Circulation pumps for heating and air conditioning systems

This three-speed pump is designed to operate in heating systems with stable or low-variable flow rates. Depending on the needs of the network, using a simple and convenient switch, you can set the required speed. Thus, from the many UPS Series 100 pumps, you can easily select the size that best suits your system.

SOLAR series

Grundfos Solar pumps are single-stage circulation pumps equipped with a glandless electric motor. The pump and the electric motor form a single unit. The ceramic rotor bearings are lubricated with the pumped liquid. Grundfos Solar pumps are designed to circulate the heating medium in solar heaters for hot water systems. They are also used in application, refrigeration and air conditioning systems.

UP series 100 FOR DHW SYSTEMS

Single-speed UP pumps with a body made of brass, bronze or stainless steel are used to circulate drinking water in hot water supply systems. A timer with day and week scales and a temperature switch are available as an option.

ALPHA + series

The characteristics of Grundfos Alpha + include those of most circulation pumps used in single-family homes. This greatly simplifies the selection of pumps. Grundfos Alpha + works in any heating system (one-pipe, two-pipe), and in the bronze version - in a hot water system.

The pump operates in any of three modes: - proportional control; - constant pressure regulation; - fixed speed.

A modern heating system maintains the required temperature in each room with the help of automatic thermostats that react to the outside temperature. It is for such systems that circulating pumps with built-in automatic regulation (Grundfos Alpha +, UPE) are needed. They change the speed depending on the needs of the system. Thus, up to 60% of electricity is saved, and hydraulic noise in pipelines is reduced.

How to choose a pump for DHW

When choosing a pump, it is necessary to take into account the technical characteristics of a particular model. This will allow you to purchase a recirculation pump that is suitable in terms of its parameters for a specific hot water supply system.

When choosing, take into account:

- noise level. The noise level may differ depending on the model. For living quarters, it is better to choose a quiet pump;

- the pressure of the supplied liquid. Measured by the maximum height of the water column. If the DHW circuit is located in the same horizontal plane with the pump, models with a column height of 50 - 80 cm are suitable. For tall buildings and structures, this parameter must be taken into account with a margin;

- electricity consumption. Depending on the pump model, its power ratings may vary.

What is important to know

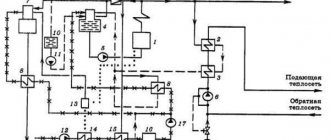

The wiring diagram and methods for connecting a device such as a circulation pump to electricity can be of various designs. The choice of a specific option is determined by the characteristics of the heated object, as well as by the place where the device is located. There are two ways to connect it:

- direct connection to the 220 V power grid;

- connection to an uninterruptible power supply, which in turn is connected to a 220 V or 220/380 V network (in the case of a three-phase UPS).

Choosing the first method, the consumer runs the risk of being left without heating in the event of a prolonged power outage.This option can be considered justified only with a high degree of power supply reliability, which reduces the likelihood of a long power interruption to a minimum, as well as, if there is a backup source of electrical energy at the facility. The second method is preferable, although it requires additional costs.

Automation for pumps

Devices for controlling and regulating pumps are of two types:

- mechanical;

- electronic.

The pressure switches installed in mechanical systems and the compulsory hydraulic accumulator ensure the operation of the pump. But, the mechanical system with long-term water intake is constantly exposed to pressure drops, which has a bad effect on the technique when using instantaneous water heaters. In addition, hydropneumatic systems require constant adjustment of the automation. But such devices are quite easy to use, reliable and cheap enough.

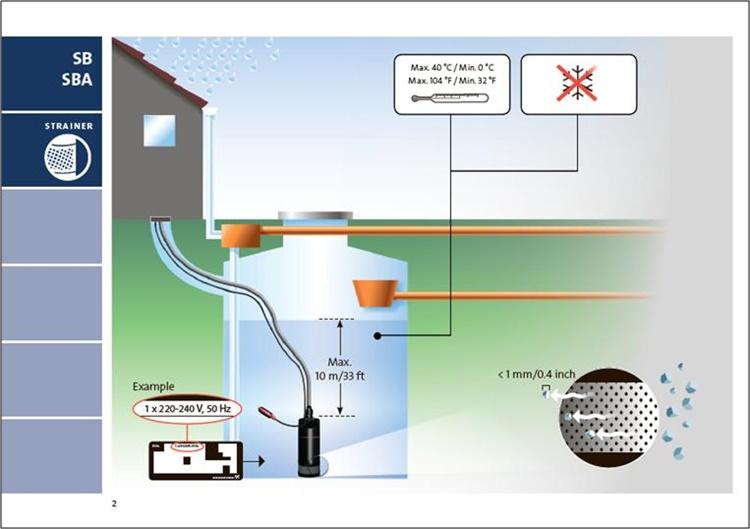

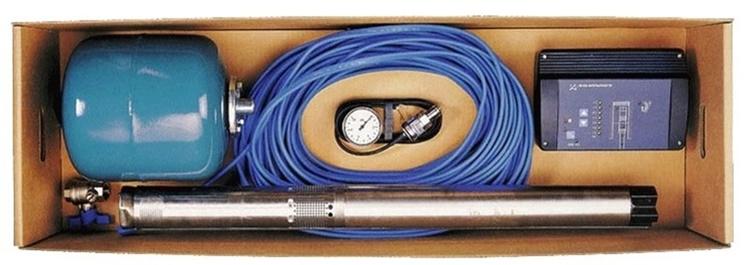

Set for automatic water supply with Grundfos automation

Hydrocontrollers, which are installed in electronic blocks, themselves track the movement of water in the pump system through flow sensors. This allows you to remove the accumulator from the electronic circuit of the device. In addition, with the help of a hydraulic controller, it is possible to significantly increase the water pressure, which could not be done in devices with installed pressure switches.

Automation for pumps Grundfos

The model range of Grundfos automation (Grundfos / Grundfos) is represented by several devices:

- automatic adjustment devices;

- control cabinets;

- complex protection devices.

For example, devices for automatic pressure control (PM1 and PM2) can be produced in several modifications. The PM1 device is a model of a pressure regulation system in the basic configuration, which automatically starts up at a preset pressure of up to 2 bar. The model has a built-in dry-running protection system. By the way, RM stands for Pressure Manager.

Model Grundfos pm2 - provides the ability to adjust the pressure regulator for various types of water supply systems in the range of 1.5-5 bar. The Grundfos pm2 automation unit is equipped with:

- convenient and intuitive interface;

- voltage range selection system;

- outlet pipe (rotating);

- protective and adaptive functions (including dry running);

- built-in hydraulic tank;

- indicators of working and emergency conditions.

In addition, the Grundfos pm 2 pressure regulation system can be powered by gasoline powered generators.

Selection of popular manufacturers

There are many manufacturers on the market, and the products of most of them are of fairly high quality. But there are also companies that are in this area, what is called "the dog ate" and their products, if not ideal, are close to this. It will be about the companies Grundfos and Wilo.

