Infrared underfloor heating

Today, the installation of infrared underfloor heating under the laminate is becoming an increasingly popular service. The number of people abandoning classic heating with conventional radiators is growing rapidly. Why is that? What are the advantages of the new heating option? Let's list the main advantages:

- The ability to adjust the temperature in the rooms. You no longer have to wait for the heating season to finally begin. Also, you no longer need to open all the windows wide open to ventilate the room in the off-season, when it is already (or still) warm outside, and the heating has not yet been turned off (or not turned on). Just turn the knob and the temperature in your apartment rises to a comfortable temperature.

- You can easily set different indoor temperatures. For example, in the kitchen and bedroom, this temperature can be lower than in the living room and nursery.

- Minimal thermal inertia - the result is noticeable in a matter of minutes after you turn the heating on or off.

- Heating of local zones. For example, it is not at all necessary to heat the floors under cabinets and a bed - this is a waste of energy and expensive materials. But the area on which you often walk will always be warm and pleasant to the touch.

- Unlike other options for electric heating, infrared underfloor heating does not dry the air, heating the laminate directly. This makes the atmosphere in the room more comfortable.

- The installation process is much simpler than that of water-heated floors. In addition, there is no danger that in case of a breakthrough, you will flood your neighbors and you will have to disassemble the entire floor to fix the breakdown.

This is not a complete list of the advantages due to which people choose an IR warm floor under a laminate. But this is quite enough to understand that you will definitely not have to regret such a decision.

The principle of operation of the IR system

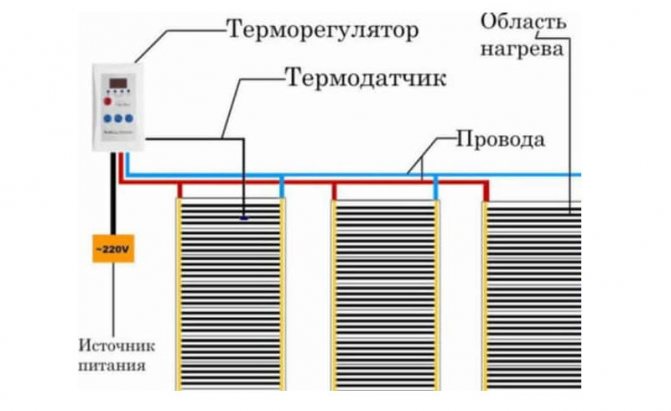

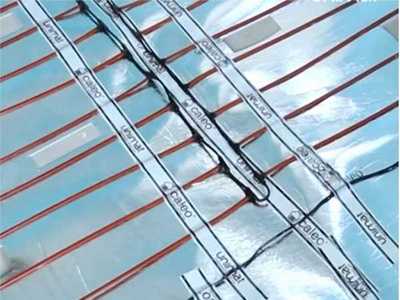

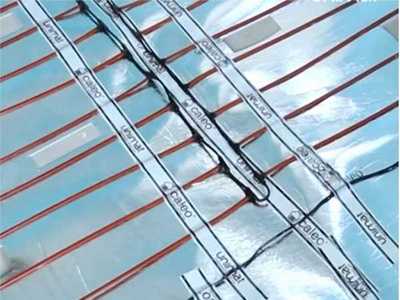

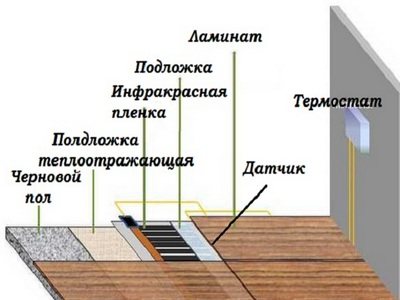

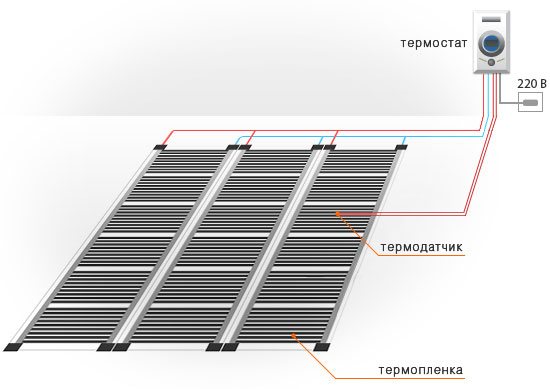

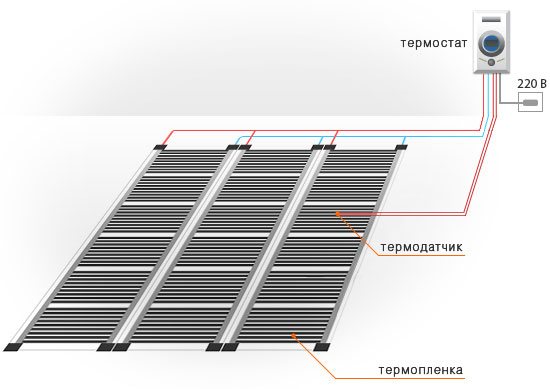

The structure of the infrared underfloor heating, in addition to the main coating, includes copper or silver strips that conduct current, a carbon emitter and a film layer. In addition, the warm coating system itself is equipped with a thermostat, a temperature sensor, special clips and clamps, and a cable for connecting to the network.

