Humanity knows many ways to heat a home. From the stove and fireplace to solar-powered convectors. When choosing a heating method, various factors are taken into account:

- Room configuration.

- Availability of various types of energy carrier (solid or liquid fuel, natural gas, electricity, etc.), as well as the possibility of using it at a specific facility. For example, in an apartment building, it is impossible to install an individual wood-burning boiler.

- Economic feasibility: in the regions, the cost of energy carriers varies significantly.

- Possibility (and necessity) of redundancy of heating systems;

- Automation of heating systems - it is not always possible to continuously monitor the heating boiler.

- Aesthetic component.

We will consider a progressive technology: carbon fiber warm floor (carbon fiber).

Why electrical floor heating systems are so popular in modern homes

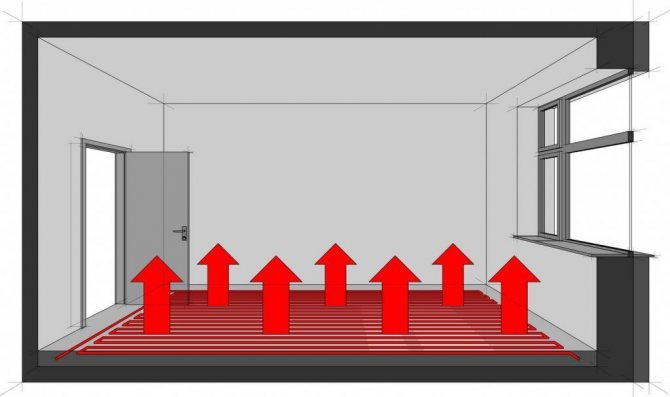

- The heated air is formed at the lowest level, evenly rising through the volume of the room.

- Large heat transfer area minimizes losses.

- You can walk barefoot on a warm floor in winter;

- Flat heating elements fit perfectly into the interior: they simply cannot be seen under the floor covering.

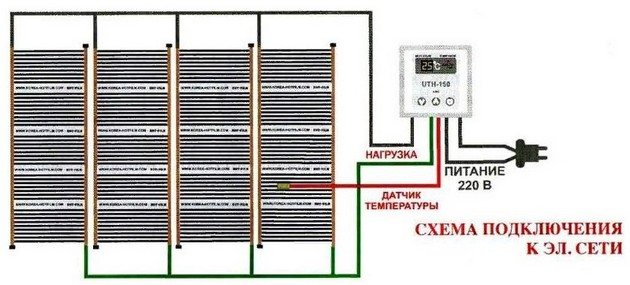

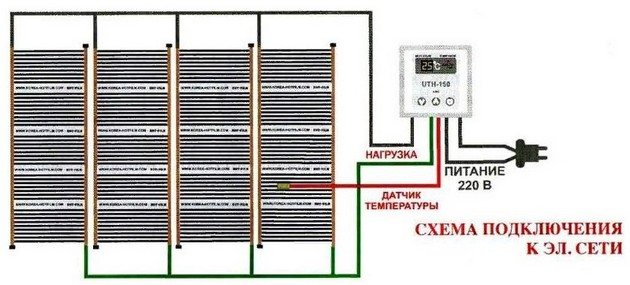

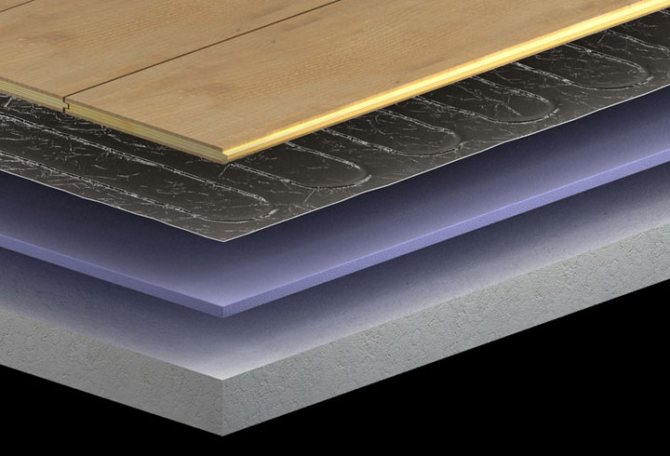

- Electric cable underfloor heating makes it possible to fully automate the climate system. The controller does not just maintain a preset temperature, you can set low cost modes (when you are not at home), or turn on heating by a timer.

- There are no problems with the delivery of energy: almost 100% of the housing stock is electrified.

- Simple installation: no need to lay pipes for liquid heat transfer agent, installation of heating radiators, fans, pumps.

- No maintenance required: a properly organized underfloor heating system lasts a long time. Any self-respecting manufacturer provides a minimum 10-year warranty.

