Circulation pumps designation

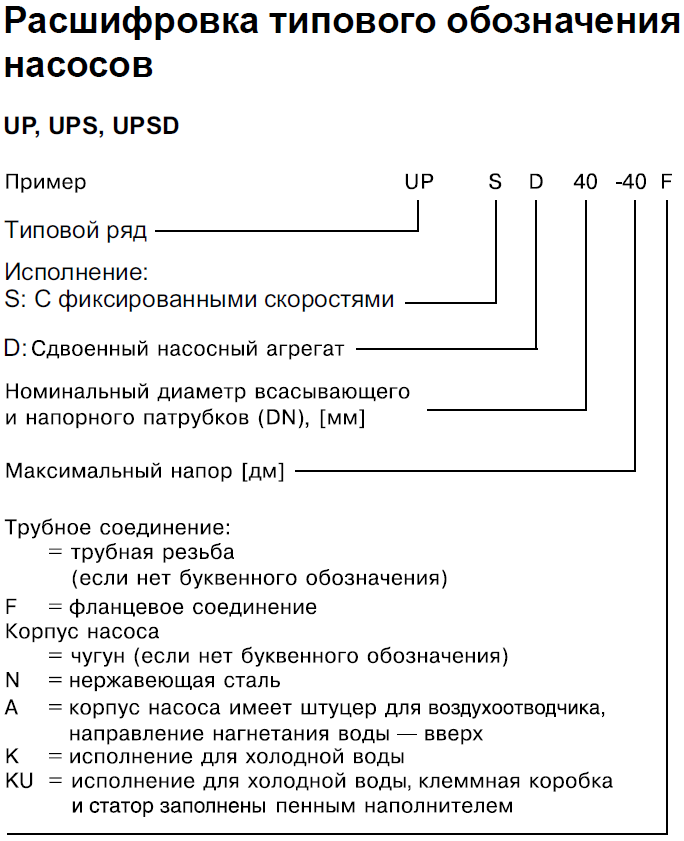

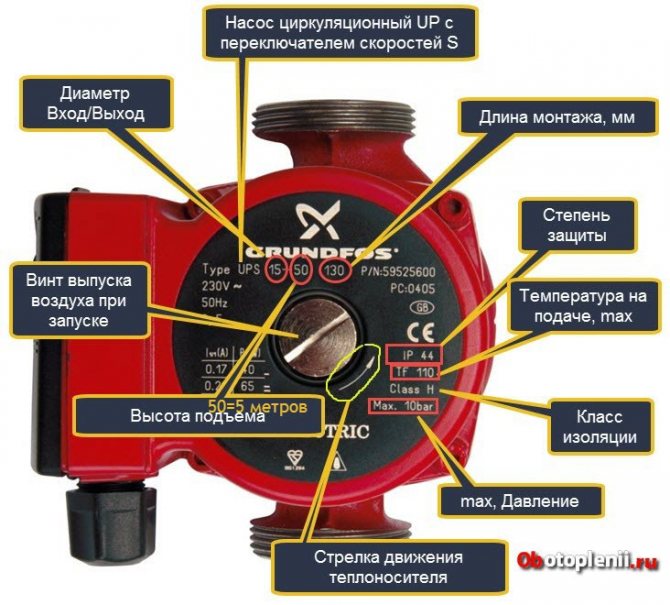

In the marking of circulation pumps, after the brand, two numbers are usually indicated.

The first of them indicates the nominal diameter of the supply pipes in millimeters... This figure can be used to judge the connecting thread of the pump. For example, if the nominal diameter of the pump nozzles is 25, then their connecting thread is 1 inch. The correspondence of nominal diameters (D.Y) and thread sizes is indicated below:

- DN 15 - thread 1/2

- DN 20 - thread 3/4

- DN 25 - thread 1

- DN 32 - thread 1 1/4

What do the numbers 25-40, 25-60 32-80 mean in the pump brand

Pump designation Grundfos UPS 25-40 or Compass 25-40 means that the nominal diameter of its branch pipes is 25 mm, which means the connecting thread is 1 inch, this pump is capable of developing a head of up to 4 meters (40 decimeters).