Carbon paste, which is applied in parallel stripes, creates rays under the action of an electric current. They, in turn, having reached a dense coating, heat it up. The system is designed in such a way that the air receives heat from the heated laminate. In this case, part of the rays passes through the coating and heats up the objects in the room.

To avoid overheating of the film element, it is not recommended to install an IR warm floor under large furniture.

For installation, film materials with a capacity of 150 to 440 W / sq. Are used. meter. For laminated boards, films with a minimum indicator (150 W / sq. Meter) are used. This power is enough to warm the floor up to 40-45 degrees. An infrared heating system is considered rational, since its installation allows you to create optimal heating conditions.

Types of infrared films

The modern market for heating equipment offers different types of underfloor heating under the laminate. Each of them has certain advantages and disadvantages. Therefore, you need to seriously study all the available options in order to make a decision, which you will not have to regret later. The greatest demand is for film and rod.

We will tell you in more detail about each of them, so that you can decide which is the best warm floor to install under the laminate.

Foil

This option is the most demanded. There are many reasons for this.

The main one is the ease of installation - if necessary, you can cope with all the work yourself, without using the services of specialists. This means that the new heating will cost much less than any others.

In addition, the power consumption when using it is about 20-30% lower than that of analogues.

It is also important that when choosing this option, you do not have to arrange a screed. This is important - if you are not planning to do a full-scale renovation in the room, then you can simply lay it on the floor. Laminate or any other material is laid directly on the underfloor heating film - except for tile and carpet.

Attention! If you have chosen laminate flooring as a finishing material for floors, then make sure that the floors do not heat up to temperatures above +28 degrees Celsius. Otherwise, the laminate can be damaged.

Externally, it looks like carbon strips interconnected by copper busbars and covered with polyester for electrical appliances. Low energy consumption is made possible by the working method. When turned on, it heats up to the set temperature, after which it goes into economy mode.

Rod

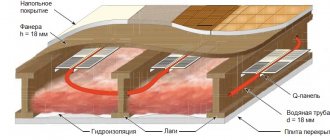

The well thought out design and the right materials have resulted in an excellent self-regulating system. The core warm floor consists of two layers: reflective material and carbon mat.

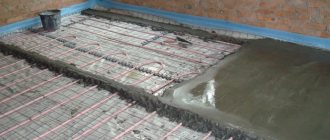

It is laid on a solid and even base, after which it is poured with a screed, on top of which a laminate can be mounted.

One of the advantages of a core underfloor heating is the small thickness of the concrete screed - no more than 3 centimeters.

Heating elements are made of composite materials. With a decrease in heat transfer, an increase in the temperature of the heating elements follows, and this leads to the expansion of the material. The distance between the graphite grains that make up the rods increases. As a result, the power decreases and the resistance increases.

No need to use expensive sensors and equipment control systems - everything is automatically controlled.

It is important that the temperature in different areas can vary. For example, if you install a cabinet on the floor in a place where core heating is laid, then the temperature will rise here, which will lead to a decrease in power. This means that there will be no overheating of equipment breakdown.

Therefore, many experts, when customers are interested in them, which warm floor is better for a laminate, recommend the core one.

Which laminate is suitable for IR underfloor heating

To get the maximum effect from the laid film and the assembled floor, it is necessary not only to carry out the installation technologically competently, but also to choose the right laminate. The shelf life of the finished floor, its environmental friendliness, heat-conducting properties depend on this. If you put a laminate that does not correspond to the type of heating equipment, then formaldehyde may be released, the lamellas deform and other problems may appear. Laying laminate is suitable if it:

- Supplied with a padlock. The glue method of assembling the lamellas is undesirable, since the glued continuous coating breaks during temperature changes.

- Conducts heat efficiently. This quality is determined by the coefficient of thermal resistance: the lower the better. The optimal limit is considered to be 0.05-0.10 m2 x ° K / W.

- Has a thickness of 8-9 mm. The lock of thinner lamellas does not withstand temperature fluctuations. And thickened products conduct heat weaker.

- Belongs to class E0 or E1.A floor made of such a laminate does not emit formaldehyde when heated to 27-30 degrees.

- On the basis of wear resistance, it is classified at least 3 classes. The higher grade guarantees a long life for the floor.

How is a film infrared floor

It is this variety that is most in demand today. So, let's talk about it in more detail.

Rolled underfloor heating has a simple device and is completely safe.

The heating element is made of the thinnest conductive strips placed at intervals of 16 millimeters. In their manufacture, modern technology of carbon nanotubes was used.

Electricity passes through the silver-copper wires. The film is completely sealed on both sides and is laminated with a fire-resistant polymer. It resists high humidity perfectly, which eliminates the possibility of rapid deterioration when used in humid climates. Even if the infrared film is damaged due to mechanical stress, only a small damaged area will fail. The rest of the area will continue to work as usual, effectively heating the room.

How the infrared floor works

Immediately after switching on, the heating film begins to emit anions (ions with a negative charge) and infrared rays. In contact with the laminate, the rays heat the latter, which, in turn, gives off heat to the entire room.

Many ordinary users note the high level of comfort provided by such a system.

