What the system consists of and how does it work

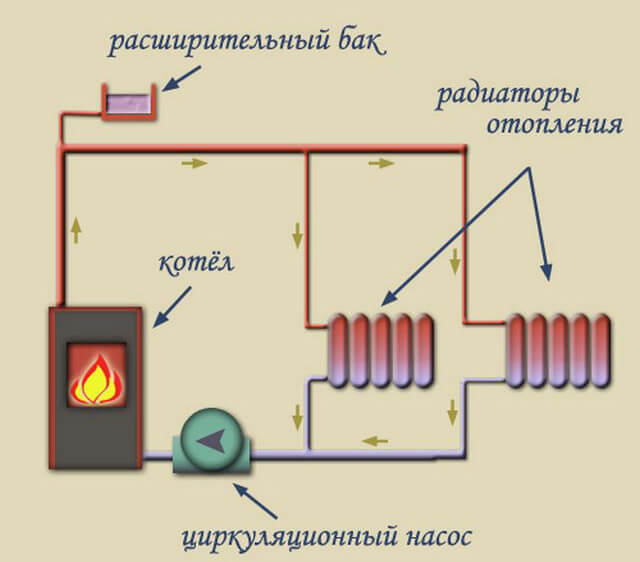

In order for the heat to flow from the boiler room to the heating devices, an intermediary is used in the water system - a liquid. A heat carrier of this type moves through the pipeline and heats the rooms in the house, and all of them can have a different area. This factor makes such a heating system popular.

