In heating, water can reach 80-90 ° C. And if for pipes with radiators this is still normal, then for a warm floor such a temperature is too high. In order to be able to stay on the floors normally, a three-way valve is used. Although it is installed far from only for these purposes, it is indispensable in a system with almost any solid fuel boiler. Let's figure out what kind of mechanism it is, what it is for and how to choose the right three-way valve for the heating and water supply system.

What is it and why is it needed

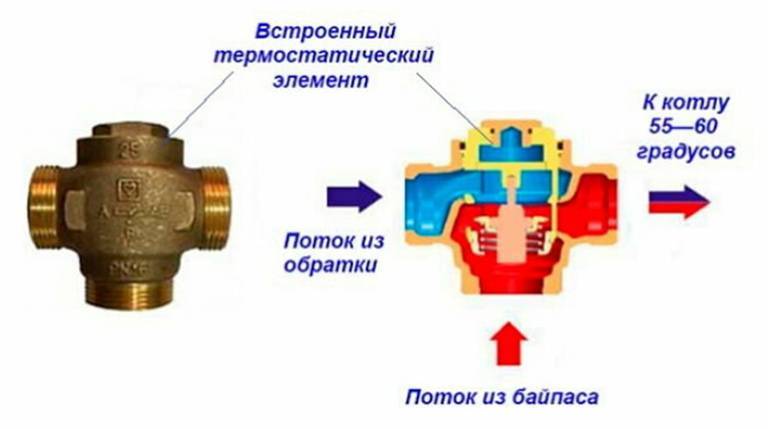

This is what a classic three-way valve for a heating system looks like.

As the name suggests, this valve has 3 strokes. You can even call it a crane, since it belongs to the shut-off and control valves. It looks like an ordinary tee, but inside its structure is much more complicated. Roughly speaking, it serves to change the temperature of the water. There are two ways: at the first, the return is mixed with the supply to lower the temperature; the second method, on the contrary, divides the streams by dumping hot water into the return line. This is useful in various cases:

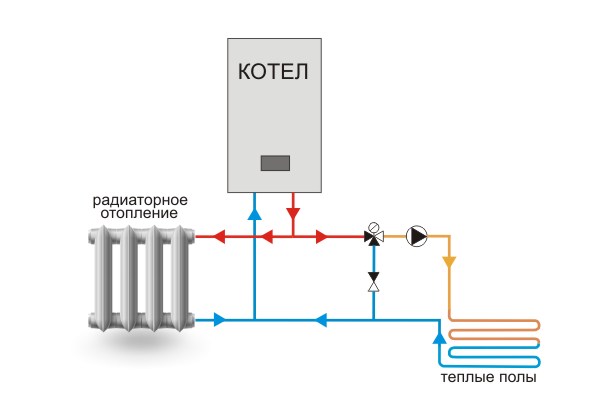

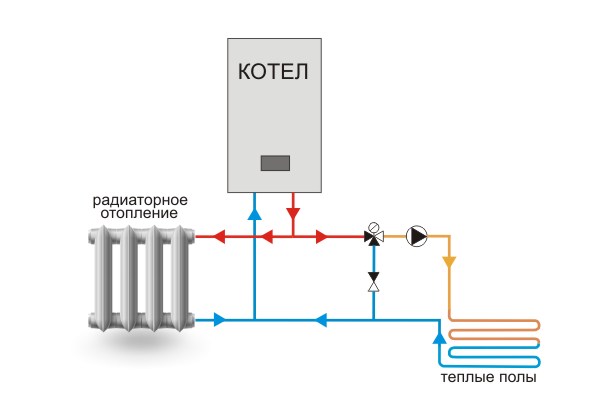

- Warm floor... The return flow and heating supply are connected to the valve. Since the return flow is colder, water at a lower temperature is supplied to the floors. In this case, the temperature of the remaining heating remains the same.

- Maintaining temperature... For the normal operation of almost any heating equipment, it is necessary that the return flow is not colder than the supply by 60 degrees. Otherwise, the boiler will not last long. Therefore, the valve takes water from the supply and sends it to the return line.

- Condensation protection... For the same reason. If water gets into the heat exchanger warmer than the dew point, condensation begins to accumulate on it.

- overheat protection... Modern boilers are equipped with various sensors. If it is, for example, a simple solid fuel boiler, it will continue to work even if it overheats. The three-way valve solves this problem.

- For piping an indirect heating boiler... To have hot water in the house, you can connect a boiler to the boiler. And then the water will be heated by heating. The three-way tap serves for uninterrupted supply of hot water. It opens when the temperature of the water in the boiler drops.

- When organizing a bypass... In some cases, it is required to direct water along an alternative path - bypass. For example, for more efficient heating. The easiest way to do this is through a three-way valve. It will open and close at the right time.

But why install a valve when you can just lower the temperature? The question seems logical, but in fact, in ordinary boilers at low temperatures, the heat exchanger quickly fails. For this mode of operation, a condensing boiler is better suited, but their price is much higher. Therefore, it is better and easier to install a three-way valve.

As you can see, there are many ways to use it. In some cases, it is used to improve the energy efficiency of the system. In others, it is an indispensable device for connecting equipment.

Maintaining a comfortable temperature with a three-way valve for heating

There are two ways to regulate the energy released by the radiator:

- A qualitative change in the properties of the radiator.

- Quantitative regulation of the generated heat.

In both cases, manipulations with the fluid circulating through the pipes are necessary.

Qualitative change in the properties of the radiator

In order to regulate the microclimate in the room, you can switch the heat generator to a different operating mode - as a result of which the temperature of the water entering the radiators changes.

The presence of a three-way valve allows you to regulate the indoor climate for any type of heating

You can switch the mode on a wall-mounted boiler, if we are talking about a country house. However, the situation is much more complicated in the case of the boiler house of the urban microdistrict.

Helpful advice! In the case of a city apartment, when you do not have access to the boiler room, it remains to regulate the energy already released by the coolant.

Quantitative regulation of heat flow using a three-way valve for heating with a thermostat

In the case when you cannot influence the temperature of the water supplied to the radiator, you can adjust its amount. For this, it is necessary to buy three-way valves for heating with a thermostat. These devices allow you to limit the amount of water passing through the radiator, and as a result, with the same area of the battery, more or less heat will enter the room, of course, within the limits limited by the power of the system.

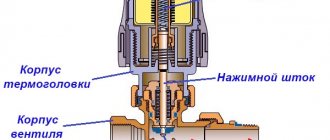

Three-way mixing valve with thermostat

The three-way valve for the heating system and the temperature controller installed on the radiator can be used separately, however, in autonomous heating systems of modern apartments and private cottages, a combined method is often used to improve efficiency. Thus, it is advisable to purchase a three-way valve for heating with a thermostat.

