District heating no longer suits most homeowners, as the heat from the radiators only comes in one direction. The so-called "warm floors" allow to achieve optimal heating of the premises. They are water and electric - film, less often cable.

As a finishing floor covering, including for heated systems, the first place is taken by laminate. To increase its service life, maximize heat transfer from the heating system and to avoid the occurrence of various extraneous noises, you need to choose the right substrate, both under the warm floor and directly under the laminate.

Characteristics of a "correct" substrate

Of course, in every case substrate requirements will be individual - they depend on the type heating elements, finishing coverings, rough basics and in general operating conditions... However, a basic list of optimal substrate properties can be applied in each case.

- The main requirement for the substrate is heat and waterproofing qualities, without which its benefits will be completely reduced to zero. The quality of the heating system will depend on these indicators.

- Professionals consider an important parameter also the ability of the substrate to provide thermal radiation reflection.

- Since the floor must be in direct contact with the heating components, it is also appreciated. ability to withstand temperature changes.

- In addition, good the backing does not allow moisture to pass through, which is formed during the heating process.

- Resistance to deformation, since changes in the structure of the base can lead to serious malfunctions in the underfloor heating system.

- Environmental purity.

- In addition, it is worth noting and soundproofing - some models of electric and water floors have a slight noise effect, which does not contribute to comfort. therefore soundproofing the substrate will not be superfluous.

In addition to the performance properties, the underfloor heating should be easy to install... This will allow reduce installation time and reduce financial costs.

Back to content

Installation technology

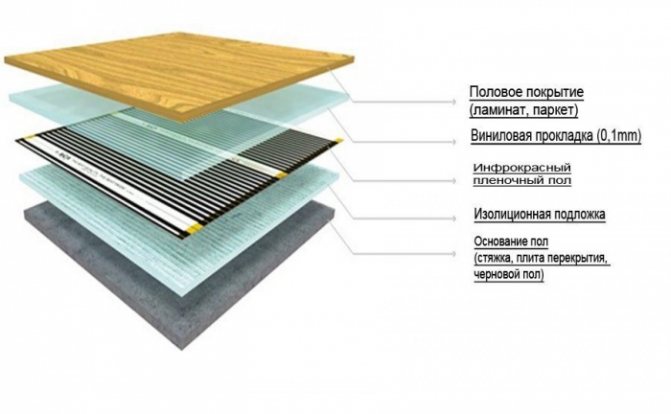

One of the tasks of the installer is to reduce the layer of the entire underfloor heating structure. Such a system can hide up to 25 cm of the room, which affects its area. To reduce the thickness of the structure, specialists use thin but effective materials.

Installation of the substrate is carried out on a previously prepared base. Lay the interlayer with the reflective surface up. The layers of the interlayer are laid end-to-end, gluing the seams with metallized tape. Such a connection protects the floor as much as possible from heat loss and moisture ingress.

When installing a reflective layer, it is necessary to use penofol, since it protects the foil from destruction when the solution penetrates.

Any type of substrate during installation must be installed on the walls. When installing the material with an overlap, it is necessary to approach the wall from 7 cm or more. Such a measure will protect the lower floors from flooding in the event of a leak or damage to the floor system.

