Any ventilation system consists of two parts: exhaust and supply. Exhaust ventilation is used to remove exhaust air from the interior, and supply ventilation provides fresh air from the outside. Both of these parts must work as a single system, otherwise the ventilation efficiency is reduced to zero. This leads to the emergence of a whole range of problems - from the deterioration of the health of residents, and ending with a reduction in the life of the building.

What happens in an apartment with plastic double-glazed windows

Most apartments in our country are naturally ventilated. Air supply is ensured by leaks in frames and door frames. Waste air flow is removed through ventilation holes in kitchens, bathrooms, lavatories. Such ventilation is sufficient if there are wooden doors in the dwelling and the integrity of the channels is not violated.

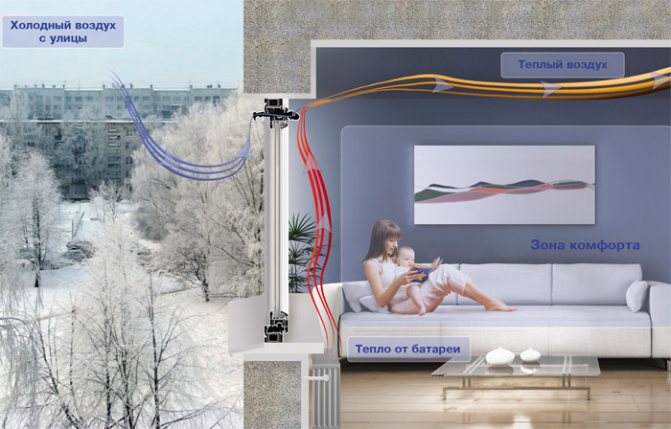

After the installation of PVC windows, even with well-functioning ventilation, changes are inevitable. After the cessation of the air flow, the channel in the kitchen or bathroom turns from the exhaust into the supply channel. The premises are filled with unpleasant odors from neighbors, the humidity rises, which contributes to the growth of bacteria and the formation of fungi.

Homeowners are forced to provide fresh air or other ventilation systems.

Determining the cost of installing a ventilation system

The calculation of the cost of installing ventilation implies taking into account all costs during the arrangement of the ventilation system. The total amount will be an order of magnitude higher if all the work is done by a master. When deciding to convert an old or install a new air exchange system, it is necessary to take into account a number of factors:

- area of the room;

- the number of people living;

- purpose of the premises (kitchen, bedroom, hall);

- location of housing, taking into account the cardinal points (north, south, east, west);

- the size of window openings, as well as their number.

This number of parameters will allow you to navigate in the choice of equipment if you plan to do the installation of ventilation yourself. For example, the total cost of organizing a ventilation system for a room consisting of two rooms with a minimum number of medium-sized windows facing the north side can be about 40,000 rubles.

However, it should be understood that with the expansion of the number of factors involved in pricing, the price of the required equipment will increase accordingly.

What are the functions of ventilation in an apartment with plastic windows

In rooms with wooden structures, fans could be installed in the exhaust ducts to improve ventilation efficiency. In winter, they didn't even need to be turned on due to the temperature difference.

Installation of plastic windows radically changes the situation. The air in your home can become more toxic over time than outside.

Of the simple solutions, tenants have four:

- regular ventilation;

- installation of electric fans in mines;

- installation of devices for micro-ventilation;

- installation of supply valves;

- installation of compact fans.

A plus of ventilation is the ingress of oxygen into the premises. But in the city it is supplemented by dust, noise, exhaust gases. This means that this method is short-term and ineffective.

Electric fans are suitable for kitchens and bathrooms. They are installed in waste shafts, turned on manually or automatically (when humidity rises or air quality decreases). These devices are offered by many manufacturers at various prices.

