How to properly wind flax onto threads and how to lubricate tow?

For the investment of metal threads, today, the following are used: sanitary flax, fum tape, anaerobic sealants. Each of the above materials for packing threaded connections has its own advantages and disadvantages.

For example, anaerobic thread sealants are highly adhesive. However, using this means for sealing the threads, it will ultimately be practically impossible to loosen the threaded joint in the future.

Fum tape is most often used with non-ferrous metal fittings: copper, brass and bronze. As for such material as sanitary linen, it, by right, has won a leading position, thanks to its considerable advantages. Among the main advantages of flax for thread packing, it should be noted low cost, excellent performance properties, and durability. Having once wound flax onto the thread, you can forget about leaks for a long time. Read about how to use sanitary flax on the website.

Linseed tow: features

Sanitary tow is a fibrous material that is used to seal threads. It is a completely natural product obtained from the primary processing of homogeneous, thin, long-fiber flax, which is extracted from the plant stem.

The scope of tow is very wide. Depending on the production technology, it can be tape, construction, jute and plumbing. Construction tow is a reliable way to isolate almost any connection. Fully combed short flax fibers are used for its production, and it is supplied in bales. This material is intended for construction work on sealing seams, laying and insulating log cabins. Being natural, linen is especially valued among those who build wooden houses. If construction tow is supplied in rolls of a certain width, then it is called tape. Linen tow tape is a material for caulking up to 1 cm thick. It is used for sealing seams and voids in log cabins, for laying crowns.

What is used for reeling? The classic version is good old flax (it is also called tow or hemp), fum tape, anaerobic sealants and Tangit polyamide thread.

There has been debate about what is best to use for many years, but no definite answer has been found. The fact is that the material is selected depending on the type of work and can be interchangeable and supplemented.

Let's talk about the advantages of flax for plumbing work:

- the main "plus" of linen tow is that its price is cheaper than any other material;

- it is used sparingly;

- its thin fibers are highly durable;

- with proper winding, it is suitable for any type of work with any joints, including for sealing cast iron and ceramic pipes;

- flax can swell, absorbing possible moisture, thereby hermetically blocking the path to leakage;

- high mechanical stability of the material allows you to fit the plumbing: without loss of hermetic properties, you can unscrew the connection by half a turn or a full turn.

The disadvantages of tow include the following aspects:

- since flax is an organic substance, it tends to rot under the influence of moisture and air that enter it, for example, during preventive examinations. For this, tow is always accompanied by additional material that prevents putrefactive processes (sealing paste, grease, oil paint, lithol and others);

- preparation of the thread is often required;

- too thick layer of material can lead to cracking of joints, especially from bronze and brass;

- this is a seal that requires knowledge of the rules of winding. On a whim, nothing good will come of it;

- accompanying materials in combination with linen can make disassembly difficult, for example, oil paint and silicone can make disassembly impossible;

- flax is not suitable for use where the temperature reaches 90 ° C. In such places, it "welded" over time and loses its sealing properties;

- if we are dealing with steel, then non-observance of the winding technology can even lead to corrosion of the thread.

Precautions

- It is not recommended to wind the sealant using two or more lengths - this will break the tightness and strength of the connection.

- The tape on the thread should not be partially unwound, since if it is applied again, the connection will lose its reliability. In case of unsuccessful winding, the material should be removed completely and the process should be repeated.

- If too much stress is created when connecting the elements, which can lead to breakage, it will not work to loosen the tape. In this case, you also need to reapply the seal, removing the old segment.

We suggest that you familiarize yourself with How much fish can be stored in the freezer

FUM tape is a material with sufficient reliability when sealing threaded connections. Its correct use will ensure the tightness of any pipeline, even for a person who does not have extensive experience in plumbing work.

How to choose linen?

The main thing is to pay attention to the quality of tow before buying it: flax should be sold, not tightly tied with a pigtail or a bay, be light in color, not have impurities, debris and lumps. There is also a tow, laid in the form of a skein of thread, from whose middle you can pull out a ready-made strand. The latter option is somewhat more expensive than the others. Be sure to pay attention that the tow is not too coarse and does not have an unpleasant odor.

In addition to flax, we purchase additional material. These can be “Multipack”, “Unipak” or “Greenpasta” sealing pastes, which serve to ensure that the tow does not deteriorate, does not burn out under the influence of temperatures and can be dismantled. The contents of the tube "Unipaka" is a light gray non-drying mass based on paraffin oil with an admixture of natural minerals.

If flax is not treated with anything, the tightness of the joint will be short-lived. In addition, the use of a paste allows for a slight adjustment of the twisting force.

It is strongly not recommended to use silicone sealant in contact with metal, as it contains acetic acid, which accelerates the oxidation process and, consequently, corrosion of the metal. Use neutral sealants. Suitable for various automotive, or designed to eliminate leaks of water, oil and other liquids.

What is fum tape and what it is used for

FUM tape, or fluoroplastic sealing material, is a thin synthetic seal produced in the form of a tape, usually having a translucent or matte white tint. Due to the content of fluorine, fum tape has a fairly high mechanical and thermal stability. It does not age, does not tear when stretched and does not lose its properties under the influence of aggressive chemical environment or high temperature.

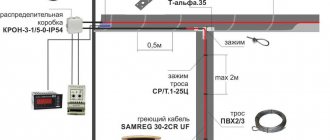

FUM 1: It is used for sealing general industrial pipelines or for systems operating with aggressive chemical media. It contains up to 20% vaseline oil as a lubricant;

How to wind tow on a new thread?

Before starting work, let's prepare the turns. Today, many manufacturers produce threaded fittings with a notch, that is, specially designed for winding flax.The fact is that along the smooth thread during installation, the flax will slide off, knocking into a clump, and the sealing process will be disrupted.