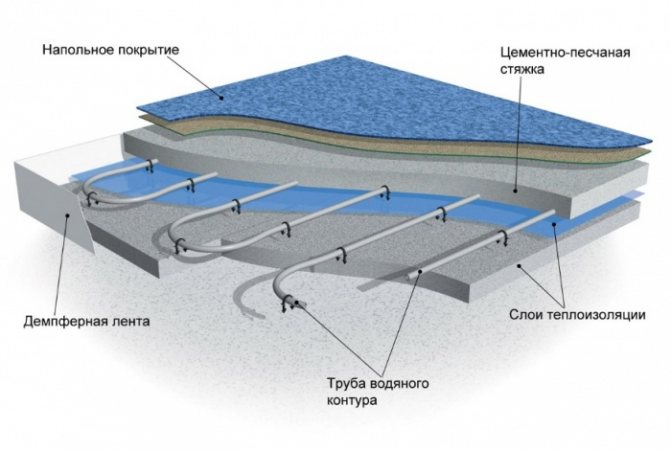

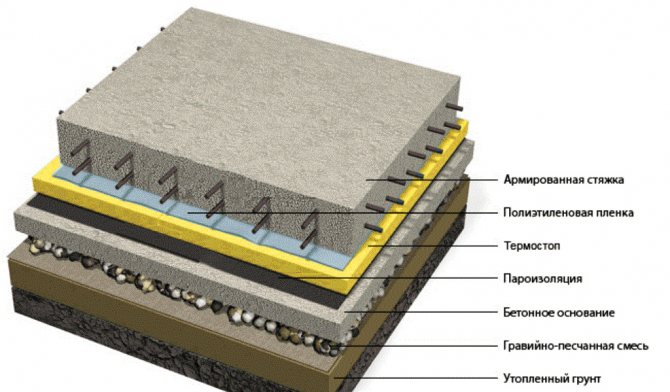

For substrates with low waterproofing performance, a water "cake" must be laid. Its installation includes the following steps:

- laying a waterproofing film;

- installation of reflective film;

- assembly of the underfloor heating system;

- filling pipes with solution;

- assembly of the final finishing of the floor.

Depending on the type of heating system, the process may have its own nuances. In general, the installation of the structure is similar for all types of structures.

Laminate underlay

When choosing a base for a warm floor, special attention is paid to compatibility with decorative coatingthat will stand on heated interlayer... Despite the fact that the substrate will be separated from the floor surface precisely by heating elements, its relationship with the finishing coating suggests its own nuances. The peculiarities of this combination can be considered using the example the most sensitive finishing surface - laminated board... Although the production of laminate does not imply the direct use of solid wood, the structure of this material contains wood inclusionsthat endow the coverage with appropriate characteristics... As a result - the panels take over both the pros and cons of a conventional board... It should be noted that substrate on a warm floor under a laminate, unlike other decorative coatings, is a prerequisite.

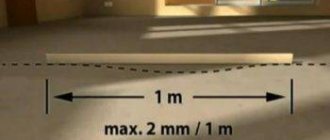

In addition to eliminating the risk of damage to laminated panels as a result of floor heating, the base under the underfloor heating thereby protrudes noise isolatorwhich reduces the noise generated during floor work, without transferring vibrations and vibration effects to the finishing surface... In this regard, the optimal floor height for laminated flooring should be from three millimeters... During the operation of the floor, such bases undergo unfavorable sealing processes, however, the insulating parameters and properties of the substrate will not be lost in this case. In general, the thickness of the underfloor heating must determined based on the specifics of the finishing layer... Too high altitude will not allow warmth pass through it, and thin-layer material, as a rule, does not possess sufficient qualities of sustainability to mechanical damage.

Now it's worth going to the procedure installation of flooring from polyethylene substances under laminated boards.

Back to content

Underlay for electric floor heating

Electric floors can be installed without a backing

Immediately it should be stipulated that the fact that heat-reflecting metallized substrates for floors with electric heating are trying not to be used. The point is, an electric heating cable and a metallized substrate are a pair of electrodes.

The heating wire creates a magnetic field around itself, which induces stray currents on the metallized surface of the substrate.

Stray currents carry a destructive force for the surrounding structures and can have a negative impact on human health.