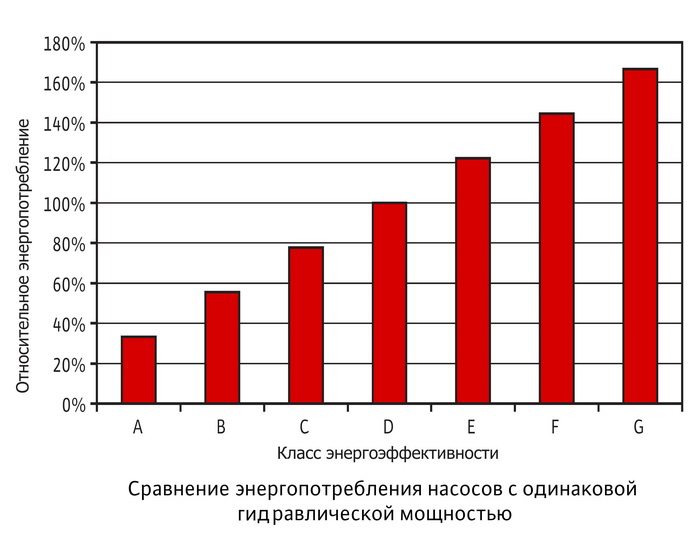

Grundfos circulating pumps

Grundfos is a Danish manufacturer, and the first Grundfos heating pump was released back in 1959 and since then the company has been improving the design of the device every year. It is also worth noting that it was this manufacturer who was the first to propose a modern classification of such devices for energy efficiency, before that no one simply thought of applying such a criterion to conventional heating circulation pumps.

Energy efficiency classification adopted by Grundfos

On the product side, the entire range can be commended for its fairly wide adjustment capabilities and excellent energy efficiency. Energy consumption is several tens of times less than that of outdated unregulated pumps.

Separately, it is necessary to note the proprietary Autoadapt technology, which the models of the upper price category are equipped with. When this mode is activated, the pump itself will find the optimal ratio between the temperature in the room and the coolant current.

In order not to list all models of devices from this manufacturer, we will focus on several popular series:

- pumps for heating Grundfos 100 series - due to their quietness, they are often used in autonomous heating of private houses and apartments. The rotation frequency is set manually using a regulator (a total of 3 operating speeds of the rotor);