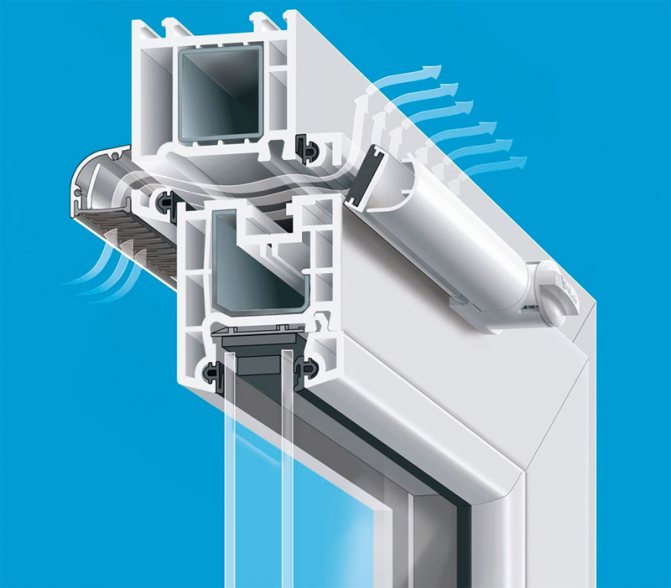

Micro-ventilation is the depressurization of plastic by installing a device into it that lets air from the street into the premises. In fact, this is the organization of slots and the installation of devices in them, the cost of which depends on the manufacturer and configuration.

The supply valves can be installed in the outer wall, at the junction between the window and the wall, in the profile, under the window board. These are plastic pipes through which the air flow from the street moves. The market offers models with different flow rates, which are regulated manually or automatically. It is best to hire a specialist to calculate the number and location of valves. To increase the efficiency of the supply unit, a fan is needed in the shaft.

Another option is an exhaust fan that blows out the exhaust air stream. It is suitable for the kitchen and can be used continuously or on demand. The check valve blocks the air flow from the street. Expensive models are equipped with sensors that turn on the fan at a certain level of contamination. For bathrooms and toilets, there are waterproof models for installation in external walls.

Specificity of the problem of supply ventilation control

At the moment, in our country and abroad, the most used in ventilation systems is a supply unit with a water heater. This is one of the "simplest" systems, at first glance. The choice stops at it when the financial investments in the ventilation system are small. Indeed, the required list of technological equipment for such systems is not large - this is an air intake grille, blinds, a filter, a water heater with fittings, a fan, a network of air ducts and automation. If we try now to find out which element in this list is the most reliable, then the answer will ask itself - something that has no moving parts and cannot be replaced, namely the heater. According to this logic, the largest number of failures should occur in the fan and the automation system. Is this so?

We will get the answer to this question in the process of discussing the problem.

Indeed, the water heater does not need frequent maintenance and the unit itself is reliable, but the quality of its operation entirely depends on the automation system.

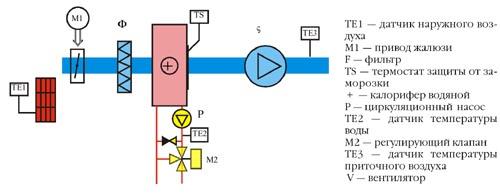

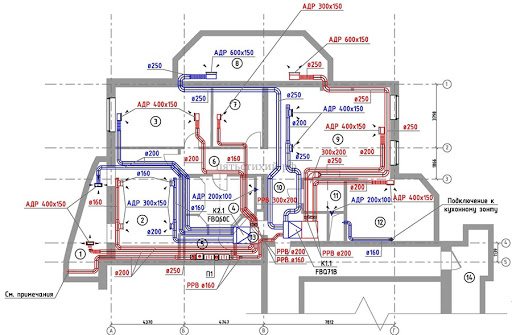

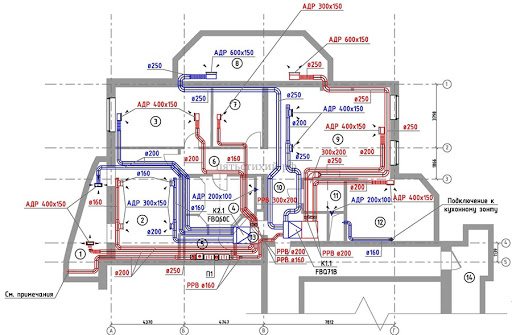

Let's take a closer look at the installation drawing.