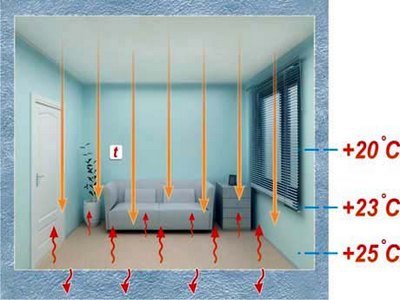

Heated wood gives off very soft heat. Rising upward, the heated air ensures an even temperature throughout the room - both near the floor and under the ceiling.

In this way, warm floors compare favorably with classic radiators - when using them, you can often observe a drop of several degrees.

Some experts confidently compare the warm air rising from the floor to the warm air coming from the ground when heated in the sun. Exactly repeating the natural heating familiar to humans, the system has a beneficial effect on the well-being of the inhabitants.

Important! To increase the efficiency of the infrared film under the laminate, the heating element is placed on top of a special heat-reflecting pad. Thanks to it, all the heat goes up, heating your apartment, and not the floor slabs.

IR floor heating - is it expensive?

There is an opinion that the purchase of materials and components for the installation of an infrared floor is very expensive. In reality, only expensive models require significant expenses. The price of high-quality film starts at 650 rubles / sq. meter. A full set of service equipment, including sensors, a thermostat, bitumen tape, wires, costs about 2,000 rubles. The one-time costs also include the payment for the installation of the heating elements and the assembly of the floor. However, these works are easy to do with your own hands, so you can save money at this point of the estimate. As a result, it turns out that the total cost of a floor heated by infrared rays is relatively small.

Preparing to install an infrared floor

When installing infrared floors, proper planning is especially important.

The heating element should only be located under open areas of the floor. It is not necessary to lay them under large furniture (armchairs, beds, sofas, wardrobes).

There are two reasons for this. Firstly, the warm floor located under the cabinet will not be of much use. But it will greatly increase the power consumption.

Secondly, in some cases, overheating is possible, leading to the failure of individual sections of the heating element.

Therefore, having decided to install IR floors in your apartment, think very seriously about the arrangement of furniture - you will have to live with such a layout. Any rearrangement of furniture must be accompanied by the movement of the heating elements. So, before you install underfloor heating, arrange the furniture as it will stand in the future and wait a few weeks or months to make sure you don't want to rearrange anything.

After that, you can measure the free area that will warm up - based on this, the required amount of material will be purchased. Be especially careful here. Film and core floors are quite expensive - several thousand rubles per square meter. Therefore, by buying too much material, you will overpay a significant amount. It will definitely not be possible to return the leftovers to the store or sell it profitably. But it will be even worse if there is not enough material. You have to decide which parts of the floor to heat and which to leave cold is not the most pleasant procedure.

In addition to the material, you will need certain tools. Nothing highly specialized is needed here - almost everything you need is in most apartments:

- a screwdriver equipped with an indicator;

- pliers;

- electric or hand drill;

- Bulgarian;

- pencil;

- double-sided tape;

- insulating tape;

- yardstick;

- stationery knife;

- scissors.

Surely there will be no problems in collecting the necessary tools.

Infrared floor laying technology step by step

If possible, then it is better to entrust the installation of a film warm floor under the laminate to professionals.

They will do everything neatly and quickly, and will also give a guarantee for the work performed.

If, for some reason (lack of money, lack of specialist services in the city), the installation will have to be carried out independently, then it is worthwhile to study the theory first.

Everything takes place in several stages.

Preparation of the base

The technology of laying infrared underfloor heating under the laminate begins with the preparation of the floors. There is nothing complicated here - even a person who does not have experience in the construction industry can easily cope with:

- Check the screed for defects. Any depressions or large protrusions should be removed. If necessary, you can fill in a new leveling screed - the surface must be perfectly flat.

- Determine the location of the thermostat. Access to it should be easy and simple - so that you do not have to move furniture to turn it on or off.

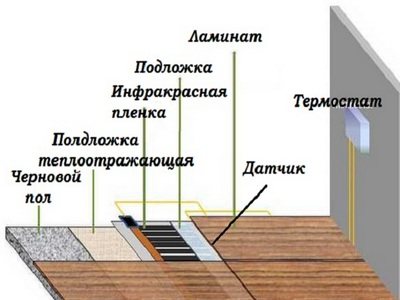

- A heat-reflecting film is laid on a smooth surface. It is best to use isolon for this. It has a relatively low cost, while effectively coping with the task, having a significant service life. It is delivered in rolls - it is easy to roll them around the room, fixing them with double-sided tape.

On this, the preparation can be considered complete. Proceed to the next step.

Installation of infrared film

This stage is considered the most important - even minor mistakes made during installation can lead to serious problems.

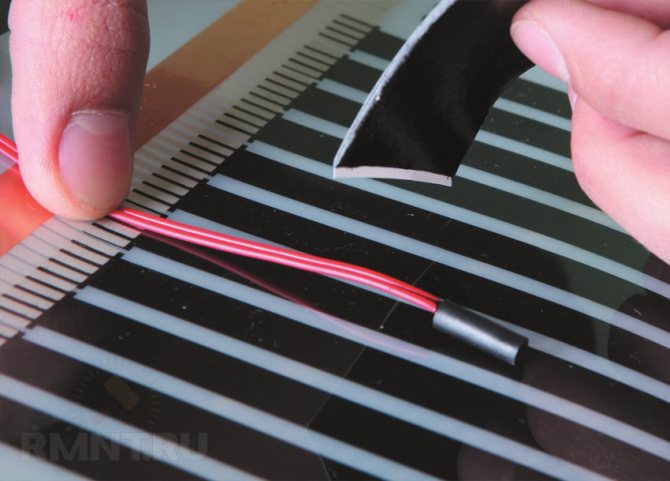

Let's start with which side to lay the film heat-insulated floor. Remember - the copper stripes should be at the bottom. If you have to cut a sheet, then do it carefully and only along specially marked lines - otherwise the film will be damaged.