There are also disadvantages, which, however, are covered by advantages:

- To install the system, you will need to open the floor covering. In the case of linoleum or laminate, no problem. And if you want to implement a carbon underfloor heating under the tiles, you will have to carry out a full renovation of the room.

- Relatively high cost of equipment, especially thermoelements. True, this problem occurs only once, when buying.

- The cost of generating heat is higher than using gas or solid fuels.

And yet, the main plus: the carbon floor can be laid and connected independently. This requires an ordinary household tool and basic skills of a home craftsman.

Carbon fiber warm floor: characteristic

The operation of underfloor heating under normal conditions requires a constant connection to a network with a voltage of 220 V. The essence of their operation is that current is supplied to the carbon elements. Heating occurs due to the electrical resistance of the resistive components. So, electrical energy turns into heat and is transferred to the floor covering. In the future, it spreads throughout the house or room where heating is installed.

Carbon fiber warm floor

Carbon fiber underfloor heating has its advantages and disadvantages. The obvious advantages include:

- availability;

- ease of installation;

- small dimensions;

- aesthetics (warm floor is not visible under floor structures or decorative elements);

- mobility of some heating systems (film floor).

Among the disadvantages, the most significant are:

- consumption of electrical energy (leveled by connecting automation);

- the presence of good thermal insulation is mandatory (otherwise the system will be ineffective);

- on most variations of underfloor heating, you cannot put weighty household items, plumbing (with the exception of infrared carbon film);

- high capital spending;

- restrictions on the temperature of the floor covering during the operation of the device, regulated by building codes and regulations.

Varieties of electric floor heating systems

Heating systems using electrical energy can be divided into three main groups (each of which offers several versions):

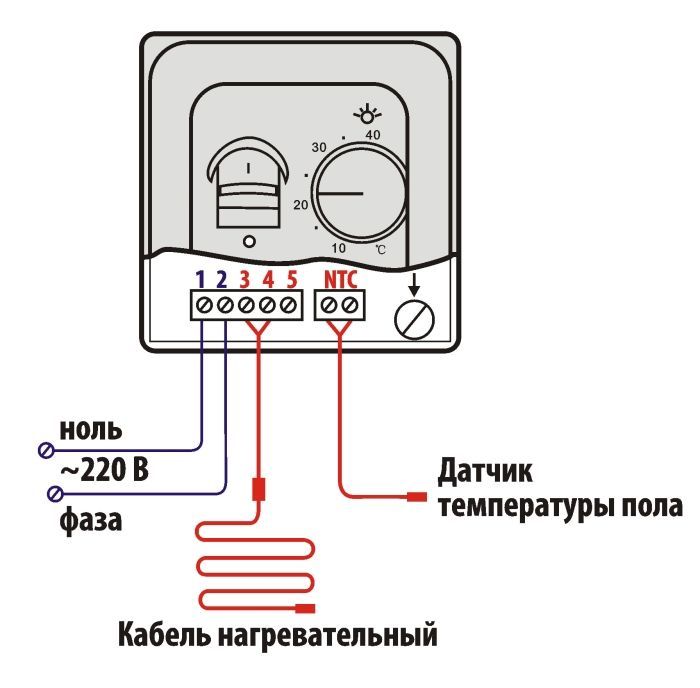

- An electric cable is used as a heat generator, the radiation is convection (heat rises up through the air).

- A simple embedded cable in the form of a thermocouple. Placed in a cement screed or self-leveling floor (wet installation). The optimal type of finish: ceramic or porcelain tiles, stone. Can be used under wood, laminate, carpet and linoleum.

- The so-called "smart cable". The laying method is the same (wet). The optimal type of coverage: ceramic or porcelain tiles, stone, wood (including parquet), laminate. Carpets and linoleum are allowed.

- Modular underfloor heating, consisting of heat-insulating plates with a cable inside. Mounted on a dry base. Ideal for all types of tiles, wood flooring, laminate and linoleum.

- Foil floors that create a uniform climatic surface that heats up over the entire area.

- Heat mats, which are a modified design of cable heating. The emitter is already installed in fixing grids, conveniently formed for mounting. Filled with "liquid" floor or stacked in a screed. The main purpose is stone, tiles. Can be used in screed under wood, laminate, carpeting and linoleum. Heating method - convection.

- Film carbon underfloor heating (the second name is carbon). Ideal for laying under natural parquet or laminate flooring. Installation under linoleum or carpet is allowed. Carbon heaters use an innovative heating method: infrared.

- Rod floor heating, also with carbon heating elements. It fits into the structural elements of the building, in other words, it is poured into a screed or self-leveling floor. Suitable for all types of surfaces, including stone, tiles, wood and artificial materials. It also uses an infrared method of transferring heat energy.

What is a carbon mat underfloor heating?