Considering that there are 10 decimeters in 1 meter, conclusions can be drawn about other designations:

- 25-60 - connecting thread 1 inch head 6 meters

- 32-80 - connecting thread 1 1/4 inch head 8 meters

The pump-building industry of our country produces hundreds of various centrifugal pumps for various purposes. In order to quickly and correctly select a centrifugal pump for specific production needs, several designation systems have been developed.

The pumps of the normal row are marked in the form:

the first number is the diameter of the suction inlet in mm, reduced 25 times and rounded;

followed by letters that denote:

- H - oil, G - hot;

- D - the first wheel of a two-way entrance;

- B - vertical;

- K - console;

- KE - cantilever, mounted in one unit with an electric motor;

- M - multistage.

The second figure is the speed factor or specific speed, reduced 10 times and rounded.

The third digit is the number of steps; letters at the end of the marking: K - acidic; C - for liquefied gases.

Examples of designation and marking of pumps:

- 8NG-10x2 - centrifugal pump, suction pipe diameter 200 mm, oil, hot (for liquid with a temperature of 220–400 ° C), speed factor 100, number of stages 2.

- 8NGK-10x1 - centrifugal pump, suction pipe diameter 200 mm, oil, hot, cantilever, speed factor 100, number of stages 1.

- 14NGD-10x3 - centrifugal pump, suction pipe diameter 350 mm, oil, hot, the first wheel of a double-sided inlet.

- 8НД-10х5 - centrifugal pump, suction pipe diameter 200 mm, oil (temperature <220 ° С), first wheel of double-sided entry, speed factor 100, number of stages 5.

- 3х10НД-9х3 - centrifugal pump for main oil and product pipelines, three pumps are connected in series, suction pipe diameter 250 mm, oil (temperature <220 ° С), first wheel of a two-way entrance, speed factor 90, number of stages 3. speed factor 100 , number of steps 3.

In addition, pumps are labeled according to the main technical indicators: flow and pressure. Most pumps are marked as follows: after the letter designation (brand), two numbers are put through a dash or a slash - the nominal flow, m3 / h, and the nominal head, m of the liquid column.

Examples of symbols: a cantilever pump with a flow rate of 125 m3 / h and a head of 30 m is designated as follows: K 125 - 30 or K 125/30, and a horizontal fecal pump with the same indicators is FG 125 - 30 or FG 125/30.

Pump K 20 / 18-5-U3: 20 - flow rate, m3 / h; 18 - head, m

Multistage sectional pumps are designated CNS.For example, brand CNS 180-212: CNS - centrifugal sectional pump; flow rate Q = 180 m3 / h; head H = 212 m.

Centrifugal pump К65-50-160 / 2 Conventional designation of the pump means: К - console; 65-50 - flow rate in m3 / h when turning the impeller; 160 - head in m; 2 - modernization index.

The following markings are also used: Pump brand KM 65-50-160a / 2-5-U3:

- KM - horizontal cantilever monoblock pump;

- 65 - diameter of the inlet pipe, mm;

- 50 - outlet pipe diameter, mm;

- 160 - nominal diameter of the impeller, mm;

- a - symbolic designation of an impeller with a turning, which ensures the operation of the unit in the middle part of the “Q-H” field;

- 2 - conventional designation of the number of revolutions of the electric motor:

- 2 at n = 2900 rpm;

- 4 at n = 1450 rpm;

- 5 - single mechanical seal;

- U3 - climatic version and category of placement during operation in accordance with GOST 15150-69;

- P - fire-fighting version with a soft stuffed gland.

Pump brand KM 50-32-200:

- 50 - diameter of the inlet pipe, mm;

- 32 - diameter of the outlet pipe, mm;

- 200 - nominal diameter of the impeller, mm.

