Installation of underfloor heating is very popular with consumers due to its convenient installation in almost all rooms and economy in use. Nowadays, almost all types of floor material are successfully used for the base when installing the floor covering. And laminate for a water-heated floor is no exception. Do not forget that when using this material, there is some specificity in the production of a heated structure called "warm floor".

The use of laminate flooring is a very well-known method in the construction market. When installing the material on a warm floor and observing the necessary requirements, you can be absolutely sure that the floor covering will evenly warm up. It is completely safe to have this gender.

Coating features

It is possible to create a water system, on top of which the laminate will be laid, on different types of bases. The main question is considered to choose the right floor covering that can easily cope with the effects of high temperatures. Modern manufacturers produce many collections of such laminate, which are distinguished by their excellent appearance, reasonable price and long service life.

Laminate for a warm water floor, correctly selected in accordance with the existing conditions, has advantages:

- optimal thermal conductivity, which ensures the formation of the desired heat transfer rate, which is approximately at the level of 45 degrees;

- due to the use of high-quality material, even a reduction in thermal energy consumption is guaranteed, and by about 40 percent;

- no magnetic field is formed, which has a negative effect on the human body;

- constant dryness of the coating is ensured, so fungus never appears on it and dampness does not appear;

- modern manufacturers offer a material of high quality and environmental friendliness, therefore it is considered safe for permanent use in residential premises;

- floor heating is provided quickly, which is considered especially relevant for many residents of houses, since it is often important to ensure prompt heating of the premises;

- under the laminate, a water-heated floor lasts a long time, and much longer than when using other floor coverings.

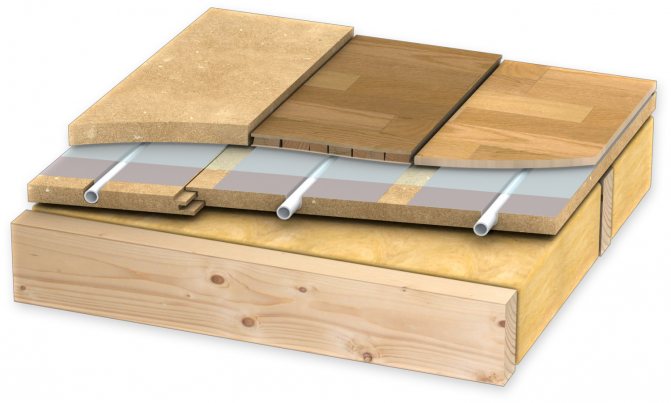

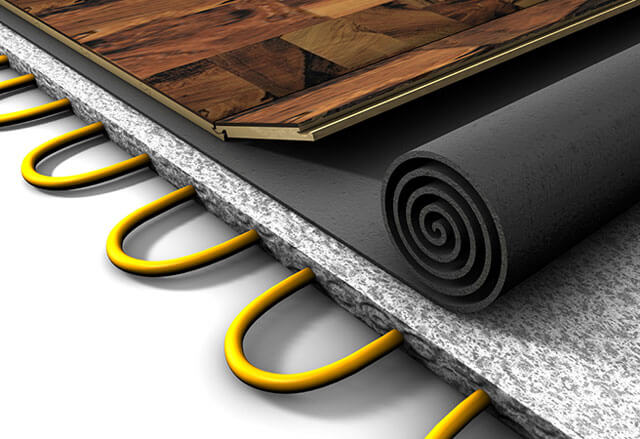

Scheme of a water-heated floor under a laminate

The disadvantages include only the complexity of the installation, which is why many people trying to carry out the work on their own make significant mistakes, so the system does not last long or the coating is destroyed.

Experts insist that laying laminate flooring on a warm water floor should be done only in residential buildings, and this work is prohibited in apartments, and this is due to legal norms and the need to install powerful pumps and tanks for pumping water that take up a lot of space.

Advantages and disadvantages

It is possible to organize water heating, where the laminate will be located on top in the future, on various types of bases. The most important thing is to choose a laminate for a warm water floor that can easily cope with sudden changes in temperature.

Today, manufacturers produce a large number of collections of this floor covering, which is characterized by an attractive appearance, affordable cost and long service life.

In this video, you will learn how to lay laminate flooring:

Correctly chosen laminate for underfloor heating, taking into account specific conditions, has several advantages:

- good thermal conductivity ensures the creation of the required level of heat transfer, which is approximately within 50 degrees;

- due to the use of high-quality materials, the consumption of thermal energy is reduced by 45-50%;

- constant dryness of the coating does not allow the development of fungus and mold;

- no magnetic field is formed, which negatively affects the human body;

- under the laminate floor with water heating will last much longer, unlike other coatings;

- almost instant floor heating is provided, which is all the more important for people living in a private house, since it is often necessary to provide quick heating of the premises;

- today, manufacturers offer a material that is of good quality and is completely environmentally friendly, therefore it is safe for regular use in living rooms.

The disadvantages include only the complexity of laying, because of this, many who decide to do this work on their own make many gross mistakes, because the system serves a short time or the coating simply collapses.

Laying a laminate on a warm floor from water heating can only be carried out in private houses, in apartments such a heating system is prohibited, since for this you need to use powerful pumping equipment and tanks for pumping the coolant, which occupy a lot of usable area.

Types of laminate for warm water floor

An important point is the purchase of a high-quality and reliable coating with the right parameters. You need to know which laminate to choose so that it can serve over the underfloor heating system without any problems. To do this, it is important to take into account in which room the work is performed, how much money is allocated for these purposes, as well as what markings are on the laminate itself. In this case, all the important nuances of a competent choice are taken into account.