Carbon underfloor heating should be considered as an additional source of heat and as an independent heating system. Panel heating of this type is carried out in different modifications, which allows consumers to choose the most optimal type. The system is highly adaptable and economical.

An innovative home heating option is powered by an infrared energy source. Most often, graphite-silver rods are used for this, connected in parallel to each other. For this, the production uses wires of increased protection against overheating.

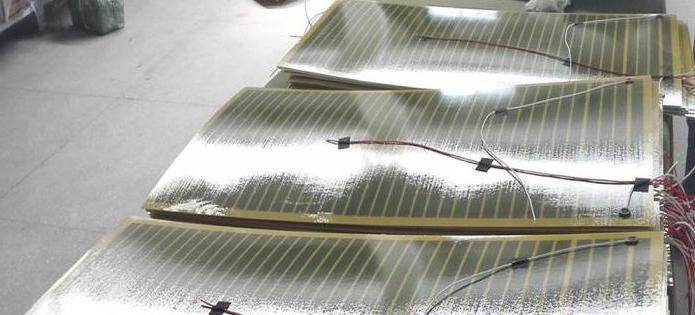

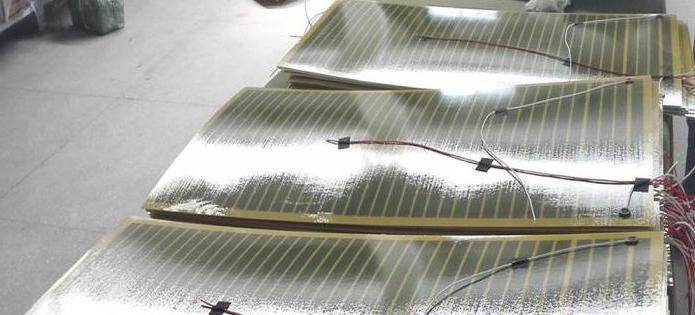

Carbon underfloor heating

The insulating material is a substance based on polyester and polyethylene. The main component of the product is a heating element, which consists of carbon and polymers. The cable used for this purpose is made of copper. Its cross section is 2.5 mm. It is insulated with a sheath up to 3 mm thick.

Everyone who has exploited a carbon underfloor heating claims that the modern market cannot offer a more profitable option for panel heating. In a house where this type of heating is installed, natural air humidity is always maintained. This is helped by an intelligent heating system with modern thermostats and temperature sensors.

All currently existing variations of carbon-based panel heating are complemented by a detailed description of the installation and instructions for use. The buyer only needs to choose the most optimal option, to show a bit of diligence in order to surround himself with warmth and comfort for a long time.

Operating principle

Since our review focuses specifically on carbon technologies, we will analyze the principle of operation of a warm floor made of carbon.

First, let's figure out the terminology. The concepts of "carbon" and "carbon" cannot be divorced: they are one and the same technology. It's just that in Russia the word “carbon” or “carbon fiber” is traditionally used, and “carbon” sounds in foreign catalogs. In fact, they are one and the same.

Manufacturers offer two types of carbon floors: film and core. They differ in the way they are laid, the structure of the heating elements, and their application.

The main advantages of a carbon floor

Consumers choose carbon floor heating for a variety of reasons, among the advantages people distinguish the following:

- the possibility of self-regulation;

- safety;

- reliability;

- profitability.

As for self-regulation, the described system is smart: it is able to control temperature and power consumption, while there is no need to install expensive equipment. The higher the temperature rises, the greater the distance between the particles of the heating elements will be. This will increase the resistance.

When the temperature drops, the opposite process occurs. In those areas of the floor where the load is higher, the heating will be less. According to the reviews, consumers can move heavy objects and furniture without encountering problems and without observing the measures to protect the system.

Carbon thermal film

Durable, heat-resistant polypropylene is used as a load-bearing base. This material is developed with the condition of complete environmental neutrality. That is, in normal operating modes of heating, underfloor heating should not emit a single harmful molecule into the room.

The film is made according to the principle of “triplex” automobile glass: 1-2 layers of a substrate, a working layer, on top there are 1-2 more layers of protection against damage. Special strips made from a mixture of carbon and graphite are laid on the lower fabric. The electrical resistance is carefully calculated, since the stability of the operation depends on it. Carbon is applied by spraying, which eliminates uneven thickness. The working strips are interconnected using the thinnest copper busbars. This metal has excellent electrical conductivity, so supply voltage losses are minimal.

The copper conductors themselves do not take part in the heating process. The protective layer (polypropylene top) not only protects the carbon strips from damage, it also acts as a heat conductive bridge between the heat source and the floor covering.

A few words about the polymer casing: It has high pressure, tear and abrasion resistance. In addition, the performance of the protective film remains stable even at a temperature of 120 ° C. This is at least twice the maximum operating temperature of the heating foil.