To date, the following letter designation of brands of general-purpose pumps has been adopted:

- K - single-stage cantilever pump;

- B - pump, single-stage, vertical, cantilever;

- D - single-stage pump with double-sided impeller;

- CNS - sectional multistage pump;

- TsN - multistage pump;

- VK - vortex pump, console;

- CV - centrifugal vortex pump;

- SVN - self-priming vortex pump.

Centrifugal pump designation

In the designation of centrifugal pumps, information is often indicated about the characteristics - the flow rate and pump head.

What do the numbers 60/35, 70/50 mean in the pump brand

Jumbo pump designation 60/35 indicates that the nominal flow is 60 l / min and the maximum head is 35 meters.

In the Jumbo 70/50 brand, it is indicated that the nominal pump flow is 70 l / min, and the maximum head reaches 50 meters.

With the selection of a circulation pump, sometimes unnecessary questions arise. The owners of heating systems do not suspect that it is very easy to make the right choice. Next, consider which pump to choose for heating in most cases that are found in private houses.

How important is it to choose the right pump

For the heating to work, a certain volume of liquid must move through the pipes. It transfers heat energy from the boiler to the radiators. If the pumping volume is small (weak pump), the boiler will overheat and the radiators will remain cold.

But the reverse is no better. If the pump is too powerful, it will consume excess electricity, which will run up a hefty amount over the years, while the speed of water movement will be unnecessarily high and noise will arise in the radiators, disturbing the residents.

Therefore, when choosing a circulation pump for heating, it is important to get into some kind of middle - all the energy should be taken from the boiler and consumed on radiators, but there should not be too much water speed, since this is not very profitable.

What happens in the heating system

The circulation pump pumps the heat carrier through the pipes, more often ordinary water. Its impeller generates a small pressure H (head, measured in meters of water column) and sets a certain speed of movement of the liquid. The result is a liquid flow rate through the pump Q (m3 / hour) - the volume that is pumped per unit of time.

Each pipe system has its own hydraulic resistance, which impedes the movement of fluid. If there was no such resistance, then any unit would pump unlimited volumes over an infinite distance…. But in order to push water through the pipes, the pump creates pressure and consumes electricity.Pipes resist the movement of water, as a result, a certain amount of liters per minute (cubic meters per hour) is obtained.

What is important when choosing a pump

The whole trick of choosing a pump for the home is that if the user does not want to understand the performance charts, he can not. And just read how to choose a circulator for your home below ...

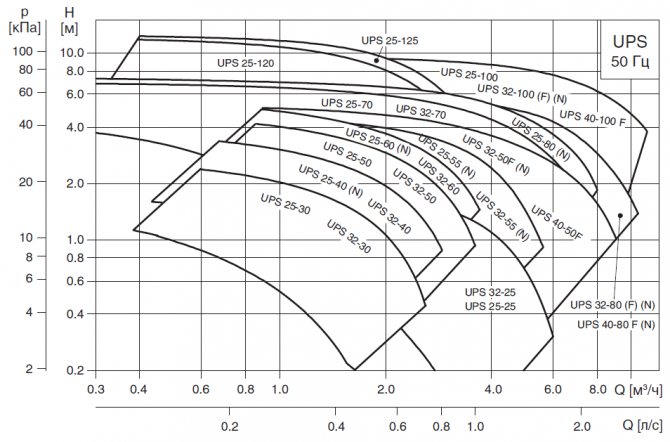

For those who want to understand the problem, the following can be reported. The main characteristics of this unit are the pressure N, m, created by it, at a certain flow rate Q, m3 / hour.

Each circulator has a performance graph. Moreover, they are different for each speed of its work.

The heating network of the house also has a dependence of the flow rate on the pressure. If this graph is superimposed on the characteristics, then they will intersect somewhere - you get the operating point of the pump. That is how much he will drive the coolant, creating such and such a pressure.

Rules for connecting to the hydraulic system

Installation of a circulation pump in the heating system is the responsibility of professional installation teams. But knowledge of simple installation rules can also be useful to a private person.

