Main varieties

Currently, we are talking about three methods of electric floor heating:

- Heating cables.

- Film warm floors.

- Heating mats.

Each of the varieties of electric heated floors has a different installation and heating principle. They are united only by the general principle of using the heat obtained by the passage of electricity through the conductor. The resulting heat energy is distributed by convection.

Another method was invented quite recently. It is built on the use of carbon, which emits energy in the infrared range when a current passes through it. This spectrum of waves has a much more beneficial effect on the body than heat waves, because similar radiation is inherent in our body. As a result, rooms heated by infrared rays are much more comfortable. Infrared floor heaters are available in the form of carbon film and carbon rod mats.

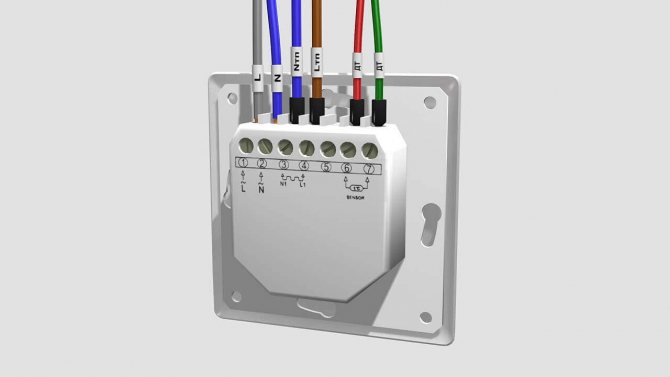

Any electric underfloor heating is equipped with a thermostat and a floor temperature sensor. These devices allow not only to set the operating mode, but also to monitor its implementation. Thanks to these devices, it is possible to reduce the consumption of electricity: they periodically turn on and off the floor heating. The beginning of the installation work is the correct placement of the thermostat and the execution of strobes for the wiring from the sensor. The subsequent actions are prescribed in the manufacturer's instructions.

What is a thermostat

Strictly speaking, any underfloor heating system with a direct connection to the mains will also work. However, there is a real risk of overheating and rapid failure. In addition, the heating level will be completely uncontrolled, with the maximum consumption of electrical energy. In this case, the heating elements will undergo a constant load.

To avoid the above situations, three types of thermostats are used:

- Electromechanical

... By design, the devices resemble similar devices on irons. The heating level is adjusted by turning the knob left / right. Electromechanical devices are distinguished by simplicity of design and ease of use. The cost of these devices is quite low. - Electronic

... If the functions are similar to the previous version, they are implemented in a different way. The digital or liquid crystal screen displays the current parameters of the system, which can be adjusted with textile or touch buttons. To increase the parameter, press the "+" button, to decrease - the "-" button. Another type of electronic controllers makes them much more expensive. - Programmable

(the so-called "programmers"). Along with the traditional regulation of the current floor temperature, in this case, it is possible to set certain indicators for a specific hour or day of the week. In some programmers for electric underfloor heating, the power adjustment of the heating elements depends on the outside temperature. For these purposes, a special sensor is being installed. Some models of programmable thermostats can be controlled from a computer.

Installation of devices is usually carried out at the most convenient points in the room. Quite often, a thermostat is installed near a switch. If it is required to equip a room with high humidity with an electric underfloor heating, the thermostat is placed outside of it.The fact is that high humidity has a bad effect on the accuracy of the indicators. One device of this type is able to provide control of underfloor heating with a total power of 3 kW. If this indicator is exceeded, the circuit is divided into two parallel zones, each of which is equipped with its own sensor.

Scope of application of heating mats

Thermomats are positioned as underfloor heating for tiles, natural stone and porcelain stoneware, but the scope of their application is much wider than the standard kitchen-bathroom set. Indeed, the heating mat turns out to be indispensable in rooms with high humidity: bathrooms, toilets, saunas, but only this does not exhaust the possibilities of underfloor heating with a thin heating cloth. Due to the minimum level of electromagnetic radiation, it is underfloor heating, in which a heating mat is the heating element, that are recommended for laying in rooms with increased sanitary requirements (children's and sleeping rooms). In addition, a warm floor with thin mats is optimal for heating the first floors of residential buildings, balconies and loggias, as well as poorly insulated residential and non-residential premises.