The principle of operation of carbon elements is the emission of long infrared waves. That is, the heat, as it were, penetrates the floor covering and directly affects the objects in the room. This is exactly how we feel infrared waves from a fire: the heat is alive, as if it is reproduced in a natural way.

The main disadvantages and reviews about the carbon field

The carbon rod floor has some disadvantages as well. As one of the disadvantages, consumers call the rods burning out over time. This happens about a year and a half after the completion of the installation of the mats. This leaves cold sections on the floor.Due to the fact that the mats are connected in parallel, if one of them fails, the rest continue to work, however, the presence of an adhesive screed can complicate the repair process, which is the second drawback.

Underfloor heating infrared carbon fiber, according to users, can burn out only if you purchase a cheap analogue. Low-cost versions of such systems are entering the market today. But the originals, according to consumers, can last quite a long time. However, it will be expensive to pay for them, and this, according to buyers, is the last drawback.

Advantages and Disadvantages of Carbon Fiber Film Systems

Undoubted advantages:

- high temperature does not destroy or deform the structure of the film;

- warming up occurs almost instantly;

- heat distribution is absolutely uniform, it is just a powerful flow of regulated energy;

- infrared radiation is not only harmless, it has a beneficial effect on the body (it is even used for medicinal purposes);

- withstands a lot of weight under pressure;

- carbon floors are not susceptible to corrosion, tolerate little moisture normally;

- there are no unpleasant odors when heated;

- absolute fire safety: this property is especially important when using carbon film in wooden houses;

- ease of installation, no additional surface preparation is required;

- the ability to use not only on the floor, but also on the walls (on the ceiling, use is pointless, warm air does not go down);

- mobility: since film floors are not embedded in structural elements, they can be dismantled and reused in another room;

- modularity of the structure: if one section is damaged, the rest continue to heat (subject to the integrity of the copper connecting strips);

- carbon heaters are so thin that when installing the film, you do not need to change the height of the floor covering;

- electric heaters are perfectly integrated into an intelligent control system "smart home";

- in comparison with cable systems "warm floor", film carbon is more economical by 30%;

- electrical safety: undervoltage on the heating elements themselves, 220 volts only at the input to the control module.

Perhaps the only serious drawback:

- the material is fragile enough to break, therefore, caution is required during installation;

- the high cost of the equipment is undoubtedly justified by its good operational properties, while the product does not belong to the category of affordable ones.

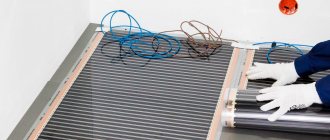

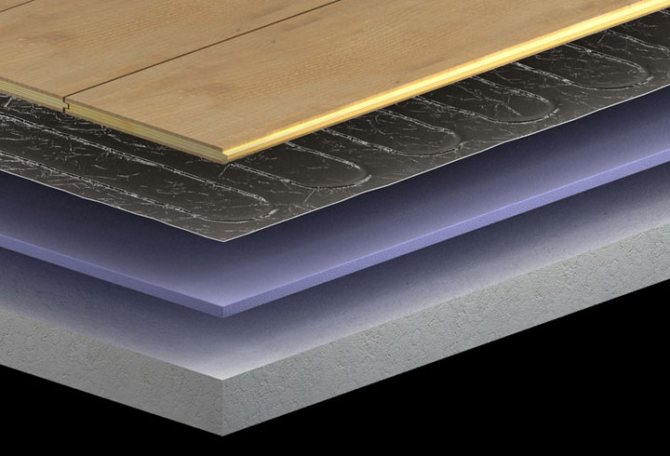

Installation of a carbon underfloor heating is carried out directly under the topcoat, directly on the heat-insulating layer (vapor barrier).

Based on the technology, there is only one limitation: Carbon electric floors cannot be placed under stone or ceramic tiles, as they are used "wet" installation. It is impractical (although not prohibited) to use it under a thick carpet. The fleecy structure will simply shield the infrared radiation.

When laying under a tree or laminate, remember that this material dries at high temperatures. Therefore, a limiter of no more than 28 ° C is set on the control panel.

Info: There is a cheaper option for infrared heating. This is a bimetallic film. A two-layer compound of aluminum and copper foil is used, which, like graphite carbon, emits infrared radiation. However, the consumer properties of such a film are much worse.

Types of carbon systems

The carbon floor heating system is produced in two types - film and core coating. The equipment has various designs and specifications.

Film floors

The device is a continuous heat-resistant film coating, between the layers of which there are carbon strips. The heating elements are soldered together using copper busbars.

The film, made of high-quality durable polypropylene, can withstand high temperatures - up to 120 degrees Celsius. At the same time, the material does not deform at all and does not lose its original characteristics.