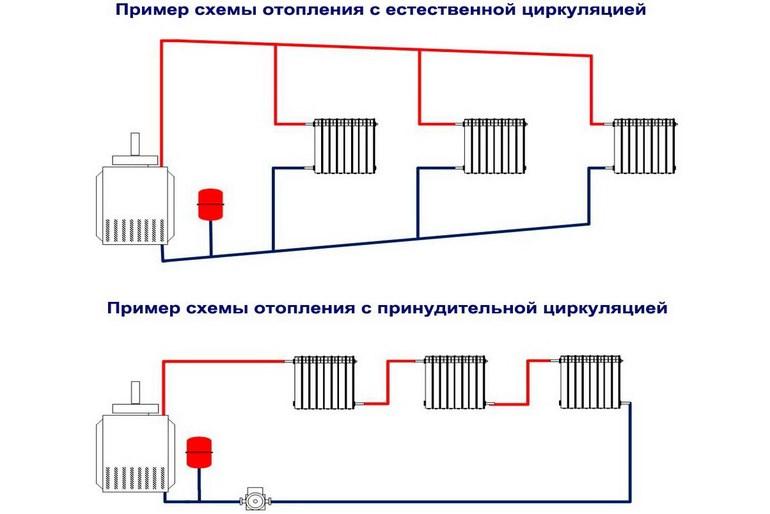

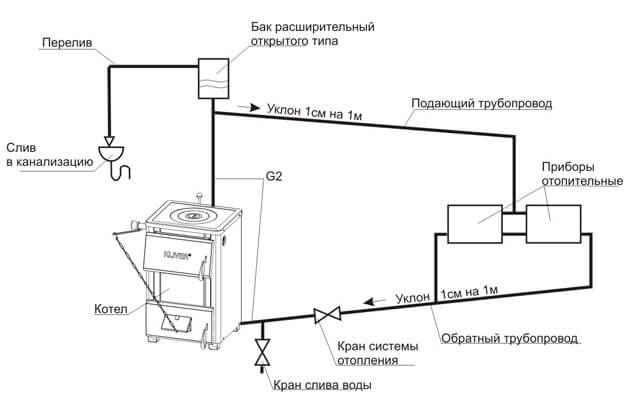

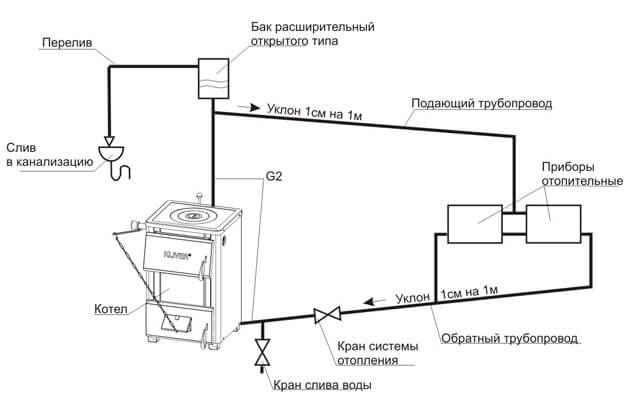

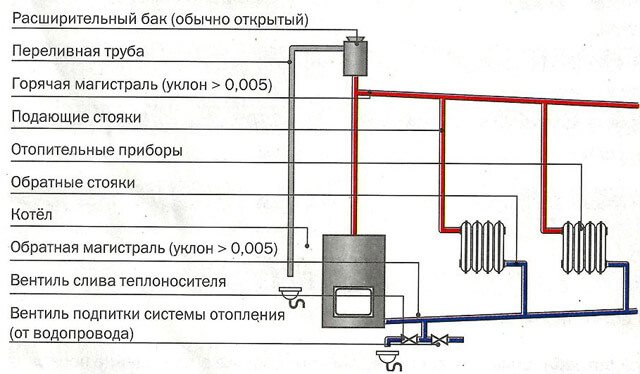

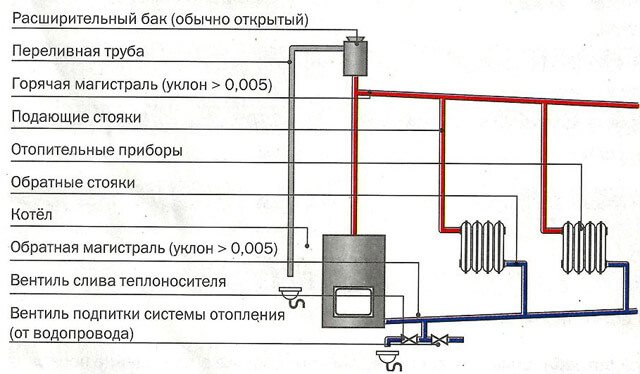

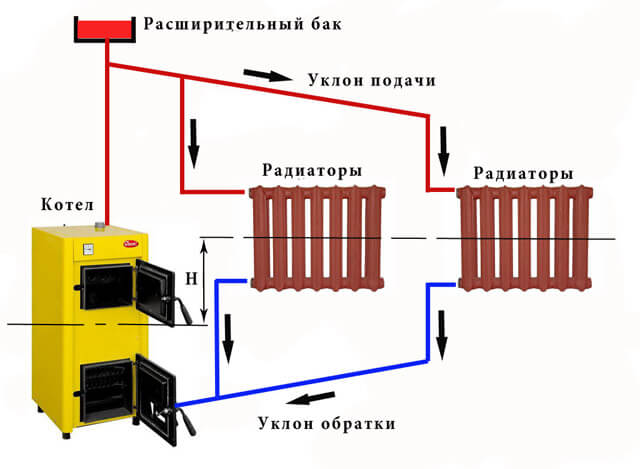

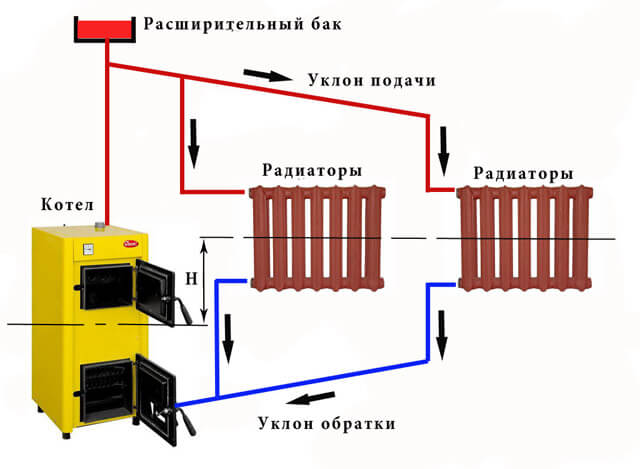

The movement of the coolant can be carried out in a natural way, the circulation is based on the principles of thermodynamics. Due to the different densities of cold and heated water and the slope of the pipeline, water moves through the system.