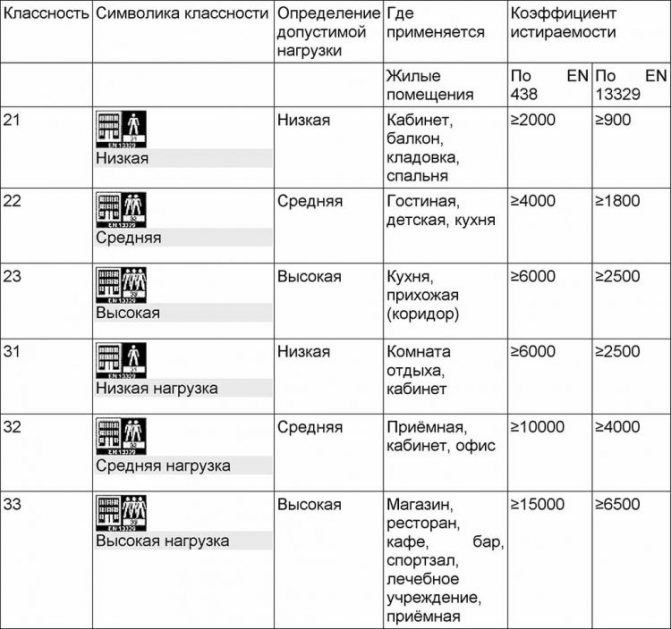

Marking

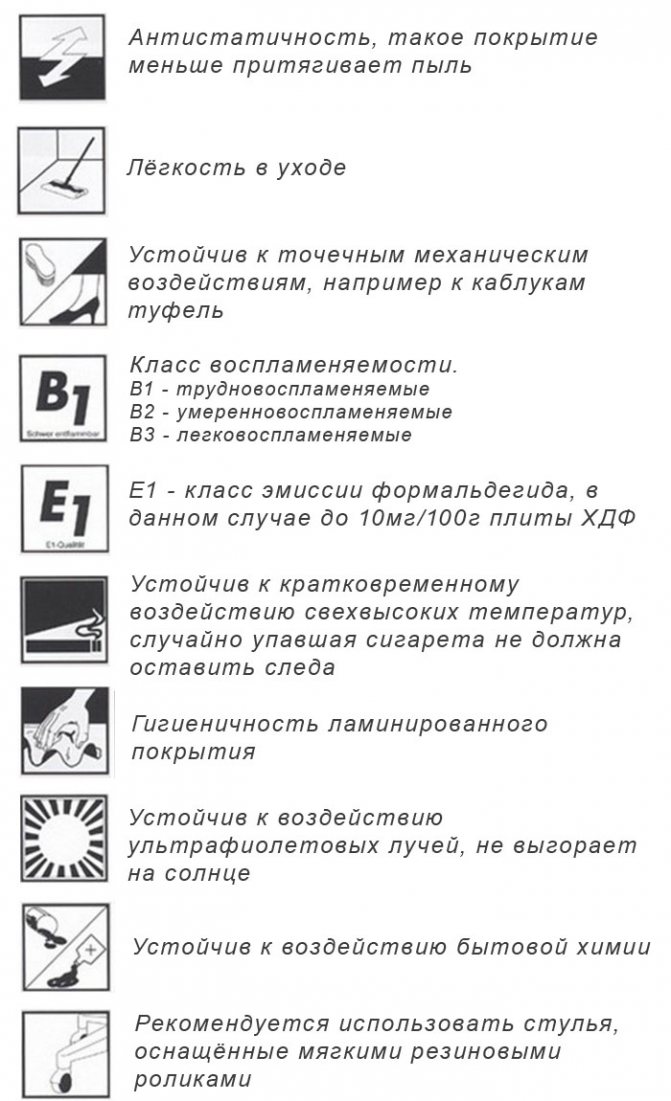

When choosing a coating, it is important first of all to look at its marking, which is considered the most important parameter. Each package has certain signs that mean certain parameters of the laminate. They are applied directly by the manufacturer, which allows you to make the right choice of laminate, ideal for warm water floors.

Laminate marking

It is advisable to take into account the following markings:

- plus with a degree - means that the coating is really ideal for installing a warm floor. It will easily withstand high temperatures, and at the same time it will not collapse or release harmful components into the room;

- a woman's foot in a shoe with a heel - shows that the laminate has a high compressive strength;

- lightning - it is guaranteed that such a coating will not accumulate static electricity;

- a teapot falling to the floor - a laminate with such markings easily withstands even significant mechanical stress, without collapsing from impacts;

- a zigzag pipe located under the covering - indicates the purpose of the covering for laying over warm floors;

- dog - a coating with such markings will not break from the claws of animals;

- flower - indicates that the material is environmentally friendly, therefore, it is completely free of any harmful components.

Laminate packaging designations

Additionally, there are many more different markings, all of which mean one or another coating parameter. Since the material is supposed to be laid on top of a warm floor, its most important property is its resistance to high temperatures. There must be appropriate markings on the packaging. If you buy ordinary laminated material, then there is a high probability that during its operation with the heating system turned on, it will begin to crack and will not last too long.Additionally, due to the low thermal conductivity, the efficiency of the underfloor heating system will be low.

The manufacturer on the packaging additionally indicates for which particular system of underfloor heating a certain material is ideally suited, therefore some panels are designed for a water system, and others for an infrared or electric system.

Thermal insulation properties

This parameter is also considered important for the correct choice of laminate. It is important not only to take into account the marking, but also on the KTS (coefficient of thermal resistance). The higher it is, the better the thermal insulation parameters of the created floor covering.

Since the material is used on a warm floor, the KTS should not be more than 0.15 m2 K / W.

This indicator is influenced by the following material parameters:

- the thickness should be small;

- the density must be minimal.

If you choose a laminate with a significant thickness and density, then the floor covering and even the substrate can overheat, and there is also the possibility that even the heating circuit itself will quickly break.