The use of heating mats as the main or additional heating means gives a good result for any premises: kitchens and bathrooms with tiles, loggias and balconies, living rooms.

What is a heating cable

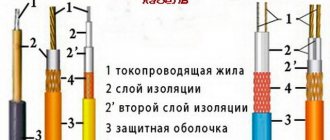

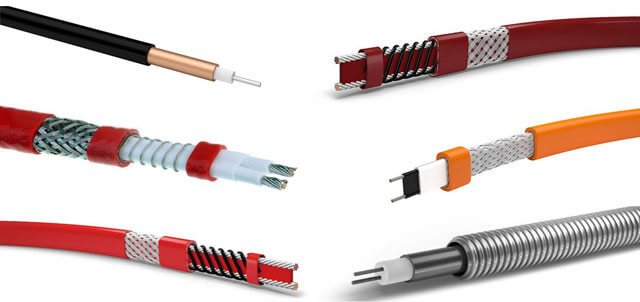

Resistive and self-regulating cables are used for arranging underfloor heating. Resistive products are characterized by a constant resistance and a stable level of heat transfer. This wiring can be single-core and two-core: the number of cores affects its switching scheme. The connection of a single-core cable is carried out by placing two ends of the coil on the thermostat. If a two-wire cable is used, then only one end is wound.

The self-regulating cable mechanism has the ability to adapt to the temperature of the surrounding space, with the adjustment of the amount of outgoing heat. Each of the sections can be regulated, which is not affected by the condition of the nearby cable. It often happens that an object is placed on the surface of the floor: this leads to an increase in the temperature under it. The self-regulating cable reacts to this by reducing the heat generated in this area by increasing its resistance (current strength and heating temperature decrease). At the same time, neighboring areas are operating normally. After the object is removed, the surface temperature is equalized.

The difference in characteristics explains the fact that the cables are laid in different ways. In the case of self-regulating products, the discount can be omitted for the arrangement of furniture items. Resistive models are mounted with great care: when developing a laying scheme, they preliminarily designate the zones for the location of furniture or objects suspended at a low height. This type of heating cable may only be installed in free areas. Therefore, the main disadvantage of resistive cable floors is their fear of overheating, which can cause them to burn out.

How to organize floor heating with heating cables

The general installation plan is as follows:

- Laying thermal insulation material on a flat, clean surface. For this, thermal insulation with a metallized coating is used.

- Installation of fasteners (metal mesh with small cells or mounting tape).

- Cabling. The developed plan of the arrangement of turns and lines is used as a diagram. It is also necessary to carry out the switching of the ends with a thermostat.

- Installation and connection of a temperature sensor to the thermostat.

- Laying concrete mortar. Layer thickness - at least 3 mm.

- Finishing coating arrangement. This can only be done on a completely dry screed after 28 days.

The heated floor can have a thickness of more than 50 mm, which is influenced by the height of the thermal insulation substrate. From above, the screed can be decorated with ceramic tiles, porcelain stoneware, laminate, linoleum, parquet. When pouring a screed or laying tiles, it is necessary to use special mixtures for underfloor heating. They are characterized by high elasticity, due to which the mortar is not covered with cracks due to thermal expansion. As for the cost, the least you have to pay for resistive cables for an electric floor heating. Self-regulating products are much more expensive.