This supply ventilation system works as follows: outside air enters through the air intake grille and, passing through the louver grill, enters the filter section, where it is cleaned from mechanical impurities and dust. Purified, it is sent to a water heater, in which it is heated by the heat of hot water from the mains of the network. Then the air enters the fan section, from which it is transported to the supply duct.

|

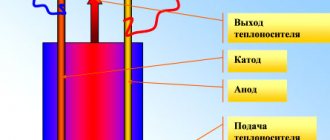

The piping of the heater, or rather the control valves, depending on the source of hot water, is presented in two ways:

a) when consuming from an urban network, where the return water flow rate is not fixed and there is only a need to maintain the return water temperature, a two-way valve is used,

b) when consuming from a local boiler room or boiler, where the return water flow is rigidly fixed and changes in it can affect the functioning of the network, a three-way valve is used.

The operation of the system, both in the first and in the second case, is practically the same. The difference is that in the version with a two-way valve, it is possible to completely stop the flow in the return line. This cannot but affect the saving of the coolant, but within the framework of this article we will consider the first and second methods to be equivalent.

Let's consider what functions the automation system should perform in this air preparation process:

- turning on / off the system (manually or by timer);

- maintaining the required air temperature in the supply channel with the fan turned on in the operating mode;

- defrost protection of the air heater;

- maintaining the return water temperature when the fan is off in standby mode;

- training start of the pump.

Let's divide the process of automation into three modes:

- pre-start warming up;

- launch;

- Work;

- standby mode.

Before proceeding to the description of the operation of the automation system in these modes, it is necessary to consider two problems: how we will regulate and with the help of what parameters we will carry out the analysis.

Let's go back to the setup diagram again. "Outdoor air sensor" - an outdoor sensor that indicates the ambient temperature. "Air temperature sensor in the duct" - a sensor installed after the fan section on the straight section of the air duct, which determines the temperature in the duct. "Return water temperature sensor" - a sensor installed immediately after the water heater on the pipe, indicating the water temperature. Note that for more accurate regulation, this sensor should be located as close as possible to the outlet from the heater, since in some systems, at low water flow rates in the circuit, strong inertia is possible. In general, for greater controllability and dynamics, it is desirable that the water circuit of the heating coil piping be as short as possible. For more reliable protection against freezing of the working medium during winter operation, a "frost protection thermostat" is installed after the heater. It is attached to the heat exchange surface of the air heater and is triggered when the temperature drops significantly or the air heater is overcooled by zones.

An important role in the control of the installation is played by the automation system, which includes a programmable controller, intermediate relays, starters and actuators.

As for the executive mechanisms, there can be any number of them. The main ones are: louver drive, fan contactor, pump starter and variable valve. As a rule, if there are no requirements for the rigid operation of the louvered grille (the impossibility of working under discharge), then its drive and the fan contactor are combined into single groups. The signal to turn on / off the fan is transmitted simultaneously with the signal to open the louver.

Before starting the system in the winter period of time, pre-start warming up is performed. At the first moment of time, when the system is not yet started (standby mode), the return water control function is maintained. To maintain this function, the valve is almost closed and opening the throttle valve and starting the fan during this period threatens to defrost the heater. Therefore, an important task at the time of warming up is to control the return water temperature sensor, in order to avoid a sharp drop in the supply air temperature. Warming up is also necessary so that at the time of start-up, already heated air is supplied to the duct, to create comfortable conditions in the room. Heating can be carried out both in time and upon reaching a certain temperature of the return water. In our opinion, the optimal solution is to warm up the water to a predetermined temperature, and the heating should be completed within a certain time interval. For the piping system of the heater, this means that the circulation pump is on and the three-way valve is operational.

After the system is warmed up, it starts and exits to the mode. At this time, it is very important to control the temperature of the return water, as it can begin to drop sharply, both due to the low outside temperature and due to a decrease in the circulation flow. It is also important to monitor the duct temperature during start-up.Therefore, we believe that the start-up process should be a curve of reaching the set temperature in the duct, based on the readings of two sensors: a return water sensor and a duct temperature sensor. Moreover, preference in control is given to the return water temperature, since the safety of the heater during winter switching on depends on it. Thus, at different points in time, depending on the readings of the sensors, the adjustable parameter can be both the return water and the temperature in the channel. As seen at the initial time (start), we control the return water temperature. What to do if it falls unswervingly? It would seem that it is necessary to turn off the system, and then start the startup procedure again. We suggest not to stop the system, but to make a short-term opening of the valve to 100%. Thus, we solve two problems: we save the system from the restart process and the time to enter the mode. If the temperature continues to drop after that, then the only solution is to stop the unit until the cause of the malfunction is clarified.