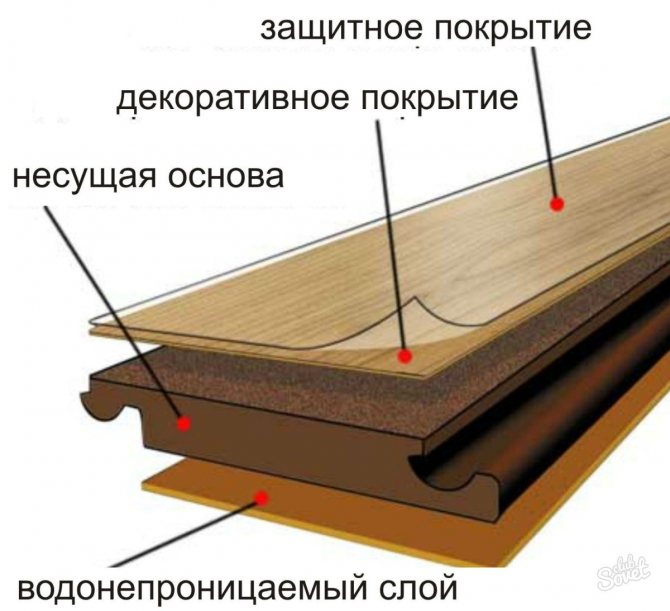

Laminate board structure

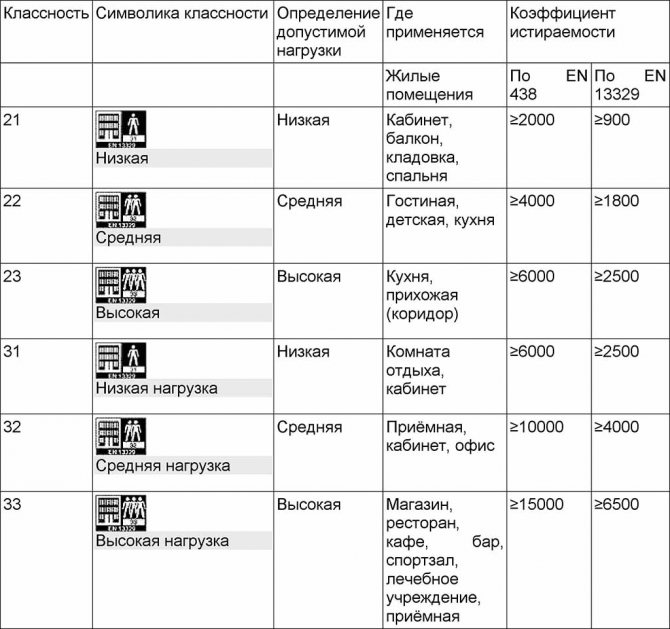

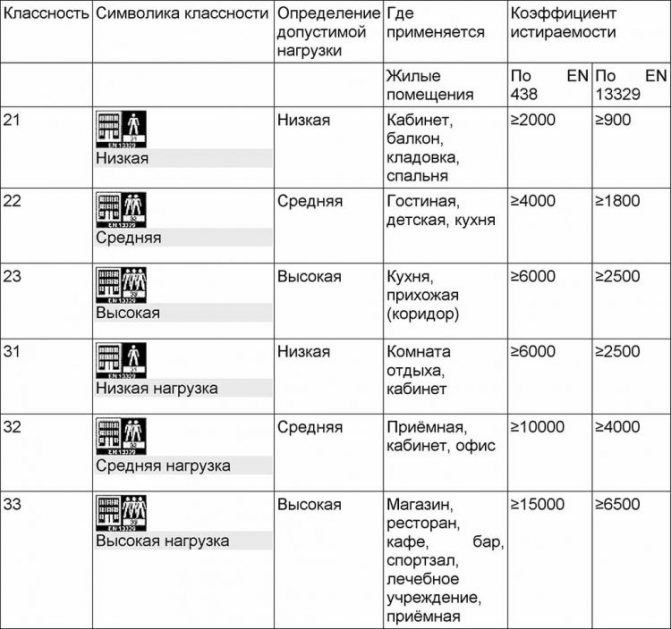

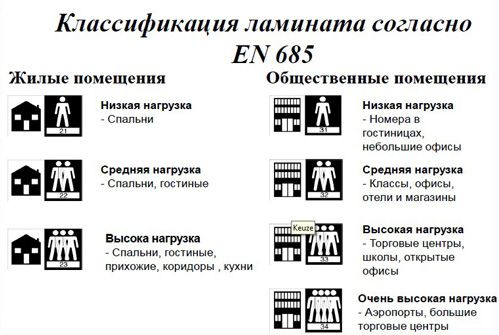

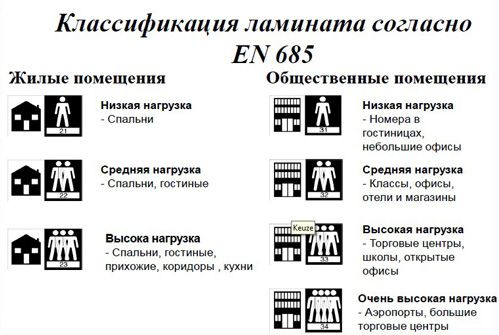

The choice of class depending on the room

Another important parameter of the laminate for a warm water floor is its class. The higher it is, the more durable and reliable the created coating will be. However, it is important to take into account that since the material will be constantly exposed to heat, it is optimal to choose class 32 for these purposes.

Also, when choosing a laminate, it is important to consider in which room it will be laid. The best option is chosen for each room. Usually, the most important zones are highlighted in any house.

Types of household laminate

As for the kitchen, here usually people are not only engaged in the process of cooking, but also accept it. Therefore, there is usually more than one person in one room. They constantly move, and also use various objects with a high weight, so the important point is the resistance of the coating to strong impacts, as well as the ease of cleaning from all kinds of dirt and stains.

It is advisable to choose a moisture-resistant laminate for this room, and after laying it, it is recommended to treat all floors with a special water-repellent solution. It is important to lay it only with the use of a special sealant, with which all joints in the coating are processed.

For the kitchen, the optimal laminate class is 32 or 33. In addition, it is important that the material has an optimal thermal conductivity. Kitchen

Bedroom and corridor - for these rooms it is advisable to use a laminate with a matte surface.

In addition, since the installation is carried out on a warm floor, moisture resistance and resistance to high temperatures are important parameters for such a coating. Good sound insulation and antistatic properties are important. For the bedroom, it is allowed to choose the 21st or 22nd class, since people rarely go here, but for the corridor it is best to buy the 33rd class, since they most often go here, and it is in shoes, therefore, it is important that the coating is durable and wear-resistant. Bedroom Hallway

Bathroom and balcony - here the most optimal use of water heating under the floor, since this provides the comfort of water procedures or relaxation on the balcony. However, maintaining the temperature not exceeding 30 degrees is considered an important point. For this, in the process of creating a warm floor, thermostats and sensors are certainly used. This will eliminate the likelihood of overheating of the laminate flooring, which can cause its deformation. The joints here are treated with a sealant, and also the top of the entire coating is covered with a special moisture-repellent agent.

Bathroom Balcony

Thus, it is important to choose the best option for each room in the house. Some people prefer to do a continuous installation, according to which the same material is used in each room, in which case it is important to purchase the highest quality and most reliable laminate that is suitable for each room.

Connection type

When choosing a floor material, it is recommended to additionally pay attention to the type of connection of individual panels in the covering. There are the following popular and demanded types:

- click - these connections are usually used on long board edges. Locking of the locks is performed by turning the inserted board into another board;

- lock - most often found on end edges. Locking the boards is performed by driving one element into another, and it is also allowed to overlap them, but in this case it is important to use additional glue. There are spikes and grooves on each panel, and everyone who does not have experience in this area can work with them. Therefore, the preference is most often given to this particular laminate, since property owners have the opportunity to carry out finishing work on their own;

- uniClick - locks can be found on the end or long edges of individual panels. Fastening can be done both by hammering and by turning.

Laminate connection

When choosing a laminate, the method of connecting the individual panels to each other is quite important. In this case, not only the locks, which the lamellas are equipped with during the production process, can be used, but also a special adhesive composition. However, an adhesive joint is not suitable for a coating located above a water-heated floor. This is due to the fact that when heated, the glue can disperse, therefore, the resulting floor will deform.

Experts recommend the Click system for underfloor heating, since such panels are highly durable and reliable, and also do not deform under the influence of high temperature or when it changes abruptly.

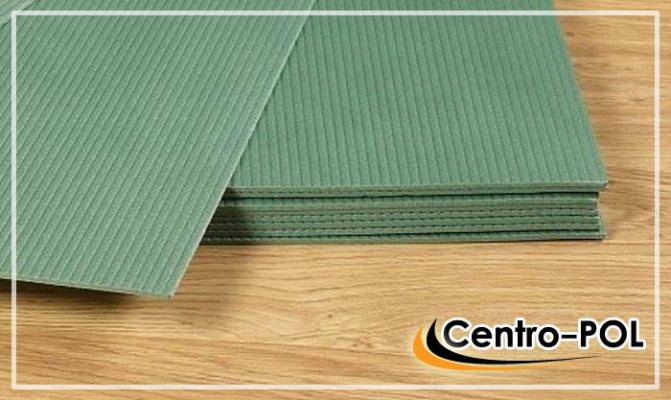

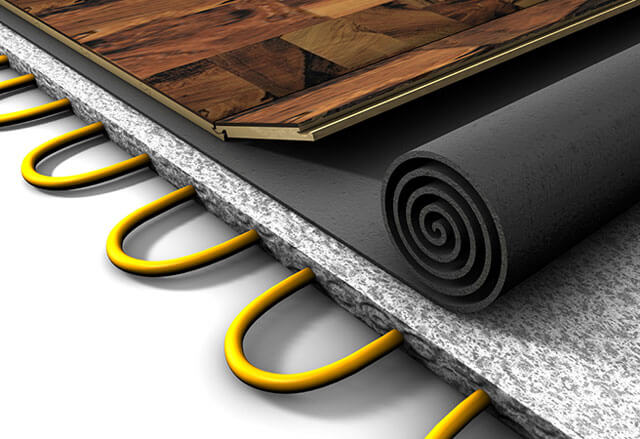

Suitable substrate

Another important parameter for creating the perfect coverage over a warm floor is the use of a correct and high-quality underlay. It should only be laid on a perfectly flat base, therefore, the alignment procedure is preliminarily carried out.