Technical characteristics of heating elements

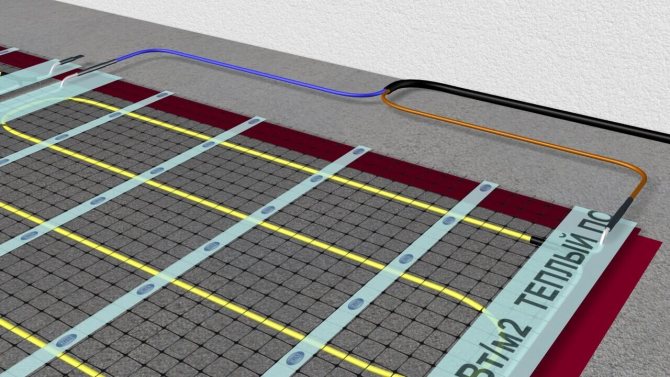

Heating mats are based on very thin cables that are glued into a reinforced mesh. Electric mats are produced with single or double core cables. A two-core cable consists of two conductors (heating and return) in one outer PVC sheath with a single-wire connection to the network.

Single-core - one heating, on a grid, return one goes back separately along the wall, connection to the network - with two wires. The power density of heating mats is usually 100 to 180 W per 1 m² for an area of 0.45 to 12 m². Basically, thermomats are used in rooms with flooring made of ceramic tiles, porcelain stoneware, natural stone and the like. When installed under the tiles, ceramics conducts heat well and quickly heats the floor over the entire surface. Two-core thermomats are considered the most environmentally friendly and high-tech, therefore they are widely used when you need to install an ultra-thin warm floor. They are also used in children's rooms and bedrooms.

For installation under tiles or porcelain stoneware with a thickness of less than 7 mm, heating mats with a power of 100-130 W / m2 are used. Thermomats with a power of 150 W / m2 or more are installed under porcelain stoneware with a thickness of more than 7 mm. The same mats are laid in rooms with high humidity (bathroom or toilet), on the first floors of buildings, on a balcony or loggia, in non-residential and (or) poorly insulated living quarters.

That is, for residential areas, you need to use thermomat with a two-core cable in the design, and for others, you can use it with a single-core cable.

Heating mats of all manufacturers are designed for a strictly defined area, each manufacturer has its own range of standard sizes.

Electric systems based on mats

There are two types of mats:

- Cable.

- Carbon fiber.

Products differ in the principle of heating, characteristics and cost. However, the way the mats are arranged is common: they look like a sheet folded into a roll. In this case, the difference between them also applies to the principle of installation and the materials of manufacture. Carbon mats are equipped with rod-type heating elements, which is why they are called rod-type heating elements.

A parallel connection is used to switch individual sections. The cable mats include a single-core heating cable with a snake. The basis here is a film with a reinforcing mesh. Installing a warm floor from mats is many times easier and faster than cable systems.

Use of heating mats in rooms with high humidity

A type of underfloor heating, in which the main heating element is a heating mat, is most often used in rooms such as toilets, showers and bathrooms when it comes to residential buildings. But such a heating system is very much in demand in public places, primarily in swimming pools, baths and saunas. For example, changing rooms and showers in swimming pools are heated with thermomat. Heating mats for tiles in baths and saunas relieve visitors from unpleasant sensations and possible diseases caused by hypothermia.

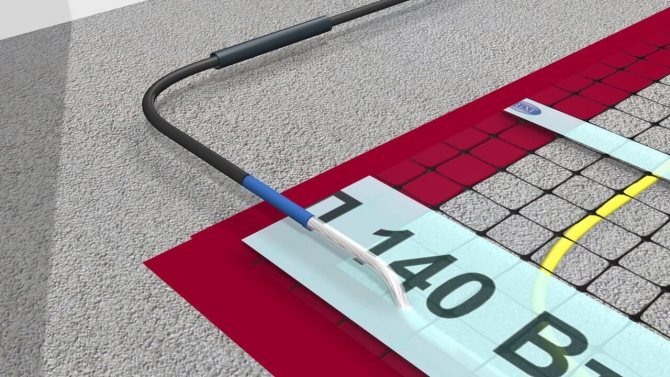

Cable mats

Cable mats are often used to equip warm floors under tiles. The total height of the cake of such an electrical structure is usually less than 30 mm. It is allowed to lay the mats on the old base: the main thing is that it is even. Before doing this, it is imperative to remove dirt and dust from the floor. An adhesive film base is used to fix the rolls. Next, the web is rolled out over the room, starting from the point of placement of the thermostat. The thermostat installation procedure completely coincides with a similar operation on cable heating systems. You will need to lay a corrugated hose for connecting cables and installing a floor temperature sensor.