As a rule, pumping equipment is installed in front of the boiler. This is done for 2 reasons:

- Air is collected in the upper part of the boiler, and the withdrawal of "excess" water from the boiler can create an emergency.

- The "inlet" temperature is much lower than the "outlet" temperature, so the life of the equipment is longer.

All parts required for installation are included. Sometimes you have to buy an additional coarse filter. It is mounted directly into the pipe in front of the pump and holds small debris. Also, experts recommend installing shut-off taps on both sides of the device so that the heating system continues to function if the pump is removed for cleaning and repair.

Important! The motor shaft must be installed horizontally. If the pump is planned to be periodically turned off without removing, a bypass is installed in the pipeline - a special section of the pipe that bypasses the pumping equipment.

Advantages of devices

Thanks to the special properties of the Wilo pump, the efficiency of the heating system is significantly increased. In this case, thin pipes can be used, which, in turn, helps to reduce material and fuel costs. Also, when using a pump, the volume of carbon dioxide that is emitted into the atmosphere decreases, and the daily consumption of electrical energy is no more than 250 watts.

Of course, such a device is not cheap. You will have to pay a large amount for its purchase, but the cost will surely pay off later when used due to energy savings and durability. The device will not need repair for a long time.

Vilo pumps have many positive properties.

The most important ones are as follows:

- There is no heat loss after the water has evaporated.

- The system can be controlled automatically. The device has an LCD screen, a built-in thermostat and other elements to allow for control. You can also manually switch the speed of rotation of the working shaft.

- Compared to many circulation pumps from other brands, Wilo devices are quite compact and therefore do not take up much space.

- The motor and rotor have a multi-stage protection system that helps prevent damage due to sudden power surges.

- The motor runs silently, making it possible to install the device in residential buildings.

Wilo pumps are used in small rooms with an area of several hundred square meters. The selection is carried out according to such parameters as power, volume of circulated water, area of the room and head height. The last parameter is the most important.

How to distinguish an original pump from a fake, you can see in the following video:

Which pump for underfloor heating to choose

Correctly calculating the parameters is not all.You need to choose the type of pump, the material from which it is made and the manufacturer. This is just as important as the correct stats.

Two types of equipment are suitable for domestic use:

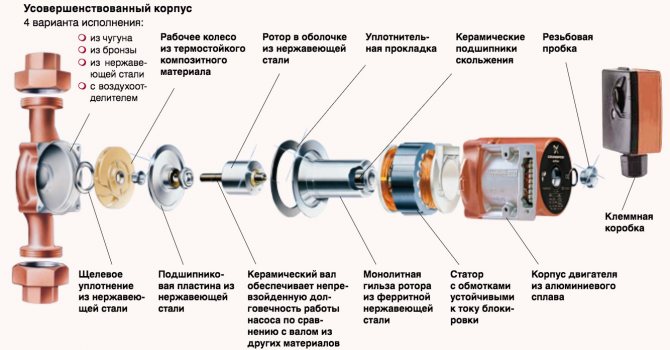

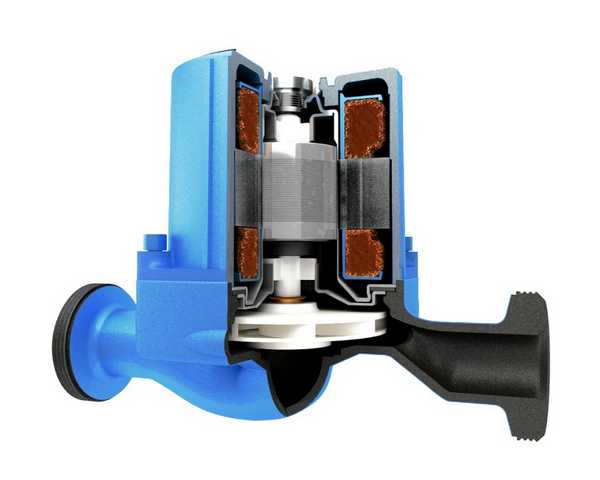

- Wet rotor pumps. These devices are not of the highest power, but in most cases their performance is sufficient to ensure the operability of a heated floor with an area of up to 400 m2. The rotor is called "wet" because the impeller is located directly in the coolant, respectively, cooling and lubrication occur with its use. This equipment is popular because of its quiet operation, low power consumption and high reliability.