Next, the substrate is spread, and it is necessary to level out the small differences that remain after the formation of a new screed. It also increases the soundproofing parameters of the floor and acts as an additional heat-insulating layer.

Most often, for a laminate laid on a warm floor, a substrate made of extruded polystyrene foam or cork is chosen, and isoplates are also suitable. As a rule, the underlay is laid with adhesive tape so that no gaps remain between the boards or rolls.

Types of substrates

Choosing a laminate when arranging a warm floor

The low coefficient of thermal conductivity of the laminate really serves as an obstacle for some to install it on a warm floor system. Also, the laminate should not be heated above 26 degrees, in this case there is a risk of volatile formaldehyde in the room. Therefore, when choosing a laminate, you should pay attention to the characteristics of the flooring.

Only a laminate marked "for warm floor" will meet all expectations, but subject to the correct installation of the entire system. The higher the load class of the laminate, the more its density and less thickness, namely the thickness determines the heat transmission capacity of the coating. It has the best protective coating, minimally reacts to temperature changes and constant heating: it does not expand, does not crack.

Laminate of load class 31 to 34 is available on sale today.Moreover, class 34 (according to the manufacturer's assurances) can be laid at train stations. The protective layer of the laminate is also classified according to the degree of abrasion, from AC 1 and higher. And you can choose the best option for arranging a warm floor in a country house so that the heat goes from the coolant without loss.

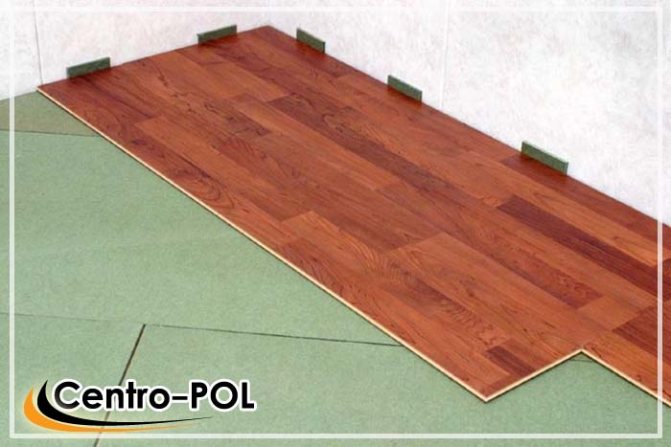

Laminate laying technology

After all the preparatory work, the choice of material and the installation of the substrate, the direct laying of the laminate on the warm floor begins. The whole process is considered standard, but it is important to consider the following nuances of work:

- initially, it is important to make sure that the created system of underfloor heating is functional, and there are no problems when using it;

- it is recommended to warm up the base before laying the material;

- joints are certainly processed with a sealant;

- a small gap of about 8 mm is left between the coating and the walls;

- the panels are connected to each other with the corresponding locking elements, which they are equipped with during the production process.

Parallel laying Spiral laying Screed Laying laminate

Thus, if you plan to create a water-heated floor, on top of which a laminate covering will be formed, it is important to choose the material itself correctly, and it must be reliable and of high quality, and also specially designed for operation in such conditions when it is constantly exposed to high temperatures. and there is also the possibility of a sharp change in temperature. In this case, you will get a durable and reliable coating, which will always be comfortable to walk on. At the same time, the choice and the installation itself can be done on their own, so you do not have to spend money on paying specialists. If all the nuances of the work are taken into account, then laying a water-heated floor under the laminate, you get a high-quality result.

Correlation of the class of the laminate with the room

The higher the quality of the laminate, the better it is and not so much amenable to erasure. After laying over a warm floor, it receives a thermal load, as a result, it functions intensively, therefore it is better to choose a material that is sufficiently resistant, class 32, 33 and higher. To choose the right material, you need to know that the room is divided into conditional zones: bedroom, office, kitchen and additional: entrance hall, corridor, bathroom, loggia. Each of them requires a material of the corresponding class.

Laminate for kitchen

There is frequent movement in the kitchen area and there is a great possibility of applying greasy stains, moisture, and various litter to the coating. A laminate coating with a water-repellent composition with the addition of wax is suitable here. When laying it, it is necessary to carefully seal the joints with a specially designed sealant.

A water-heated floor under a laminate will come in handy in the kitchen, you just need to take it with a class of 32 or 33. The thermal conductivity coefficient is not so high here, but by laying pipes and covering them with a sand-cement screed, maximum heat transfer is ensured.

Laminate for water heated floors for the kitchen

Tips for choosing a bathroom material

For bathrooms and toilets, it is better to use laminate flooring designed for rooms with temperatures not exceeding 29 ° C. It is adjusted using a sensor that takes readings of the functioning of the system. Thanks to smooth heating, thermal drops and deformation of the panels are excluded. A material marked "aqua" is suitable here.

Moisture-resistant wood floor in the bathroom

Laminate for rooms: nursery, bedroom, hallway

A material with a matte surface is best suited for a children's bedroom and hallway. Its positive properties:

- antistatic;

- sound absorption;

- moisture resistance;

- Fire safety.

The presence of different shades in the color of the laminate will help to harmoniously match the color scheme of the room.The material of class 21 and 22 is more suitable for a children's room. It is better to provide a warm floor here with aluminum mats with a heating cable. No additional cement screed is required here, the process of laying the slabs takes place directly on the floor.

Selection criteria for cladding

Installation of water or electric heating systems for the further laying of a conventional laminate can result in a host of problems associated with the constant heating of the material to 25-27 ° C.

When laminate sheets are heated to temperatures above 25 ° C, harmful formaldehydes are released, which are used in the composition of resins and binders involved in the manufacture.

The use of conventional laminate up to 25 ° C absolutely does not cause any harm to human health and others, which has been confirmed by a number of studies. Specialized laminate for underfloor heating is devoid of this drawback due to the use of a special manufacturing technology based on reducing the amount of harmful binders.

The accessory and the possibility of installing the laminate on top of the installed underfloor heating system is indicated on the packaging and in the installation instructions that are attached to the material. For most manufacturers, this is evidenced by a special marking in the form of a stylized icon indicating underfloor heating, spiral heating elements or an accompanying comment like “Underfloor Heating”.

Next to the marking, the recommended type of heating systems and the temperature range in which it is allowed to use this material are indicated, without any problems.

From a technical point of view, a laminate for underfloor heating must have a certain coefficient of thermal conductivity. According to European standards, the thermal conductivity index for the finishing cladding laid above the heating system should be no more than 0.15 m² * K / W.

