What is the difference between forced circulation and natural circulation?

With natural circulation, the coolant in the pipes moves by itself, under the influence of gravity. Forced implies the presence of a pump that pushes the coolant in the pipeline, accelerates its movement. There are advantages and disadvantages to such a system.

Pros:

- inertia decreases, movement speed increases. A pump for heating in a private house allows you to fill the circuits with hot coolant in a short time. This also applies to long paths too. With natural circulation, water often flows to distant radiators already cooled, and does not rise to the second floor at all;

- uniform heating;

- since the water flows under pressure, the number of air locks decreases;

- in gravitational systems, pipes with a large cross section are used - the lack of speed is compensated for by a large volume of water;

- for natural circulation to work, the pipeline must be installed at a certain angle. If there is a pump for the heating system, the pipes can sometimes even have a negative slope, the pump will cope with this obstacle. Installation of such a pipeline is much easier.

Disadvantages:

- additional equipment costs - the cost of the pump itself;

- the cost of electricity from which the pump runs;

- volatility. In the event of a power outage, the system will stop working, the house will cool down.

The last problem is the most serious when installing a circulation pump for heating: how to install it correctly depends on the characteristics of the system. If you put it in parallel on the bypass, in the absence of electricity, the coolant can circulate naturally.

But at the same time, the aforementioned difficulties will arise: low speed, uneven heating. It is better to go for additional costs: purchase an autonomous energy source for the house (what is a generator for a heating boiler).

Do you need a bypass?

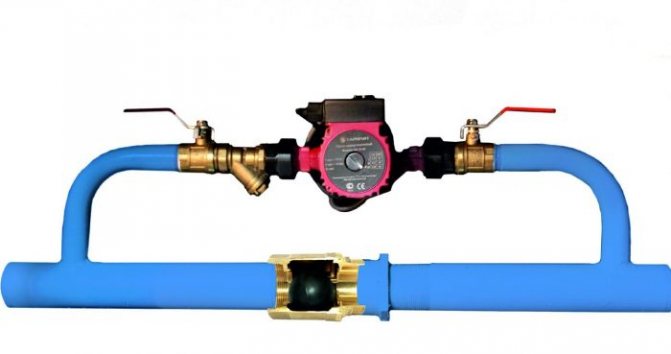

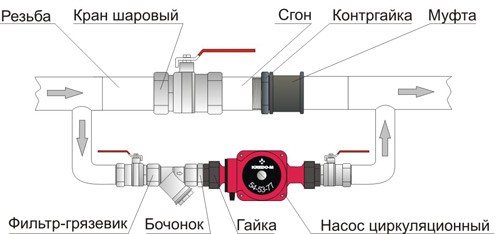

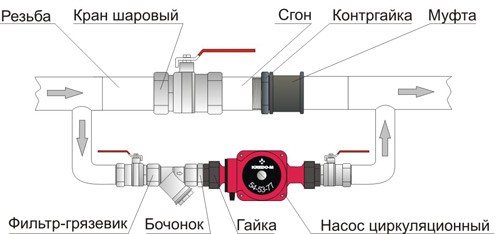

Experts advise installing a circulation pump on the bypass, which can be disconnected from the main system by overlapping two ball valves. This approach to installation will allow repair or replacement of equipment without any special losses for the heating network. In order to save electricity, the circulation unit is turned off in the off-season using the same ball valves, leaving the system with natural circulation. When the air temperature drops, the shut-off valves are opened, re-connecting the pump to the system.

Device and types

The pump consists of a rotor, shaft, impeller, electric motor and housing. The principle of operation is centrifugal. An impeller (impeller) is two discs connected by curved blades. The discs have holes for the intake of the coolant and for attaching the wheel to the shaft.

When rotating, the impeller draws water into the pump and, due to centrifugal force, pushes it further into the circuit under pressure. A vacuum is formed in the intake zone, and increased pressure in the outlet zone. The rotation of the shaft with the impeller is carried out when energy is supplied from the motor.