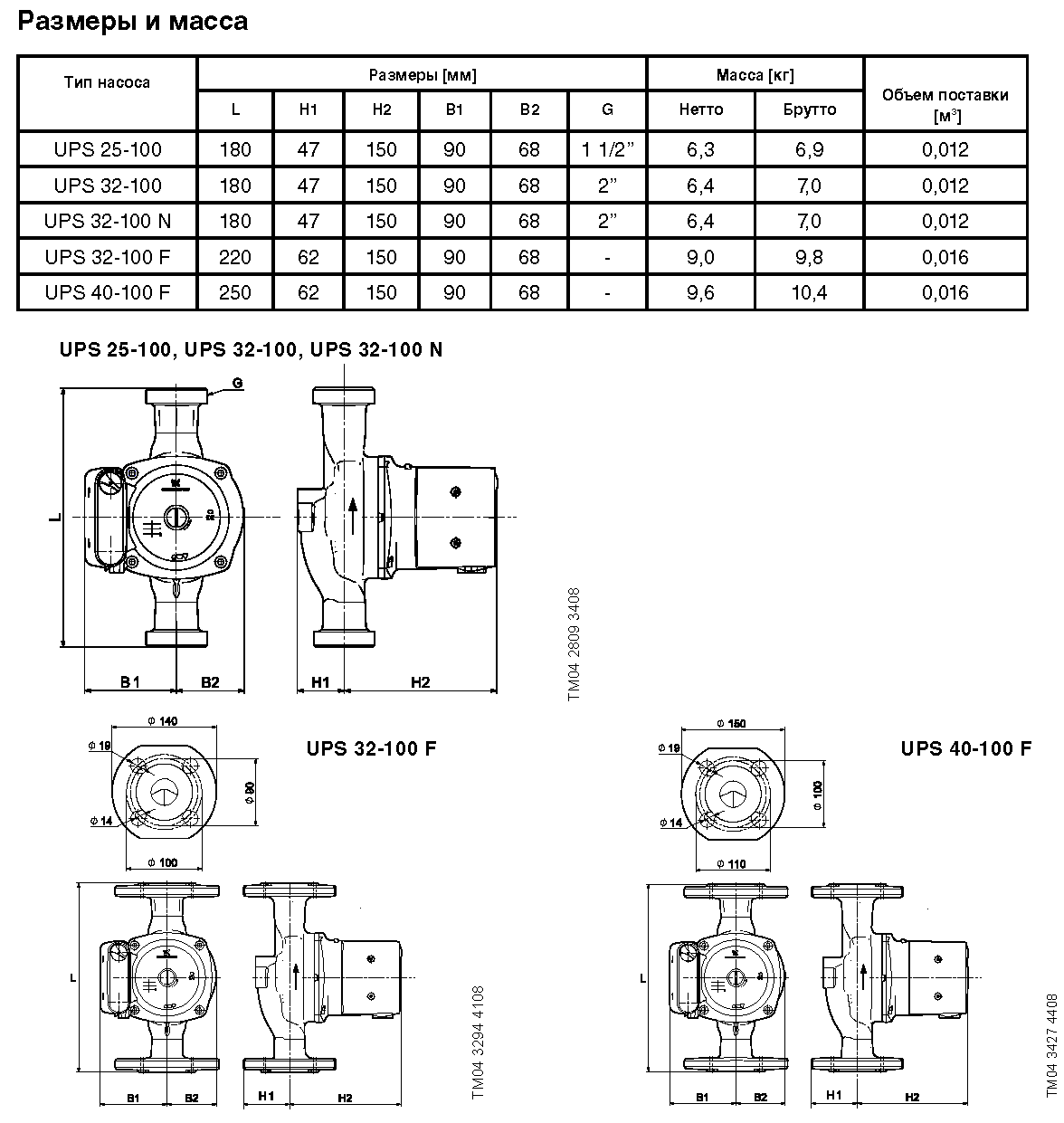

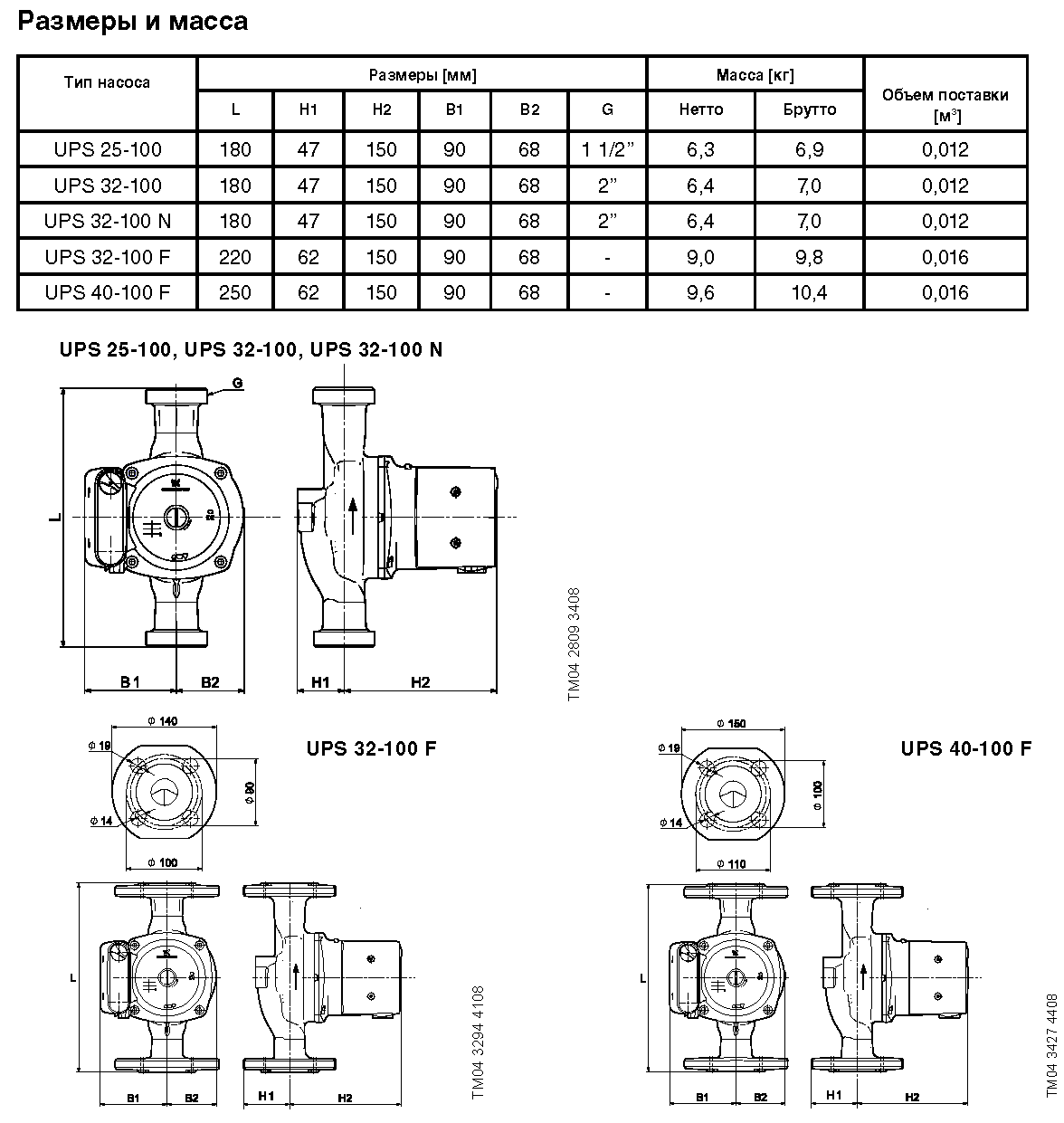

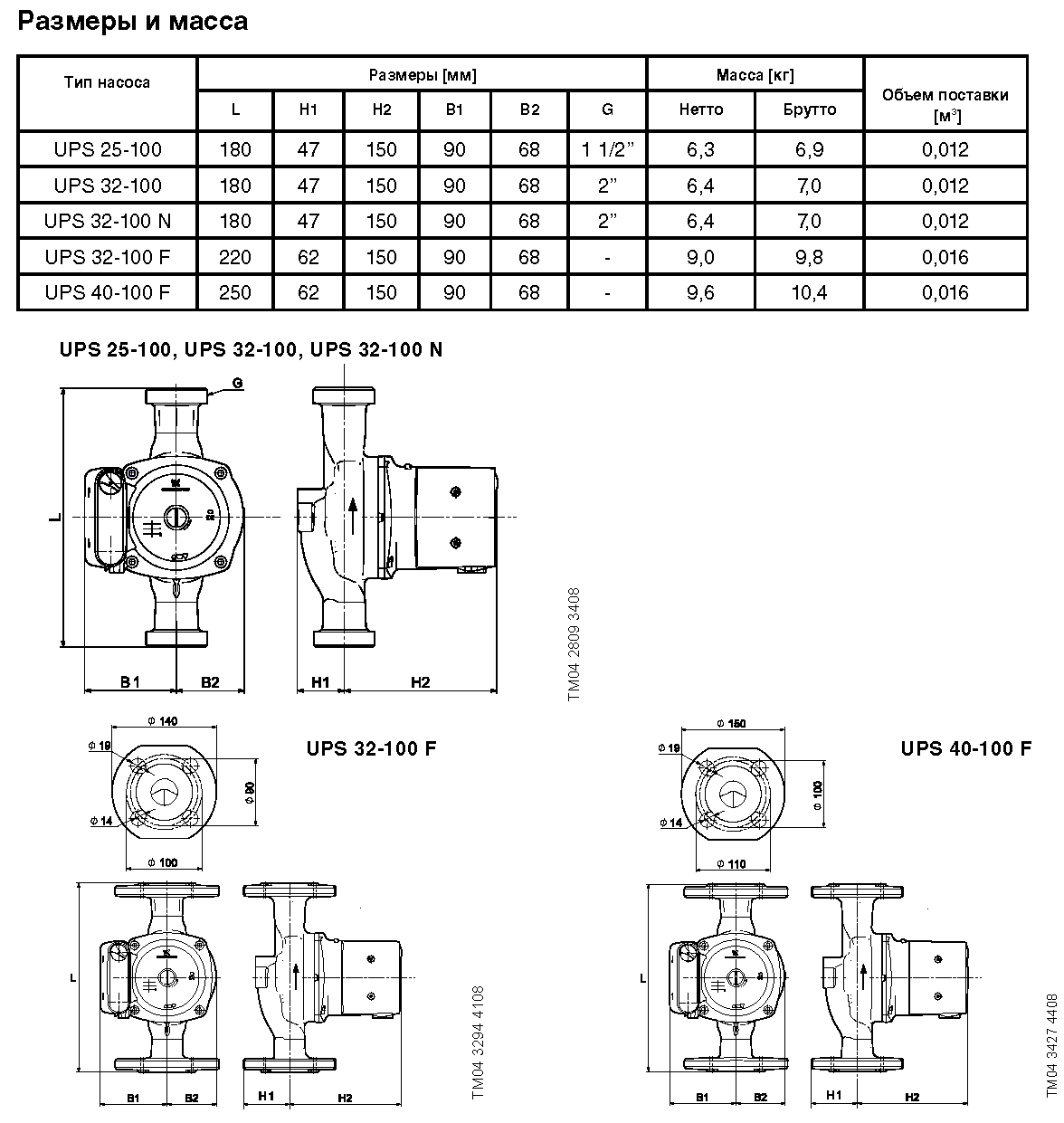

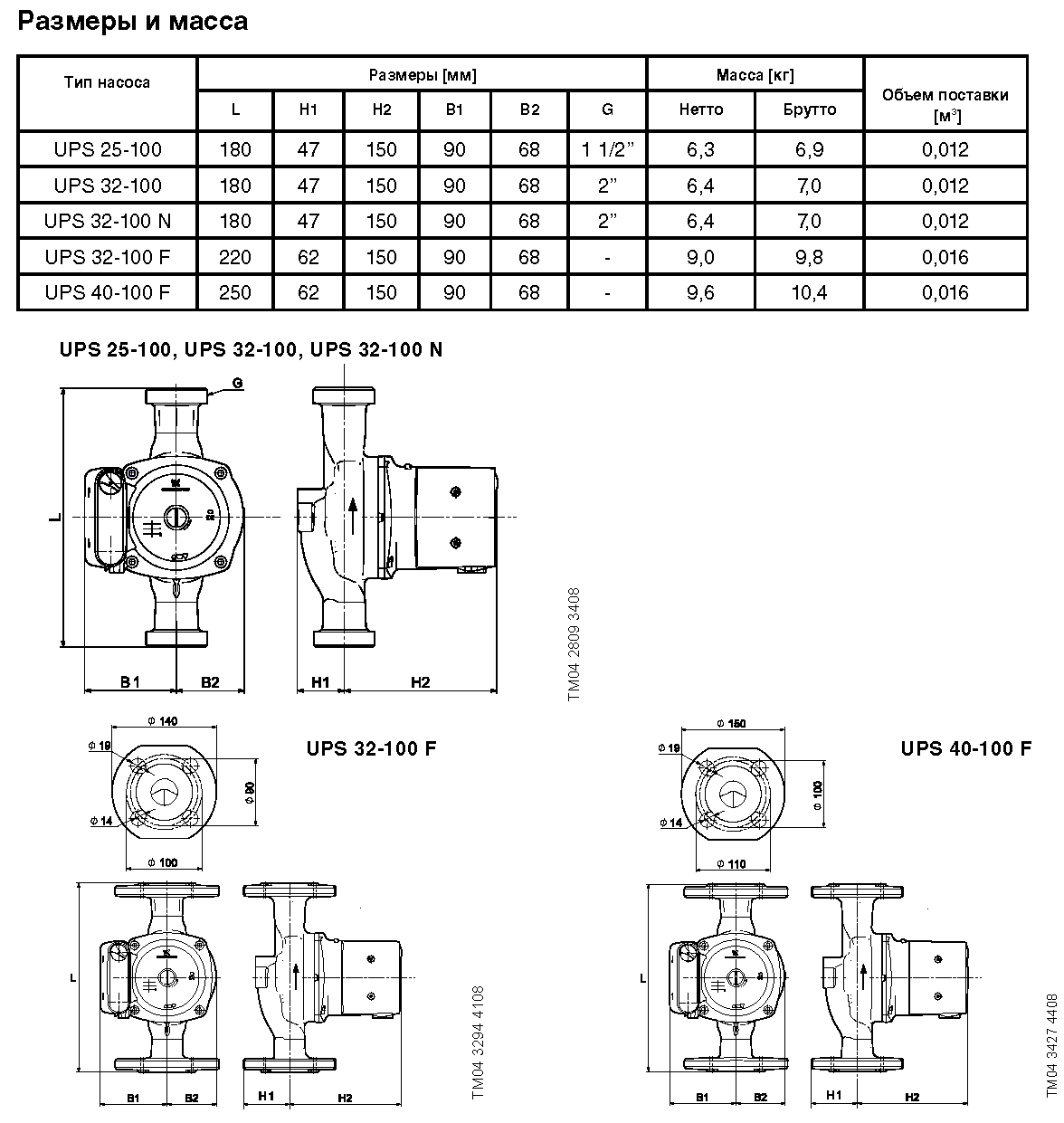

Features of some models in the 100 series

- 200 series - can be considered universal, such devices can be used not only in heating, but also in building air conditioning systems. If they are used in hot water supply systems, you will have to purchase a thermal relay, which will provide protection against overheating;

200 series models

- pumps for hot water supply - it is worth noting the UP (1 operating speed) and UPS (3 operating modes) models. Considering the working conditions, the body of such devices is made of steel or bronze.

In general, all models of this manufacturer are created in order to make the installation and operation of the device as easy as possible for a person. The installation instructions are to simply connect the pump with threaded connections on the section of the pipe that feeds the cooled coolant back to the boiler.

Pumps from Wilo

If we compare Wilo pumps for heating with the same Grundfos, then there will not be so many differences. The German manufacturer has perhaps a much more impressive development history - the company was founded in 1872, but the quality of the products is comparable.

The products of the German manufacturer are also distinguished by their durability, efficiency, high efficiency, flexible regulation and a multi-stage protection system.

Such series are quite popular:

- Star-RS - most often used in private construction, such a device is used with a house area within 200-750m2. Since pumps of this series can also be used in air conditioning, the operating temperature range is in the range -10ᵒС - + 110ᵒС;