The 0.15 m² * K / W value includes the resistance of the laminate used and the substrate used to install it. For example, a coating was purchased with a coefficient of 0.078 m² * K / W and a substrate with an indicator of 0.066 m² * K / W. In total, this gives 0.144 m² * K / W, which is quite consistent with the requirements.

The choice of materials with appropriate thermal conductivity should be approached with complete seriousness, since the further operation of the coating depends on this. If the stated standards are exceeded, there is a risk of overheating of the underfloor heating system and damage to the floor cladding.

Thermal insulation properties

Thermal insulation properties

The coefficient of thermal resistance indicates how much heat can pass through the coating. The smaller it is, the better thermal conductivity the material has. It should not exceed 0.15 m² * K / W. This factor applies to the entire flooring system, i.e. the laminate and the backing.

In other words, the sum of the thermal resistance coefficients of these two elements should not exceed the above figure. Ideally, when this figure is 0.1 m² * K / W. Therefore, when buying, you first need to select each component of the system, while summing up their coefficients. Only after that should you decide which material you can choose.

If the indicator is too high, then the coating will overheat. This will lead to its destruction, as well as the appearance of the problems described in the first paragraph. The heating system will fail faster.

Coverage class and type of room

The class of the laminate directly affects its quality - the ability to withstand mechanical stress, abrasion resistance, durability, etc.

When used in conjunction with additional heating systems, the material is constantly subjected to thermal expansion, which affects its service life not for the better.Based on this, almost all specialized coatings with a resolution marker have 32 and 33 product class.

Of much greater importance is the choice of coverage appropriate for the type of room. That is, it is completely irrational to use especially durable types of material in places where the time for heating the floor above 25 ° C is rarely exceeded 2-3 hours per week, and the degree of traffic intensity is minimal.

So, when laying laminate for warm water and electric floors in various rooms, the following points can be taken into account:

- kitchen is a place with high traffic intensity and traffic. With a high probability of spilling liquid and debris on the floor. A place where it is possible to simultaneously find several people and a pair of pets. It is recommended to install water systems with 33 strength class cladding and water-repellent properties;

- bathrooms - premises with average traffic and average traffic intensity. Permanent exposure to moisture and abrasive particles is possible. It is desirable to install water-heated floors with a 32-class coating with water-repellent qualities;

- living room - a place of frequent or permanent stay of one or two people. Debris and abrasive particles may enter. It is possible to lay both water and electric heating structures. It is desirable to lay 32 class laminate with fire protection, anti-static and sound-absorbing qualities;

- nursery - a room where the laying of safe material is required. It is desirable to use materials of class 32 with a matte surface and the presence of anti-slip and antistatic qualities, fire protection and a protective water-repellent layer.

When installing the floor in storerooms or other technical rooms, you can use simpler coatings of 31-32 class. Lower quality laminate can be installed if necessary, but the lifespan of such a coating is very short.

Laminate for underfloor heating water - criteria and markings.

The first thing to pay attention to is the marking "allowing" to lay this type of laminate on a heated floor. It depends on what thermal properties the material has, whether it is suitable for covering a warm water floor.

There are two sides to the coin. Laminate on a warm floor from water heating can have a high degree of thermal insulation, in this case, it will not suffer from thermal effects and will not give off a sufficient amount of heat. In another embodiment, the material itself is not suitable for thermal action, and deformation of the sections may occur.

To avoid such troubles, you need to know that there are special lamination coatings designed for warm floors.

The manufacturer must indicate the temperature values at which the floor covering can be used:

- the usual heating values of the floor covering vary from 27 to 28 degrees Celsius;

- this information is indicated on the packaging or in the instructions;

- the documents indicate the type of heating systems suitable for this type of flooring;

Laminate for water floor heating must not be used in conjunction with electrical heating systems.

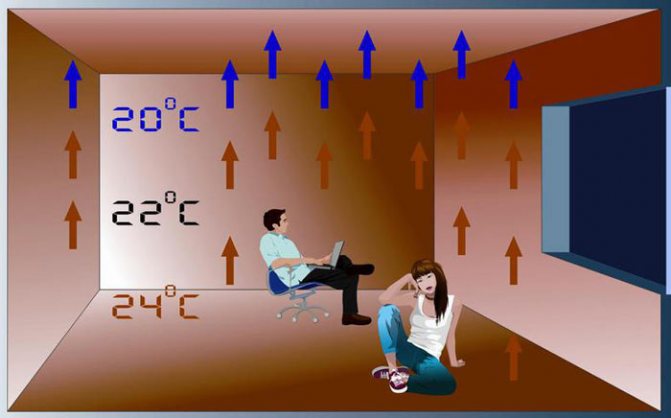

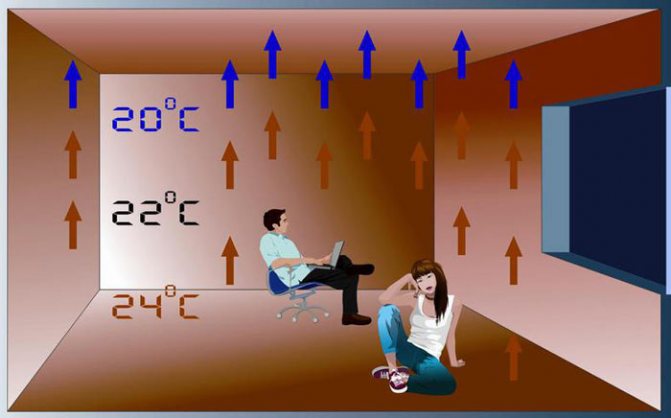

- up arrows indicate heating air;

- High temperature

- H2O - it is this sign that indicates the conformity of the laminate for warm water floors;

- The “E” mark indicates the environmental class.

Thermal insulation characteristics of a laminate for a warm water floor

Thermal conductivity is perhaps the most important criterion when choosing a laminate for a warm floor.

In the instructions for use of the coating, a number is indicated, which means thermal conductivity, the higher its value, the higher the thermal insulation of the material, respectively, the risk of overheating of the floor covering.

The permissible rate for underfloor heating is 0.15 m² * K / W.This figure complies with European quality standards.

Do not forget that this is a single value and is influenced by several factors that will change the heat conduction properties of the coating:

- the resistance of the insulating material and its heat transfer;

- the resistance of the coating itself.

From which it follows that the figure of thermal conductivity varies depending on the thermal insulation properties of the materials used in the work. To select the correct thermal conductivity coefficient, it is enough to add up the coefficients of the laminate and the substrate.

If the result is the required standard, then you have selected all the materials correctly. In the opposite case, overheating of the coating leads to damage to the coating, and to the breakdown of heat pipes.

The properties of laminate in terms of heat transfer directly depend on its thickness, therefore, you need to choose a coating for a warm water floor within 8-10 mm.

Remember that underfloor heating does not generate enough heat to heat residential and non-residential premises, therefore it requires additional heating systems.

The choice of laminate depends on the room and its functional purpose.

The zoning of the room is divided into several categories, depending on the properties of which the laminate class should be chosen:

- relaxation area: this includes a nursery, a bedroom and a guest room;

- active zone: kitchen, hall, dining room, etc .;

- movement area: corridors;

- hygienic area: restroom, bathroom.