After approaching the preset temperature in the duct, the system enters the operating mode.

When the supply ventilation is turned off, the system goes into standby mode. Its main functions are to maintain the return water temperature and protect the heater from defrosting.

In our company we use two types of controllers: TAC Menta made in Sweden and TPM 33 of the Russian industrial association "OWEN".

TAC Menta is a freely programmable controller with a developed interactive environment that allows you to make mobile changes and corrections, both in the settings and in the body of the program. The program in it is presented in the form of blocks and a set of basic elements. Having a laptop (NoteBook) at his disposal, a specialist can interactively configure and correct the operation of the system on site.

The controller has a set of digital and analog inputs-outputs for connecting a complete list of the above devices. It also has expansion modules for connecting additional devices, such as differential pressure sensors on the filter and fan, water flow sensors at the request of the customer.

TPM 33 is a controller using the program described above. It is programmed using assembler for a specific supply unit. It has inputs for 3 temperature sensors, an input for remote start as well as outputs for damper and fan control, an analog output for valve control and an output for alarm indication.

The only drawback of the first controller is its cost.

The disadvantage of the domestic controller is the limitation on inputs-outputs and the need for a sufficiently large amount of initial information for the programmer.

What works for one system may not work for another, but the main points described above apply to them. Great results can be achieved by upgrading the program.

Grachev P.V.

Technical department engineer

Parameters and composition of forced ventilation

The best option is a split system for the whole apartment on the balcony, in the closet, in the hallway. During installation, it is necessary to take into account the need for maintenance and repair. The structure can be placed in the wall, under the ceiling, on the floor. The air flow from the street is supplied by a collector connected to the premises by air ducts installed in the suspended ceiling. The waste stream is removed from the bathroom, bathroom or kitchen. After connecting to the mains, such forced ventilation in an apartment with plastic windows works automatically all year round.

Before the development of the project, the dew point and air exchange are calculated in accordance with the requirements of SNiP.If the project is designed correctly, the balance is restored, which does not allow the formation of condensate.

The system can consist of:

- devices for forced inflow and natural exhaust;

- devices for forced inflow and exhaust electric fans;

- supply and exhaust device with a recuperator;

- supply valves and hoods.

The equipment is selected based on the characteristics of a particular apartment, preferences and financial capabilities of the customer. First, the dew point and air exchange rate in each room is calculated. Then devices are selected (supply valves with cleaning and heating, electric fans) and a project for the distribution of air ducts is developed.

Such a system is easy to adjust, fully provides the required air parameters, practically does not depend on external factors.

Drafting a project

In this case, it cannot be said that a high-quality project is easy to create with your own hands. Typical schemes also do not exist, the reason is simple, this is a wide variety of buildings, features of the location of premises in them. The design consists of 2 stages: the first is the development of technical specifications, the second is the selection of the optimal ventilation scheme.

Technical task

At this stage, the requirements for air exchange are determined: for its volume and type. Moreover, for each room of the house (apartment), there are certain parameters. It is always necessary to take them into account.

- Living quarters, rooms converted into gyms. They need a constant supply of fresh air. Its volume depends entirely on the number of residents in the premises. It is often required to take into account not only the volume of air exchange, but also the temperature and humidity of the supply air.

- Rooms are always "wet": bathroom, toilet, toilet, laundry. The best option would be "tandem" - natural and forced draft. The first will work all the time, and the auxiliary equipment only when needed. For example, when you turn on the lights.

- A kitchen is a room where moisture, soot, and fat regularly accumulate. She also needs a combination of natural and forced ventilation. The hood installed above the hob should be switched on while the appliance is in operation, when a significant generation of steam occurs during cooking.

- Boiler room, furnace room. In this case, the construction of a chimney is provided.

- Corridor, storage room. They imply natural ventilation.

- Garage, workshop. They need an autonomous system.