Advice!

Make sure that the distance between the walls and the film is at least 10 centimeters.

After carefully marking the film, carefully cut it with scissors or a utility knife.

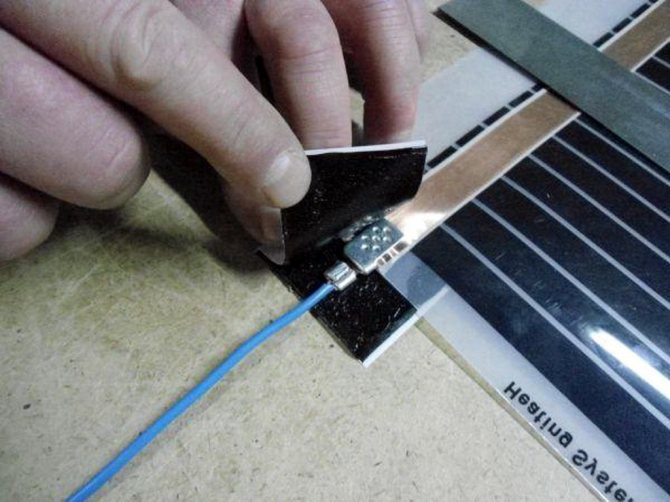

Insulate damaged busbars with electrical tape. The contacts on the copper busbars are crimped with pliers.

Then the wires are stripped and placed in the clamps. Attach them securely with pliers. Insulate all connections to avoid short circuits.

The next step is to install a temperature sensor. Do not forget to fix it and isolate it. The last step is to install the thermostat in a predetermined place and connect it to the circuit.

Now you can turn on the heating using the thermostat.After two or three minutes, turn it off and explore the entire area - you can just walk on the floor with your bare feet. If cold spots are found, check the connection points with an indicator screwdriver. Eliminate all identified shortcomings.

As you can see, the instructions for installing a warm floor under a laminate are quite complicated. But, having studied the process in theory, you will surely cope with it in practice.

Installation of infrared underfloor heating under the laminate

Self-laying infrared heating film under the laminate

Laying an infrared heating film under a laminate is a simple process, all stages of work are easy to do with your own hands. This variety is optimal for installation under floor coverings with minimal thermal resistance, such as carpet, parquet or linoleum, it is allowed to be used as a mobile warm floor. The choice of power and scheme is carried out in advance, if necessary, the infrared film is easily cut into pieces of the desired size. The nuances of the technology include: the need for the most even and clean base, installation of a thermostat, reliable insulation of contacts and placement of wires in specially designated grooves.

It is recommended to adhere to the following scheme of actions:

1. Calculation and planning of the placement of heating strips, the allocation of zones with furniture and appliances.

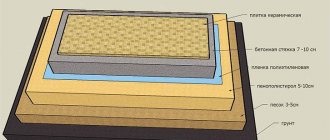

2. Preparation of the base: cleaning from debris, leveling (all possible cracks and protrusions are eliminated). The permissible level difference is up to 4 mm.

3. Laying a heat and waterproofing layer, maximum efficiency is achieved when using reflective materials (but not based on aluminum, especially when combined with cement mortars).

4. Marking and cutting of infrared floor heating strips (carried out exclusively along the lines marked with dotted lines).

5. Preparation of the site for the thermostat. Temperature sensor placement.

6. Laying pieces of film, stripping and insulating wires, connecting the floor to the mains and thermostat.

7. Testing the operation of the entire infrared floor system.

A clever meter that saves energy Pays off in 2 months!

8. Coating with a top protective layer.

9. Installation of laminate.

In order to properly lay the infrared film, it is recommended to adhere to all the requirements of the technology, in particular, to minimize the amount of differences in the level of the floor screed. The permissible deviation is 3-4 mm, it is noticed that if it is violated, the system increases the power consumption. The elements are maximally insulated from moisture and heat loss from below, experts advise to lay a polypropylene or polypropylene film with a thickness of 50 microns or more on the floor, while it is better not to use materials foiled with aluminum.

The cut pieces are placed with a copper strip downwards, the minimum indentation from the walls is 10 cm. A prerequisite for the technology is the installation of a thermostat (1 device per 15 m2, unless otherwise indicated in the manual for the infrared film floor, the total resistance should be 20%). A mid-sized section is selected for it, this will save wires, since all the strips are connected to it in parallel. The connecting cables are stripped 8-10 mm and inserted into the shank of the terminal clamp, one edge must be laid on the copper bus, the other remains inside the heating element.

All connection zones are insulated with special tape, it is advisable to place the wires under the plinth, if necessary, some of the cores are removed under the heat-insulating film, but do not go over the heating strips. Overlapping or overlapping of adjacent elements is unacceptable, the temperature sensor is located in an unloaded area. The latter is especially important when using an infrared warm floor with soft or thin floor coverings, then it needs enhanced protection.After connection, a trial switch-on and testing of the system is carried out: the film should not spark, and the contacts should not overheat, it is required that the entire surface evenly emits heat. If there is no spark, then you can proceed to the finishing stage.