Kitchen area

The kitchen area is the most busy in terms of the number of visits, respectively, and the impact on the floor surface increases significantly. Which laminate to choose for a warm water floor in the kitchen?

It is necessary to be guided by the high classification rates of the outdoor product. The presence of a moisture-repellent coating is mandatory (most often wax is such a material).

The class of the laminate itself must be at least 30, this will not only give strength and resistance to heavy loads, but also prevent the surface from overheating. Which can happen not only from the heating system, but also from constant friction from human feet.

Hygienic area

It might be interesting

Thermal insulation

Distinctive features and variety of ceiling tiles ...

Thermal insulation

How to insulate the ceiling in a wooden house?

Thermal insulation

What is a heating cable?

Thermal insulation

Warm "pie" for a metal chimney

Do not assume that laminate flooring is unsuitable for the bathroom. With proper installation and selection of materials, this type of floor will last a long time.

For the bathroom, choose a laminate of at least class 30, specially designed for rooms with high humidity "aqua-laminate". The heating temperature should not exceed 29.

It is best to install temperature control sensors. It contributes to the correct and uniform heating of the entire surface of the bathroom, which will not create sudden changes and protect the surface of the room from unwanted temperature effects.

Recreation and active movement areas

For such premises, there is a range of floor coverings that prevent various types of damage, have a different range of properties and purposes.

So, for children's rooms and bedrooms, you need to choose laminate with a matte surface, which acts as an antistatic agent. Sound absorbing floor types are recommended. It is important for children's rooms to take a laminate with a fire-resistant surface.

Class can be within 20to allow the installation of aluminum surfaces that are heated by the cable. For this type of underfloor heating, an additional screed is not needed.

After the desired laminate is selected and purchased, it must undergo "acclimatization" for up to 48 hours, in the room that will serve as a place of installation. Otherwise, the panels may be deformed.

Glue or lock type of lamella connection

The type of connection of laminate lamellas can be as follows:

- Glue - it is carried out according to the standard “thorn-groove” scheme with the obligatory processing of the “thorn” with an adhesive composition. For styling, use improvised means in the form of a hammer or mallet. During dismantling, the lamellae may break or the fasteners may be scrapped.

- Castle - does not require the use of binders and adhesives. It represents a system of locking connection, when on one side there is a recess of a certain shape, into which a “spike” of a suitable design is placed.

For laying over the underfloor heating, it is allowed to use a coating only with a lock type of connection, since the adhesive composition heats up and rather strongly fixes the facing lamellas.

The lock connection, in turn, is divided into several types, but the most popular are the "Click" or "Lock" systems. The first is a snap-on lock that provides a more secure connection, even when mounted on a relatively uneven base.

Second, it is a more familiar fixation by means of a lock similar to a standard “thorn-groove”. This type is very demanding on the quality of the base, since even with slight differences in height, there is a risk of fracture at the junction of the lamellas.

The use of material with the "Click" system is preferable due to its resistance to possible swelling, thermal expansion, etc.

Criteria for selecting a suitable substrate

The selection of the substrate is carried out taking into account the used floor covering and its thermal conductivity coefficient.

It is important to take this indicator into account, since the use of non-specialized substrates of various thicknesses can lead to overheating of the heating system and uncontrolled energy consumption.

The specialized substrate is made of extruded polystyrene or expanded polyethylene foam. Standard thickness - 1.5-3 mm, thermal conductivity coefficient - 0.04-0.08 m² * K / W.

For example, a substrate of the Arbiton company under the IZO-FLOOR THERMO brand is made of extruded polystyrene, has a thickness of 1.6 mm and a resistance of no more than 0.06 m2 * K / W. The Quick-Step Uniclic Plus backing is made of foamed polyethylene, has a thickness of 2.1 mm and a thermal conductivity of 0.059 m² * K / W.

In practice, the polyethylene substrate lends itself well to cutting, it is easy to fit and join. The polystyrene coating is characterized by high heat and waterproofing properties, which makes it possible to lay it together with a water-heated floor.

In addition to the above materials, a natural cork backing can be used for installing a laminate for a warm floor. This material meets all the requirements - thermal conductivity 0.042 m² * K / W at a thickness of 2 mm.

Cork is an environmentally friendly material, does not rot, does not contribute to the vital activity of fungi and parasites. It is a direct alternative to coatings made from synthetic products. The only negative is the price, which, together with the laminate, can exceed 1000-1300 rubles / m2.

Material tips for different types of systems

Using wood cladding on top of a warm water floor sets aside a number of limitations on the floor to be used. This is largely due to high humidity and the possibility of direct contact with moisture.

When choosing a laminate for a floor with water heating, the following nuances should be considered:

- marking - the presence of a specialized stylized badge or marking "H20" indicating the possibility of using in conjunction with water heating systems. These coatings are highly dense and water-repellent;

- class - it is preferable to use class 32-33 with a lock type of connection.The type of connection is “Click”, since in the case of using “Lock” locks and swelling of the laminate, damage to its fixing elements is possible;

- safety - it is possible to use only safe coatings marked “E1” or “E0”, indicating the amount of formaldehyde substances included in the composition.

When laying on a water-heated floor, the use of especially thick types of coating is not recommended. This greatly affects the thermal conductivity of the system and indicates a low density of the material used.

The purchase of a laminate for a warm floor is carried out in a similar way. The first step is to check for the presence of special permissive marking, compliance with the class and the presence of a coating that prevents fire.

Otherwise, the choice of material, both for water and electric heating systems, is carried out taking into account the type of room and the requirements for the cladding.

Decoding of marking

Having learned from friends that they had purchased a "cool laminate" inexpensively, heating elements were laid under it and now they are not happy with their lives, you need to find out what signs the manufacturer indicated on the packaging of the wonderful product. A priori, dies containing wood have excellent thermal insulation properties. This means that the material heats up poorly and, practically, does not let heat through itself.

But the laminate for a warm floor, for example, water, is devoid of this drawback. It is inferior in thermal conductivity to ceramics, but certainly better than natural wood. A special production technology makes it possible to present to the consumer a laminated coating capable of transmitting a large percentage of heat through itself. Find one of these icons on the product packaging:

If the manufacturer has indicated a similar icon on the packaging of their products, then the laminate is suitable for a warm floor.

At the same time, do not forget that the laminate purchased specifically for the upper part of the warm water floor cake should be laid in a room where the relative humidity will be at the level of 40 - 60%. And another important point. The temperature of the coolant in the system should not exceed 26 - 28 0C. When buying, you should be guided by the manufacturer's recommendations regarding where this product should be used. So, a laminate for a water floor is incompatible with the electrical system and vice versa.

We carefully read the marking

The limitation on the installation of laminate on a warm water or film floor lies in the method of production of this flooring. Fiberboard used to be the stabilizing base of laminate boards. In the process of its manufacture, synthetic resins were used to bond the fibers. When heated from a warm floor, they could emit toxic substances, which was a problem for installation on a warm water floor. Everything changed with the arrival of MDF and HDF boards. By their structure, these are fiberboards. The second type has a higher density than the first. Thanks to this, it was possible to reduce its thickness, and hence to increase the heat-conducting properties. By themselves, these boards are environmentally friendly if the manufacturer honestly adheres to the technology. The binding of fibers occurs due to a substance that is part of the wood itself. Natural resins are added. Further problems lay in other components of the laminate.