Glandless pump design

- Dry rotor units are characterized by increased power. In this case, the rotor is in a separate sealed container. It requires periodic maintenance - cleaning and lubrication. But such equipment in private households can be used, perhaps, only for the installation of fountains.

Dry rotor pumps have increased power and corresponding dimensions

With the choice of type, everything is simple: we install a unit with a wet rotor. The parameters were calculated. But there are also such subtleties as marking and the size (length) of the pump.

How a pump with a wet rotor looks like, how “loud” it works, see the video.

Applications

The Wilo brand produces pumps that are designed for different purposes and therefore have different characteristics.

With the help of such a pump, you can water the beds directly from a well, well or the nearest reservoir.

Their area of application is extensive and varied:

- Wilo devices are used in heating systems in closed circuits.

- They are used in the water supply of private houses and in water production wells.

- Such pumps are also suitable for pumping groundwater when creating basements, cellars.

- They are also used at the construction site when working with polluted waters.

- The owners of private suburban areas have found good use for them, in particular, those who are engaged in the cultivation of plants on their personal plot.

The Vilo pump can operate in the most difficult conditions, and it does not matter what temperature the water circulating through the pipes will have and what the pressure will be.

You can connect the device yourself without any problems. For this, it is equipped with special spring terminals. It does not have a fan, so there is practically no noise during operation.

Pump selection methods

The most correct way is to make a full-fledged hydraulic calculation and accurately determine the main parameters of the pump - the developed head and productivity. This is how district heating for apartment buildings and industrial buildings is designed.

Not all masters involved in the installation of autonomous water systems, let alone ordinary homeowners, have an engineering calculation methodology. How can you choose a circulation pump for heating in a simpler way:

- In case of replacing an old worn-out unit, a new one with the same parameters is purchased. The price and quality of the product come to the fore.

- Order a project of a home heating system for a heating engineer. Below we will explain the advantages of this option.

- Calculate the required pump head yourself using a simplified method.

- Believe the long-term practice of our experts and buy a device, guided by their advice.

Boiler room made by our expert Vladimir Sukhorukov. Convenient access to all equipment, including pumps

Expert recommendations. In country houses and apartments with an area of up to 250 m², a domestic pump, which develops a pressure of 4 m of water column or 0.4 bar, is sufficient. For a square of 250 ... 500 m², it is better to buy a more powerful unit with a pressure of 6 m (0.6 Bar), over 500 m² - 8 m of water. Art.

Ordering engineering calculations and developing a circuit costs money, but it will pay off with interest.When you install heating yourself or hire workers, components and equipment are purchased with a decent margin - just in case. A sensible designer will clearly justify why you need to supply a low-power pump and a pipe of a smaller diameter. As a result, there will be savings on materials, and in the future - on electricity costs.

Varieties of pumps used in autonomous heat supply schemes

If you trust only numbers or want to check the installers, choose a heating pump according to your own calculations, using the method below. Do not forget to compare the calculated characteristics of the unit with the recommendations of experts - the result will most likely come out the same.

Varieties of circulation pumps

Wilo-branded circulators fall into two categories. Some of them may have a wet rotor, while others, respectively, dry. Those devices that are equipped with a wet rotor can be used in a heating system for a room with an area of 100 to 750 m², while the liquid circulating in the pipes can be heated up to 120 ° C.

In a cold climate, the presence of a heating system is simply necessary for a person to feel comfortable

Main technical characteristics of Wilo pumps:

- The minimum temperature that a heat-transfer fluid can have is minus 10 ° C.

- The head height of such devices can be from 2 m to 12 m.

- The speed value ranges from 950 rpm to 4800 rpm. The pumps have three different operating speeds.

- The weight of the equipment also varies. The lightest devices weigh just over 2 kg, while the heaviest can weigh up to 8 kg.