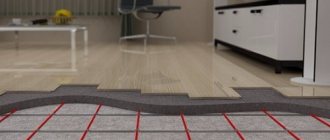

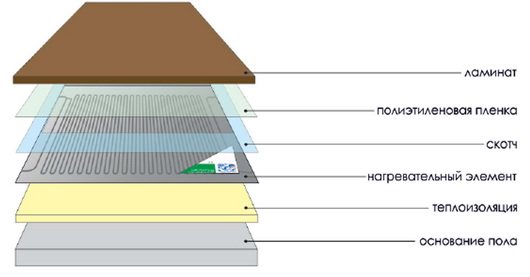

Flooring

To protect the heating elements and wires from accidental ingress of moisture under the finishing panels, a dense polyethylene film is provided. The recommended thickness is 200 microns, it does not represent an obstacle to infrared rays. Laying the laminate with your own hands proceeds according to the usual scheme: the cured flat panels are joined to each other and the locking joints snap into place. Damage to the thermal film is avoided in every possible way, they do not walk on it and do not scatter tools.

After the installation of the infrared underfloor heating under the laminate is completed, do not suddenly start the system to the maximum mode, this can damage the wood. It is recommended to increase the temperature by no more than 5 ° C per day. Another nuance of operation is wet cleaning: the surface is cooled before washing, especially when aggressive detergents are added to the water.

What to consider when working?

The gross violations of the installation of an infrared (film) underfloor heating include:

1. Placing wires and heating elements on an uneven, dirty or damp surface, no backing.

2. Fastening the film with nails, staples, punching carbon strips, the only admissible fixation is scotch tape.

3. Laying the infrared floor system without grounding.

4. Bending the heating strips 90 ° over a 5 cm area.

5. The strip is too long, the exact permissible value is prescribed in the instructions, but in general it should not exceed 15 m.

6. Installation in unsuitable conditions: with high humidity or subzero air temperatures.

7. Operation in rooms with high humidity is not recommended (in this case it is more expedient to buy cable heat-insulated floors).

Plumbers: You will pay up to 50% LESS for water with this tap nozzle

8. Laying infrared film at a close (less than 30 cm) distance from heating devices or radiators.

9. The absence of a top vapor and moisture insulating protective layer or its installation without overlap.

10. Placing one section (strip) of floors in two adjacent rooms with different operating conditions (a vivid example is the combined loggia).

11. Fastening laminate or other type of flooring without preliminary testing of the system, laying carpet on sparkling floors is strictly prohibited.

Tips & Tricks

Correctly placed and connected strips have a service life of at least 15 years. When carrying out all the work on your own to achieve maximum reliability, it is worth consulting with specialists, in particular, at the stage of choosing an infrared floor heating system for a laminate, this will exclude the costly purchase of an unsuitable option. It is noticed that the uniformity of heating partially depends on the location of the temperature sensor, the best option is the coolest area. Heavy furniture should not be placed on it; it is advisable to place all connecting wires with a thermostat in a corrugated tube (for a stationary version, in a specially provided channel).

If an infrared film floor is placed over a basement or damp subfloor, a thicker layer of dense polyethylene film should be laid on the concrete. Climatic conditions are very important: in some regions, the use of this variety is impractical even as a source of additional heating, that is, with significant heat loss in the floor structure itself, laying an infrared film does not make sense. To reduce the heat escape zones, before installing the system, tape insulation is glued along the perimeter of the room along the wall, which does not overlap or creep onto the film.

This type of underfloor heating is the only mobile one; when asked whether it is possible to put a carpet on top, manufacturers answer positively, of course, provided that the upper protective layer is sufficiently reliable. But such operations are best done with solid (uncut) strips, ideally specially designed for this, this will reduce the risk of contact separation. Laying in tile glue or cement screed is not only unnecessary, it even worsens the heat transfer of a film-type infrared heated floor (but if this does happen, then the system is started no earlier than a month later). There are no complaints about other types of flooring, you can lay the carpet immediately after testing. At the same time, the softer the outer material, the tougher the heat-insulating layer is required and the base should be smoother; in terms of reliability, laminate and parquet will benefit.

Author: Sergey Isaev

The most reasonable option for arranging a warm floor, followed by laying a laminate, is an electric, in particular an infrared film warm floor. Due to the fact that the principle of its operation consists in radiation in the infrared range, as a result, the surfaces of surrounding objects are heated, and not air convection upwards. Therefore, the IR floor has proven itself well as a heating base under the laminate.

Laminate is a moisture-resistant material, resistant to mechanical damage, with a reasonable price / quality ratio. Laminate flooring is 90% shredded wood bonded with various adhesives.

Laying an electric underfloor heating under the laminate is questionable for many. After all, wood is distinguished by its ability to dry out at high temperatures, crack when it drops, and formaldehyde, which as a binder is part of the laminate board, begins to release intensively.