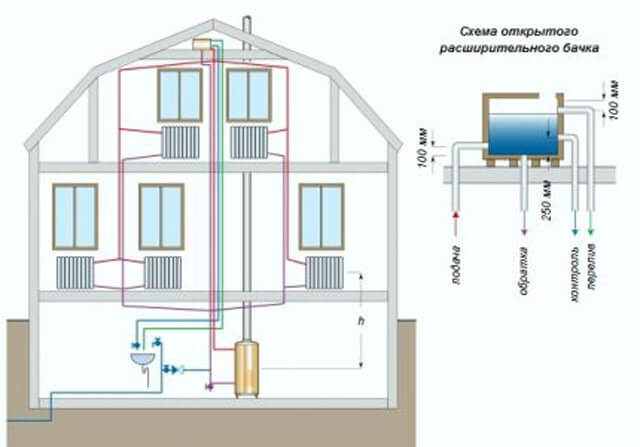

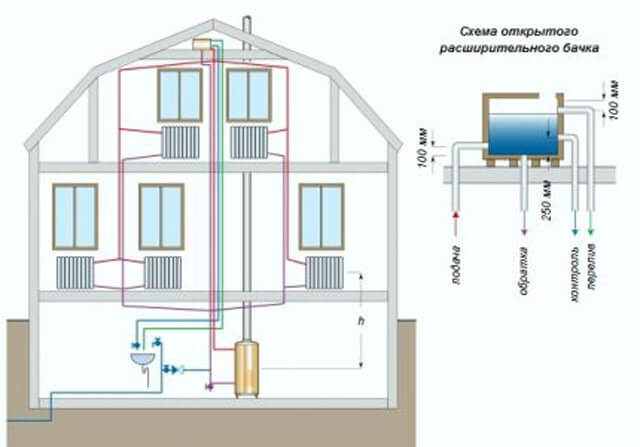

One of the important elements of the heating system is an open expansion tank, which receives excess heated liquid. It is this element that stabilizes the coolant pressure. The main condition is that the tank should be located at the highest point of the heating system.

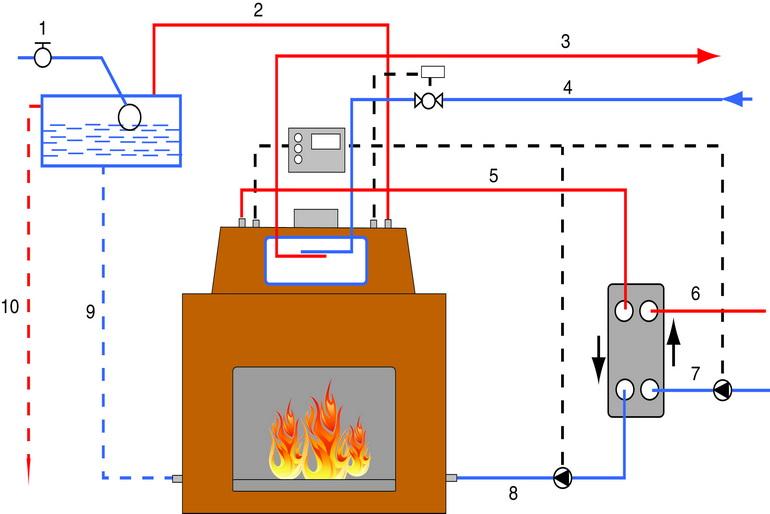

Open heat supply operates according to the following scheme:

- The boiler heats up water and is supplied to heating devices in every room of the house.

- On the way back, excess liquid goes into the open-type expansion tank, its temperature drops, and the water returns back to the boiler.