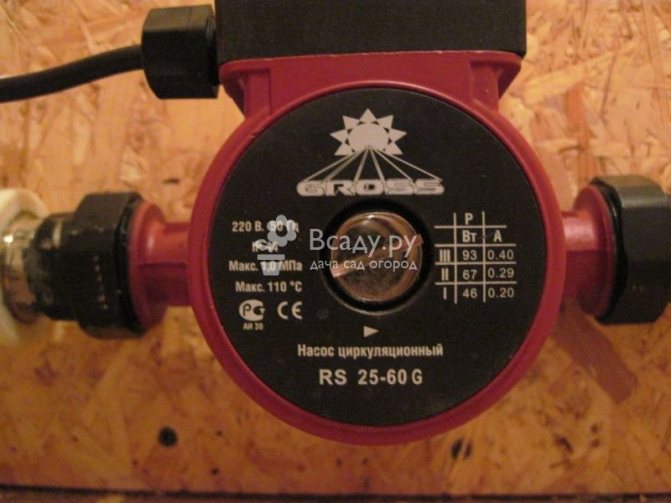

Pumps are divided into two large groups: dry and wet. To install a circulation pump in the heating system of private houses, wet ones are usually used: in this design, the coolant washes the engine and performs the function of lubrication.

In dry cases, the engine does not come into contact with water, it easily overheats, which affects its durability.

The power of dry pumps is high; as a rule, there is no need for it in a private house.

Selecting a location for the pump

The pumping equipment requires periodic maintenance, therefore it is necessary to provide free access to it. As far as the location itself is concerned, a few years ago, the circulation units crashed only into the "return", where the temperature of the coolant is no longer so high. Now on sale you can find products made of materials that calmly contact with hot water - they can be installed on the supply pipe.

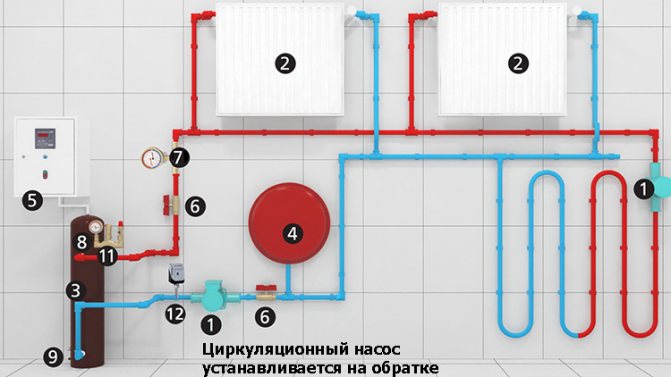

Having ascertained the ability of the selected unit to withstand the pressure of the hot heat carrier, install the pump on the "supply" not far from the expansion tank. This tactic will ensure the highest possible temperature in a given area, which will increase the efficiency of the heating system. When reconstructing a heating system with a membrane compensating tank, it is better to cut the circulation device into the "return", bringing it as close as possible to the expansion tank.

Bypass makes the heating system more comfortable to operate

Installation features

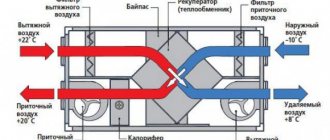

How to install a heating pump in a heating system? To minimize obstacles in the path of the coolant, to ensure complete cooling of the working parts, the working shaft must be located strictly horizontally.