Film infrared warm floor under the laminate - advantages

- uniform thermal radiation - makes it possible to warm up the laminate over the entire surface;

- economical energy consumption. Allows you to save up to 30% in comparison with other floor heating systems;

- there is no risk of damage to the integrity of the laminated coating, because there is no need to heat the system to high temperatures. Thanks to the use of infrared radiation, first of all, objects in the room are warmed up, and not the air;

- no need to perform "wet" works. Laying the laminate does not require pouring the screed;

- the ability to use any type of substrate;

- availability. In large shopping pavilions there are demo models where you can visually (visually and tactilely) evaluate the operation of the system (available in large cities of Moscow, St. Petersburg, etc.) or order in the online store, based on the technical characteristics and reviews of the owners.

Recommended

detailed description - do-it-yourself infrared film underfloor heating device (types, calculation, installation)

Laminate for a film warm floor - which is better to choose

Despite the fact that manufacturers and craftsmen recommend laying a film underfloor heating under the laminate, you should not discount the features of the laminate itself.

In particular, when choosing a laminate for an infrared warm floor, you need to pay attention to several factors:

- laminate marking

... Most manufacturers quickly reacted to the changing market trends and added laminate flooring specifically for underfloor heating to their product range. Whether it is possible to use laminate for underfloor heating will be indicated on the packaging (the corresponding icon on the label). Moreover, some manufacturers indicate the maximum heating temperature;

Note. The maximum temperature up to which the laminate floor can be heated is 27 ° C.

- structure (density) of the laminate

... The ability of the lamellas to conduct heat depends on how "loose" the structure of the floor is. The denser the laminate, the higher its thermal resistance value. In practice, this means that the underfloor heating system will heat the lamellas, and not the surfaces of the surrounding objects;

- laminate thickness

... All other things being equal, the thicker the lamella, the slower it will transmit heat;

- formaldehyde content

... This component is part of MDF, which serves as the basis for the laminate board. At a temperature of 20-26 ° C, formaldehyde is released normally. Those. according to this indicator, most sexes belong to the E1 class. However, when the lamellas are heated, the release of formaldehyde is activated, so you need to pay attention to this indicator. It should also be borne in mind that the intense release of formaldehyde begins when heated above 27 ° C;

- laminate cost

... Many reviews contain complaints not about the operation of the underfloor heating system, but about the need to lay the laminate again because of attempts to save on material;

- substrate

... Laminate installation technology involves the use of a substrate. The installation of the substrate will allow leveling the pressure on the locking connection of the strips from moving along the lamellas. Due to the fact that the substrate is laid not under the floor film, but on it, the choice of the film must also be approached responsibly.

What kind of substrate can be used for laying on a warm film floor

- technical plug;

- liquid composite system;

- extruded polystyrene foam;

- polystyrene backing;

- material with a reflective surface.

Note. It is unacceptable to use foil-clad material (aluminum foil, pnofol) as a substrate.

DIY installation of an infrared film underfloor heating under a laminate

The laying technology involves performing several sequential steps.

- Choosing a set of infrared film underfloor heating

... Please note that each manufacturer has a different package content. For example, the company K-Technologies (Russia, trademark Caleo) provides a choice of several types of floor heating systems. Naturally, the price of the set depends on the configuration. You can reduce the cost of a warm floor by assembling it yourself.Note. For autonomous heating (the main source of heating), it is necessary to install a film floor on 70% of the area of the room. With an additional - by 40%. In this case, it is taken into account that the film does not fit under furniture, heavy and low objects in order to exclude its overheating.

- Preparing the site for installing the thermostat

... For ease of use, the thermostat is set at a height of 0.9-1 m. from the floor height. - Preparation of the base

... Both the film floor and the laminate put forward special conditions for the surface quality. Floor drop in height over 3 mm, the presence of obstacles on the floor (depressions, protruding parts), debris are not allowed.Note. When installing an infrared floor heating system over a basement, ground or garage, a waterproofing film should be laid on the prepared base.

- Laying thermal insulation material

... The insulation is installed in accordance with the manufacturer's recommendation. The joints of the insulation should be glued with tape so that the strips do not disperse. The thermal insulation material is placed no closer than 100 mm. up to the wall. The joint is glued with a damper tape. - Cutting out underfloor heating films

... The infrared heating foil may only be cut in the designated area. The film cut not along the cut line is not suitable for use. The maximum length of one strip should not exceed 8,000 mm. - Installation of underfloor heating film

... To minimize the number of cuts and joints, craftsmen are advised to lay strips of infrared film along the longer side of the room.The film is laid at a distance of 100-400 mm to walls and other bulky objects, the distance between adjacent strips is 50-100 mm. Overlapping film is not allowed and will lead to overheating of the system segment. To exclude the movement of the film, it is fixed with double-sided tape to the surface of the base. The adhesive tape is not laid in strips, but in separate pieces to compensate for the thermal expansion of the materials. - Insulation of contacts

... If the contact is not used in the underfloor heating system, it must be insulated with a sealing tape (bitumen). To connect and connect the wires, you need to make special clamps (terminals) for the warm floor. The contact terminal is mounted in this way: one part of it is passed between the copper bus and the film, and the other is pressed against the film. The whole structure is fixed without pressure with pliers. - Connecting underfloor heating wires

... A wire is connected to the terminal and insulated. When installing the wire, it should be taken into account that the high performance of the system is ensured by the parallel connection of its elements. This means that the right side of the tape is wired to the right side. For convenience, we recommend using a multi-colored wire. - Installing the underfloor heating sensor

... Wizards recommend to wind the sensor under the second strip of the IR film closer to the middle. This will make it possible to obtain adequate information about the temperature in the system itself, and not on the floor surface. The sensor is glued on the underside of the film to a black strip on the film. In order for the laminate not to create an additional load on the sensor, the device should be "drowned" in a heater.Note. The sensor wire can be laid on top of the insulation, or you can cut a hole in its thickness and place the sensor wire in the corrugation. So, if necessary, you can repair the wire or sensor.