One roll of film underfloor heating has a length of 50 meters, and its width ranges from 50 to 100 centimeters. The thickness of the polypropylene layer can be in the range of 0.23 - 0.47 millimeters.

The installation of the film heating system is carried out immediately under the topcoat, provided that there is a correctly formed flat base of the floor. This greatly facilitates the entire process of stacking and dismantling the equipment.

Depending on the category of carbon film material, the power consumption of such warm floors can range from 130 to 400 watts per square meter. In this case, the corresponding maximum surface heating temperature is from 40 to 80 degrees. The energy consumption during the operation of the system does not exceed 25, -35 watts per hour.

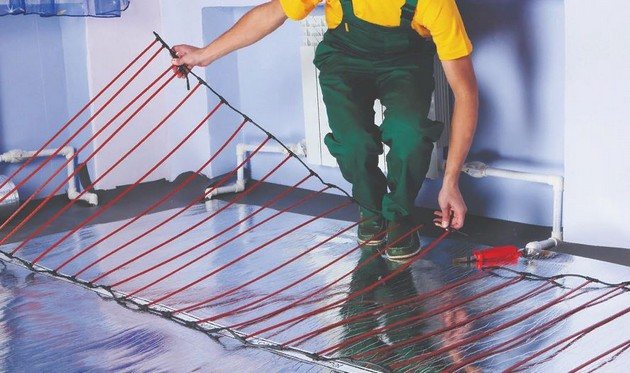

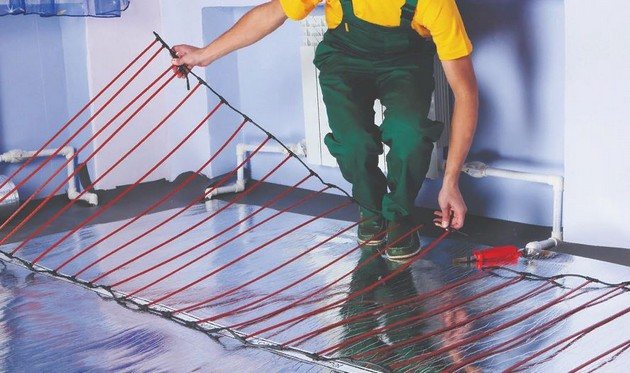

Laying heating carbon film

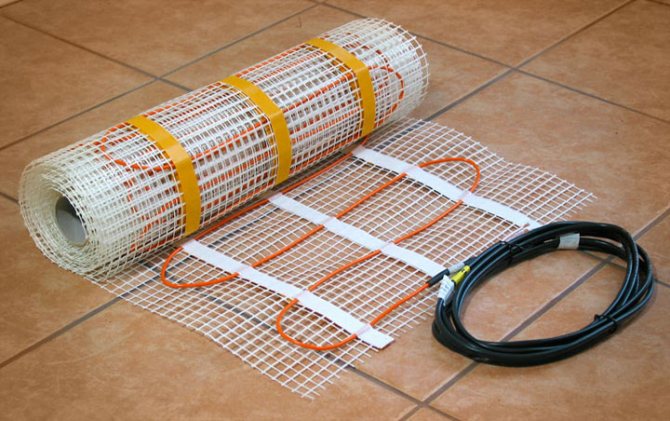

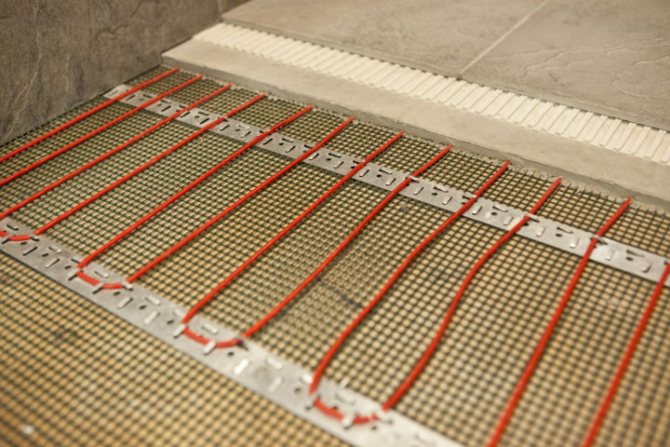

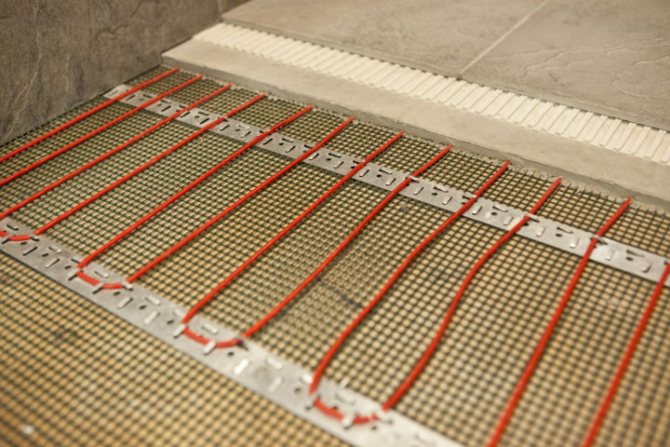

Rod floor

This type of carbon warm coating has a different design. The system consists of rods filled with a mixture of carbon. These flexible heating elements are made of a tough polymer that is highly heat resistant.