The end line for rolling out the mat is the turning point: here the mesh must be cut off (the cable will not be damaged). After that, you can change the direction of the roll in the desired direction. When placing the next segment above or below the end point of the previous rolling, it is allowed to remove the cable of the required length from the mesh, followed by placing it in the form of a snake. The main thing is to completely roll out the entire roll (if not enough, take the next one). The second and third rolls are stacked in exactly the same way. Further, using a tester, the electrical resistance is checked for compliance with its passport values. The difference is allowed within 5-10%.

On the back there is a film that hides the adhesive surface. It is removed and the mat is glued to the floor surface. The next step is to place and connect the temperature sensors. A pipe or corrugated hose is used for laying. Taking into account the total thickness of the underfloor heating pie (no more than 30 mm), it is necessary to equip a seat in the rough base under the corrugated hose. Installing the sensor in an unprotected state is prohibited, otherwise it will quickly break. The option of placing it under the screed also has its flaws: when replacing it, you have to break the floor. Therefore, the most convenient option is to lay in a hose or pipe.

In the next step, tile adhesive is applied. The process is completely identical to laying concrete mortar, however, the thickness of the adhesive mixture is much thinner. After the glue dries, the decorative tiles are laid. This type of electric under-tile floor heating has the same weaknesses as the resistive cables that are part of it. Due to the danger of overheating, they should not be placed under furniture or carpets.

Features of installing a thin warm floor

Before laying heating mats, it is necessary to determine the area of the heated surface, clean it and (if necessary) leveling and priming, as well as determine the location of the thermostat. The floor temperature sensor is placed in a corrugated tube, for which a groove is made in the floor approximately 1.5x1.5 cm at a distance of about 0.5 m from the wall. After completing the installation of the thermomats, the temperature sensor must be placed between the heating cable strings. The end of the corrugated tube must be sealed to prevent the ingress of solution inside it.

When laying heating mats, the following basic rules must be followed:

- avoid self-intersection and shortening of the cable during installation;

- the heating cable should be evenly, without the formation of air pockets, covered with a tile adhesive solution;

- in the event that 1 mat heats 2 rooms, a good heat dissipation must be provided to the connecting section of the heating cable;

- the serviceability of the heating mat is checked only with a tester or by connecting an unwound roll for a few minutes;

- the connecting sleeve (the junction of the heating cable with the power cable) must be placed in a layer of glue, if necessary, a recess is created for it in the floor;

- the first switching on of the heating system is carried out only after the tile adhesive has completely dried.

Floor surface - the base under the heating mat must be solid. Cracking of a new concrete screed, warping of a wooden base, or deformation of insulation can lead to cable breakage. Before installing a heating system with heating mai, it makes sense to carry out work to strengthen the floor (csp, screed from 3 cm, screed reinforcement, etc.).

In a situation in which the heated area exceeds 12 sq. m, 2 heating mats can be connected in parallel to the thermostat. The disadvantage of this solution is that there is only one floor sensor, and the floor temperature will be measured only in one room, and the heating will turn on in two at once.

Features of IR rod mats

For carbon mats, overheating is not terrible, because their design provides for the ability to independently adjust the temperature. The basis for laying this type of electric floor heating is a layer of metallized thermal insulation. This makes it possible to ensure that the infrared radiation diverges in all directions. The same part of the flow that goes towards the floor is reflected back into the room.