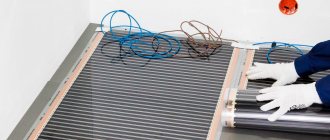

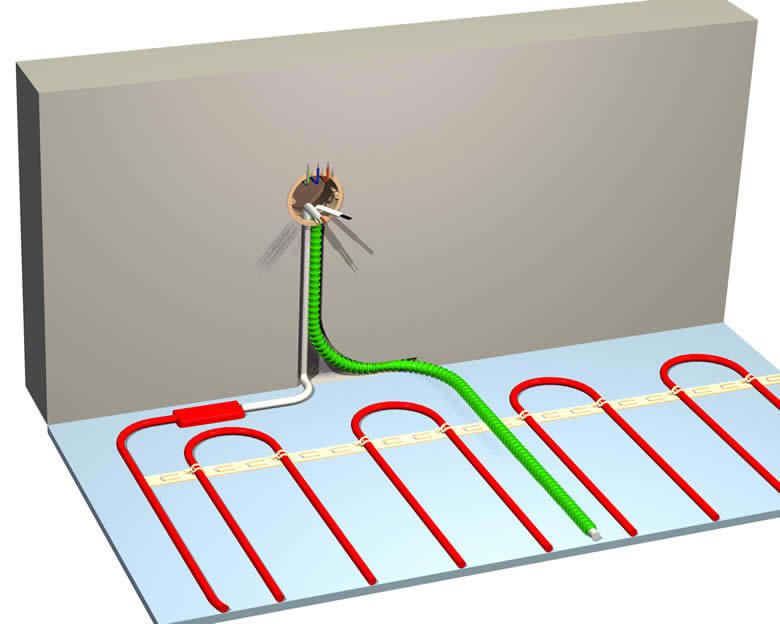

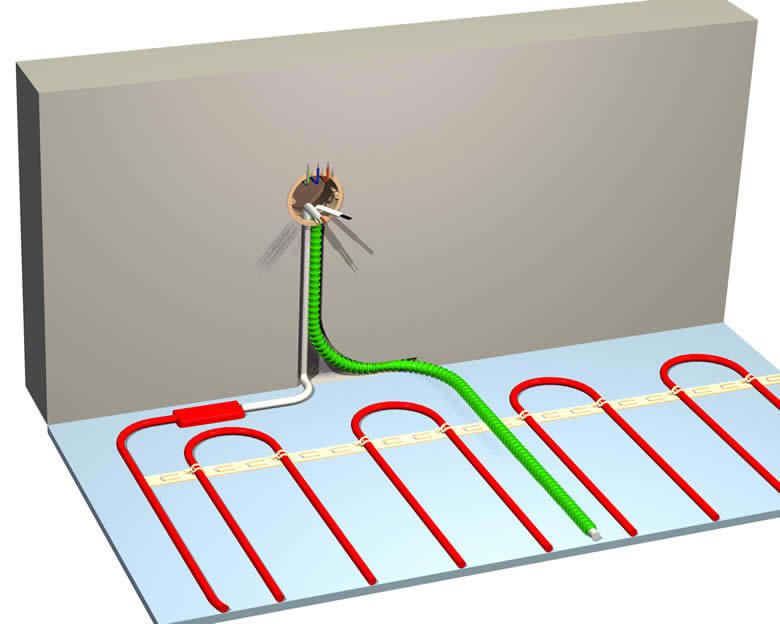

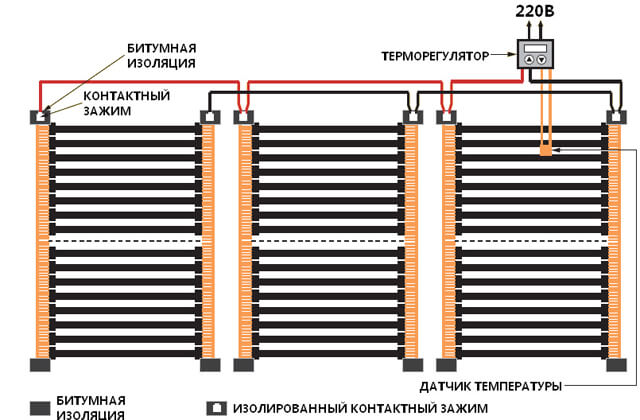

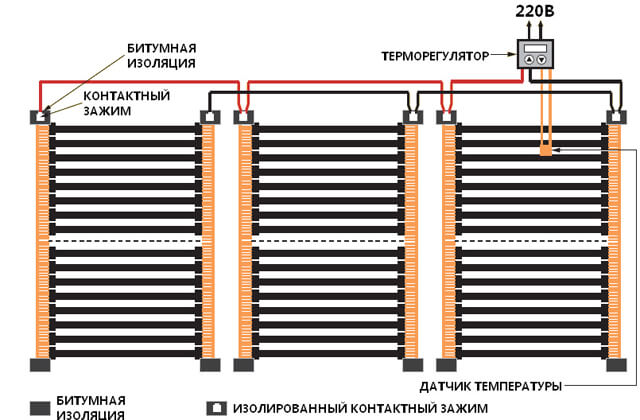

Electric cable heating installation technology

Like the technology of erecting warm water floors, the electrical system requires the following sequence of actions:

- A slab polymer insulation is laid on a clean base.

- The vapor barrier is laid over the entire area of the room.