The development of the technical task can be done independently, or you can invite experienced specialists. They themselves will adhere to all standards regarding the speed and frequency of air exchange, which means that the owners will not have to deal with mandatory calculations.

Choosing the optimal scheme

What should be the ideal system? Convenient, functional, as efficient as possible. High-quality ventilation must meet several requirements.

- A good system is one that is understandable and enables owners with no special knowledge to easily and easily regulate the microclimate.

- The prescribed maintenance of ventilation equipment cannot create insurmountable difficulties that the residents themselves cannot cope with.

- The minimum number of complex elements is encouraged. In this case, the owners do not have to wait for the failure of any part of the system.

- The presence of a safety net. If a breakdown of the unit nevertheless happened, then a backup solution will be able to guarantee the further operation of the ventilation.

- Stealth. This requirement is one of the most important conditions, since any system should not spoil the interior of the rooms.

- The main line must have a minimum length, which means not too many air ducts, bends.

The choice of ventilation scheme also depends on other factors. They are:

- area of premises;

- materials of walls, floors:

- cleanliness or pollution of the outside air;

- financial capabilities of the future owners of ventilation.

The project must take into account the costs. However, he cannot contradict common sense. The main rule is maximum efficiency at minimum cost, but saving even on small things can lead to big troubles in the near future.

It is better for real estate owners to immediately take into account all the funds: both a one-time investment for the purchase of all elements of the system, and the amount that will be required for ventilation maintenance. This list also includes the cost of electricity spent on maintaining an optimal microclimate.

Do I need to additionally ventilate the frame house

The tightness indicators in a frame house are high if it is built using modern technologies. Natural ventilation works well only in winter, but it reduces indoor temperatures. For permanent residence, a compulsory system is required. By design, it does not differ from those that are mounted in apartments.

The type of system depends on the size and characteristics of the house. The most economical option is natural inflow and forced drainage. But such ventilation lowers the indoor temperature. Therefore, it is better to install an expensive structure that maintains the set temperature and humidity parameters.

All of the above does not apply to the house or country house in which they periodically reside. In summer, ventilation is provided by airing.

Scheme of organization of commissioning works

- Checking the performance of ventilation networks

Before starting commissioning, you must:

- get acquainted with the SLE project;

- get acquainted with the technological processes of production;

- familiarize yourself with the acts for hidden work;

- inspect the premises;

- inspect the installed equipment;

- check the conformity of the installed equipment to the design data and identify deviations;

- carry out work to identify leaks in air ducts and other elements of systems;

- check the presence and compliance with the requirements of the project of the thickness of the thermal insulation of the air conditioner sections, air ducts, pipelines and other equipment.

Based on the results of diagnostics, statements are drawn up for identified faults and deficiencies (lists of defects). Adjustment work should be carried out after the elimination of all identified deficiencies.

- Adjustment of ventilation and air conditioning systems

Inspection of the ventilation system should begin with measuring the actual pressure and air flow rate in the air ducts immediately before and after the fan.

If the actual performance of the ventilation units is greater than or equal to the projected one, then you can start adjusting the network.

If the performance is significantly less than that laid down in the project, then you should check the compliance with the project of the geometric dimensions of the network and achieve reworking of individual sections of the network in order to increase its throughput.

What does the lack of normal ventilation lead to?

The supply and exhaust system is considered normal if it provides the standard norms of humidity and air cleanliness in the room specified in SNiPs. This directly depends on its performance and the correct location of the supply valves. Unsuccessful arrangement of ventilation or lack of its capacity can lead to the following consequences:

- Increased humidity in the room. The walls get damp, drips form on the glass, water accumulates on the windowsills.

- Blackening in the corners. Moisture promotes the formation of fungal colonies, which settle in shaded areas.

- Deterioration of health. In a poorly ventilated building, pathogenic bacteria actively accumulate.In addition, mushrooms release microscopic spores, which give allergic reactions and complications to the respiratory organs.

- Damage to furniture and interior elements. Dampness contributes to the flaking of parts of wood boards, swelling of coatings.

- Excessive dryness in the room. The problem arises when there is no ventilation and the heating batteries are very overheated. It is hard to breathe in the house and the furniture is drying out.

Dry air is poorly tolerated by indoor plants; additional humidifiers are required.