The face layer is responsible for the wear resistance of the entire material. Therefore, it must be made quite durable. This can be easily achieved using various polymer compounds. It can be acrylic or melamine composite resin. The constant influence of the elevated temperature of the warm floor on them did not bring much benefit. Additional pitfalls were layers of paper that could be soaked in paraffin or other chemicals to provide additional moisture protection.

Each package with laminate boards has a large number of different designations.One of them has the preceding Latin letter E. It indicates the level of emission or release of various chemicals. For a cold floor, this figure can be 2 or 3. But if you plan to cover a warm water floor with laminate, then there should be 1 or better 0. This means that the emission level is the lowest, which does not harm health or is practically absent.

Additional identification marks that will tell you about the correct choice for a warm floor will be a temperature icon indicating specific values. They can range up to 30 ° Celsius. Typically, a laminate for a water-heated floor has a schematic mark of a curved pipe with a water icon or its chemical formula. Other pictograms, such as the heel of a lady's shoe, a thrashing kettle, or animal paws, indicate resistance to abrasion and other physical influences. A zigzag of lightning will inform that the laminate does not accumulate static electricity, which means it is safe for sensitive equipment and electronics.

How well it gives off heat

If we take into account ceramic or porcelain stoneware tiles, then in relation to them there are no questions about the thermal conductivity from the warm floor. It has a high value, which is good for a warm floor. This becomes apparent even with simple daily use. If you stand on a cold tile, then the sensations will not be the most pleasant. This is due to the fact that the area of contact with the surface of the foot is significant, and the density of the material itself is quite high. This means that it is able to quickly pick up heat and give it to the screed, which is located below. This is not the case with laminate flooring. If you tried to walk on it barefoot, then such unpleasant sensations did not arise. This suggests that its thermal conductivity is lower, which means that it will give worse temperature from the water floor heating to the air.

It is also important to pay attention to the markings in order not to be trapped. The value of the thermal conductivity coefficient is indicated by a number, followed by W / m × K. According to European standards, for a floor covering that is laid on a warm floor, this figure should not be more than 0.15. But a laminate with such a value is also not worth taking. You need to look for the value below. This must be done, since it is necessary to take this coefficient from the substrate. Together with the laminate, the figure should not exceed 0.15 W / m × K in value. You can find out by putting them together. For example, 0.8 W / m × K will be written on the laminate, and 0.6 W / m × K on the substrate, the total will be 0.14 W / m × K, which is quite acceptable for a warm floor.

Thermal resistance of floor coverings

It is not easy to find a laminate that will have a suitable marking on the packaging, but also to consider the coating by such a parameter as the coefficient of thermal resistance (CTR). With an increase in this parameter, the heat-insulating characteristics of the material also grow (read: "What kind of heat-insulating materials for the floor to choose").

In European countries, the optimal value of the CTS when laying on top of the underfloor heating system is no more than 0.15 kW per square meter. The same value applies to the underlayment under laminate flooring. The final CTS is a combination of the above indicators: for the coating and for the substrate.

The level of thermal resistance of the laminate is formed due to its main parameters: thickness and density. Naturally, the maximum heating will be ensured by how the values of these parameters decrease.

The use of a coating with a high CTC value is fraught with overheating of the substrate and coating, and the heating circuit of the heating system can also be damaged. Accordingly, it is very important to calculate the CCC even before purchasing materials. A high-quality underfloor heating system will provide a higher efficiency of the heating system.

Why laminate

In principle, this is a matter of everyone's choice. But the laminate does have some properties that have not yet been replicated, for example, tiles. Among them are:

- a unique structure that repeats the surface of a tree;

- a variety of prints with patterns;

- a special way of styling;

- ease of combination with the interior;

- ease of cleaning and cleaning;

- resistance to physical influences;

- resistance to UV rays;

- resistance of some types of laminate to moisture;

- the possibility of laying by the deck method, observing a single contour;

- long service life;

- high environmental friendliness.

And now, laying together with a water-heated floor makes this material ideal. The disadvantages include the high price for elite models. It also requires special scrupulousness during installation on a warm floor, so some inexperienced craftsmen may not be able to cope with the task.

How to choose a laminate floor

Laminate for underfloor heating is laid almost everywhere: in office, residential premises.

The technical characteristics of the laminated flooring exceed those of real wood. And laying it on a warm water floor is within the power of even a non-professional.

But before starting work, you need to have some knowledge and choose the right laminate for a water-heated floor.

How laminate is labeled

Not every laminate model is compatible with underfloor heating. Conventional laminated strips are characterized by high thermal insulation properties. After laying, they may not change their shape from temperature, but they may not warm up well enough and conduct heat insufficiently. To avoid annoying oversights, manufacturers have developed special technologies for the manufacture of laminate coatings, which can be perfectly combined with the construction of a water-heated floor. They marked this material. The packaging or instructions contain this marking and next to the icon is usually marked the maximum temperature to which it is allowed to heat this material, approximately it is 27-28 ºС. In addition, the instructions contain markings that indicate the possibilities of using the laminate on a warm floor and the recommended types of coating for heating structures.

For underfloor heating, it is allowed to use laminate of classes 32, 33 and higher

Determination of thermal insulation qualities

When choosing a laminated coating, it is best to focus on the figure of the thermal resistance coefficient. If it is high, then the features of the thermal insulation of the material are also high. The generally accepted standards in the world provide for the level of its coefficient up to 0.15K / W. Consideration is given to the resistance of the laminate and the substrate used. When adding up their coefficients and obtaining a joint calculated value, you need to correlate it with generally accepted norms. The density and thickness of the material influences the value of the resistance coefficient.

It is better to choose lamellas of low density and thickness, somewhere around 8-10mm, for a warm floor.

Exceeding the coefficient of thermal resistance can create a situation of overheating of the lower part of the laminate and the floor system. In such a situation, the coating may deteriorate and the heated floor model will fail.

Each room has its own class

You may have noticed that the greatest floor scuffs are observed at the doorstep, in the dining room and in the kitchen. It is in these rooms that people are most often, which leads to deterioration of the coating. The same situation will occur with laminate flooring. If you are planning to install laminate flooring in all areas, then it is worth considering choosing its strength. Manufacturers distinguish several strength classes for the laminate. If we are talking about laying laminate in an office or corridor of any institution, then you should look towards the 33rd or 34th. It will carry the highest load with the stated service life.

For household needs, the twentieth grade is usually chosen, but if it is planned to have a warm floor, then you will have to pay more for the 31st or 32nd grades. It is these subspecies that are allowed for installation on a water-heated floor. In the case when, according to the plan, the laminate should be in the bathroom and in the kitchen, on a warm floor, then make sure that it is with additional moisture protection. This can be expressed in the fact that the stabilization layer will be made of various types of plastics that are insensitive to water. It is important to observe this nuance so that the laminate does not swell and the seams do not come apart, which would lead to expenses for repairs.

Laminate for film (infrared) warm floor. Which one is right?