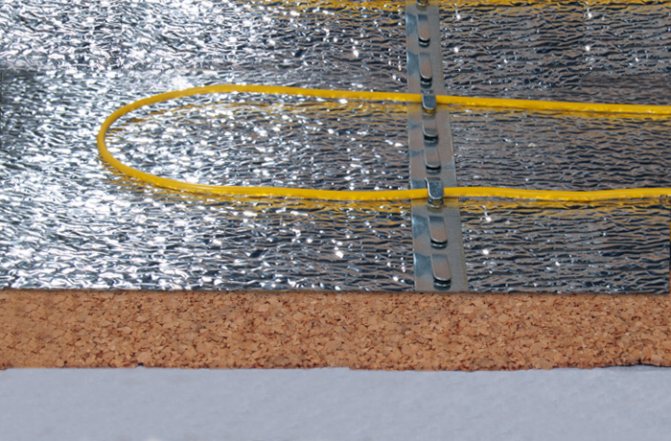

- Spread a polymeric mat with a laminated coating with aluminum filaments.

- Reinforcement plastic mesh is laid.

- An electric cable is attached to the mesh with polyethylene clamps.

- The entire area is poured with liquid concrete.

- The floor covering is laid on the hardened concrete screed.

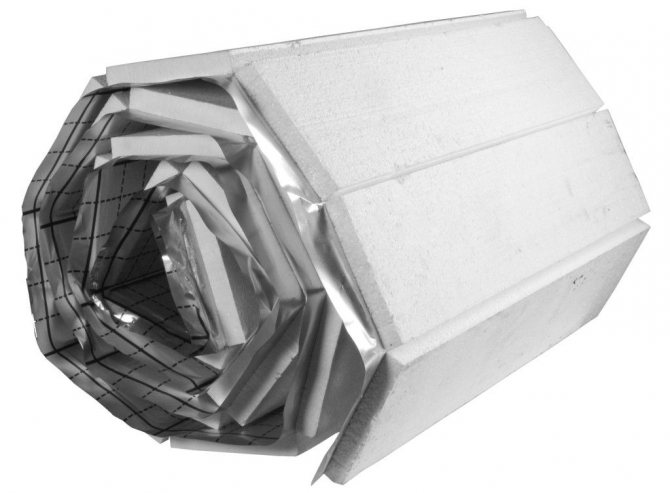

Roll materials made of foamed polyethylene and penofol are used as an underlying layer for electric warm floors. The litter is covered with a laminated film with aluminum threads. For more information on installing a cable floor, see this video:

The film is indifferent to the effects of electromagnetic fields and directs heat upward without loss, effectively heating the floors.

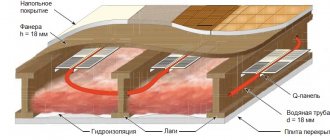

Underlay for water floor systems

Regardless of the design of the warm floor, the role of the substrate will boil down to ensuring maximum heat transfer, which will allow the heating layer to more efficiently distribute heat through the decorative coating.However, in the case of floors in which work is envisaged liquid heat carrier, the functions of the substrate are complemented by the need to create waterproofing barrier - that is, it must be impervious to moisture. This quality is not so important if the substrate is laid under the film warm floor, but for the operation of water floors this circumstance is direct determines heating efficiency.