- The working parts of the motor are placed in the coolant, due to which it is lubricated and its operation becomes noiseless.

In rooms with an area exceeding 750 m², as well as in heating systems that serve not one, but several buildings at once, another type is used - equipped with a dry rotor. Their rotation speed does not exceed 3 thousand rpm.

What are the differences between devices of the "premium" category from cheap counterparts

The selection of a circulation pump for a heating system is made taking into account its technical characteristics and price / quality ratio. The most reliable are the products of the Danish concern Grundfos. The company is one step ahead of the competition with innovative pumping technology and unparalleled quality control of materials.

Note. Sometimes Grundfos is called German. In fact, the company has 40 factories located in different parts of the world, including Germany, Poland, Serbia, and Russia.

The prices for the products of this brand are quite high ($ 80-100 per unit), but the price is justified by the exclusive quality. The company's engineers are developing special alloys that are resistant to corrosion; make their products noiseless, insensitive to operating conditions and media quality. Also a good reputation with Wilo (Germany), Dab, Lowara (Italy).

Common labeling

When choosing a Wilo brand pump, you should pay attention to the letters and numbers that follow the main part of the name. Each of the letter designations indicates the type of product, and the numbers in the product labeling indicate its most important characteristics.

Drain TMW 32/11

This Wilo pump model is a vortex sump made of various materials. The device is capable of pumping slightly contaminated water (meaning those with the diameter of pollution particles not exceeding 1 cm).

Brief technical characteristics of the circulation pump fork Drain TMW 32/11:

- The maximum depth at which it can be used is 3 m.

- This device has overheating protection. In 60 minutes of operation, it will be able to pump 15 cubic meters. meters of water.

- As the name implies, the head height of this device is 11 m, the cross section is 165 mm.

Its average cost is 10,500 rubles.

Pump marking

In order to choose the right pump for heating in your home, you need to find out the marking.

Take, for example, the pump range: Wilo-Stratos, Wilo-TOP, Wilo-Star:

Wilo-Stratos.

Infinitely variable pumps:

- Stratos is a simple pump;

- Stratos-D is a double pump.

Wilo-TOP.

Infinitely variable pumps:

- TOP-E - simple pump;

- TOP-EV - simple pump with support armature;

- TOP-ED is a double pump.

Has 3 stages of switching of motor power:

- TOP-S - simple pump;

- TOP-SV - simple pump with support armature;

- TOP-SD - double pump;

- TOP-D is a simple pump with one switching speed of the engine power.

Pumps designed for FGP devices have 3 stages of switching the motor power:

- TOP-Z - simple pump;

- TOP-ZV is a simple pump with support fittings.

Wilo-Star.

Pumps with increased energy savings in the house have a stepless system:

- Star-E is a simple pump;

- Star-EL is a simple pump with an air vent pipe.

Has 3 stages of engine power switching:

Star-RS is a simple pump;

Star-RSD is a double pump.

Has 4 steps for switching engine power:

RP, P - simple pumps;

DOP - double pumps.

Pumps for FGW systems:

Star-Z they have 1 or 3 stages of motor power switching;

Star-ZE - continuously variable pumps.

The series of pumps for heating is followed by numerical designations, for example: Wilo STRATOS-Z 25 / 1-8:

- 25 - conditional passage.

- 1-8 is the minimum and maximum amount of water pressure through the pump (m / s).

There may also be special designations when ordering a pump individually:

- PN16 - permissible maximum working pressure in the sediment - 16 bar.

- RG - material of the pump casing which is made of bronze.

Where is the pump made

Pay attention to this icon on the plate, from it you can understand where exactly the pump was produced.

Many residents of the private sector are familiar with the phenomenon of cold batteries. This happens due to insufficient fluid pressure in the heating system. To solve the problem once and for all, it is necessary to select a water sediment for heating, which is mounted in the water supply system next to the boiler. How to choose the right device? What characteristics should you pay attention to? What brands of goods are in great demand on the market?