Heat flow adjustment limit

It is important to take into account that the principle of operation of the three-way mixing valve allows you to increase or decrease the temperature of the radiator only within the established limits. These limits are dictated by the technical characteristics of the thermal device, namely, the value of its maximum heat transfer, and depend on each specific radiator.

The device and principle of operation of the three-way valve in the heating system

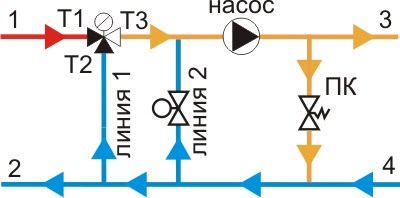

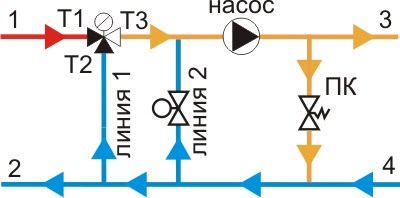

To make it easier for you to understand the principle of operation, I propose to consider this scheme:

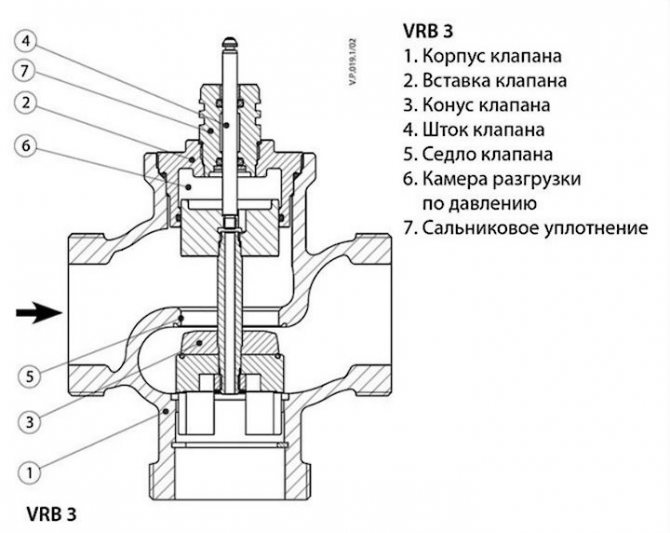

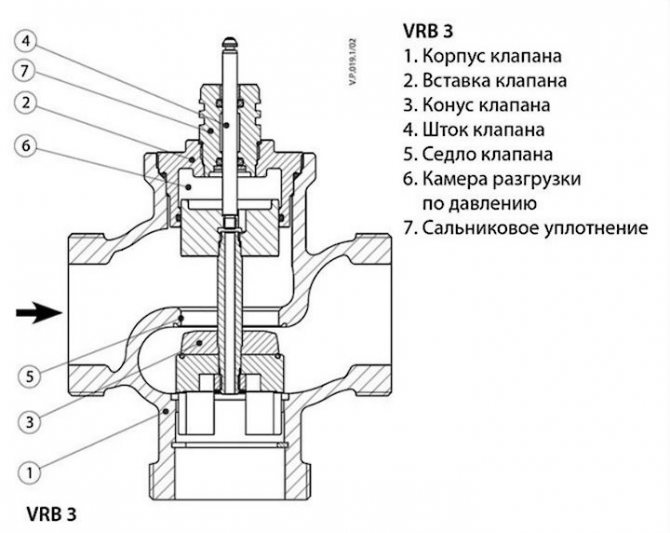

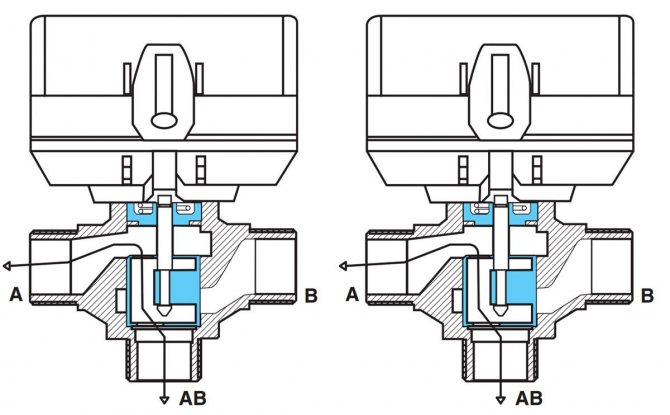

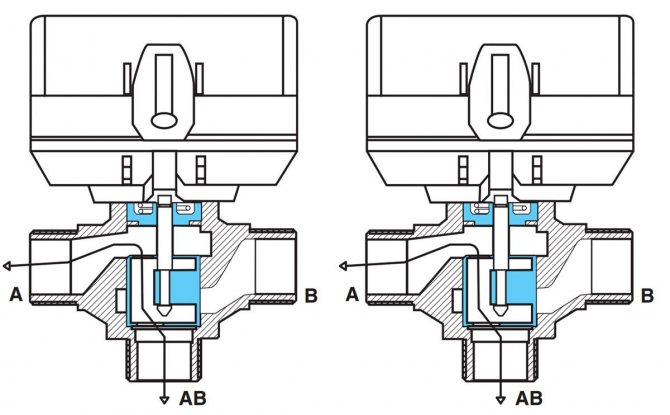

Sectional design of the three-way valve.

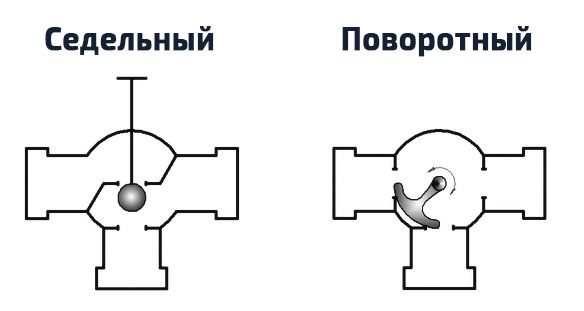

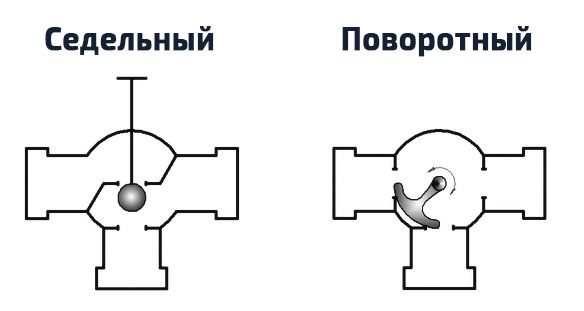

When a certain temperature needs to be reached, the stem rises, opening the duct. This is similar to the principle of operation of shut-off valves. And the mechanism itself is called a saddle. Instead of a rod, a ball or rotating sector is sometimes used. Exactly the same as in conventional ball valves. This mechanism is called rotary. On the diagram, they can be depicted as follows:

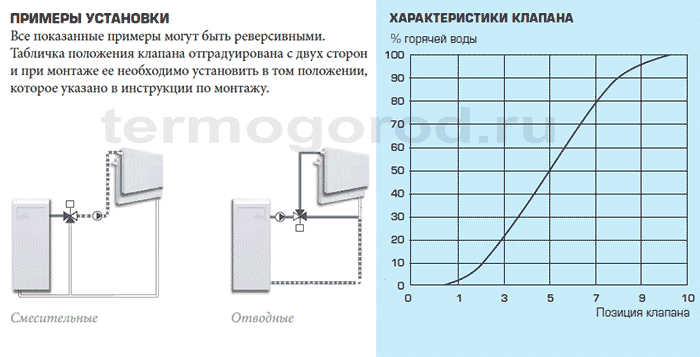

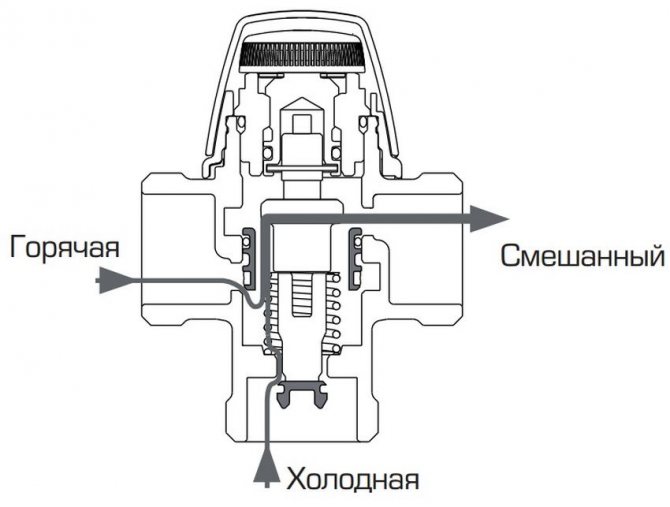

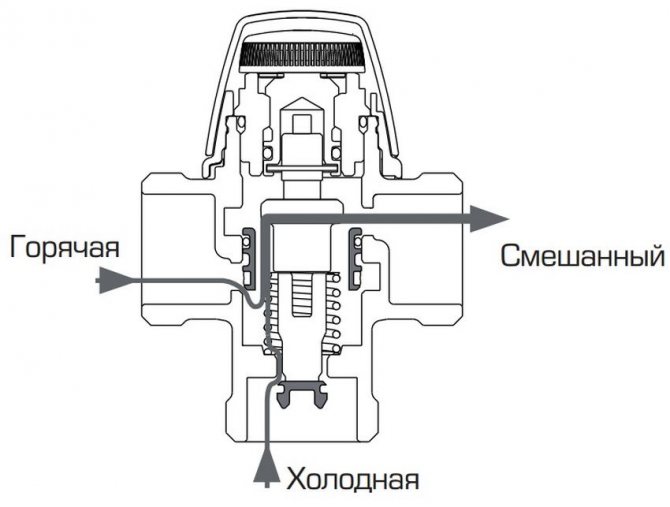

I will talk about what exactly controls the rod or the ball a little later. For now, let's take a look at each view. Let's start with the mixing valves:

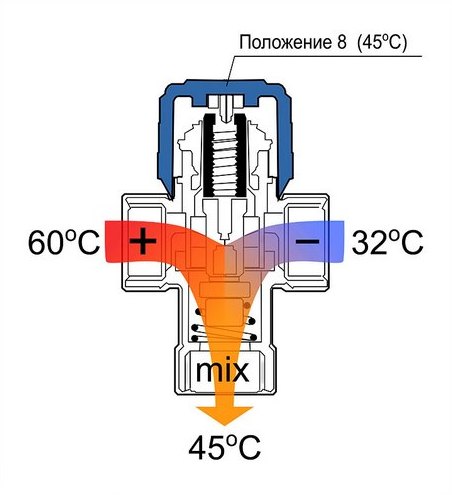

As you can see, hot water comes in on the left, and cold water from below. The stem rises if necessary, allowing the two streams to mix.

And this is how the separating valve works. Here, on the contrary, hot water enters on the right, and can come out to the left or down. If the temperature is normal, the stem rises. If a higher temperature is required, the stem is lowered, sending hot water down. That is, to the return line.

From the instructions for the valve type VMR from Mut International.

Typically, thermo-mixing and separation valves do not overlap completely. But the switches, as you can see, close one of the pipes, and open the other. There is no mixing or separation.

Sectional view of a typical 3-way valve.

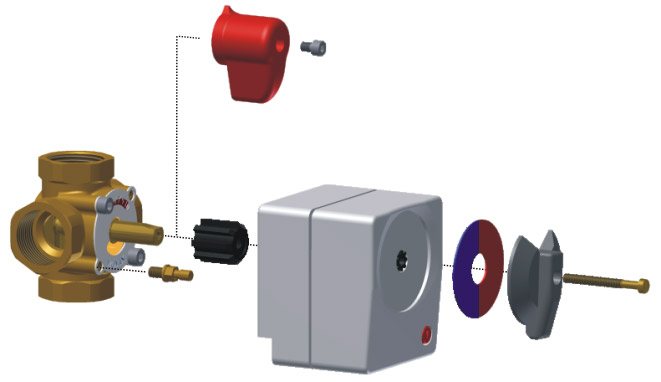

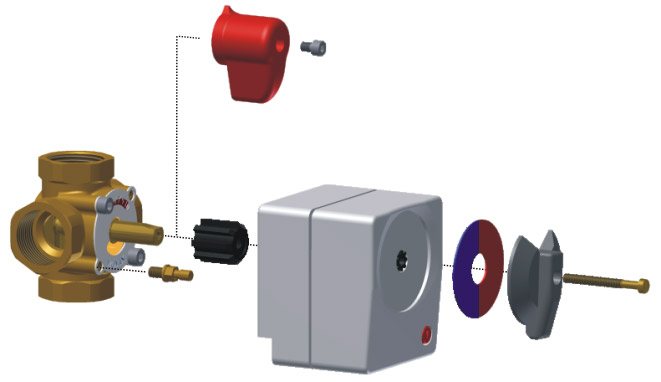

Design features of the motorized valve

The design of the motorized valve is different for the separating, mixing and switching models.All types of control valves have a metal body, which is internally divided into three parts, between which there is a regulating device - a stem. It is in its shape and principle of operation that the design of the three-way valve differs.

We recommend that you familiarize yourself with: How to calculate and make a staircase from a profile pipe in a private house?

An electric actuator is a part that combines all three types of three-way valves. With the help of a built-in drive with a controller, automatic regulation of the water temperature is carried out due to the response of the device to changes in the water temperature. An electric drive, which is also called a servo drive, is a motor, but it does not rotate around its axis, like conventional devices, but makes a turn in a limited radius.