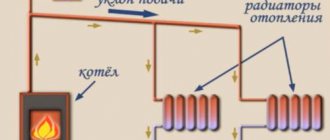

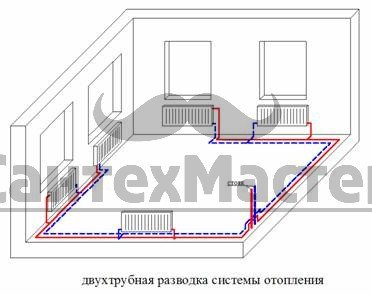

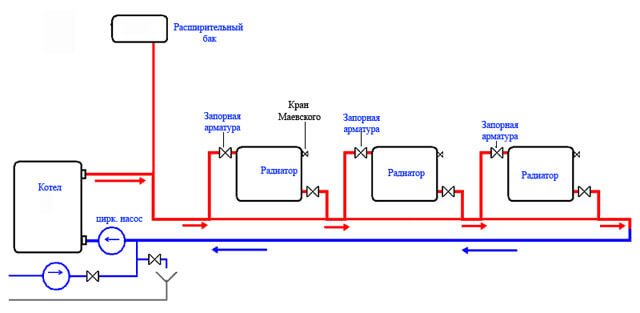

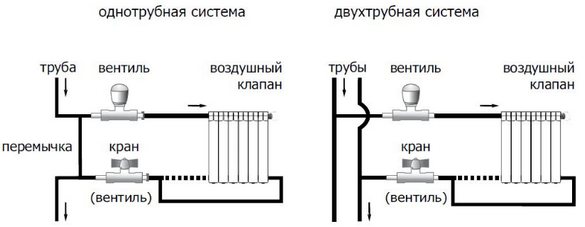

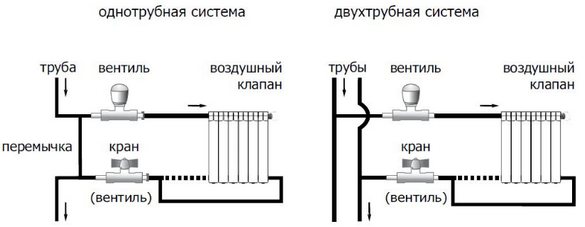

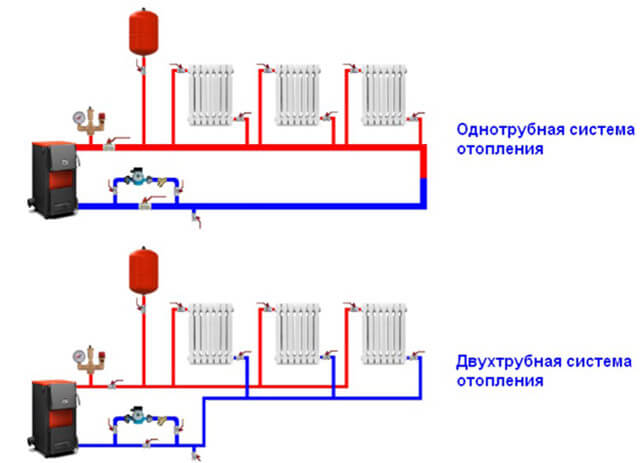

One-pipe heating systems involve the use of one line for supply and return. Two-pipe systems have independent flow and return pipes. When deciding to independently mount a dependent heating system, it is better to choose a one-pipe scheme, it is simpler, more accessible and has an elementary design.

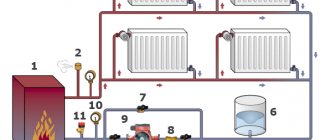

One-pipe heat supply consists of the following elements:

- Heating boiler.

- Batteries or radiators.

- Expansion tank.

- Pipes.

A simplified scheme implies the use of pipes with a cross section of 80-100 mm instead of radiators, but it should be borne in mind that such a system is less efficient in operation.