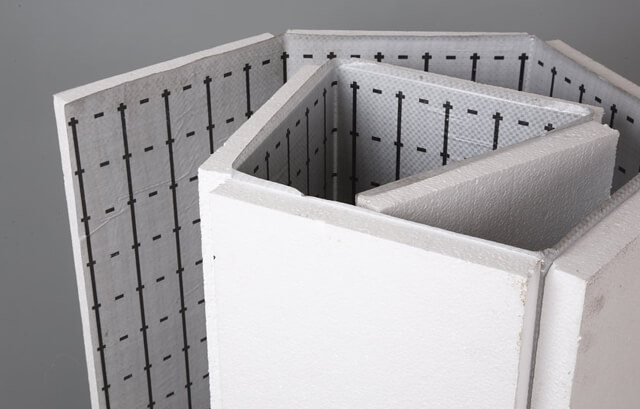

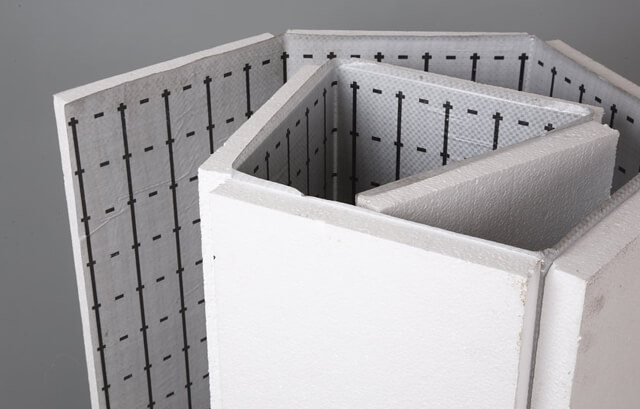

When laying plumbing it is recommended to use decking, which will also perform the task of a reliable basis for the installation of elements that regulate the circulation of the heat carrier. Such layers are characterized by the presence of special protruding components, intended for the installation of the entire water supply complex. Often such schemes are made of polystyrene.

In addition, during the installation of a heating coating with an aqueous thermal carrier, the need to lay an auxiliary reinforced mesh... This component will serve as plumbing fixer heating floor.

Such underfloor heating has the form of a "pie"including an interlayer with a heat insulator and a mesh layer.

Back to content

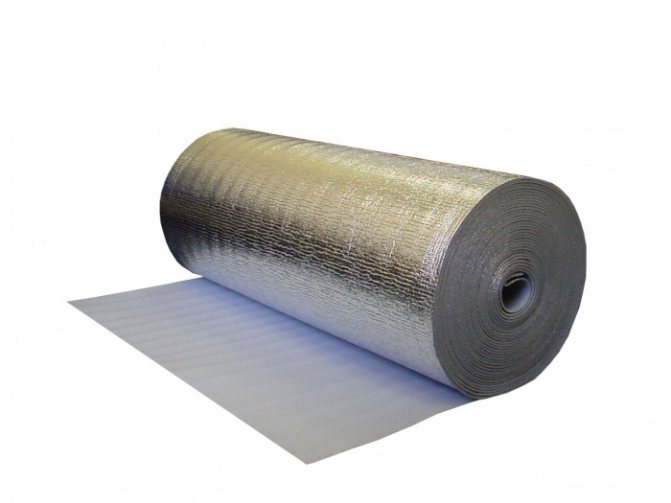

Substrate requirements

The main material for the underfloor heating is polypropylene, polyethylene foam. They are covered with a lavsan film with a metallized layer. The latter serves to distribute heat evenly. All other components do not allow heat to escape to the lower floors, but is completely transferred to the room to warm the air from the base of the floor.

The porous underfloor heating substrate has very high permissible temperatures, which reach 90 degrees. This allows the heating elements to be laid directly onto the foil. All this indicates the excellent qualities of the heat and waterproofing material. In addition, other qualities that the substrate possesses are distinguished - these are sound insulation and a high degree of reflection.

On each element of the underlay for pouring the floor there is a special marking that resembles a grid. This contributes to the rapid and high-quality distribution of the electric underfloor heating cable over the surface, depending on the step that is selected.

The substrate allows you to save about 80-90% of thermal radiation. In this case, all energy costs are reduced to a minimum.

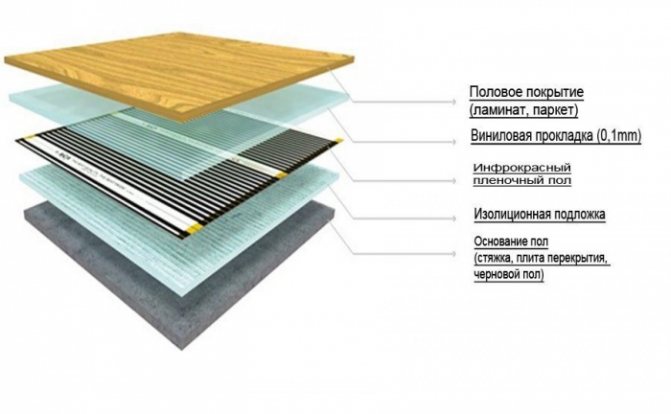

Infrared flooring

When laying infrared structures, use flooring with heat-reflecting thermal insulation qualities... In this case, the installation of the substrate is carried out right under the cover tape... In addition to roll flooring as a thermal insulator cork backing can be used under floor heating, fiberboard tiles and magnesite parts... In the absence of such a flooring foil layer - you can use the above technology creating a "pie" from a thermal insulator and a foil layer.