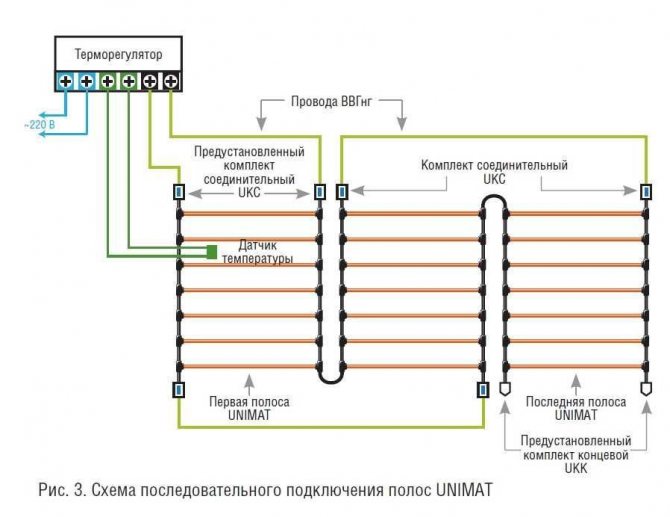

Each rod is interconnected by a stranded copper alloy conductor. All wires are covered with a protective polypropylene layer. Their parallel connection will allow the equipment to operate smoothly in the event of failure and construction of individual heating sections.

Rod carbon underfloor heating

Infrared radiation, generated by the flow of electricity to the carbon rods, completely heats the entire flooring area. At the same time, with strong heating of individual zones, the power of the system decreases. This property makes it possible to exclude the possibility of overheating of the structure and to lay equipment in places where large interior items are located.

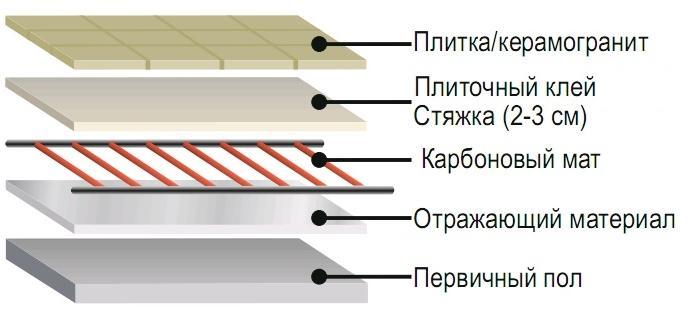

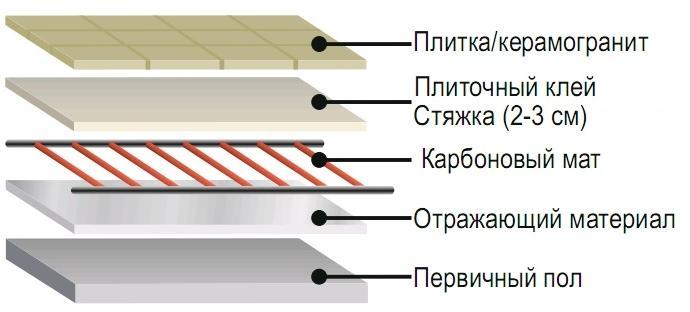

Installation of a rod heating device is carried out exclusively in a screed. If a ceramic tile finish is intended, then the system can be placed in layers of adhesive. At the same time, for laying a carbon underfloor heating of a rod type, a specially prepared base with good thermal insulation is required.

Rod heated floors function with a maximum heating of the working surface of 60 degrees. Electricity consumption during operation ranges from 20 to 50 watts per hour.

The film and core heating system is distinguished by its versatility, since the equipment can be installed under any type of finish floor covering. At the same time, the quality of heating does not decrease at all.

Laying rod heating mats

Carbon fiber rod floor

Contrary to the advertisements, this is not a new generation of carbon fiber technology: core mats have not come to replace film carbon. This configuration is used where film cannot be used (it is poured into a screed or self-leveling floor). It is a set of parallel connected hydrocarbon rods with an admixture of graphite and silver, connected in parallel.

Technologically, a heating element is not even a rod. A bundle of carbon fiber threads is assembled to the required diameter and reliably covered under insulation. The shell material conducts heat well, and protects material, which is quite fragile to break, from mechanical stress during installation and use.