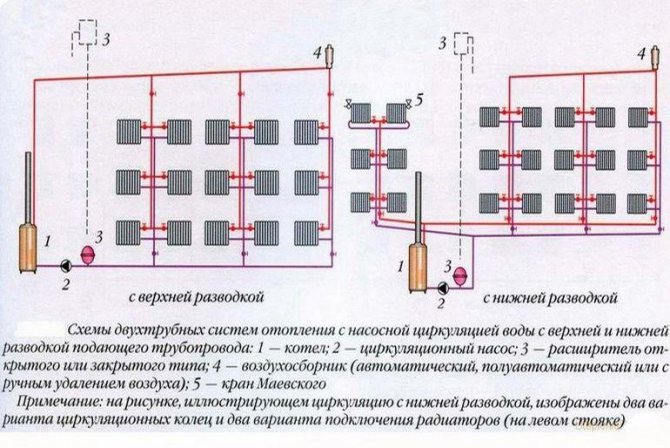

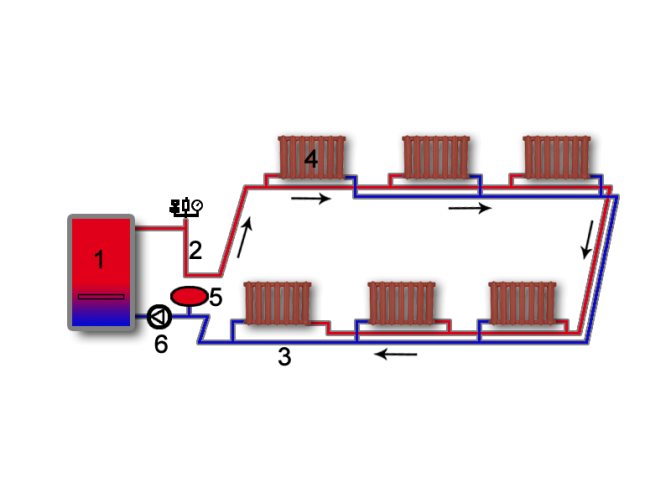

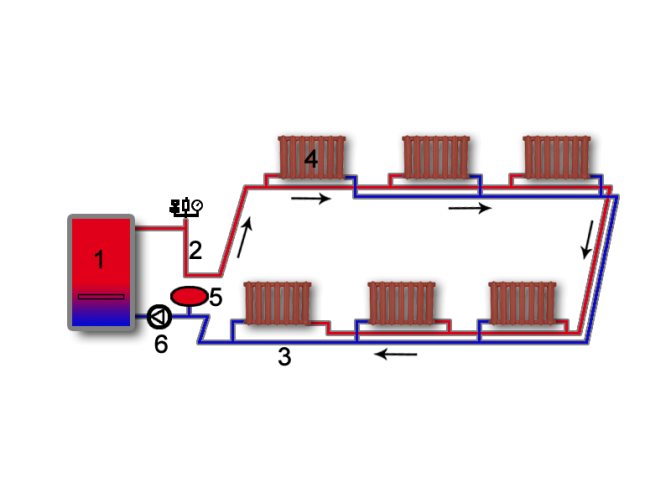

A two-pipe open heating system with a pump is more costly in material terms and is characterized by complex installation. However, in this case, all the disadvantages of a one-pipe system are practically eliminated, which makes it possible to compensate for the costs and complexity of the device. All heating devices receive a coolant with the same temperature, while the cooled liquid is sent to the return line.

Young Engineer Notes

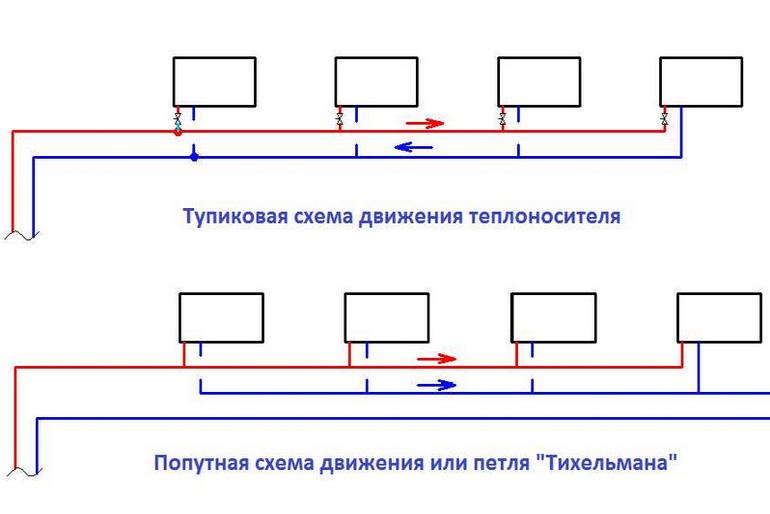

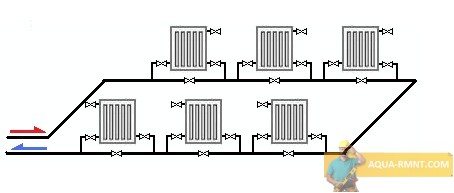

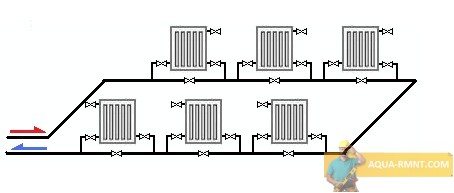

In two-pipe heating systems, the associated movement of the coolant is often used. Why? What are its advantages? Why is a dead-end scheme worse? First, let's figure it out, “who is who,” so to speak. So, the associated movement of the coolant is such a movement of the coolant in which water in the supply and return pipelines flows in the same direction (Fig. 1). With the opposite (dead-end), everything is just the opposite (Fig. 2)

Fig. 1

Diagram of a two-pipe heating system with a passing movement of the coolant.

Fig. 2Diagram of a two-pipe heating system with a dead-end movement of the coolant.

Consider both the one and the other scheme from the point of view of hydraulics and balancing, the length of pipelines and installation. I.

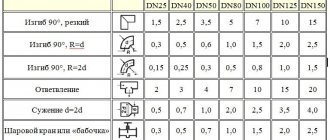

Hydraulics and balancing. By hydraulics, I mean the direct calculation of the pressure loss in the branches / rings. Balancing is the linking of the branches with each other, namely, we strive to ensure that all rings / branches have the same pressure loss. We all know that when calculating network pressure losses, we need to calculate pressure losses in the main circulation ring

(the most loaded and longest) and in the rest of the rings to match them with the main circulation ring.

Everything is simple: if in some ring the pressure loss is less than in the others, then the water will tend to this very circuit, therefore, in other rings it will not be enough.