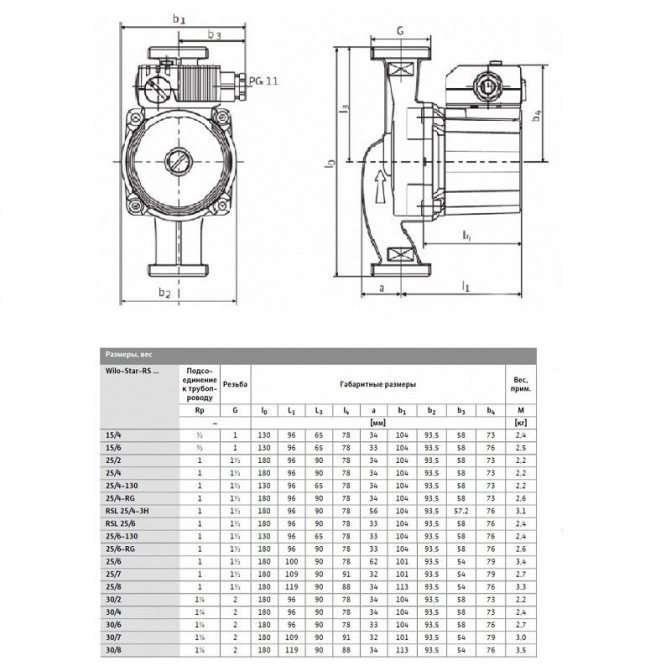

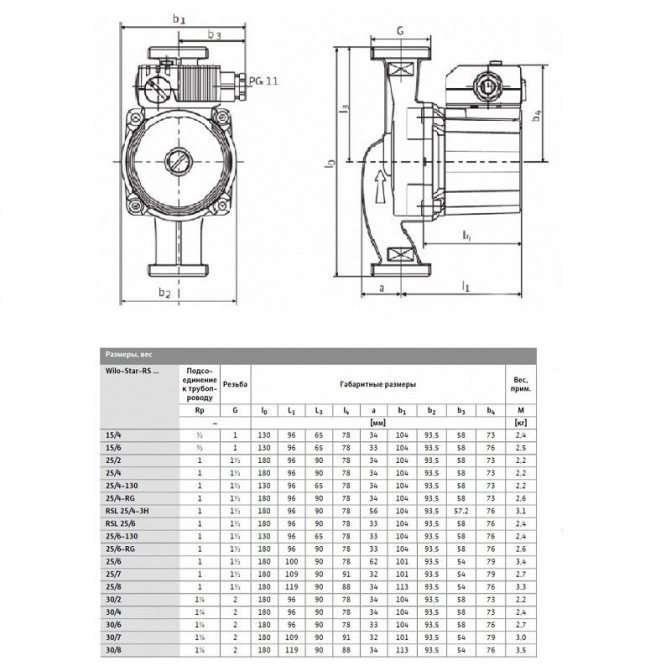

Characteristics of the Star-RS models

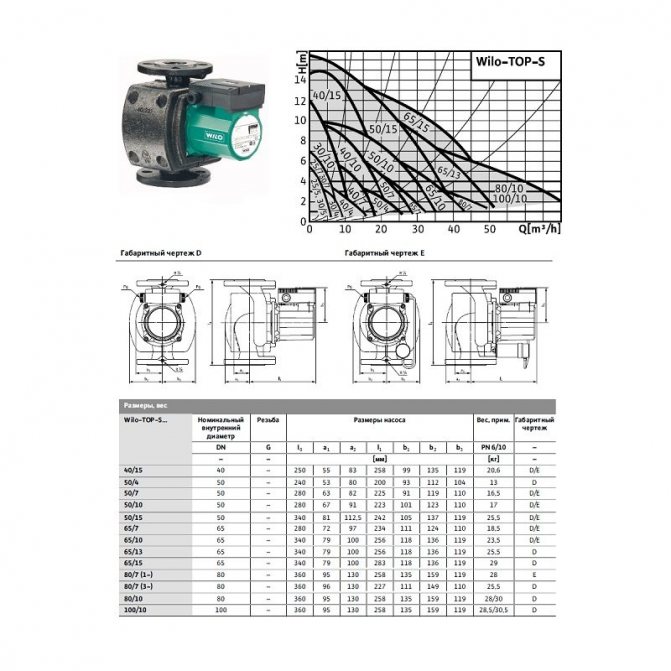

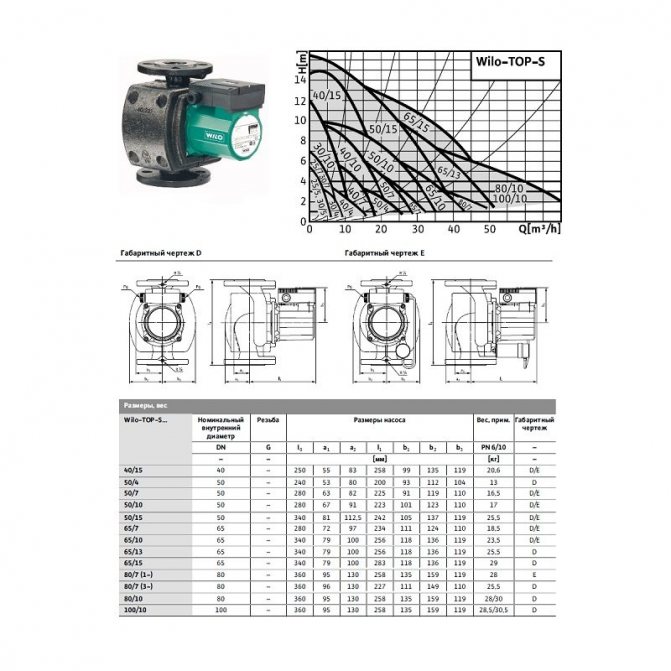

- The Wilo heating pump of the Top-S series is used in heating systems for heating large areas, about 1000 - 1400 m2. The operating temperature range is within -20ᵒС - + 130ᵒС, it can work in 3 modes.

Features of Top-S models

- The Stratos and Yonos series use electronically commutated motors so that the operating mode changes automatically. They can be used in heating systems of both private houses and industrial workshops.

Grundfos Upa pressure booster systems and their design

Their common parameters will be the following mandatory characteristics:

- wet rotor;

- their cast iron body with an anti-corrosion compound;

- ceramic bearings.

The rest of the models may differ slightly.

Pump for increasing the pressure in the water supply system

Grundfos Upa 120

There is a dual-mode control switch here: manual and automatic. This is necessary in order to ensure the operation of the equipment regardless of the presence and serviceability of the pressure / fluid flow sensor. If there is no sensor, the manual (forced) mode is set for the device. If there is a sensor in the pipe, the pump will turn on in automatic mode only when the water flow exceeds 90 liters per hour.

This model does not come with a flow sensor. You will need to buy it separately. But this installation can be used to connect to the water supply system directly and for open water systems.

The noiselessness of the device is achieved due to the internal cooling of the rotor, and, therefore, the absence of a fan. Therefore, it can be installed in apartments and houses without worrying about additional sound insulation.

With its relatively low power of 235 W, the device is capable of generating a head up to 13 meters. And the protection of the cable against short-circuits reliably protects the operation of the electric motor.

Uninterrupted operation is guaranteed at air humidity up to 95% and air temperatures from +2 to 40 ° С, in the range of water heating from 2 to 60 ° С and at a minimum pressure of 0.5 bar on the branch pipe. Water consumption during normal operation is up to 2.8 cubic meters per hour.

Grundfos UPA 15-90

The model 15-90 grundfos pressure boosting pump can be used for direct piping installation due to its in-line design. Built-in protection against running without water (dry running) automatically turns off the pump in case of interruptions in the water supply.

Three-position terminal box: full shutdown (OFF), automatic shutdown with installed water flow sensor (AUTO) and manual control of the system (MANUAL), which puts the unit in forced operation mode.

In this model, unlike the 120th, there is a built-in sensor, which is also called a flow switch. The noise level peaks at 35 decibels. The pump is designed without the use of oil seals. The rotor type is wet. The installation type of the device is vertical.

The power of the device is 118 W and the head is 8 meters with a throughput of up to 1.5 cubic meters per hour. The maximum water temperature is 60 ° C. The system is equipped with protection against voltage surges and overheating due to an increase in water temperature, and monitors the water level in the device automatically.

Rules for installing a pump to increase pressure

What you need to remember when connecting any pump:

- be sure to ground the connector;

- squeeze out excess air;

- turn on for the first time in auto mode.

Control cabinets

They are installed to control groups of pumps operating in heating complexes and complex water supply systems. Controller for the pump, which in the drawings will be designated as a module of different series (cu 100, cu212, cu 300, cu 301, cu 352).

For example, the Cu 100 model control cabinets in a plastic casing, which provide an IP 54 protection level, are suitable for single-phase (up to 9 A) and three-phase (up to 5 A) pumps. Cu 100 for three-phase motor are supplied with a float switch as standard.

The electronic equipment of the Grundfos Cu 212 is equipped with liquid level indicators and can be operated alternately with two pumps. The emergency warning system is triggered by an audible signal. The device can work in automatic and manual mode.

Grundfos Cu301

The device provides complete control and management of the entire pump system. It makes it possible to control devices remotely using the remote control and monitor possible emergency situations that may arise due to overheating or overvoltage. This system is designed for well pumping equipment.

Automation Grundfos Cu301 in the water supply system

Comprehensive protection devices are designed to monitor voltage surges, monitor overloads and overheats. The automation unit is designed for two versions of pumps (one and three-phase) with a voltage range of 3-120 A (if an external transformer is connected). The devices can operate flawlessly at temperatures ranging from -20 to + 40 ° C.

Automation for heating systems

Alpha 2 grundfos are specially designed for use in hot water and heating systems. The pump casings are made of stainless steel and equipped with frontal control panels.

They work in the "auto" mode in order to independently adjust the level of productivity depending on the needs of consumption at different times of the day.

Pump control

Circulation of water around the clock in the system is economically disadvantageous. Depending on the control method, there are 2 types of recirculation pumps:

- Controlled by the control unit based on the readings of the temperature sensor. Recirculation of water in the system is carried out as it cools. The sensor is installed in the hot water circulation circuit.When the temperature of the liquid is within the specified limits, the rotor of the electric motor and the impeller that is pumping the liquid stop. As the indicator drops, the pump automatically turns off. This allows the fluid temperature to be constantly maintained within the desired range.

The pump is controlled by the controller, depending on the outdoor temperature - Timer controlled. The DHW recirculation pump is automatically switched on and off after a certain period of time. The time interval between operations is set by the user. In this case, it is necessary to calculate the length of the circuit, the speed of fluid movement and the presence of heat loss. Depending on the model, the device can be programmed for 24 hours or 7 days.

Connection methods

Electrical connection with plug and socket. This method involves installing an electrical outlet in close proximity to the place where the circulation pump is installed. Sometimes they can come with a connected cable and plug included, as in the photo:

In this case, you can simply plug the device into the mains using an outlet located within the reach of the cable. You just need to make sure that there is a third, grounding contact in the outlet.