Graphite filaments combined with carbon and silver, when electric current passes through them, emit infrared waves. The material allows you to calculate resistance with precision accuracy and obtain the required thermal characteristics.

Since each rod is connected independently (on parallel buses), the failure of one (or several) elements will not affect the performance of the system. Unless there will be less heat. However, the method of laying (pouring into concrete) implies high requirements for reliability. Unlike carbon film, these heaters cannot be changed just like that, you will have to destroy the entire surface of the screed.

Since the system is a monolith with overlap, care must be taken to direct the thermal radiation (infrared waves). They diverge evenly in all directions, therefore, when laying, it is necessary to provide a screen on the back side.

Otherwise, a significant part of the energy will go to heating the neighbors below (or the basement in a private house).

An interesting feature of carbon rods is the ability to self-regulate temperature. When overheated, the resistance decreases, and the rod cools down somewhat. This allows the heaters to be stacked over the entire area of the room, without highlighting the place where the furniture will be installed. This is very convenient, especially considering the impossibility of reconfiguring the location of the heat mats after the concrete has hardened.

Graphite underfloor heating: basic types

Similar designs are divided into 2 types:

- rod mats;

- film floors.

The first type has recently appeared on the heating appliance market. The core mats are considered to be a high-tech fixture, ushering in a new era in panel heating. The core carbon underfloor heating is made of heating materials and a conductive bus. The design is as simple as its operation.

Rod carbon underfloor heating

The base of the mats, the rods, are made of a composite material. They are a mixture of graphite, carbon and silver. To connect them together, a copper cable with increased resistance to thermal effects is used. To ensure safety, a protective polymer shell is used. It is believed that such a design can last a little over 50 years without replacement.

In the event of damage, you do not need to worry about the performance of the product. The series connection of the heating rods allows the appliance to function properly even if it bursts. The mats will keep warm even if several elements of the system fail.

carbon floor as main heating

The high degree of heat dissipation makes it possible to use the carbon floor as the main heating.

Among the advantages of the pivot model are the following:

- does not create large working loads on floor slabs;

- high durability of high humidity;

- anti-corrosion characteristics;

- low power consumption;

- the presence of automation that protects against overheating and fire;

- absence of electromagnetic impulses harmful to human health.

The high reliability of the system is also noted. Such a warm floor is versatile and easy to install. The parallel connection of the rods makes it possible to cut the warm floor almost anywhere and lay in the desired direction. Therefore, with the complex architecture of the house, you can easily cover all the necessary areas.

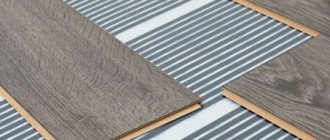

Carbon underfloor heating for laminate and linoleum

A significant drawback of the system is that it must be installed under the tiles. At the same time, the screed is made thin so as not to raise the floor level and ensure high thermal conductivity. Otherwise, there will be no use from the device, because a thick layer of glue or concrete will not have time to warm up in a quick time.

The method of installation under the screed deprives the heating of the mobility that analogues have!

Carbon underfloor heating under laminate and linoleum video

The second option is a carbon film for warm floors. They differ in many ways from rod heating. First of all, you do not need to do a screed for laying them. This significantly saves time during installation. In addition, the floor level does not rise even by those millimeters that concrete could occupy. And the heat transfer from the film models will be higher due to the thin layer of the floor covering.

Structurally, infrared heating can be described as follows: carbon strips connected by polymer-coated wires (tires).

You can cover the carbon film with any material. The only exceptions are carpet, parquet boards and tiles.

It is allowed to use wood as a topcoat, provided that the heating elements do not warm up by more than 28 degrees.

After connecting the structure to the power supply network, it warms up to the temperature set on the thermostat with a subsequent transition to economy mode. The use of automation can reduce energy consumption by up to 30% when compared to other heating systems that are powered by electricity.

carbon film for warm floors

The advantages of a carbon film floor include:

- fast heating;

- uniform heating of the surface;

- high strength;

- resistance to moisture and steam;

- anti-corrosion effect of the coating;

- the design does not react to mechanical stress.

If part of the carbon film is damaged, then only a certain section will not function.

An infrared carbon floor installed under the laminate has a high degree of fire safety. Its melting point is 120 ° C.

Infrared carbon floor

The film warm floor, in contrast to the core floor, has high mobility. If you move, you can always take it with you. In addition, it is characterized by quiet operation and hygiene. Therefore, it can be used to heat medical facilities.