- Installation and connection of a warm floor to a thermostat

... The thermostat is connected to the wires from the heating film and the temperature sensor. The system is connected via an RCD.Note. The number of thermostats depends on the capacity of the system. If the installation of the system is carried out over a large area, it is reasonable to use several thermostats.

- The first switching on of the film underfloor heating (test run)

... The main indicators of the system operation (voltage, speed and uniformity of heating, etc.) are evaluated. - Laying laminate flooring

... Installation of the laminate has no specific features and is carried out in accordance with the type of lock and the manufacturer's recommendations. Before proceeding with the installation, the laminate needs to “pick up the temperature”. To do this, they leave it in the room for several days, and only then proceed to the installation. In this case, it is important to know how to properly lay the substrate under the laminate. The substrate is placed not under the heating foil, but on top of it. - width;

- power consumption.

Installation of an infrared film underfloor heating under a laminate - video

In order for the infrared floor heating system to run smoothly, it is recommended to gradually increase the floor temperature (by 3-4 ° C per day) to the set value.

The price of installing infrared underfloor heating under the laminate

For many years, the main source of heat in apartments and private houses was radiator heating. Recently, however, there have been great changes in the heating equipment market. Many new systems have appeared to create a comfortable temperature in your own home.

Relatively recently, film thermal conductors have become available to consumers in the Russian market, which can be installed under any floor covering... They, like other home heating solutions, have their merits. Further in this article we will talk in detail about how to arrange an infrared warm floor under a laminate.

Types and nuances of choice

Currently, there are two types of infrared heating systems:

What unites them is that they, differing in their price, have the same principle of operation. As for the differences, the former are film of minimum thickness with graphite elements... For floors of the second type, the structure is based on rods made of carbon or copper, fastened together with polyurethane jumpers.

Rod type mats used only for underfloor heating purposes. Laying is done directly on the concrete screed. Installation of the infrared floor is carried out on a vertical, as well as on an inclined surface.

And one more thing that unites both systems - they are powered from a common power grid. However, for the reason that such systems are connected through a thermostat, the consumption of infrared heated floors during operation varies from 160 to 200 watts.

If performed throughout the dwelling installation of a "warm" floor made of foil or core mats under a laminate, you can provide a comfortable temperature in any of the rooms of your apartment. Such solutions can be used not only in city apartments, but also in the country, as well as in country houses.

How much is?

Many people who are thinking about arranging an IR film warm floor under a laminate in their home, of course, are of interestt the question of the price of such a heating system... In this regard, it should be said that the price of an infrared floor device largely depends on factors such as:

The popular film underfloor heating system currently on the market, Caleo Gold has a film width of 50 cm and its power is 200 watts. As for the price, it will cost a potential buyer 730 rubles. If the owner decides to arrange a less powerful heating system in the home... then you can choose underfloor heating NanoThermal Premium. It is also produced by Koreans, and the power of the system is 140 watts. As for the price, it is noticeably lower - 430 rubles.

Cost calculation

Now let's calculate what costs the owner bears when arranging such a heating system in his home under a laminate:

- costs for a roll of film floor - 1720 rubles;

- it is necessary to purchase a thermostat with a temperature sensor separately. The price for it varies from 2250 to 2900 rubles. In this case, the channel power of the devices matters;

- to create a screed 3 cm thick on an area of 4 sq. m. 6 bags of dry mix are required at the price of 230 rubles. In general, it turns out 1380 rubles;

- when performing work on the installation of an infrared warm floor, you will need to use foam foam with a foil layer. The price of this material is 40 rubles. for one square meter. In some underfloor heating systems, it is already included in the kit.

Having carried out simple calculations, you can see that by spending 6500 p. you can arrange a system infrared film underfloor heating under the laminate on your balcony. If you decide to carry out the work not on your own, but by the forces of specialists, then in addition to this you will have to pay for the services of a master at the rate of 240 rubles. for one square meter on a finished base or 650 p. per square meter with the creation of a concrete screed.

Will cost more core underfloor heating... Using Unimat Rail mats with a similar area to create it, you will have to spend 7990 rubles for such a system.

Infrared floor device for laminate flooring

Earlier we talked about the fact that a film infrared heat-insulated floor can be laid on a concrete screed or flooring made of boards. What basis to arrange - each owner decides for himself, starting from the state of the base floor surface.

It is also necessary to take into account the structural features of the structure. So that everyone work on the installation of film heating systems was completed quickly... and after the completion of the work, it could be used; during installation, it is necessary to strictly follow the instructions that are attached to any underfloor heating system.

If an infrared film heat-insulated floor is arranged in a wooden house in which there is no concrete covering, then it is not worthwhile to carry out work to create a concrete screed. These are just additional costs. Using plywood or OSB boards, you can mount the top layer of the beam structure. Such a base will be quite suitable for laying heating elements. If the house is just being built, and it has already been decided that warm film floors will be used as a heating system... then cement-particle boards should be used for the base device. In this case, you can save a lot. If you want to get a better base, then the choice should be made in favor of magnesite sheets.