In the absence of a cord with a plug, they must be purchased in addition, or removed from an unused electrical appliance

Pay attention to the cross-section of the conductors of the cord. It should be between 1.5 mm2 and 2.5 mm2

The wires should be copper stranded to resist multiple bends. A cord with a plug for connecting electrical appliances to the network is shown in the photo below:

Before connecting the circulation pump, you need to find out which of the three wires of the cord is connected to the grounding pin of the plug. This can be done with an ohmmeter, while checking the integrity of the remaining wires.

Open the terminal box cover. There are three terminals inside the box, designed to connect the device to the network, with the designation as in the picture:

We unscrew the clamp of the cable box (in the first photo it is a plastic nut into which the cable is inserted), put it on our cord, put the cord into the box. If there is a cable clamp inside the box, thread the cord through it. We connect the ends of the wires of the cord pre-stripped from insulation with the terminals.

You need to connect the wires connected to the plugs to the L and N terminals (do not be afraid to mix them up, this is not critical), to the PE terminal you should connect the wire of the grounding contact of the plug (but you cannot be mistaken here). The instructions supplied with the product prohibit using it without protective grounding. Next, tighten the clamp (if available), tighten the cable gland clamp tightly, and close the terminal box cover. The pump is ready to be connected to the mains.

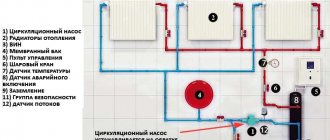

Fixed connection. The diagram for connecting the circulation pump to the mains with grounding is provided below:

The requirements for the cross-section of the wires are the same as in the previous version. With this installation, the cable can be used both flexible and inflexible, copper, VVG brand, or aluminum, AVVG. If the cable is not flexible, the installation must ensure its stability. For this, the cable is secured with clamps along the entire route.

In this version, a residual current device (differential circuit breaker) is used. Instead, you can use a conventional single-pole circuit breaker, passing only the phase wire through it. If the machine is installed in a panel where there is a PE bus, then the cable from the pump to the machine must be three-core. In the absence of such a bus, the PE terminal should be connected to the grounding device. This connection can be made with a separate wire.

Separately, I would like to consider such an installation option as connecting a pump to a UPS. It is the most preferred and ensures the independence of the heating system from power outages.The connection diagram of the circulation pump to the uninterruptible power supply is provided below:

The power rating of the UPS should be selected based on the power of the pump motor. The capacity of the storage battery is determined by the estimated autonomous power supply time of the circulation pump, that is, the time when the power grid is disconnected. We talked about how to choose a UPS for a boiler in a separate article. Requirements for cable cross-section, as well as for the presence of protective earth, apply to all connection options.

Finally, we recommend watching the video instructions for connecting various pump models to the electrical network:

Grundfos

Wilo Stratos-PICO

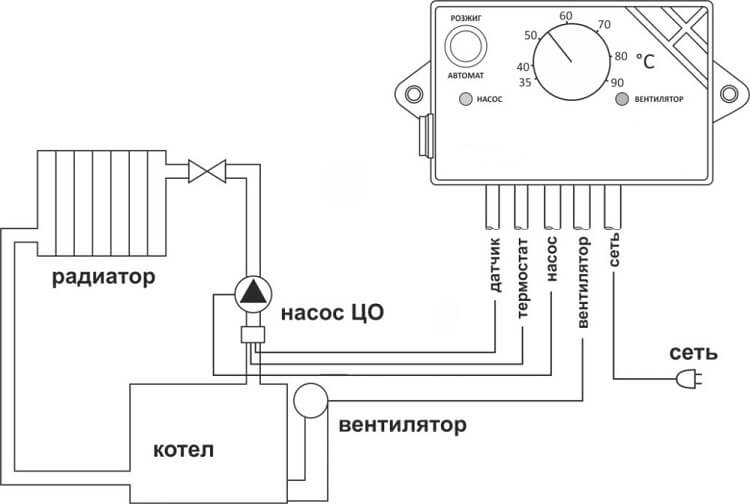

Connection diagram of the circulation pump to the thermostat

So we examined how the circulation pump is connected to the mains correctly. The diagram and video examples helped to consolidate the material and clearly see the nuances of the installation!

Varieties of devices

If we consider the range of the company, then the following types of grundfos pumps can be distinguished in it:

- Dry rotor.

- Wet rotor.

Dry rotor

One of the features of this type of pumping equipment is its high efficiency. In addition to this, it has a lot of power. Similar grundfos pump models are designed to work with a large volume of liquid... For this reason, they are common in manufacturing plants or are used in heating systems of large buildings. But for residential buildings of a private type, they are used extremely rarely.

If we consider the design of this device, then it excludes the contact of the rotor with the liquid, which determines the name of these pumps. A cuff serves as a separator between this part and the chamber in which the fluid circulates.

When operating dry-type Grundfos circulation pumps, keep in mind that they generate a lot of noise. This is due to the presence of a special fan in their design, which, during rotation provides cooling of the body of the device.

Wet rotor

If we consider heating systems for residential buildings of a private type, then the Grundfos UPS pump is the best choice for them. Let's try to decipher the abbreviation of this device: UP indicates that this model represents a class of circulation pumps, S gives a hint that the device uses a three-speed switching system. In other words, during the operation of the grundfos circulation pump, the owner can choose any of three speeds, which can be switched mechanically or automatically.

Against the background of devices of the previous type, installations equipped with a wet rotor, are characterized by high efficiency, the value of which reaches 50%. Its advantages should be called the absence of noise during operation. True, for effective use, a high-quality coolant must be supplied to the system. By fulfilling this requirement, you can count on a grundfos pump to perform effectively for at least 10 years.

According to experts, the best choice for the heating system of a private house would be a Grundfos pump with automation. This will enable the owner to choose the desired operating mode for several days. In addition, when using such a pump, the energy consumption will be small. An important point is the absence of the need to carry out maintenance activities for such equipment. It is enough just to set the necessary settings for the device, after which you will not need to change anything in the equipment.

Where to put

It is recommended to install a circulation pump after the boiler, before the first branch, but on the supply or return pipeline - it doesn't matter. Modern units are made of materials that can tolerate temperatures up to 100-115 ° C.There are few heating systems that work with a hotter coolant, therefore considerations of a more "comfortable" temperature are untenable, but if you feel calmer, put it in the return line.

Can be installed in the return or direct pipe after / before the boiler before the first branch

There is no difference in hydraulics - the boiler, and the rest of the system, it does not matter at all whether there is a pump in the supply or return line. What matters is the correct installation, in terms of strapping, and the correct orientation of the rotor in space

Nothing else matters

There is one important point at the installation site. If the heating system has two separate branches - on the right and left wings of the house or on the first and second floors - it makes sense to put a separate unit on each, and not one common one - directly after the boiler. Moreover, the same rule remains on these branches: immediately after the boiler, before the first branch in this heating circuit. This will make it possible to set the required thermal regime in each part of the house independently of the other, as well as to save on heating in two-story houses. How? Due to the fact that the second floor is usually much warmer than the first, and much less heat is required there. In the presence of two pumps in the branch that goes up, the speed of movement of the coolant is set much less, and this allows you to burn less fuel, and without compromising the comfort of living.

There are two types of heating systems - forced and natural circulation. Systems with forced circulation cannot work without a pump, with natural circulation they work, but in this mode they have a lower heat transfer. Nevertheless, less heat is still much better than its complete absence, because in areas where electricity is often cut off, the system is designed as a hydraulic system (with natural circulation), and then a pump is cut into it. This gives high efficiency and reliability of heating. It is clear that the installation of a circulation pump in these systems is different.