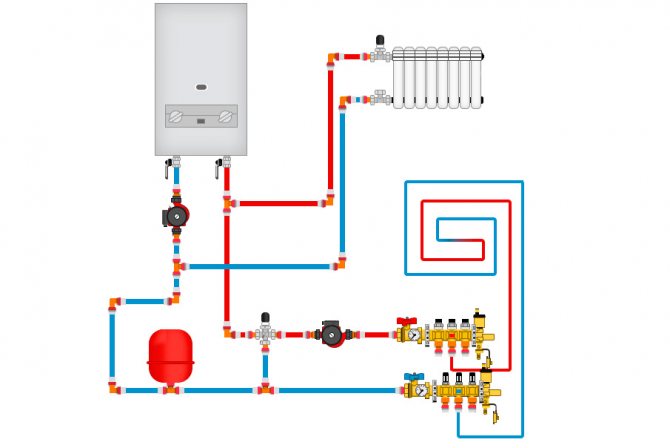

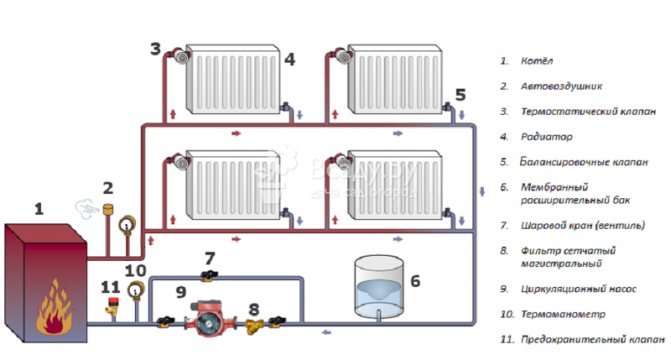

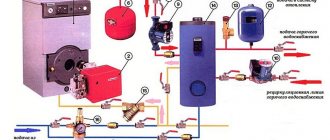

In most cases, the connection diagram of the circulation pump to the heating system looks like this: the device is placed on the return pipe in front of the boiler entrance. A mud filter is installed in front of the pump. Its task is to retain sand, scale particles, scale and other abrasive elements that can damage the impeller or bearings, and reduce the service life of the device.

Why installation of a circulation pump in the heating system is preferable for the return flow: bearings and plastic elements of the device are sensitive to high temperatures. Hot water reduces their resource.

If the house is heated with underfloor heating, installing the pump into the heating system with your own hands can also be done on the supply, since the coolant in the underfloor heating is low-temperature, within 50 degrees. If the heating is radiator - only for the return.

Direct installation

The process of installing a pump for heating requires the preliminary purchase of equipment with detachable threads. If it is absent, installation will be complicated by the need for self-selection of transition elements. For long-term operation, you will also need a deep filter and check valves to ensure operation under pressure.

Installation is carried out using a set of wrenches of appropriate sizes, valves and bypasses equal to the diameter of the riser.

The final heating power will be influenced by the choice of the place where the equipment can be placed.

Place for insertion

When connecting the pump, take into account its periodic maintenance and place it within a direct reach. The priority installation location is also determined by other nuances. In the past, wet pumps were often installed in return circuits. The cooled water that washed the working part of the equipment extended the service life of the oil seals, rotors and bearings.

Parts of modern circulation devices are made of durable metal, protected from the effects of hot water, and therefore can be freely attached to the supply pipeline.

Improving efficiency

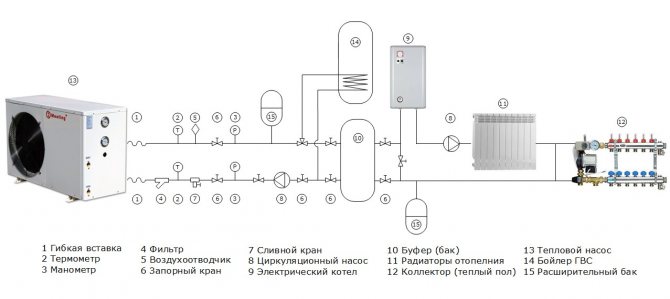

A correctly assembled pump unit can increase the pressure in the suction zone and thus increase the heating efficiency. The connection diagram implies the installation of the device on the supply pipeline near the expansion tank. This creates a high temperature zone in a given area of the heating circuit.

Before inserting a bypass with a pump, you will need to make sure that the device can withstand the onslaught of hot water.If a private house is equipped with a warm floor, the device must be installed on the coolant supply line - this will protect the system from the appearance of air jams.

A similar method is suitable for membrane tanks - bypasses are mounted on the return line in the minimum proximity to the expander. This may complicate access to the unit. Mounting on the supply circuit with a tie-in vertical check valve will correct the problem.

Structural scheme

Installation of circulation equipment requires compliance with the rules regarding the sequence of fastening elements:

- ball valves mounted on the sides of the pump make it possible to remove it for inspection or replacement;

- a filter embedded in front of them protects the system from inclusions that clog the pipes. Sand, scale and fine abrasive particles quickly destroy the impeller and bearings;

- the upper parts of the bypasses are equipped with air relief valves. They can be opened manually or work in automatic mode;

- the correct installation scheme for a "wet" pump assumes its horizontal mounting. In this case, the arrow on the body must coincide with the direction of movement of the water;

- protection of threaded connections is ensured by the use of sealant, and all mating parts are reinforced with gaskets.