The installation of heat-insulating material with a reflective surface is carried out on a flat, clean base. To fix it, pieces of double-sided tape, staples or glue are used. For gluing the joints of thermal insulation, you will need metallized tape. Installation works completely repeat the same procedure with cable mats. The starting point is the location of the thermostat. Upon reaching the opposite wall, the connecting cable is cut between the two rods, followed by the unfolding of the web in the desired direction. Crossing of lanes is prohibited.

Fully unfolded mats should be taped to the floor or to each other. The thermal insulation material in the areas between the carbon rods is equipped with small cutouts: in these places the screed and the rough base will be fastened together. Electric cables are used to connect the individual strips of the heating sheet at the cuts. Upon completion of the commutation, the temperature sensors are installed. Finally, all nodes must be connected to the thermostat. For testing, the system is turned on for 15 minutes. If successful, start pouring the screed.

Other options:

- Arrangement of concrete screed with a thickness of more than 20 mm. In this case, it is allowed to use any kind of flooring.

- Installation of tiles directly on tile adhesive. The total height of such a design must exceed 20 mm.

Different rooms are suitable for using these methods: bathroom, kitchens, living quarters. In each of these cases, the work is carried out using special mixtures for underfloor heating.

Film type warm floors

In film systems of electric floor heating, the method of infrared radiation is used, therefore they also belong to infrared heated floors. The infrared film consists of strips of carbon fiber connected by a copper bus. Further, this frame is sealed in a polymer film (polypropylene or other material). When using electrical films, it is important to avoid overheating. For this reason, as with resistive heating cables, they must not be placed under furniture or low overhanging objects.

The installation method is very similar to that of other types of electric underfloor heating. On a flat rough surface, a layer of metallized thermal insulation is laid. The film is rolled on top of the heat-insulating material. To switch individual strips, you will need wires going to the thermostat. Having made the connection, the system must be tested at an operating temperature of up to +30 degrees. A sign of serviceability is the uniform heating of all strips with cold terminals.

On top of the rolled heating rolls, lay out a plastic wrap or non-woven windscreen. This will create protection from damage. If you originally planned to lay the laminate, this can be done now. During work, it is important to be very careful not to injure or move the electric film of the warm floor. Thermal insulation can be replaced with a conventional underlay.

If you plan to lay carpet or linoleum, you will first need to install hard plates: plywood, OSB, etc. During installation, you need to act very carefully, avoiding the slightest damage to the heating elements of the film. Such a substrate will become a reliable base for the floor covering. Also, sometimes a mobile warm floor is laid under the carpet, which does not require repair work. The use of film floors in combination with ceramic tiles is a bad idea, because of the threat of rapid deterioration of the web in the tile adhesive layer.

Temperature regime

The use of a temperature sensor and a programmer makes it possible to independently enter the desired mode.

However, each of the types of heaters has its own limit:

- Heating cables withstand +100 degrees, at a maximum operating temperature of +65 degrees.

- The mats have a maximum temperature range of + 80-104 degrees. The operating temperature depends on the material of manufacture: +60 degrees for cable mats and +55 degrees for rod mats.

- The operating temperature of infrared film systems is about +55 degrees.

Since the thermostat can vary the temperature over a wide range, it is impossible to indicate the exact power consumption. However, in any case, these systems will be more economical. Rod heaters are famous for the lowest energy consumption; in second place in terms of efficiency are film.

How to choose an electric underfloor heating for a specific floor material

Each type of flooring works best with specific heating elements. It is recommended to combine tiles and porcelain stoneware with resistive and self-regulating cables, cable mats and core-heated floors. It is better not to use infrared film for heating the floor under the tiles, because it does not tolerate tile adhesive.

Laminate flooring works well with the following types of electric underfloor heating:

- Infrared film.

- Heating cable

- Electric or rod mats.

The most suitable option in this case, due to the ease of installation, is considered to be a film. When selecting heating cables, it is better to give preference to self-regulating ones. As for linoleum, it is allowed to lay any type of electric floor under it. The most inconvenient are resistive cables and electrical cable mats. This is explained by their fear of overheating. When using such systems, a temperature sensor must be installed. The easiest way in this regard is with rod mats and self-regulating wires protected from overheating.

