Floor quality

The main function of the floor is to provide a solid structure that meets the standards of sound insulation, heating technology and hygiene. As a rule, materials of different strengths are used in the construction of the floor for optimal efficiency. Usually they are located in structures from more durable to less durable from the bottom up, or an option is adopted in which materials with different strengths alternate.

An example of alternating materials in a floor structure can be the use of a dense concrete screed, laid on less dense sound and heat insulating materials (mineral wool, expanded polystyrene). In some floors, sturdy parquet boards are laid on logs, which in turn are laid on a sand cushion. A perfect example of alternating layers is a laminate floor construction, where a durable laminated board is laid on a soft backing laid on a concrete screed. The most durable material in any floor structure is a reinforced concrete slab.

Requirements for pipes for a warm water floor

A number of requirements are imposed on modern structures, the observance of which will allow you to get a floor that works with dignity throughout the entire period of operation. The pipes must be:

Also read the materials:

- durable

- heat resistant

- with smooth inner surface

- durable, corrosion resistant

- environmentally friendly

- suitable in diameter and size

Since the diameter largely determines the heat transfer and affects the energy consumption, then you should carefully consider its choice. The length of the pipe must correspond to the dimensions of the room, since connections are an object of danger of leakage and failure. Therefore, the size and correctly selected pipe fittings will be the key to durability and serviceability.

Constructive floor "pie" depending on the face layer

Depending on the type of existing topcoat, conclusions can be drawn about the presence of certain layers in the construction of your floor. This will help you when carrying out repairs. So, under the face layer of parquet boards or boards, there is a high probability of a screed made of a cement-sand mixture or a prefabricated-board screed made of hard fiberboard grades. By the way, if you have a solid monolithic base, it is enough to make minor repairs to it, and you will get an ideal base for laying any floor covering. If a prefabricated screed is found under the front layer, then it is enough to inspect all the shields and replace or repair the damaged elements.

If you are replacing a ceramic tile flooring in a bathroom or toilet, then try not to damage the screed layer, since there is a waterproofing carpet under it, damage to which will cost you dearly. If the waterproofing layer in these rooms is violated, you will have to tear off the entire layer of the screed and restore the damaged coating from the waterproofing material, after which you will have to perform a new screed.

Under the linoleum on an insulated basis, as a rule, a lightweight expanded clay screed was made. Tearing off this layer is not recommended as it is an ideal base for any kind of flooring.

The base device for non-insulated linoleum is made of fiberboard or chipboard boards on a cement screed. When repairing the bases of such floors, you need to pay attention to the condition of the base of the slabs, especially in the places where they are adjacent to the walls. In case of damage to the plates, they must be replaced with new ones.Slabs that have rotted from the edges need to be cut down or replaced completely.

If your house has floors made of parquet piece elements or boards, then the front layer was laid using lag - beams made of wood of a significant section. The bars, in turn, were laid on a substrate made of rolled materials or fiberboard.

When repairing wooden floors, special attention should be paid to the condition of the front layer. If the parquet boards or boards do not creak, rot or crack, then the new facing layer can be laid directly over the existing flooring without dismantling it. Small irregularities can be eliminated with a grinder, and the cracks can be putty.

If the old floor along the logs is not suitable for further use due to the fact that some of the boards have rotted, then the floor can either be dismantled completely, or the rotted elements can be replaced. When completely dismantled, the new floor covering is placed over the cement screed.

Which floor heating to choose?

Warm floors can be electric or water.

- Electrotype. The heating element for the electric underfloor heating is cables, special films or rods. Electrical energy is converted into heat. This type is usually used to cover small spaces such as a balcony, bathroom or corridor.

- Water type. Water floors are connected to a general heating system or boiler and can heat large rooms.

However, before installation, you need to compare both the general characteristics of these types, and your conditions in which the floor will have to work.

FEATURES OF THE ELECTRIC FLOOR

For electric underfloor heating, only electricity serves as a source of energy. Other power supplies are not possible. This heating system is more expensive to maintain, although it is cheaper to install.

Most often, to save energy, this type is used in a certain small area: in the corridor, in the bathroom in the kitchen. At the same time, it is very important to determine in advance where the furniture will stand and not to lay a warm floor under the interior items. The fact is that warm air will not rise up, and overheating may occur. It is also not recommended to move furniture after installing a warm floor. At best, overheating can lead to cable burnout, at worst to fire. If the cable is mechanically damaged together with the floor covering, an electric shock is possible. If underfloor heating has to be repaired and the damaged area cannot be found and installed with a special coupling, the entire floor area has to be replaced.

When operated, this type of warm field creates electromagnetic radiation that can affect the health of humans and animals. This only applies to cable electric floors.