For safety reasons, pumping equipment can only be connected to a grounded outlet. If grounding has not been carried out yet, it must be provided before using the device.

The dependence of the pump on the availability of electricity is not an obstacle to normal operation. When developing a project, it is necessary to include in it the possibility of natural circulation.

Sequence of work

When connected to an existing heating network, you will need to drain the coolant from it and blow out the system. If the pipeline has been actively used for many years, it must be flushed several times in order to remove any scale residues from the pipes.

The functional chain of the circulation pump and its fittings is mounted in a pre-selected place according to the connection rules. When the installation cycle is completed and all additional devices are attached, the pipes are again filled with coolant.

To remove the remaining air, you need to open the central screw on the cover of the device. The signal for successful bleeding will be water flowing from the holes. If the pump is manually operated, gases will need to be vented before each start. To save equipment and reduce interference with the heating process, an automatic pump with an operation control system can be installed.

System expansion

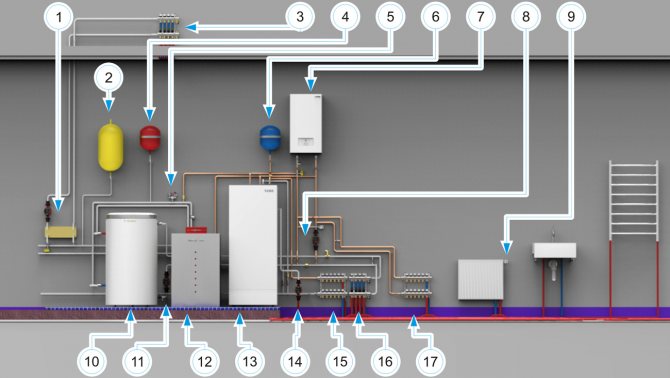

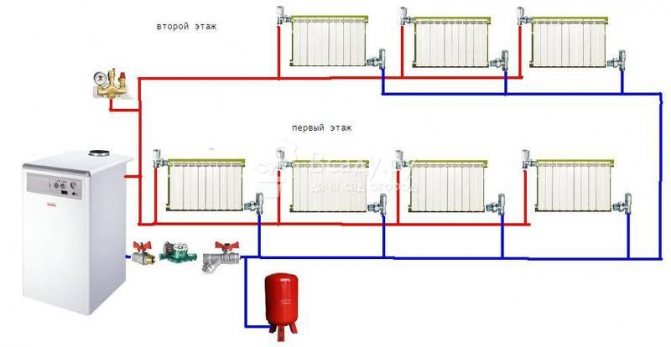

If the area of the house has increased, the old equipment is no longer enough for full heating, a second boiler and an additional pump in the heating system are needed. The place of its installation will depend on the general scheme with two boilers.

In some cases, the installation of an additional pump in the heating system is also recommended with one boiler: if it is powerful, the house is large, there are many circuits, the scheme is combined (underfloor heating + batteries). In the latter version, it is desirable to also have two collectors (for radiators and for the floor), each with its own pump.

Installation

How to connect a pump to a heating boiler when the scheme and location are selected?

The procedure is as follows:

- Drain the coolant, clean the pipeline.

- Cut the bypass into the pipe, put the pump on it.

- Insert ball valves on both sides of the device - in case of shutdown / repair / dismantling of the pump.

- On the section of the highway next to the bypass, a shut-off valve is also needed.

- Install a cleaning filter in front of the pump itself.

Video about installing a circulation pump in a heating system.

The main rules for installing the pump

The purchase of products equipped with split threads will help to facilitate the installation of pumping equipment.Otherwise, you will have to additionally buy special adapters. Like any other technique, the pumps are accompanied by an instruction, which reflects the basic recommendations regarding installation. You need to read the document before starting work.

Correct and incorrect positions of the circulation pump

When self-installing circulation equipment, it is important to correctly determine the position of the unit relative to the horizon. Remember that the shaft of the electric motor must be located horizontally, otherwise it will not be possible to avoid the appearance of air locks, which will quickly disable the equipment. During installation, be guided by the arrow on the body, indicating the direction of movement of the coolant in the network.