- In order for the fibers to have something to cling to, there must be jags on the coils. They can be applied with a file, a file, a metal hacksaw, using pliers or a plumbing wrench, grabbing the thread and applying serifs with light pressure. The main thing is to achieve a slight roughness on the turns.

- Now we separate one strand from the flax braid. Try to grab enough fibers so that the winding is neither too thin nor too thick. It is believed that its thickness should be like one, maximum two matches. If you notice lumps, small villi in the strand, they need to be removed.

- How to apply is an individual matter. Someone twists flax into a bundle, someone braids it into a weak pigtail, someone puts it loose, as it is, a strand.

- The procedure for applying additional material can also be different: you can lubricate the thread with it, wrap it with fibers, and then apply another layer; you can soak the fibers of the tow in advance, and then wind them up. Both options are correct. Someone recommends winding the strands along the thread, someone is against it, there is no single rule here.

- We pinch the end of the strand with a finger outside the turns, making the first turn crosswise to secure the tow.

- Then, as tightly as possible, without making gaps, loop to loop, we wind the flax. Such a nuance: if you connect, for example, a steel sleeve and an iron pipe, then an excess of flax will simply be squeezed out of the fitting, due to its power. Brass connections, especially of modern production, will simply burst from strong pressure.

- We take a small amount of plumbing paste or other sealing material and distribute it around the wound flax with rotational movements. We try to keep the work neat.

- We glue the other end closer to the edge of the thread with an accompanying material.

- Before tightening, be sure to check if the pipe hole is clogged with flax.

- We twist with moderate effort. If the nut goes too easily, it means that little flax was put in. If the winding is done correctly, the linen should not come out and it should be clean around the connection.

Advice: for gas compounds, it is not recommended to use organic tow in combination with silicone, since these materials are destroyed under the influence of gas. The use of fum tape will be most appropriate here.

Anaerobic gel sealants santechgel

Another modern material for sealing pipe threads is santechgel. Reliable sealing is due to the polymer component of the gel. After hardening, sanitary gel does not shrink or expand, is resistant to temperature changes (from -60 to 150) and pressure surges, has proven itself well in various media: water, natural and liquefied gas, heating antifreezes.

How to seal the plumbing connection: flax, fum tape, anaerobic sealant - the specialist decides

Santekhgel is produced in three types:

- In green tubes - easy dismantling.

- In blue - medium dismantling.

- In red (Stop Master Gel) - heated dismantling.

Installation using santechgel is simple: shake the tube and apply the gel in a thick layer along the entire circumference of the thread, distribute it evenly (with a brush, a special spatula), and assemble the structure. Remove excess gel with a cloth. Gel polymerization takes 15–20 minutes.

How to wind tow on ecoplastic products?

Like brass threads, plastic also tends to burst. Therefore, the main thing is not to overdo it. Connect both fittings by counting the number of turns before winding. Then wrap the flax evenly, coat it with additional material, and connect the fittings. If there were 5 "idle" revolutions, then make about 4.5 revolutions - you do not need to reach the end.Note: In this case, it is preferable to use investment paste instead of sealant.

If you feel very tight when tightening, disassemble and wind less tow.

Material properties

The main advantage of fluoroplastics is their high plasticity.

In addition, the material is durable, non-toxic, chemically inert, and thermally stable.

FUM-tape is capable of operating at pressures up to 40 MPa (relevant for antler baths).

The temperature range is minus 60 - plus 200 degrees.

When heated above 260 degrees, the destruction of the structure of the material begins, and highly volatile fluoride compounds are released.

Average material characteristics:

- thickness 0.04 - 0.2 mm;

- width - 10, 15, 20, 60 millimeters;

- fracture tension 40 - 60 kg / cm2;

- grease content 0.3 - 20%;

- 100% elongation before breaking.

How to work with an old fitting?

If the package leaks or it is required to dismantle the connection for other reasons, after unscrewing, inspect the thread. At the “mother's” we go through the turns with the edge of a knife or an awl, removing all the accumulated debris.

We also pick out the contents of the "father" with a knife, cutting off the remains of the tow together with the sealing substance. We clean the turns with a metal brush until shine appears. With its tough lint, it removes dirt, rust and sealant residues in the most inaccessible places. If the used thread is damaged, it will be useful to drive it out on the "father" with a threading tool, and on the "mother" to correct it with the tip of a knife.

Further, the packing process continues according to the indicated scheme.

Preparatory stage

Before winding flax or tow on the thread, you need to prepare the joint surface and determine the required amount of tow. Screw the fitting onto the threads as is, without winding anything. This will help determine how much tow will need to be taken.

If the thread is smooth and even (in the case of factory cutting, it most likely will), it is recommended to apply notches on the threads for better adhesion. For this, a water wrench, naphthyl trihedron or ordinary pliers are suitable; all that needs to be done is to cut across the thread without being too zealous. This is done to prevent the tow from sliding along the threads.

The notches should not be too deep, you do not need to literally tear the metal (watch the video). How the tow is correctly wound will determine the reliability of the connection in the future. If you put too little and rarely, it will leak, the excess amount can be much more dangerous - a too tightly wrapped section can burst when the temperature rises (as you know, the metal expands when heated).

Order sanitary flax wholesale

carries out wholesale and retail trade, and is also a manufacturer of sanitary flax (tow) supplied to private plumbing stores and large DIY stores. We provide a detailed price list for the entire assortment, have ample opportunities for payment and delivery, and also provide advice on any issue. Over the years, we have established partnerships with many stores and suppliers.

Our experts will help you organize your own business and select the necessary products.

Still have questions? Call or write - we will answer. Phone: +7 E-mail Address: St. Petersburg, st. Zastavskaya, 5/1.