Infrared underfloor heating has good heat dissipation, accompanied by a not too high heating temperature of the floor covering, which makes it possible to choose a laminate as a floor covering. In addition, the heating of the floor and heating of the air in the room occurs evenly, which is important for creating the desired atmosphere in the house.

Criteria for choosing a laminate for a film warm floor:

- the laminate for the film underfloor heating must be marked accordingly, allowing installation on the underfloor heating;

- 33 or 34 class of wear resistance of the laminate;

- the thickness of the laminate must not exceed 8.5 mm.

Laying type

The user may also be faced with the question of which method of fixing laminate boards for a warm floor to choose. Until now, a couple of basic tool joint processing techniques have been used. One of them is called Click. Thanks to him, the connection of adjacent laminate planks occurs in a few touches without much difficulty. It is enough to bring one laminate plank to another at an angle of 45 °, insert it into the groove and lower it to the characteristic click, thanks to which the lock got its name. No further action is required.

Another method requires the use of an adhesive backing. This is due to the design features of the Lock. If you look at it in section, it becomes clear that this is an ordinary spike that goes into the groove. At the slightest deformation or displacement, the spike of the laminate can slip out and a gap is formed. To prevent this from happening, a special glue is used for the laminate, which tightly holds the components together. The advantage of using this method is to reduce the gaps between the laminate planks. But the main disadvantage is the impossibility of repairing a separate section, since it is necessary to destroy the locking joints of the laminate. This method of fixing the laminate cannot be used for warm floors. When heated, a significant expansion occurs, and such a laying of the laminate will not be able to play to the required size. Also, in the process, harmful substances will be released from the glue.

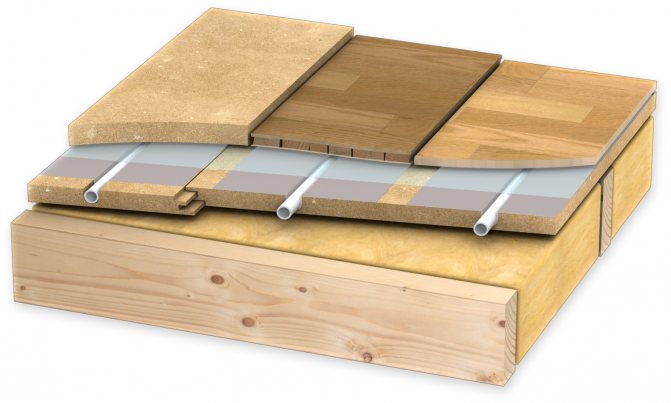

Laying technology

When performing repairs and installing water heating, someone prefers that the warm floor is laid in a wet way, and someone wants the water heated floor to be without a screed. Which one is really better, everyone decides for himself. But to put it simply, laying a warm floor in a wet way implies a monolithic pouring of the pipe contour into a screed. This will not affect the laminate in any way, but it will affect the maintainability, as well as the height of the warm floor. If the ceilings allow, then it is better to prefer this method of installing a warm floor, since the base is more reliable.

The dry method of laying a warm floor under the laminate is faster and does not require additional spending on building materials. Such a warm floor is suitable even for those rooms where 20 cm of rise will already be critical. The advantages of such a warm floor is the ease of access to pipes from under the laminate, since they, in fact, are on the surface. Also, the heat is released to the air faster, because the screed layer under the laminate also does not warm up. But careful control of the temperature is required so that its value does not exceed the permissible value for the laminate.

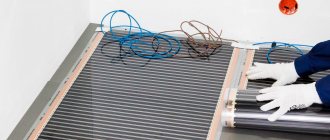

Infrared floor under the laminate

According to experts, the most suitable option for a laminate is an IR film floor. Warm film floor under the laminate does not require a screed, is easy to fit, it is quite suitable for self-assembly without the involvement of hired workers. It is enough to carefully study the instructions and follow them exactly.

IR radiation does not provide for high temperatures and this excludes deformation of the floor. Its heat is transferred by radiant energy, heating all surfaces in the room. In terms of energy consumption, this is the most economical option. But its application is somewhat limited. Do not lay the film floor under furniture, heavy, low-standing interior items.

Tips for good styling

According to feedback from users and craftsmen, laying laminate flooring on a warm water floor does not differ in its method from the usual one. After the question of which flooring to choose and all the materials have been purchased, you can proceed to the practical part. By the time of installation, the screed should already stand well and gain the required rigidity and strength. This can take about a month. It's worth the wait in order to lower the humidity level. Two weeks after pouring, the heating can be turned on. Every day you will need to monitor the temperature of the circulating fluid of the warm floor and raise it by 5 ° once a day. This will allow the entire surface to be heated evenly without temperature distortion. Two days before installation, the temperature of the underfloor heating must be set to the permissible maximum.

The laminate is brought to the installation room not one hour before the operation. It is advisable to do this in a day, or even more. This will enable the laminate to pick up the temperature of the warm floor and go through the process of deformation expansion. If this is not done in advance, then the problems will begin after installation, when everything is covered with cracks. It is advisable to keep the laminate boards closed for the first day, and then unpack them for another day. If the weather is not frosty, then you can unpack the laminate immediately.

The first step is to inspect the level of the surface that formed after laying the warm floor. Before installing the laminate on a warm floor after wet pouring, it is necessary to treat the area with a primer. This will hold the base together and eliminate the appearance of sand and dust on the surface. The area difference should not exceed 2 cm by 10 m. There is no need to use a waterproofing layer. The substrate is immediately laid. The latter for a warm floor must be used without a foil layer, otherwise the heat waves will not pass sufficiently.

The substrate is laid over the entire area with an overlap of 5 cm on the walls. The excess will be cut off after the process is completed. Neighboring sheets are glued together using ordinary adhesive tape, metallized cannot be used. A gap of 1 cm must be made from each wall. It will allow the laminate to take the required shapes without deformation when the temperature changes. You can mark this space for the laminate with wedges or pieces of wood. Subsequently, it will be covered with baseboards and will not be visible.

Everyone begins the installation of the laminate in the way that is most convenient for him. But professionals advise to do this from the far left corner of the door and move to the right and down. Thus, it will turn out to lay the contour more efficiently. If in the first row the initial board was intact, then in the second row the laminate board must be shortened by 30–40 cm. This is necessary for bandaging the seams. For a more dense arrangement, each row of the laminate is tapped with a mallet through the block. An additional skill can be learned from the laminate installation video.

How to prepare underfloor heating for laminate

Arrangement of a water floor means pouring a screed into which pipes with hot water are mounted, due to which the floors are heated. Laying is done in several stages.

Before laying a warm floor, level the surface and clean it of debris

Related article: Dome houses

Work order:

- First you need to level the floor surface and clean it of dust and debris.

- Next, you need to put insulation and a reinforcing mesh.

- Then metal-plastic or polyethylene pipes are laid.

- The next step will be filling the cement-sand screed. For this, it is necessary to purchase special self-leveling construction mixtures.

- A week after pouring the screed, the "warm floor" system must be tested in action.

- The latter must be laid with a special soft shock-absorbing substrate. It can be penofol or extruded polystyrene.

- Lay the laminate on top.

The lamellas should not rest tightly against the walls, otherwise, when heated, they will increase in size and the floor will deform.