Attention! Externally, a three-way motorized valve can be recognized by the presence of a rotary lever made of plastic, on which there is a mark for denoting a scalar value.

How to choose a three-way valve for a private house heating system

Now you know for what cases certain types of valves are used. But this is not the only selection criterion, because the valves have several methods of temperature control and different flow rates. And the material of manufacture may differ. Let's take a closer look at this.

Temperature control method

Manual.

Let's start with manual adjustments. Here the stem is connected to a valve or handle, under them there are marks, with the help of which the temperature is regulated. This is the simplest and cheapest way, so some people consider it more reliable. But I believe that everything depends on the company: if the valve is of high quality, then it will work no less with automatic adjustment than with manual adjustment.

| Benefits | disadvantages |

| Low price compared to other types of valves | You have to independently react to all changes in environmental conditions |

| Works without connecting electricity | The heating circuit does not heat up evenly |

Thermostatic.

If a thermostat is built into the structure, such a valve is called thermostatic. It is usually configured only once. Then he himself selects the position of the stem, based on temperature fluctuations. A heat-sensitive liquid or gas is responsible for this: when the temperature rises, they expand and begin to move the stem. These valves are electronic and mechanical. A three-way valve with a thermostat is much more convenient than a manual one, since they work automatically, but it also costs more.

| Benefits | disadvantages |

| Automatic temperature control | High price compared to manual valves |

| Uniform heating of the heating circuit | |

| Mechanical models run without electricity |

Servo driven.

The most accurate are three-way valves with an electric drive. They have a built-in thermostat, but they are controlled by an electronic unit that works on a servo drive. When the temperature changes, the thermostat sends a signal to the controller. And he already controls the drive by raising or lowering the stem.

| Benefits | disadvantages |

| Does not require human participation in temperature control | High price |

| Highest precision of all three-way valve types | Dependence on electricity |

| The highest quality and uniform heating of heating | Higher energy consumption compared to electronic thermostatic valves |

I think it is better to opt for the middle option. Manual adjustment is inconvenient, and the motorized valve is expensive. And such accuracy is rarely required in a domestic environment.

Manufacturing material

The durability of the product depends on the material used for the manufacture of the case. I want to say right away that sometimes there are valves made of silumin. Although they are much cheaper, I do not recommend paying attention to them.And there are many other reliable materials:

- Black carbon steel valves are durable and relatively cheap. Unfortunately, they corrode, which is why they are usually plated with nickel or chromium. Stainless steel is also often used, but such products are more expensive.

- Cast iron is strong, durable and non-corrosive. But usually these are old-style valves, since more advanced materials are now used.

- The most popular are brass and bronze products. They are durable, strong and rustproof materials. In industrial conditions, where the temperature exceeds 200 degrees, they cannot be used, but they are ideal for domestic needs. I advise choosing these three-way valves, if the material is not listed in the specifications, it can always be identified by its characteristic color and texture.

I would also like to say about ceramics. It is practically not used as a material for the body. But the internal details are often made from it. This is due to the fact that ceramics are not attacked by chemicals. It is also durable.

How to choose and connect to the system the most important element - a security group

Temperature range and working pressure

When choosing a three-way valve, the temperature adjustment range should also be taken into account. For example, a thermo mixer for an underfloor heating is usually set to 30-40 ° C. Although this range is the most comfortable for obtaining hot water. The maximum pressure that the valve can withstand also differs. Some models can withstand up to 16 bar. Although usually in domestic conditions more than 6 bar is not required. In general, the working pressure values for these devices are regulated by GOST 26349-84.

Other

Of course, do not forget that three-way valves have different diameters of the connecting pipes. The most common home sizes are 1 and ¾ inches. The thread can be internal or external.

The number of liters that passes through the valve per hour depends on the throughput indicators. It should be chosen so that the valve has a coefficient slightly higher than the calculated result. For example, if 2 m³ per hour flows through the system, a valve with a capacity of 2.5 m³ per hour should be selected.

But the capacity varies depending on whether the valve is fully open or slightly open. The ratio of these indicators is called the dynamic range of regulation. The higher the ratio, the better the throughput is maintained. The best ratio is considered to be 100: 1, but it is quite rare. The most common indicators are 50: 1 or 30: 1, valves with such indicators can be safely taken.

Three-way valve working principle

Most commonly used spool valves with manual adjustment

The force from the actuator is applied to the valve including the seat and plug. The piston blocks a portion of the port, which reduces the flow through the valve. The flow rate increases and the static pressure in the pipeline decreases. The plunger is placed in the seat when fully closed, and the coolant flow is shut off, there is no water pressure downstream of the valve.

Single-seated and double-seated valves are available, while the piston is rod, needle or poppet type. Double-seat are used more often due to the good balance of the valve and effective tightness. They are used to change the pressure up to 6.3 MPa in lines with a diameter of up to 300 mm.

The principle of operation of a three-way valve for heating with a cage action is that the saddle simultaneously serves as a guiding device (cage) and a place for fixing the hollow valve when closing. The flow rate of the medium is regulated by perforation in the walls of the cage.

Diaphragm valves use external or built-in hydraulic or electric actuators. In the case of a separate actuator, the force is applied to the rod bearing through the diaphragm, then to the control link.After the pressure drops, the membrane returns to its original position. With a built-in actuator, the water flow is coordinated by closing the hole in the membrane.

In three-way spool valves, the coolant flow rate is regulated by turning the movable element at a certain angle. The modules are used as control devices.

The best known manufacturers and models: characteristics and prices

Now I want to tell you about the most popular and reliable three-way valves to make it easier for you to choose the right model.

TIM

Manufacturer from China. Offers fairly high quality products for heating and water supply at a relatively low price.

| Photo | Model | Specifications | Features of the | Cost, rub. |

| (ZEISSLER) BL3110C04 | Material: brass Temperature range: 35-60 Operating pressure: 2-5 bar Diameter: 1 inch | Mixing, for heating and hot water supply | 2 300-3 000 |

| BL8803 | Material: brass Temperature range: 38-60 Operating pressure: 3-10 bar Diameter: ¾ inch | Mixing, external connection via American | 2 800-3 500 |

| BL8804A | Material: brass Temperature range: 38-60 Operating pressure: 3-10 bar Diameter: 1 inch | Mixing, with electric drive | 2 000-2 600 |

Esbe

This Swedish company is engaged in the production of various models of valves and controllers. I believe that the products of this company are of the highest quality. Expensive though.

| Photo | Model | Specifications | Features of the | Cost, rub. |

| VTA321 | Material: brass Temperature range: 35-60 Operating pressure: 2-10 bar Diameter: ¾ inch | Mixing, for heating and hot water supply | 6 000-6 500 |

| VTA372 | Material: brass Temperature range: 20-55 Operating pressure: 3-10 bar Diameter: 1 inch | Mixing, high throughput | 7 000-8 000 |

| VTC511 | Material: cast iron Temperature range: 60-75 Operating pressure: 3-10 bar Diameter: 1 inch | For solid fuel boilers | 8 000-9 000 |