This means that we will not receive the required flow rate of the coolant in each branch and, accordingly, the necessary heat transfer from the heating devices, in this case the system is considered unbalanced. The hydraulics for the passing movement of the coolant is surprisingly simple. If you have a branch of radiators of the same power and standard size (Fig. 3), then it is enough to calculate the pressure loss in the circuit through any radiator, in the other circuits the pressure loss is the same. The system is, by default, hydraulically coupled, i.e. balanced and does not require any pre-setting radiator valves.

Fig. 3

Scheme with the passing movement of the coolant at the same power of the devices. However, if the power of the heating devices is different or they have a different standard size (which affects the value of the local resistance of the device), then you will have to count the losses through each circuit and interconnect the devices with each other using thermostatic valves (Fig. 4).

Fig. 4

Scheme with the passing movement of the coolant at different power of the devices. When using the counter flow of the coolant, in any case, the pressure losses through each circuit are considered and a thermostatic valve is installed on each device. But, we can say that in the case of installing thermostatic valves on devices with a passing flow pattern of the coolant, it is most likely that the valve setting will be enough for balancing. If we have a dead-end circuit, then on the first device on the branch (Fig. 5) we must set the maximum setting, ie. Clamp the cross-section as much as possible, and if the system is very long, the valve setting may not be enough, or if we set the maximum setting, the cross-section will be reduced so much that water does not flow into the heater.

Fig. 5The valve setting is a scheme with a dead-end movement of the coolant.

According to the criterion "Hydraulics and balancing", the scheme with the passing movement of the coolant is more preferable.

However, there is one pitfall in this scheme. In this scheme, there are so-called "points of equal pressure". If the connections to the heating device are connected to the mains in this place, then water will not flow into the device. What are these points? I suggest you familiarize yourself with Figure 6.

Fig. 6Points of "equal pressure" - a diagram with a passing movement of the coolant.

The figure shows that these points are located in the middle of the path, but in the case of more complex routing, it is more difficult to predict where these points are. And the physics here is simple: At point 1, located on the supply pipeline, and point 2 - on the return, the pressure is the same and due to the fact that there is no pressure difference between these points, water does not flow through the device.

Advice: try to avoid such points and connect the device further from them !!!

II.

Length of pipelines and installation.

Often, a passing circuit requires longer routes, but this is not always the case. It all depends on the room and the location of the devices. As for the installation, the dead-end scheme is easier to mount, if only because the diameters of the parallel sections and the standard sizes of the fittings do not differ. According to the criterion "Length of pipelines and installation", the dead-end scheme is more optimal.

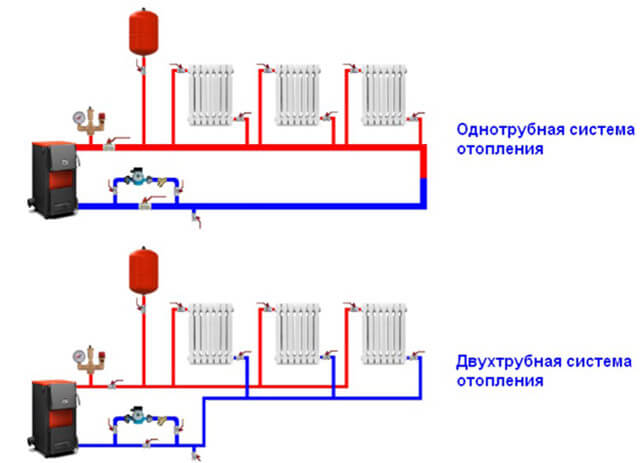

For simplicity and ease of comparison, the given facts about the flow patterns of the coolant are presented in summary table 1.

Table 1.

Comparison of the flow patterns of the coolant associated and dead-end

| Criterion | Coolant flow diagram | |

| Passing | Dead end | |

| I.Hydraulics and balancing: - heat output / standard size of heating devices are the same | 1. Calculation of pressure losses through any one circuit 2. The system is hydraulically linked without the use of additional. fittings | 1. Calculation of pressure losses through each circuit 2. It is necessary to link the circuits to each other by setting the thermostatic valves on each device |

| - heat output / standard size of heating devices are different | 1. Calculation of pressure losses through each circuit 2. It is necessary to link the circuits to each other by setting the thermostatic valves on each device | |

| II.Length of pipelines | Longer | Shorter |

| III.Installation | Harder (diameters of parallel sections and standard sizes of fittings differ) | Easier (diameters of parallel sections and standard sizes of fittings do not differ) |

| IV.Presence of points of "equal pressure" | + | — |

If you have any questions, something is not clear or there is any other information on this topic, do not hesitate and post your comments.