Advantages and disadvantages of carbon rods

Advantages:

- fast heating, uniform distribution of thermal radiation (in the presence of a reflective substrate on the rough side);

- high design reliability - service life of at least 50 years;

- convenient installation: you just cut the required length from the roll, and connect the surface with wires;

- infrared radiation does not adversely affect people and interior items;

- it is not the air that heats up, but the details of the room;

- 100% fire safety: firstly, carbon does not burn, and secondly, the system is walled up in concrete;

- the system is not afraid of high humidity: even if you have a flood, after collecting water, the heaters can be turned on immediately;

- when leaving the dwelling without heating (with a long stay), the system will not defrost;

- just like the foil panels, the carbon core floor is integrated into the smart home system;

- energy consumption is lower than that of cable underfloor heating;

- if you can make a screed yourself, you can also do the installation of carbon rods yourself: saving on installation.

The kits are offered in different price and size categories.

Cons of technology:

- the cost is too high for mass use;

- for laying, it is required to fill the floor with a mixture, this reduces the height of the room;

- an error during installation or a malfunction (this is unlikely) does not give a chance to fix the problem: all the wiring is under a layer of concrete.

Major manufacturers of carbon underfloor heating

The market for electrical floor heating systems is diverse. An inexperienced user may get confused about offers from different manufacturers. As an example, it is worth considering the main manufacturers, their advantages and disadvantages:

- Carbontec - warm floors made of heating fibers and thermoplastic. The main advantage of heating is hidden installation. Even installation under decorative accessories (paint, wallpaper, etc.) is allowed.With the help of structures from Carbontec, it is possible to organize heating of columns, corner zones.

- Unimat carbon heat-insulated floors. The company offers self-regulating and resistive structures for space heating. The price segment of products ranges from low to elite class. The end consumer chooses the company for the quality and reliability of heating systems. The disadvantage is the high power consumption. When laying tiles, there will be problems with the glue - it will not cling.

- Heat Plus carbon floor heating. The South Korean organization occupies a leading position in the Asian market. The disadvantages include the fact that all the consultants and salesmen of the company give false information that such a warm floor improves the functioning of the cardiovascular system, increases tone, and has a beneficial effect on the nervous system. The positive effect of warm infrared floors has not yet been proven. Therefore, to believe such statements is to deceive yourself. Otherwise, they are distinguished by good insulation, ease of installation and durability.

Heat Plus carbon floor heating

It should be understood that in any case, the manufacturer will be responsible for the quality of its products, therefore it is always possible to replace the devices if there is no consumer's fault in their damage. Otherwise, the choice of a company depends on the preferences of a particular person, information received about heating systems from friends, on thematic forums.

conclusions

When planning your home's heating system, consider carbon fiber technology. Perhaps the carbon underfloor heating will be the only source of heat. In fact, the best use case is a redundant system. You can always choose which energy carrier is more profitable in a certain period. In addition, underfloor heating can be used simultaneously with traditional heating.

And if you are leaving the house for a long time, you can set an economy mode with intensive heating on a timer by the time you return.

General classification

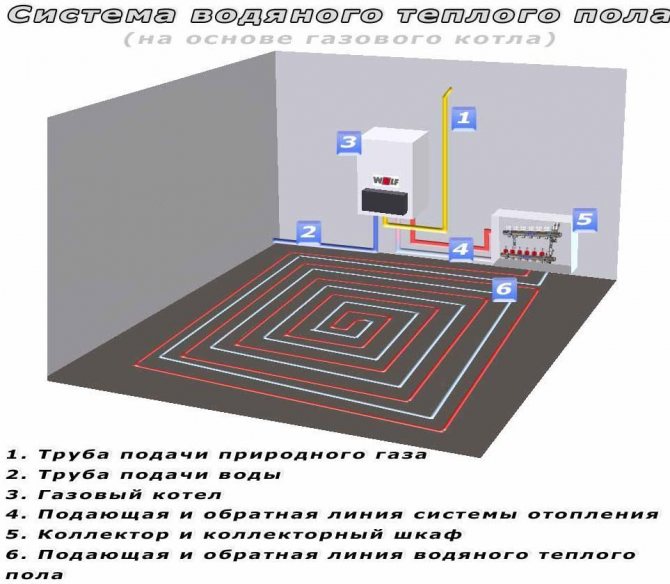

Choosing additional heating is not as difficult as it seems. There are two main types of underfloor heating, and they differ from each other in terms of the heat source in the heating elements.

- An electric underfloor heating is connected to the electrical network, and any kind of heating elements heat the flooring using electricity.

Connecting a cable type underfloor heating system - A hot water floor heats the surface using hot water in heating elements in the form of a pipe system.

Underfloor heating system

Based on the general classification, it is easier to determine which varieties belong, for example, a rod, film or infrared floor. All these are types of electric floors that run on electricity, but have different heating elements: rods, film, cable, and others.

Types of electric floors

The thermal characteristics of the heating elements also play a decisive role, for example, an infrared carbon floor heating heats the surface due to radiation in the infrared range, which, of course, differs from the thermal radiation of an electric cable.