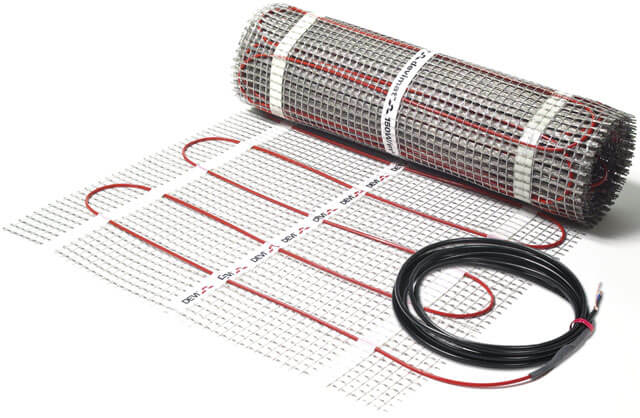

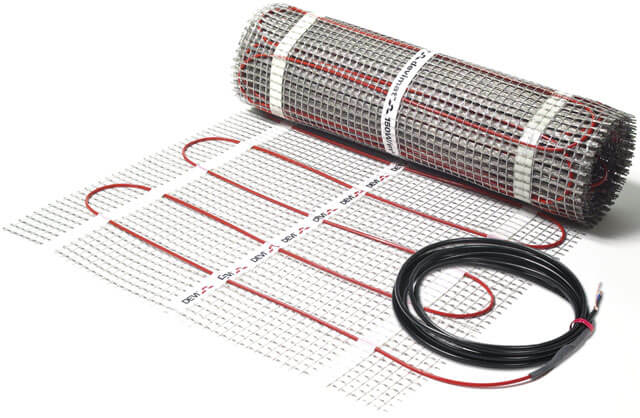

Electric heating mat - a modern and reliable option for underfloor heating

If a heated floor was required in rooms with a ready-made cement screed or in a room without the possibility of laying it, such a type of electrical heating system as heating mats is used. They are also called "thin underfloor heating" or "underfloor heating without screed". The heating mat consists of a thin heating cable fixed to a glass mesh with a constant pitch. The basis of such a mat is a reinforced fiberglass mesh, which is an environmentally friendly and fireproof material. The heating cable is securely fixed in such a mesh, since it is impregnated with a special adhesive. The heating mat is a completely finished structure that does not require laying and fixing the cable, it is easy and quick to install.

Operation of heating mats is simple and does not require additional maintenance, the function of maintaining the required heating temperature is performed by a thermostat connected to the mats.

Heating mats are supplied in the form of a roll, the standard width of which is 50 cm, and the length depends on the area of the room to be heated. To install a heating structure with mats on the floor, there is no need to fill in a new screed or special preparation of the base. The heating mat can be easily cut into separate pieces without compromising the integrity of the heating cable and loss of performance. Since the cable is already fixed with a certain pitch, there is no need to calculate the optimal distance between adjacent turns, and this greatly simplifies the installation process. The mat can be simply laid out on the area of any configuration; in some cases, installation of the heating element is possible even over old ceramic tiles. Thermomats can be installed in any room and at any stage of renovation (for example, immediately before laying the tiles), both on a concrete base and on the previous coating. In addition to ease of installation, the use of a heating mat has the following advantages:

- the possibility of laying under ceramic tiles;

- the small thickness of the construction of the mats implies a minimum rise in the floor level;

- cost-effectiveness of installation work, the possibility of self-assembly;

- comfortable heat distribution over the entire floor surface;

- ease of use without the need for special maintenance;

- reliability and durability.

The price of an electric heating mat is quite affordable, especially considering the ease of installation and impeccable performance. The heating mat is a long-term product - the service life of the system reaches 30-50 years or more on average. The equipment warranty from trusted manufacturers is 15-16 years. Even if a separate part of the structure with mats is damaged, the damaged heating element must be repaired.