FEATURES OF THE WATER FLOOR

The water floor is connected to the central heating system. It is difficult to install, you need experience and certain qualifications. Water underfloor heating can only be connected in new buildings, where apartments can be connected to this type of heating. In old high-rise buildings, connection without permission is prohibited. Differences in pressure and temperature occur. In addition, difficulties are possible due to the end of the heating season.

This heating system can be connected to any energy source. If such a floor is damaged, water flows out. From 3 liters if the system is autonomous, up to 10 liters with general heating.

Restrictions on the use of underfloor heating

- This heating system is not recommended for installation in public areas. Energy consumption in this case is not economically viable due to the large loss of heat energy.

- Underfloor heating is usually recommended as additional heating. The main source of warm floors can only be made if strict international standards are observed. For the main source of heating, a water-heated floor is used.When installing it, it is important to take into account the heat loss of the room and make detailed calculations.

- In high-rise buildings with a common water heating system, it is almost impossible to obtain permission to install water floors. The general heating system is not designed for underfloor heating technology. The hydraulic resistance of water floors is higher than that of general heating, which can cause malfunction. It will become cold either in one, or in several, or in all apartments.

Note! Installation of warm water floors without permission is an administrative offense.

The quality of the flooring is very important. Do not use linoleum of dubious quality together with warm floors! Heating the floor leads to the evaporation of harmful substances. It is best to use ceramic tiles or laminate flooring. Parquet or carpet has low thermal conductivity and will reduce the efficiency of underfloor heating.

For your information. In private houses and apartments, it is best to use an additional water-heated floor, and leave the main radiator, but use it with a lower temperature. In high-rise buildings, it is better to install an additional electric floor. Then, in the event of a power failure, the central heating will work.

Repair of squeaky floors

Separately, I would like to say about the repair of wooden creaking floors, since here the situation is solved in a slightly different way. The first thing to do to eliminate the squeak is to determine the cause. Usually there can be several reasons:

- the top layer of the wooden floor has crumbled;

- the fastening of the floor slat to the log bar is weakened;

- the log beams have rotted;

- creaking lags, which have lost their former horizontal position.

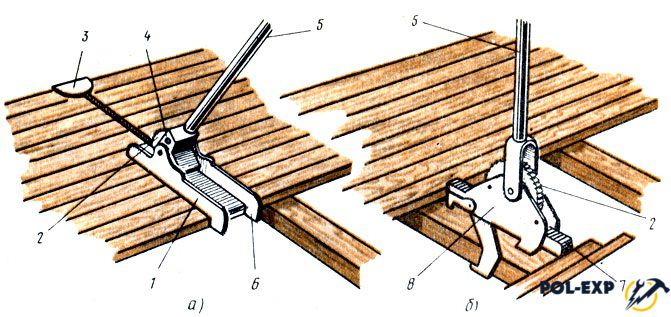

With a weak fastening of the floor slats, everything is simple: just screw the floorboard with a self-tapping screw to the joists. Moreover, the head of the self-tapping screw must be recessed into the body of the floorboard.

With lag creeps due to their uneven position, the situation is more complicated. There can be many reasons why they began to lie unevenly, and most of them are associated with violations during the construction of the building (lining under the logs of wedges, laying on a brick or several layers of loose fiberboard and roofing material). To eliminate such a squeak, you need to restore the evenness of the lag. To do this, you need to remove the front layer and align the bars or change them to others. By the way, you need to know that it is impossible to rigidly fasten the logs to the reinforced concrete slabs using bolted connections, since in this case any blows are easily transmitted through the floor slab.

Classic water floor device

To mount pipes on the floor surface, you must choose one of three ways of their device:

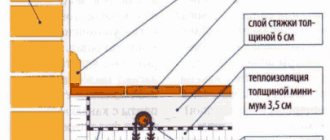

- Concrete screed... The pipes are bulky enough that they cannot be covered with tile adhesive. To secure them, a concrete screed is used, which must be poured to a height of at least three centimeters above the surface of the pipe.

- Expanded polystyrene... This method is less popular due to its greater labor intensity. When using it in expanded polystyrene, it is necessary to cut the grooves. You will have to do this manually. Then the pipes themselves are laid in the grooves, on top of which the screed is poured.

- Wooden grooves... This is the most time consuming method sometimes used in dwellings with wooden floors. By stuffing boards on the floor, they create a gutter of the shape that is needed to accommodate pipes.

Now imagine what is the cost of an error when performing a calculation or choosing a heated floor installation scheme, if it is arranged using a concrete screed. You will have to partially or even completely dismantle the screed itself.

Of course, the interior decoration of the premises will also suffer. Therefore, each stage of work should be treated with full responsibility.

Some features of floors using lag

If your room is located on the 1st floor of the house, then timber floors using log beams should be made using insulation.In most cases, sheets of glass wool are used, which are laid between the logs on a reinforced concrete slab. By the way, in constructive "pies" of floors with insulation, a vapor barrier must be used. A layer of glassine is used as it. The glassine carpet is laid on the logs without tension, that is, it can sag freely on the insulation. This is necessary to provide an air gap in order to ventilate the underfloor space.