More articles on heating here in this section

If you like this project and want to support it, follow the link

Features of arrangement and operation

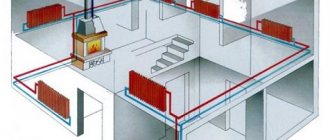

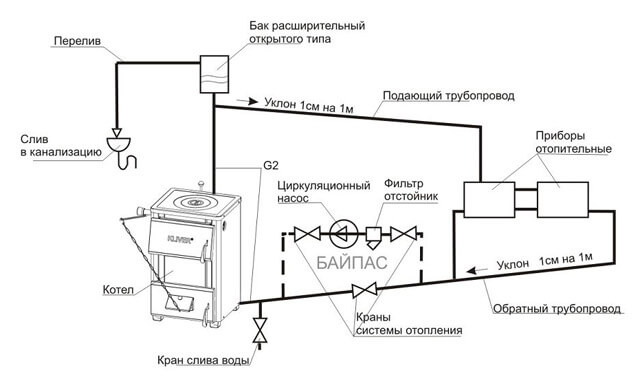

If the choice is made in favor of heating with a pump and an expansion tank, then when arranging heat supply in a house, some of its features should be taken into account:

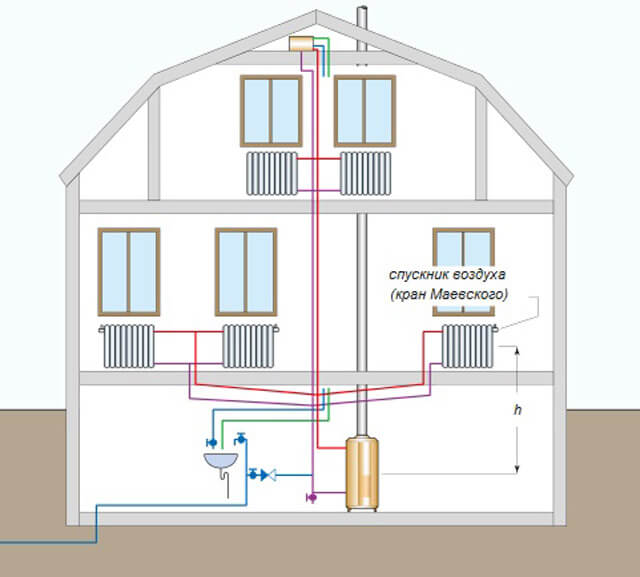

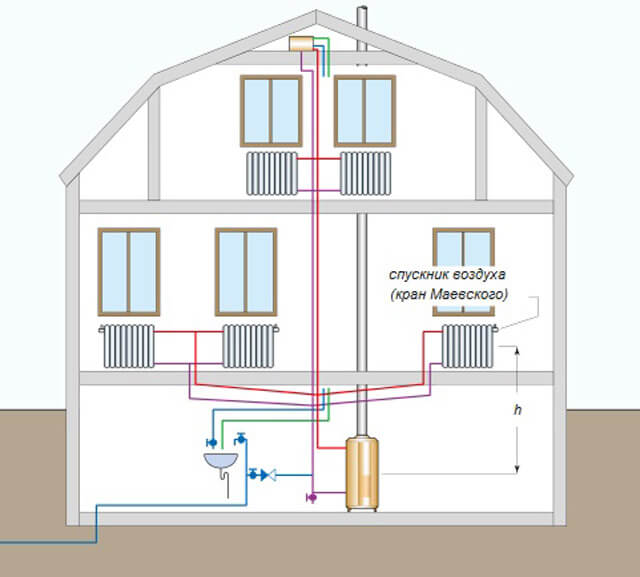

- In order for the coolant to circulate normally, the boiler should be located at the lowest point of the system, and the expansion tank at the highest point.

- It is best to place the expansion tank in the attic of your home. If this room is not heated, then the tank and the riser require good thermal insulation during the cold season.

- The system should have a minimum number of turns, connections and fittings.

- Due to the slow circulation of the coolant in the system, strong heating must not be allowed. Boiling water significantly reduces the service life of heating devices and pipes.

- If in winter time the operation of the heating system is not planned, then the liquid must be drained without fail. This will help to avoid the destruction of pipes, batteries and boiler.

- It is very important to constantly monitor the water level in the expansion tank and add liquid if necessary. Failure to comply with this rule will lead to the formation of air jams, therefore, heating devices will work less efficiently.

- The best option for the coolant is water, since antifreeze is highly toxic, which makes it impossible to use it in open heating systems. This option can be used if it is not possible to drain the coolant in winter.