It should be noted that all of the above materials can be used in a house built from reinforced concrete floors. In such a situation, pThe installation of the coating is carried out directly on the logs... Before laying them, it is necessary to arrange a waterproofing layer on the floor surface. The following can be used as materials for its creation:

- mastic;

- liquid glass;

- deep penetration impregnation.

A crumb of polystyrene or vermiculite is usually poured into the cells between the logs, then the flooring is laid.

Self-installation of IR underfloor heating

The process of installing a warm floor under the laminate involves laying a thermal insulating layer. To create it, a roll-type insulator of small thickness is used. On the one hand, it has a foil coating.

Most often, the following materials are used for the device of such a layer:

Work technology

To avoid gaps, when laying the material, it is necessary to fix the edges of the strip using adhesive tape. After that, you can proceed to the most important stage - installation of a warm floor and its connection... First of all, it is necessary to resolve the issue with the place where the thermostat will be installed. Once you've decided on this, you will know where to pull the cable. Usually this device is placed on the wall.

Next, you need to roll the film on the floor with a metal line down. After that, you should cut the strips to the sizes you need and insulate them.

Thermal Reflector Laying Procedure should start from the central part of the room... If work is being carried out to insulate the floor over the entire area, then it is necessary to leave a gap of at least 10 cm from the wall.

- Cloths of a film warm floor must also be fixed using adhesive tape. Special clips can be found on copper busbars. You need to connect wires to them.

- The contacts should be well pressed and wrapped with electrical tape.

- The temperature sensor should be placed in the corrugated tube, and then placed inside the structure.

- The wire, which is protected by a corrugation, can then be connected to the regulator. Connection should be made through a residual current device.

Underfloor heating installation is a simple task. Its device can be done by hand. The main thing is to adhere to the recommendations contained in the instructions.

Before proceeding with the installation of the topcoat, it is necessary to run the system in test mode and check its operability. To simplify the task, you can use a portable infrared sensor... By directing this device to separate areas, you can see the temperature on the display. If, after starting the system, individual sections of the warm floor remain cold, then in this case it is necessary to check the connection.

Perhaps the lack of the required temperature is due to a poorly clamped contact, which should not heat up. When you have checked everything and made sure that all sections of the underfloor heating are working, they are necessary cover with polyethylene foam backing... Cork covers can also be used. Laminate panels must be placed on top of the laid layer.

Base flooring is optional.You can make the screed using a common mortar of cement, sand and water. Alternatively, you can create a self-leveling floor, for which a dry mixture with a certain composition of components is used.

It should be noted that when installing a concrete screed, the quality will be higher when using factory mixes, since they contain plasticizers. They not only increase the strength of the coating, but also make it moisture resistant... Before pouring the base, it is necessary to treat the surface with concrete contact, and the corners and joints must be glued with insulating tape. After seven days, you can proceed to the next stages of work, which were indicated above.

Conclusion

Many apartments use laminate flooring. Under it, you can easily arrange a warm floor if you want to add an additional heating system to your home. There are no difficulties with this work. Each owner can do the installation of a warm floor under the laminate with his own hands. For this, the most important thing is to choose the right heating system, and strictly follow the instructions when performing installation work. Then the warm floor will serve for a long time, and a warm atmosphere will reign in your home.

- Porcelain stoneware for laminate flooring What is better than porcelain stoneware or laminate? Step 12. Check again the quality of the tiles, if you find ...

- Laying infrared underfloor heating under laminate Laying infrared underfloor heating under laminate - what you need to know about the installation process? For the last…

- Electric underfloor heating installation under the tiles Electric underfloor heating To increase comfort in the house, many property owners install underfloor heating. IN…

- Installation of underfloor heating under tiles Selection of equipment and materials Technology and instructions How ...

Tips & Tricks

If you do not know how to choose an infrared warm floor for your laminate, you can give some tips.

- Avoid complex systems, the installation of which requires special skills and specialized equipment, if you are not going to use the help of specialists.

- By placing an additional layer of thermal insulation on the base under the heating element, you will reduce heat loss by significantly increasing the temperature in the room.

- If you decide to install an underfloor heating system in your home, where there is soil or a cellar directly under the floor, take care of reliable waterproofing.

- The best location for the temperature sensor is in the center of the structure. This will reduce the number of wires. It is also advisable to place it in the coolest place.

This article will help in solving many issues related to the described type of heat supply organization.

What users say about infrared floors

Despite the fact that the tape heat-insulated floor under the laminate began to be laid relatively recently, the technology received very flattering reviews from users. Here are a few of them.

“How great it is in the morning to stand with your feet not on a cold floor, but on a warm, pleasant to the touch. Immediately, the mood is good for the whole day. "

Leonid, Tomsk

“Electricity bills come in the same way as for a regular electric water heater, and the house has become much warmer. I didn’t regret the money and time spent on installation ”.

Mikhail, Tambov

“The floors are working, but the room heats up rather slowly. True, I am more likely to blame here, because I made the layer of screed under the laminate too thick - seven to eight centimeters. In general, there are no complaints, everything is cool ”.

Vladimir, Perm

Thousands of people in our country have already appreciated the advantages of this method of heating apartments and private houses. Surely you will not be disappointed if you give up conventional heating radiators in favor of infrared underfloor heating.