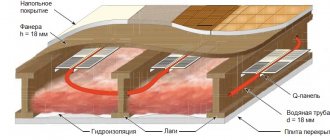

All heating systems with underfloor heating are compulsory - without a pump, the coolant will not pass through such large circuits

Forced circulation

Since the forced circulation heating system is inoperative without a pump, it is installed directly in the break in the supply or return pipe (of your choice).

Most problems with the circulation pump arise due to the presence of mechanical impurities (sand, other abrasive particles) in the coolant. They are able to jam the impeller and stop the motor. Therefore, a strainer-sump must be installed in front of the unit.

Installation of a circulation pump in a forced circulation system

It is also desirable to install ball valves on both sides. They will make it possible to replace or repair the device without draining the coolant from the system. Turn off the taps, remove the unit. Only that part of the water that was directly in this piece of the system is drained.

Natural circulation

The piping of the circulation pump in gravity systems has one significant difference - a bypass is required. This is a jumper that makes the system operational when the pump is not running. One ball shut-off valve is placed on the bypass, which is closed, all the time while the pumping is running. In this mode, the system works as a forced one.

Installation diagram of a circulation pump in a system with natural circulation

When electricity fails or the unit fails, the crane on the lintel is opened, the crane leading to the pump is closed, the system works like a gravity system.

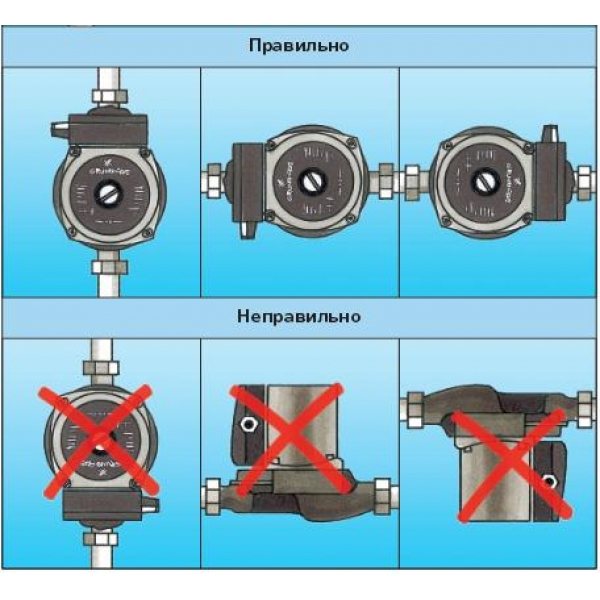

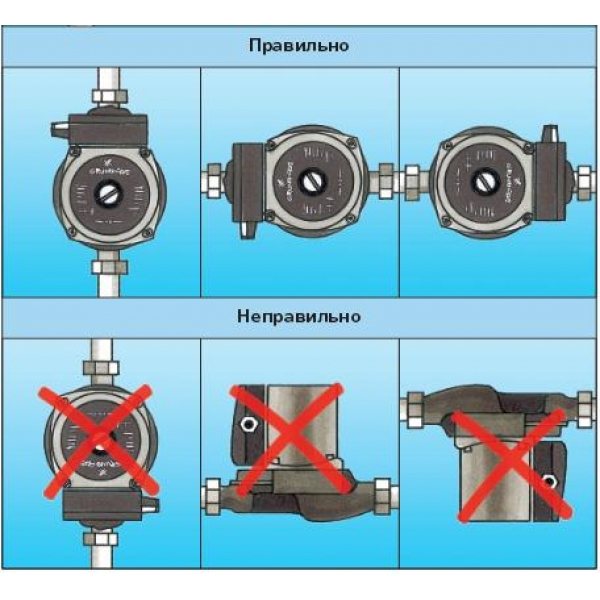

Installation features

There is one important point without which the installation of a circulation pump will require alteration: it is required to turn the rotor so that it is directed horizontally. The second point is the direction of the flow.There is an arrow on the body indicating which direction the coolant should flow. This is how you turn the unit so that the direction of movement of the coolant is “in the direction of the arrow”.

The pump itself can be installed both horizontally and vertically, only when choosing a model, see that it can work in both positions. And one more thing: with a vertical arrangement, the power (created pressure) drops by about 30%. This must be taken into account when choosing a model.

Installing a Grundfos circulation pump

Own house! People associate this concept with a sense of security and comfort - both psychological and everyday. And if quite recently, for everyday comfort, many were content with a wood-burning stove and cold water from a nearby well, now most consumers would like to have water heating, a shower, a bath in their home. The famous concern Grundfos produces pumping equipment that makes this dream a reality, and in this article we will tell you how to install it and what rules you need to follow.

The installation of a Grundfos circulation pump in heating and hot water systems is necessary in order to provide the required flow rate of the coolant and make it constantly circulate at this rate. The presence of such equipment in the heating systems of spacious private houses is especially important. If in a small house it is quite acceptable to use the classical method of natural circulation - due to the force of gravity and the expansion of liquids when heated, then with a large building area and an extensive pipeline system, it turns out to be insufficiently effective. The water pressure will weaken as the stream moves away from the boiler, and as a result, distant rooms will heat up worse. In addition, thanks to forced circulation, the entire house will warm up equally quickly, while with its natural option, only the rooms closest to the boiler are heated quickly.

If the boiler for the hot water supply system in your house is installed in the basement, then without pumping equipment the network will not be able to work at all, since the water heaters themselves do not pump water. Another problem is also familiar to many - by opening a hot water tap, to find that instead of it, at first, it goes cold for some time. This feature of storage water heaters leads to unjustified costs, since in anticipation of warming of water, part of it is wasted into the sewer system. Therefore, there is a variant of the device of a closed hot water supply system, in which unused water is fed back to the boiler for reheating. And here, of course, you cannot do without installing a grundfos circulation pump.

These devices are designed to be installed directly on the pipe. Pumps for improving circulation are lightweight, and their power is consistent with the goal of maintaining a pressure in the networks of a house or apartment sufficient for the normal operation of household appliances. It is worth thinking about choosing a suitable device even at the design stage of water supply and home heating systems. Here you need to take into account such parameters as the values of the required water pressure and its flow rate at rated load, as well as the length and branching of the network.

The installation of a grundfos circulation pump with a wet rotor, which is most often used in everyday life, is carried out so that its shaft is located horizontally, since when installed vertically, not only performance is lost and cooling becomes insufficient, but air accumulates inside the device. Because of this, the process of lubricating the bearings with the pumped liquid is disrupted and the device fails. Dry rotor units are available for both horizontal and vertical installation.In a heating system, a device with a wet rotor can be installed both on the supply pipe and on the return pipe, and with a dry one - only on the return pipe. This is due to the fact that dry rotor motors, when used in very hot water, shorten the life of the stuffing box packing and more often require replacement of the bearing grease. All this reduces the resource of devices with a dry rotor, so it is more rational to use them in cold or lukewarm water.

The device should be located in a place where it can be easily accessed. Before installing a grundfos circulation pump in an existing system, you must first drain all the water from it. Place the device on the pipe according to the arrow on the casing, indicating the direction of movement of the coolant. Before and after the device, there must be shut-off valves in order to make it convenient to repair or replace. A check valve can be installed downstream of the pump to allow fluid to flow in only one direction. By eliminating the reverse movement of water, it improves circulation and protects the device from malfunctions. It is best to use a ball check valve to avoid head losses that are common with spring-loaded valves. In order for the device to last longer, a filter for coarse water purification is placed in front of it.