STOUT

Joint production of Russia, Italy, Spain and Germany. The products are perfectly adapted to Russian conditions.

| Photo | Model | Specifications | Features of the | Cost, rub. |

| SVM-0120-164325 | Material: brass Temperature range: 20-43 Operating pressure: 3-10 bar Diameter: 1 inch | Mixing, for heating and hot water supply | 4 500-5 000 |

| SVM-0125-186520 | Material: brass Temperature range: 30-65 Operating pressure: 3-10 bar Diameter: ¾ inch | Mixing, for heating | 4 000-4 300 |

| SVM-0120-256025 | Material: brass Temperature range: 35-60 Operating pressure: 3-10 bar Diameter: 1 inch | Mixing, high throughput | 5 200-5 800 |

WATTS

One of the largest manufacturers of heating equipment in Europe. Huge range of products.

| Photo | Model | Specifications | Features of the | Cost, rub. |

| Aquamix 61C | Material: brass Temperature range: 32-50 Operating pressure: 3-10 bar Diameter: ¾ inch | Mixing, for hot water supply | 5 200-5 700 |

| Aquamix 63C | Material: brass Temperature range: 25-50 Operating pressure: 1-10 bar Diameter: ¾ inch | Mixing, for underfloor heating | 5 500-6 000 |

| V3GB Watts Classic | Material: brass Temperature range: 20-50 Operating pressure: 3-10 bar Diameter: 1 inch | Mixing, with electric drive | 12 500-14 000 |

Choosing a three-way valve: features of models from different companies

To choose a suitable valve, it is necessary to compare all the characteristics of different models, namely the type of actuator, type of actuator, availability and type of thermostat, as well as the manufacturer and price of a three-way valve for heating. It is worth paying attention to models from leading manufacturers.

Esbe three-way valves: installation instructions and features

Among the main advantages of the Esbe models are simplicity and affordable cost.

Esbe three-way valve for heating

Helpful advice! If you need to adjust the valve, discard simple models, the main drawback of which is the inability to stabilize the outlet temperature.

When installing the valve, take into account a number of features:

- The mixing unit allows you to create an additional circuit in the system, connected to the distribution manifold by two points, which guarantees continuous circulation of water at the outlet.

- At the inlet, the flow is ensured if additional heat is required.

- A valve with a thermostat is connected to the mixing unit.

- To increase the flow rate of pumping equipment, which is often insufficient due to the narrowness of the valves converging at one point, an additional line is required to reduce the power consumption of the pump. However, such measures are not relevant for all Esbee models.

- If a second line is needed, it is planned to install a balancing valve or connect the pump to this additional line, which leads to equalization of the temperatures of the inlet and outlet flows.

Esbe valve integrated into the heating system

Navien three-way valves: features and benefits

The Navien company specializes in the production of heating boilers. The three-way valves of this equipment are designed to change the priorities between heating water for water supply and the heating system. These valves are worth buying if you have Navien equipment, because components and equipment from one manufacturer are the key to long and efficient operation of the system.

Danfoss 3-way valves: features and benefits

Danfoss valves are used in heating and water supply systems. Among the advantages of this type of equipment:

- stability and accuracy of regulation;

- perfect compatibility with other Danfoss thermostatic elements;

- reliability and long service life without loss of performance;

- ease of installation, maintenance and operation;

- fully automatic work;

- the ability to install on the pipeline in any position, except with the valve down.

Danfoss three-way valve

Having carefully studied the technical characteristics and tips for choosing a three-way valve for heating systems, you can choose the right device for a specific room and operating conditions.

Fittings installation rules

Usually, on the body of a three-way valve, the manufacturer indicates the movement of the water flow with arrows. By these landmarks, you can also determine the type of valve. Connection to the system proceeds as indicated by the arrows. The place of installation should be convenient for subsequent adjustments or replacement in the event of a malfunction. For this, both return and supply are suitable. But read the instructions carefully, since not all valves can be installed for supply.

Since most of the valves are made of ceramic inside, they do not tolerate dirty water well. Therefore, it is better to install a filter in front of the valve. If this is not done, the appliance may become clogged. In some cases, it is enough to clean it, but sometimes even this does not help. Therefore, do not skimp on filters.

The electric drive should not be located at the bottom, and mechanical thermostatic mixers are also not advised to install this way, exclusively vertically. But I will say from my own experience that in some cases this is possible. And the reviews of some owners confirm this.

Device and principle of operation

To understand what the three-way thermo-mixing valve of the most common saddle type consists of and how it works, you should study the diagram below. Inside the brass body with three nozzles, 3 chambers are arranged by casting, the passages between which are blocked by poppet valves. They are fixed on one axis - a rod coming out of the body from the fourth side.

The principle of operation is as follows: when the rod is pressed, the passage for one stream will begin to open and gradually close for another, as a result of which water of the required temperature will be obtained in the mixing chamber of the valve. It leaves the brass body of the element through a third pipe. Adjustment of the force of pressing the rod is carried out by a thermal head with an external temperature sensor installed in accordance with the diagram.

The whole process is worth explaining in more detail. Imagine that an insufficiently heated heat carrier enters from the hot water side.Then the mechanism passes it further, and the third pipe is closed. The remote sensor is filled with a temperature-sensitive liquid and is connected by means of a capillary tube to a reservoir (bellows) inside the thermal head.

When the sensor heats up, this liquid expands, its volume in the tube and the bellows increases, as a result, the latter begins to press on the stem of the three-way valve. The moment of pressing is determined by the adjustment on the scale of the thermostatic head, set to the required temperature. After that, cold water from the third branch pipe is added to the flow of heated water and the temperature of the water at the outlet from the thermo-valve remains unchanged, although at the inlet the coolant continues to heat up.

If the incoming water continues to heat up, the thermostatic valve can completely close the inlet and open the side flow to maintain the set outlet temperature. In this case, the stem is lowered to the lowest position. As soon as the sensor marks the cooling of the coolant, the head will slightly release the stem, the valve seat on the hot side will open and the heated water will begin to mix.

The method of adjusting a three-way valve with a thermostatic head with a sensor is the most popular, since it is quite accurate and simple, and does not require electricity.