Quite often, log floors are made using a sub-floor. For the device of such a floor, ordinary non-grooved boards are used. Subfloors are a kind of basis for laying the front layer of parquet boards and boards. By the way, in subfloors, you can use plywood or particle boards instead of boards. These subfloors are an excellent base for any kind of topcoat. As a rule, subfloors are arranged where the height of the screed, according to calculations, should exceed 15 cm. In this case, it is more logical to make a subfloor using a lag on the posts. Since subfloors are made of wood, all the problems inherent in wood structures are inherent in them.

In connection with the above, the following conclusions can be drawn. If you are planning to renovate the floor in the room, then you can draw conclusions about the degree of costs and the work required only after inspecting the base of the existing floor. So, it is possible that it will be enough for you to replace the face layer or overhaul the entire floor. By the way, when changing the constructive "pie" of the floor to a more massive and heavy one, you will need to obtain permission from the appropriate authorities.

Recommendations

The choice of the type of underfloor heating is based on:

- on the type of room in which the installation will be carried out;

- for the purpose of installing the heating system (whether it will be additional heating or the main one);

- on your financial capabilities, since each system costs differently;

- on installation skills (installation of infrared film does not require special skills, while installation of a water system requires more effort and skill).

In any case, each system has the right to be installed, since the choice depends only on you. Just do not forget to take into account the principle of operation of underfloor heating and the type of room in which they will be installed.

- Similar posts

- How to install Devi underfloor heating?

- How are XLPE pipes for underfloor heating laid?

- How to install cable underfloor heating?

- What are the advantages of Heat plus underfloor heating?

- What kind of underfloor mats are there?

- Features of the Korean underfloor heating

Collector connection to the boiler

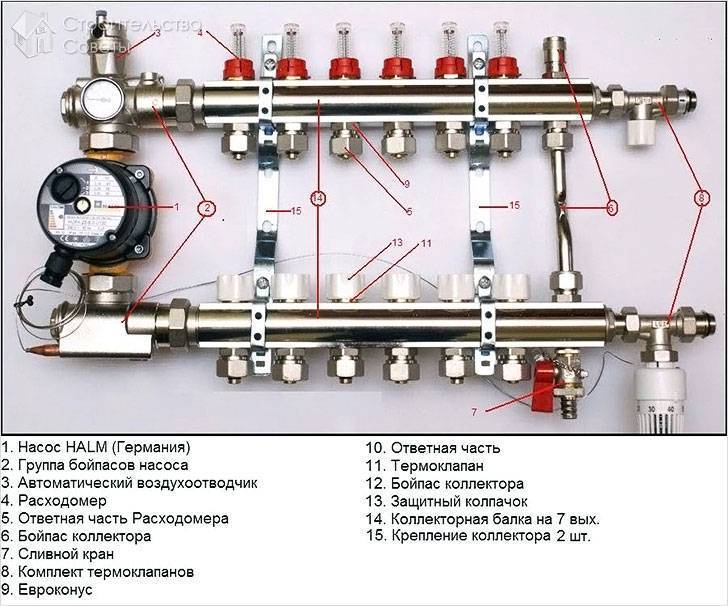

The process of connecting a warm water floor with a comb is very simple and boils down to connecting the pipes of the heating circuits to the collector, and the collector itself to the boiler. However, there are differences in the configuration of the collector. This is what we will consider in this subsection.

The collector must be installed in such a way that it is convenient to lead the heating circuit pipes to it. So, install shut-off valves on the manifold. Connect the side outlet to the pipe both for supply and return.

If you buy a ready-made manifold kit, then it will already have all the necessary valves, even at the outlets of the pipes going to the boiler. The presence of taps will allow you, if necessary, to carry out repairs or temporarily disable one of the circuits. If you assemble the manifold yourself, then the assembly of the connection of each element is performed with a compression fitting. As a result, underfloor heating will be connected to the boiler through the collector.

To automate the control of the temperature of the coolant, the following set of equipment is additionally installed in the collector:

- Pump and mixing unit, which includes a three-way mixing valve.

- For forced circulation pump.

- Drain cock.

- Air vent.

So, instead of shut-off valves on the manifold, install thermostatic control valves. In their design there is a thermocylinder with paraffin, which, pushing off from the air temperature in the room, narrows or expands. These actions set the capacity of the thermostatic valve. As for the pumping and mixing unit, the principle of its operation was described above.

So, we examined the basic and working schemes for connecting a warm water floor. As you can see, it is not enough to know how to properly install a water floor. It should be connected correctly. We hope this article will help you understand the intricacies of this work. And if you already have personal experience, then leave feedback and comments at the end of this article regarding the water heating floor connection schemes you use.