The pump intended for heating systems can be installed on a bypass - a horizontal pipe branch parallel to the main pipeline. The diameter of the bypass must be equal to the diameter of the main pipe. On both sides of the device, shut-off valves are placed on the bypass, and another one is placed between the tie-ins on the main pipeline. This valve must be closed when the pump is running. With circulation pumping equipment, only ball valves are used, and during the operation of the system, they must be fully open so as not to impede the movement of the coolant flow. Otherwise, the pump will work with increased load, which will lead to a decrease in its service life. A bypass with shut-off valves allows you to temporarily switch to natural circulation in the system in the event of a power outage or device malfunction. However, the possibility of the system operating not only with forced, but also with natural circulation should be provided for by the design during its construction.

At the end of the installation work, it is necessary to check the tightness of all connections, after which you can start filling the system with water or antifreeze. This is done gradually in order to fill the lower part of the pipes first and only then complete the filling. This technology prevents the formation of air pockets. Grundfos ALPHA series pumps are designed in such a way that the removal of air from them during operation is not required, and the UPS series devices have a device that separates air from water and provides a seat for installing an automatic air vent. In addition, there is a screw plug on the casing of the UPS pumps, which must be unscrewed before starting the device in order to allow the air accumulated in the pipes to escape.

After filling with water, the pump can be connected to the mains. For the Grundfos ALPHA2 series, this is done using the advanced ALPHA plug, which can be easily connected with one push without the use of any tools.

Experts will help you solve the difficult task of choosing the right pumping equipment. We will also provide delivery of the purchased device and make its connection to heating and water supply networks in accordance with all the rules and recommendations of the manufacturer.

.

Basic rules for installing the pump

When installing an electric pump for heating, one must remember to observe a number of important rules:

- on the sides of the pump, ball valves must be fixed. If it is necessary to dismantle the pump, using ball valves, the likelihood of the coolant leaving the system will be excluded;

- a filter cuts in front of the pumping device. This is necessary to protect the device from various particles that are present in the coolant;

- there must be an air valve at the top of the bypass. It will remove the air accumulated in the system. You can choose automatic or manual valve type;

- threaded connections must be made with gaskets and sealant. This is necessary to avoid leaks;

- there is an arrow on the pumping device that shows the direction of movement of the coolant. This direction must be observed during the installation process;

- to make the process of using the pumping device completely safe, connect the device only to a grounded outlet. Therefore, before installing the pump, a number of steps are required to ensure grounding.

An electric pump is connected to heat the house according to the following algorithm:

- choice of location. The connected pump needs periodic maintenance. You also need to ensure that there is access to the mains. Therefore, the location must be chosen taking into account these factors. Of course, proximity to the mains is not a requirement: you can extend the mains power cable to the required installation location. But this will create additional inconvenience. It is best to install the pumps at the entry point to the expansion tank. Thus, it is possible to achieve the highest possible temperature indicators in a given place;

- if the pump is installed in an existing network, the coolant must first be drained. If the heating system has been in operation for a long time, it must be thoroughly cleaned of accumulated dirt inside. To do this, fill it with water several times and then empty it;

- the installation of the pump and the functional chain of fittings is carried out in accordance with the rules described above;

- when the installation process is completed, the heating system must be filled with coolant again;

- now you need to check the system for performance. For example, if the heating pump does not turn on, there may be some problem with the power supply. It is necessary to check the fuses and phases. If everything is normal, the drive winding is probably burned out. All errors at this stage should be corrected;

- after that you need to open the central screw. It is located on the housing cover. This procedure is necessary in order for the excess air to come out of the pump. When the water comes out, then everything is in order: the air is completely removed. It should be noted that the manual pump should be vented every time before turning on the device.

Knowing how to put an additional pump in the heating system, you can easily do this procedure yourself. Positive changes in the use of a heating system with an embedded pump are noticeable in the first days of operation.

It is better to buy a pump for an automatic heating boiler. In this way, you can protect the device against misuse. When connecting equipment to the network, it is better to use an automatic fuse with a flag, which will perform two functions: a fuse and a switch. Install the fuse at a distance of more than 50 cm from the boiler.

It is possible to install the pump in a heating system where there is already one pump. But here you need to take into account some of the nuances. The pumping device turns on when the thermal relay is activated.

In order for both devices to work synchronously, the second device must also be connected to a relay.

An additional pump can be connected to the main one by means of a parallel connection. Knowing how to connect the heating pump to the mains, this will not be particularly difficult.

Most often, pumping equipment operates from 220 volts. But there are units operating from 380 volts. Today on sale you can also find a 12 volt heating pump with a smooth speed variator. Such units are irreplaceable if there is no possibility of connecting to a 220 volt power grid.Thanks to the electronic speed variator, the pump turns on smoothly, it is possible to set the exact parameters of the device. But still, a 12 volt heating pump is used extremely rarely.

The main types of breakdowns of Grundfos pumps

If you know how to handle equipment, and have an idea of the technical structure of water-pressure equipment, you can repair the pump with your own hands.

To do this, you need to correctly establish the cause of the breakdown, and choose a way to eliminate it. Pumping equipment breaks down almost always suddenly, without any special preliminary "bells".

All pumps, regardless of their technical characteristics or principle of operation, are most often subject to the following faults:

- There is no torque on the moving parts of the equipment.

- Spontaneous shutdown of the device.

- High level of noise or vibration.

- Low water pressure.

If the apparatus hums, but does not spin, then there is a high probability of oxidation of the torque shaft, or limescale of the rotating parts. This is possible as a result of prolonged downtime of internal mechanisms. When the device not only does not spin, but also does not buzz, most likely, the problem is in the power supply of the engine. Spontaneous shutdown of pumping equipment indicates the presence of mineral deposits between the starter and the rotor.

Loud noise during operation is usually caused by air leaking into the water pipes due to the depressurization of the unit. Vibration, on the other hand, indicates bearing malfunctions on the rotating pump assemblies. A drop in pressure is usually caused by clogged filters, or by incorrectly connecting the device to a three-phase power source.

Distinctive features of circulation pumps

Each modern model has its own special technical characteristics of the Grundfos circulation pump. Thanks to the timely familiarization with the properties and parameters of a particular model, you will save your time, which could have been spent on searching and checking similar equipment purchased in the store. Grundfos is a famous Danish company that manufactures pumps.

The most attractive thing about Grundfos models is their small size and relatively low weight. These parameters of the Grundfos pump will simplify installation and placement in rooms of all sizes.

Installing a circulation pump in the heating system near living rooms will not create any inconvenience. Consumption during operation of a small power of electric current determines the efficiency of heating. In addition, the developers offer some pump models that do not require special installation. Self-installation of pumps from the Grundfos company will not be difficult. Since, especially for such cases, on the Internet, you can easily find detailed video instructions with step-by-step installation of the pump

Which pump is better than Grundfos or Wilo

Grundfos DHW pumps and similar products from Wilo are high-quality pumps for hot water recirculation from European manufacturers. Grundfos pumps, like Wilo devices, have their own advantages and disadvantages. When choosing, you must rely on the technical characteristics of certain models.

Regardless of the manufacturer, the pump must be suitable for the operating parameters. Violation of this rule will shorten the life of the product. Hot water circulation pumps are used for uninterrupted supply of liquid, regardless of the length of the pipeline. Product specifications differ depending on the model. This must be taken into account when choosing a device