If we are talking about a separating valve, the principle of its operation is practically the same, only when the stem is pressed, one flow begins to be divided into two. But in the switching element, the direction of movement is changed by the electric drive, which is described in detail in the video:

Layout of the three-way valve in the heating system

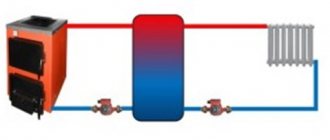

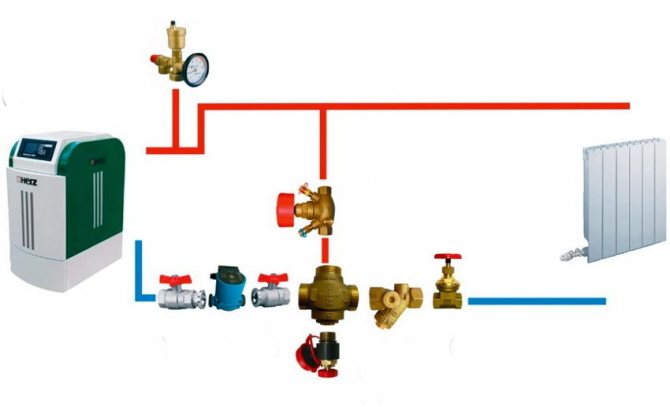

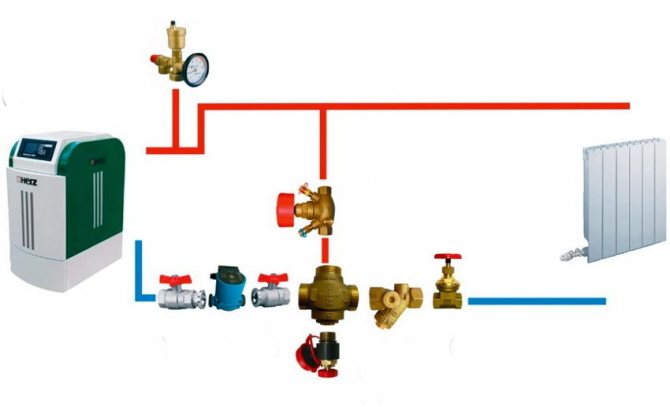

The simplest scheme in a system with a solid fuel boiler. Purpose: protection against condensation and overheating, maintaining the temperature in the heating circuit.

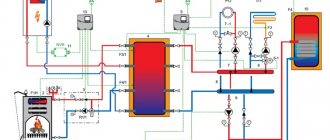

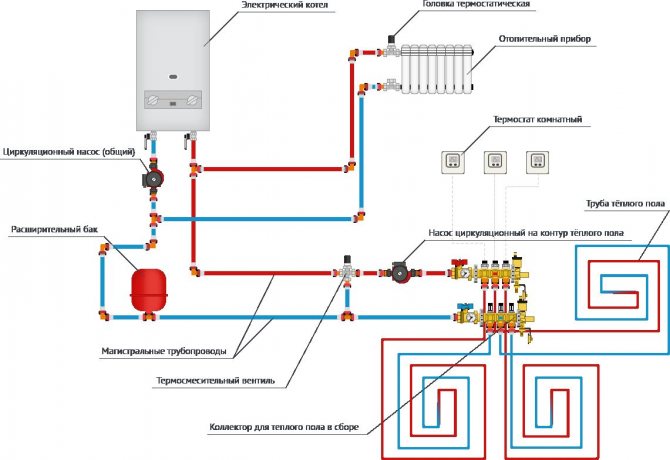

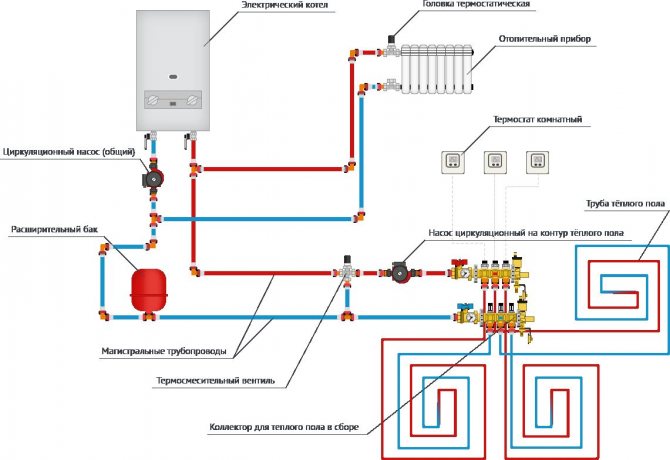

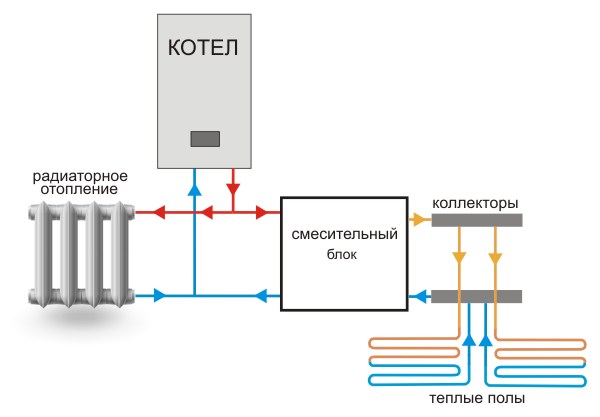

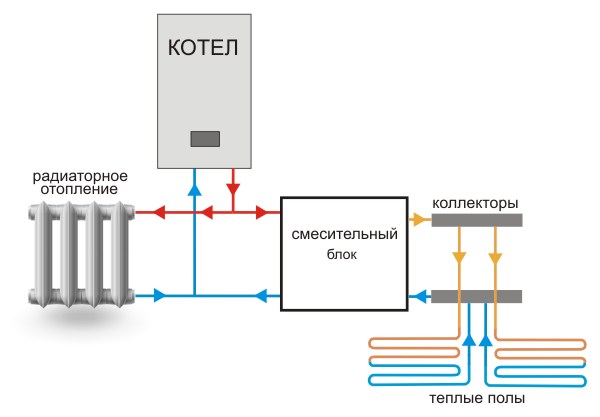

Heating scheme with an electric boiler and underfloor heating. Hydrocollectors are used to distribute underfloor heating to several circuits.

Use in piping using an indirect heating boiler, which allows you to organize hot water supply with a single-circuit boiler.

What is the responsibility of a three-way valve for heating with a thermostat

The thermostatic valve guarantees the practicality and efficiency of the system. Three-way valves for heating are designed to regulate the heat flow, which ensures indoor comfort and economic use.

The three-way valve ensures the efficiency and economy of the heating system by regulating the heat flow

Why regulate heat flow

Before proceeding with the design of the heating system, a thermal calculation is performed. Based on its results, a suitable power and type of heating devices are selected that can maintain an optimal temperature regime in the room.

The area of the room is taken into account, after which possible heat loss is analyzed. Based on this, the capacity of the heating system is calculated, which is necessary to create a comfortable microclimate in the rooms. After that, a heat balance is compiled for all rooms.