Not a bad choice of material for insulating decking under the film coating will become and penofol with reinforced structure. It is different good thermal insulating qualities and the presence of a foil layer that minimizes heat loss in the room.

Flooring for a film floor can be made from ordinary fiberboard or from the same magnesite panels. But in such cases, it is installed directly onto the cement screedpre-coated with aluminum foil.

Back to content

Underlay for a film warm floor

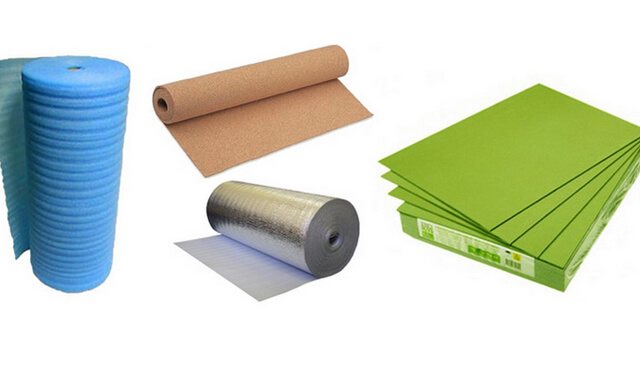

For film-type floors, a pressed cork backing or foamed polymer (polystyrene) is recommended. The latter can be laid even under a concrete screed, since it is able to withstand heavy loads without deformation.

If you need to level the base before laying the warm floor, then plywood, OSB or chipboard sheets are perfect as a backing layer.

IMPORTANT! It is categorically not recommended to use a substrate with an aluminum layer without additional protective vacuum deposition under an electric warm floor, since there is a risk of current breakdown if there is a violation in the insulation of the warm floor.

General nuances of installation

When installing the substrate under different types of finishing coat the following laying rules should be observed:

- In all cases, foil the reflective surface must point up... By the way, a substrate under an infrared warm floor with a foil layer capable of holding up to 97% heat fluxes, which is essential increases productivityb installed warm floor.

- Base flooring fits only by the "butt-joint" method... It helps to avoid heat loss in these areas. metallized tape - with its help you should perform all connections substrate. In addition, such a mount will perform and moisture barrier and steam vapors.

- Heating components regardless of the heat source and the heat carrier itself must be installed on top of the layer, which will reflect thermal radiation.

Similar articles:

Purpose of the underlay

Today, three types of warm floors are produced:

- water pipes with a pipe system;

- powered by electricity;

- heated film mats (infrared).

All types of systems have their own advantages and disadvantages, which are taken into account during installation. Each design has its own nuances during installation, but one thing is invariable for all floors - they require a substrate. Such a screen increases the efficiency of the system, protecting it from heat loss.

Note! The minimum effective interlayer thickness must be at least 30 microns. The correct coating has a protective layer.

Choosing based on the topcoat

In order for the lining to be able to last a very long time, and also work only in the positive direction for your floor covering, it is necessary to select it in accordance with what kind of finishing material you choose. Let's first take a look at what types of floors can fit on a heating heating system and how they interact with the lining:

- Self-leveling floor - produces significant pressure and moisturizes the surface.

- Laminate, linoleum - they do not produce strong pressure, but they need a substrate that is correctly selected for laying them.

- Ceramic tiles are very similar to self-leveling floors and require sufficient density, but they have some differences.

Types of substrates and recommendations for their selection for the underfloor heating system under the laminate

If you decide to make yourself a self-leveling concrete floor, then very dense materials should be laid under it, which are not afraid of moisture and can easily withstand a lot of weight. Also, only a water heating system is compatible with such a floor, infrared foil heating will be practically useless.

Laminate and linoleum must be laid on surfaces that do not emit any creaks, fit securely on the starting surface and do not move on it, ideally should be able to be fixed. Compatible with film foil systems and similar.

For ceramic tiles, the base should not only be dense and withstand heavy loads, but also create a monolithic surface, not move apart, not move and not have other possibilities for displacement. Because of this, a crack between the joints of the tiles will be inevitable, and this will have a bad effect on durability.

