm basis, and the other is made as an insulated coating. There are very important differences between them not only in the structure of the canvas, but also in quality characteristics.

Linoleum care

Proper care will keep your floor looking cozy, beautiful, and warm. Most users do not consider such measures necessary, but if they are not followed, then its surface will quickly become unusable. In addition, all these activities are not labor intensive:

- regular cleaning of dust and dirt;

- polishing, it will be useful even if the coating is already shiny.

If you do not neglect such manipulations, then the coating will delight the eye for a long time.

To prevent linoleum from losing its original appearance, it is worth taking care of it properly.

Which coating is suitable for a cold floor?

The choice of floor covering for thermal insulation is determined by a number of factors. The budget allocated for the purchase of the material will play a key role. If its size does not matter, then it is better to opt for natural linoleum. But if the amount intended for the purchase is rather modest, it is worth purchasing a household type of coating or looking in stores for the remains of high-quality linoleum, which are sold at a low price.

The choice of linoleum can be influenced by the purpose of the room for which a new thing is planned. For example, for a nursery or bedroom, you can choose a household floor, and for the rest of the common rooms you can buy a semi-commercial floor.

The base for linoleum is also important. For uneven wooden surfaces, a felt-based coating is the best option. This recommendation is due to the fact that the felt hides the gaps between the boards and small differences. But for a perfectly flat surface, you can choose any linoleum.

If the surface of the subfloor is perfectly flat, you can choose any type of linoleum

For a bathroom, it is worth making a choice in favor of linoleum with foam insulation. It is not afraid of the effects of fungi or mold, moreover, it calmly reacts to temperature changes and high humidity.

Is thermal insulation needed

Installation of a warm floor under linoleum raises another question, which is associated with the installation of an insulating layer. Of course, you can't do without it. Thermal insulation is even needed if the warm floor is installed on a wooden floor. Wood can take up some of the heat energy, which will reduce the efficiency of the entire system.

The thickness of the thermal insulation layer must be at least 3 mm. There must be a layer of reflective film on top of the thermal insulation. It is good if the insulation immediately has a reflective layer. In this case, all heat energy will be directed up the room. As a result, the efficiency of the warm floor will be at a high level.

Important! When installing thermal insulation, it is unacceptable to leave any joints and gaps. The insulation is connected to each other with adhesive tape.