However, these calculations are made under specific conditions that may change during operation. The factors affecting the operation of the radiator are different:

- temperature drops outside;

- solar Activity;

- wind strength;

- the presence of household appliances that generate heat.

Heating circuit with three-way valve

As a result, the calculated temperature balance is disturbed, and it becomes hot in the room. However, it is impossible to remove parts of the radiator from the room or drown out the heat radiation. Thus, it becomes necessary to control the energy generated by heating devices in order to maintain a comfortable microclimate in the room.

How to check a three-way valve for operation

First of all, an external examination should be carried out: there should be no cracks on the plastic and metal cases.As for the regulator, it should turn smoothly in all directions. To check the thermal head, it needs to be heated. For example, a building hairdryer. In this case, the stem should move in accordance with the indicators. If the valve has an electric actuator, you can check its operability using a tester, but for this you have to disassemble the electric actuator.

Conclusion

Three-way valves only look like a tee. Their device is much more complicated, and the scope of application is quite diverse. Choose a valve responsibly, consider models only from well-known, reputable manufacturers, fortunately, there are enough of them. And then this small but very important device will work for many years without causing problems.

Boiler room equipment

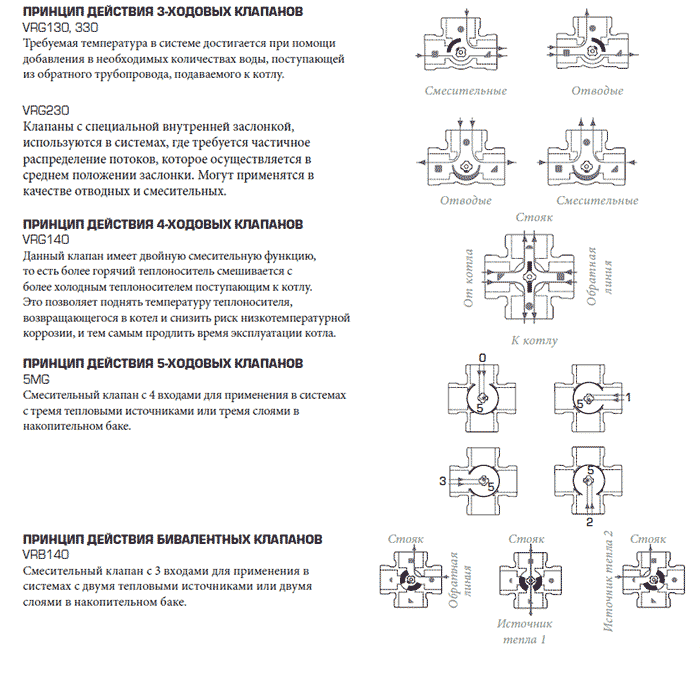

Principle of operation.

Internal regulation of the valves is carried out automatically due to the presence of a thermosensitive element that contacts the mixed flow and contracts or expands depending on the deviation of the mixture temperature from the set output value, thereby increasing or decreasing the hot or cold water inlets.

How does burn protection work?

Most of the thermostatic valves on the market today have a thermal protection device called “scalding protection”. In the event of an unexpected interruption in the supply of cold water to the valve, the hot water supply is automatically shut off, thereby excluding the possibility of supplying hot water without preliminary mixing with the consumer.

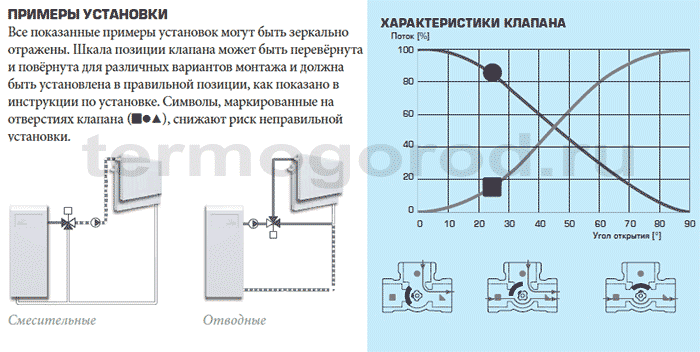

Direction of streams.

There are two flow patterns in a thermostatic valve - symmetrical and asymmetrical. The choice of a particular scheme depends on the type of installation and ease of installation in a particular heating system or hot water supply. Let's take a closer look at each of them.

GW

- hot water;

XB

- cold water;

SV

- mixed water.

Symmetrical

T-shaped flow pattern

Cold and hot water is supplied from opposite sides, mixing takes place in the middle. This scheme is very common in Europe due to the compactness of the valves.

Asymmetrical

L-shaped flow direction diagram

Hot water is supplied from the side, cold water from the bottom. It gained its distribution due to the versatility and simplicity of the resulting mixing unit.

Examples of the appearance of thermostatic valves with symmetrical and asymmetric flow patterns:

| Esbe VTA (Sweden) | Watts AquaMix (Germany) | Danfoss TVM-H (Denmark) |

It is about thermostatic valves with an asymmetric flow arrangement that will be discussed further.

Areas of application for thermostatic mixing three-way valves.

Thermostatic mixing valves

are universal devices. They are used as

for hot water supply

and in

heating systems

... It all depends on the correct choice of the valve itself and its connection. Below are the different connection diagrams for this type of valve. These are not all possible options, but they are most often used.

Water supply

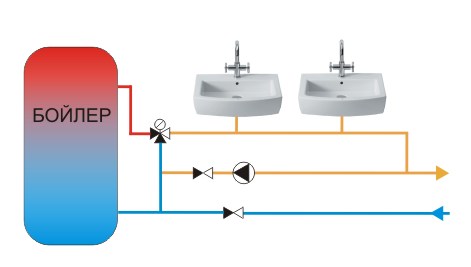

The simplest and most used wiring diagram for a three-way thermostatic valve in the water supply is as follows:

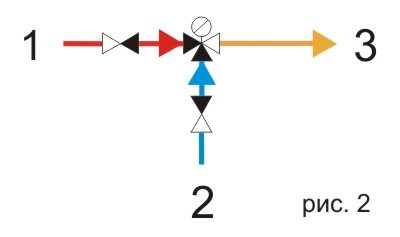

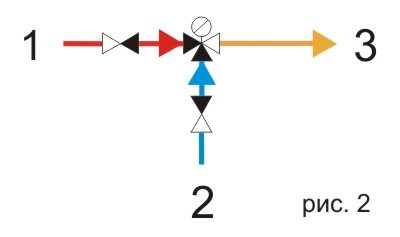

A: non-return valve B: three-way thermostatic mixing valve. 1: DHW line 2: Cold water line 3: mixed flow

This circuit is designed to stabilize the temperature in the supply line for hot water supply. How it looks in practice:

Fig. 3

Fig. 3

This connection diagram is used in cases where there is no hot water circulation line. In this case, the thermostatic valve must be equipped with non-return valves on the hot and cold water supply lines.