How to choose the right underlay

Before proceeding with the installation of the heating system, you should decide which substrate under the warm floor will better perform certain functions.Do not forget that each manufacturer tries to sell as much of its products as possible, and, often, the advertised product does not meet the qualities that were declared.

There are a number of factors that determine a high-quality substrate, and one should proceed from this when choosing it:

Thermal conductivity of the material

... The best substrate is considered to have these indicators less, and they are determined by the thickness of the product and the material of execution. At the moment, there are substrates with improved energy conservation rates, they are coated with foil.

Energy saving occurs due to the reflection of infrared radiation - as a rule, this figure is 20-30%. All materials used in the manufacture of substrates meet the required building standards for residential premises.

Strength characteristics - resistance to constant and dynamic loads

... There are materials that are compressed due to prolonged constant stress. Because of this, the thermal conductivity indicators increase. This effect should be avoided by selecting the correct load so that the mechanical effect over the entire surface is as uniform as possible.

Manufacturability

... Laying the material will be the cheaper, the easier it is to work with it. This characteristic is quite different for many materials. It is best to give preference to expanded polystyrene. It is very technological, the underfloor heating made of it is often thin, no more than 5 mm, while it is easy to cut with simple scissors.

The underfloor heating underfloor made of expanded polystyrene is flexible, its edges can be easily docked with the walls. This material is easy to measure, cut off parts, adjust, it can be simply bent near the walls. In this case, it is much easier than installing chipboard or OSB.

Additional qualities

... To simplify installation work even more, some manufacturers draw a grid on the front side or leave special bosses that protrude.

This modification greatly simplifies the installation of pipes, making it possible to fix them during the installation of the lining. The result is faster repairs, improved efficiency and longer heating system life. The heat carrier can be installed at an equal distance, so that overheating in individual zones is excluded, that is, the entire floor is heated evenly.

Price

... This parameter is quite significant. With special technical knowledge, it is possible to install heating in such a way as to obtain high heat saving rates, as well as to largely save the finances required for the purchase of materials.

Environmental friendliness of the material

... Although any of the materials tends to emit toxic fumes, their quantity and intensity are not always the same. Due to the fact that the substrate for underfloor heating pipes will be used in conditions of high temperatures, it is worth paying special attention to indicators of environmental safety and harm to human health.

Considering the brochures of various manufacturers about certain lining materials, not everything needs to be taken on faith, and you can even ignore some of the characteristics.

Sound absorbing effect.

Anyone who remembers at least something from physics lessons knows that sound is transmitted through air. Since absolutely any insulating material does not allow air to pass through, therefore, the same thing happens with sounds.

UV resistance

... Since the underfloor heating underfloor heating, as well as under the water one, is not directly exposed to ultraviolet radiation, this characteristic of the material does not in any way affect its performance.Unless, it is required to isolate the X-ray source, but there is hardly one in the living room.

Waterproofing properties

... Let's say right away that the presence of moisture under warm floors, both water and electric, should be excluded even during the installation of heating. If a leak suddenly occurs in the heating water pipes, then the sooner it is eliminated, the less costs the owner will have, and the materials will not be exposed to prolonged exposure to moisture. But in the case of an electric underfloor heating, the presence of moisture is in principle excluded, otherwise short circuits of the circuit are possible. Therefore, how well the substrate resists moisture is irrelevant.

Price factor

... In most cases, the cost of the material includes the cost of advertising and product promotion. That is, buying a product from a well-known company, you significantly overpay for the brand. However, there are many types of quality products on the market at more affordable prices, just not as advertised. Competitive pricing allows new firms to promote their products in the marketplace, interest buyers and earn a business reputation.

Thus, all of the above indicators will help you not to make a mistake when choosing a substrate for a warm floor, no matter what design, so that it lasts as long as possible, and you can save on assembly.

Electrical

Heating occurs due to the energy released by the conductors under the influence of an electric current.

By their design, warm floors of this type are film, that is, infrared, and cable, having a heating element in the form of simple flexible cables with conductive elements inside. During the installation of electric floors, complications can arise, therefore, all the parameters of the existing wiring should be taken into account in advance, as well as the correct calculation of the protective fittings.

For heating to be effective, the calculated power per m2 must be at least 0.25 kW. When installing a warm floor, it is very important that the correct substrate for the warm floor is selected. There are a wide variety of substrates, and each is designed to perform a specific function.