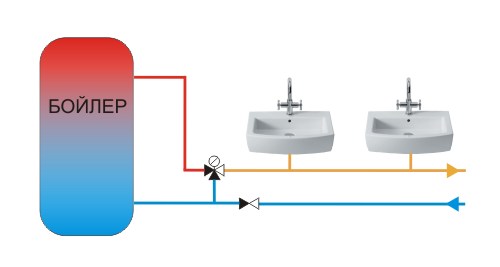

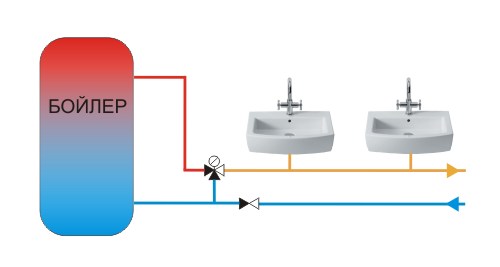

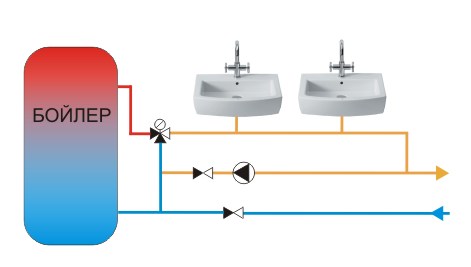

Fig. four

Fig. four

An example of installation in a hot water supply system with a circulation line. The recirculation loop in this example serves to supply heated water to consumers without any delay.

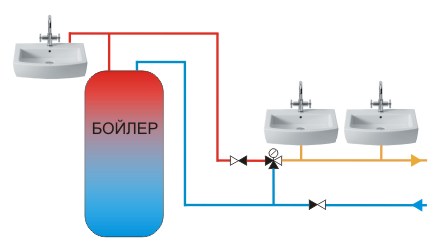

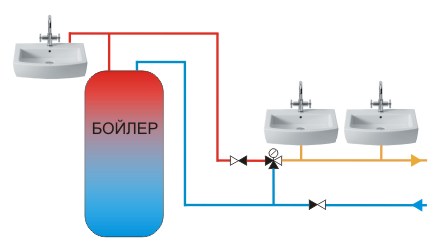

Fig. five

Fig. five

In this example, one of the taps is installed in front of the thermostatic valve. With such a scheme, a check valve must be installed in front of the hot water supply to the mixing valve.

Wiring diagrams for thermostatic valves in underfloor heating.

Now we turn to the schemes for using three-way thermostatic mixers in heating systems. Most often, the valve is used in a mixing unit for underfloor heating.

Single underfloor heating circuit

fig. 6

Fig. 6

The thermostatic mixing valve maintains a constant temperature set in the valve settings. The underfloor heating circuit must be equipped with its own circulation pump.

Diagram with several underfloor heating circuits Fig. 7

Let's dwell on the mixing block in more detail (Figure 8).

Fig. eight

Fig. eight

The main task of the mixing unit is the presence of an additional circuit with a separate circulation ring. For this reason, the mixing block has two entry points and two exit points. The two points on the right are the connection of the distribution manifold for powering the underfloor heating circuits. The two dots on the left are the circulation of the coolant to generate heat as needed.

Below are two options for the mixing block circuit (in fact, there can be many of these options, but we will focus on the most common).

Fig. nine

Fig 9

In this scheme, line # 2 is needed to increase the pump flow. Since thermostatic three-way valves have low flow capacity, which can create hydraulic resistance and, as a result, the pump flow will be small, which will lead to inefficiency of the system (the pump will work with unnecessary loads and consume excess energy). Also, without line 2, it will be problematic to pump a large number of circuits. If a thermostatic valve with a large capacity is intended to be installed, then the need for line 2 is eliminated.

With such a scheme, a situation may arise in which the flow on line 1 drops below the critical one and the contours of the underfloor heating will be insufficiently heated. The most common reasons for this situation:

a) Insufficient head on line 1, as a result of which the valve passes the flow poorly at point 1.

b) The valve, due to its characteristics, is not capable of passing sufficient flow at point 1. In this case, the only option would be to replace the valve with a device with a higher flow capacity (KVs).

If the first reason is assumed, then you can narrow the section of line 2, or put it on line 2 balancing valve

(fig. 10).

Fig. 10

Fig. 10

With a balancing valve, you can regulate the amount of flow through line 2 and thus increase or decrease the flow on line 1.

We hope this article has helped you understand the basic principles of operation and use of 3-way thermostatic valves. Summing up, we want to especially note that the main advantages of these devices are the relatively low price and ease of installation, and the disadvantage is the low throughput of the valve itself. (Kvs)

, which limits its use in systems with high coolant flows.

There are more advanced alternatives on the market with good bandwidth, but all of these options are significantly more expensive and require some skill in their installation. We will talk about this and much more in the following articles.

Choose a thermostatic mixer from us >>

Valve types

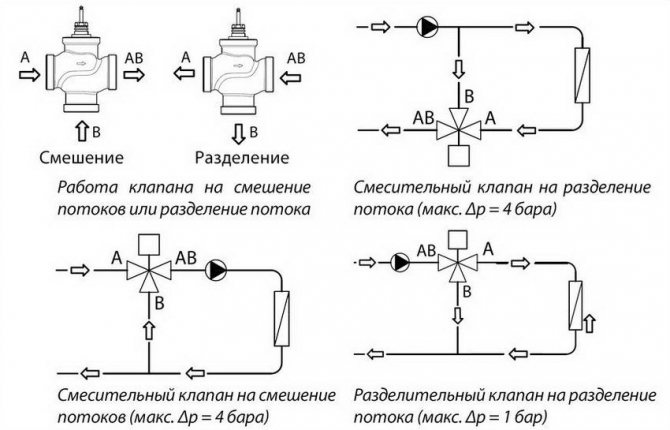

According to the principle of operation, this valve is subdivided into 2 types:

- Mixing valve... Has 2 inlets and 1 outlet. Hot coolant from the boiler is supplied to one of the branch pipes, and the inlet of the second branch pipe is connected to the "return". Thus, by mixing these two streams in the required proportions, they achieve the desired temperature of the coolant at the outlet.

Working principle of three-way mixing valve - Isolating valve... It does exactly the opposite job, dividing one stream into two circuits. Accordingly, it has only 1 input, but 2 outputs. Such taps are popular in water heater piping systems. If it is necessary to divide the coolant flow into 2 parts, then it is simply impossible to do without such fittings. Moreover, it is possible to regulate the amount of fluid entering the different circuits.

The internal design of the two valve types differs markedly. The mixing valve has a stem with one shut-off element, which moves between two delivery pipes. In the dividing valve, there are 2 such elements on one rod. When one valve opens the first passage, the second valve automatically closes the second port.