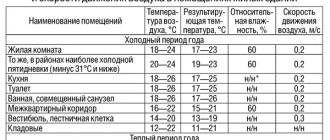

When assembling a heating system, including a heating scheme for a garage with a circulation pump, it is important to correctly calculate the cross-section of the pipes and the degree of their slope. These values are regulated by SNiP 2.04.01-85. In systems where the coolant circulates naturally, the pipes have a larger cross section than in forced circulation heating. Moreover, in the first case, the length of the pipes is much shorter. As for the slope, it is recommended to do it in systems with natural circulation of liquid, while the regulatory documents establish a slope of 2-3 mm per one meter of the contour.

Heating schemes

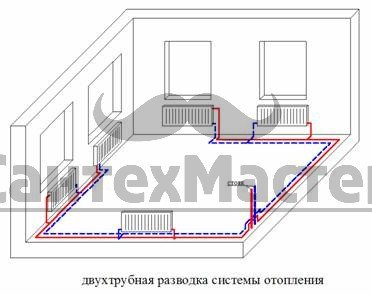

Heating scheme with a passing movement of the coolant

In a system with a passing movement of the coolant, the circulation circuits are equal. Simply put, the sum of the lengths of the "supply" and "return" to each radiator is the same, therefore, the hydraulics of the radiators does not depend on its distance from the boiler room. The coolant feels more confident in this system. Radiators warm up evenly, unbalancing such a system, with proper installation and operation, is quite difficult.

Disadvantages: high labor intensity, slightly higher pipe consumption, compared to the dead end, it is not always possible to perform technically, especially when there are many different levels in the house.

Dead-end heating circuit

In dead-end heating systems, the movement of hot water in the supply line is opposite to the movement of cooled water in the return line. The length of the circulation rings is not the same here: the farther from the boiler the heater is located, the greater the length of the circulation ring, and, conversely, the closer the heater is to the boiler, the shorter the length of the circulation ring. The circulation circuits in such a system are not equal, the system is set up for a long time and can easily be unbalanced. In order to expand the use of dead-end systems, as the most economical ones, the length of the highways is reduced and instead of one long-distance system, several are made. In such cases, the best horizontal adjustment of the system is ensured.

One-pipe heating scheme "Leningradka"

The one-pipe system is also called "Leningrad". It is far from perfect, but popular because of its simplicity. "Leningradka" is a system in which all heating radiators are connected in series to one pipe, which serves as a supply and a return. It turns out that the line is looped to the boiler, and radiators are connected to it in the right places. The heat carrier in the direction of movement sequentially enters each of the heating devices. This is the main disadvantage. The hottest coolant enters the first radiator. Part of the heat is taken to heat it. The coolant becomes colder, is mixed into the line, reducing the overall temperature. After that, already with a slightly colder one, it enters the second radiator, where it cools down a little and, adding to the main stream, cools it even more. As you progress, an increasingly colder heat carrier enters each subsequent heating element. With a sufficiently long chain and a large number of devices, the last radiator is completely ineffective.

To get around this property and achieve approximately equal returns from each device, you can increase the number of radiator sections as they move away from the boiler. Thus, it is possible to compensate for the system, to equalize the heat transfer of each device.

It is also necessary to install regulators and taps, which can be used to regulate the flow rate of the coolant in each heating device, equalizing the temperature if necessary. This allows you to achieve more or less equal heat transfer from each of them.

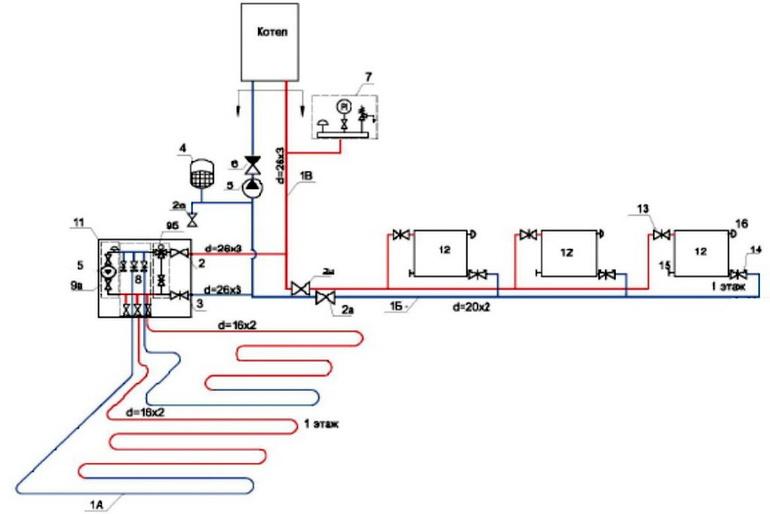

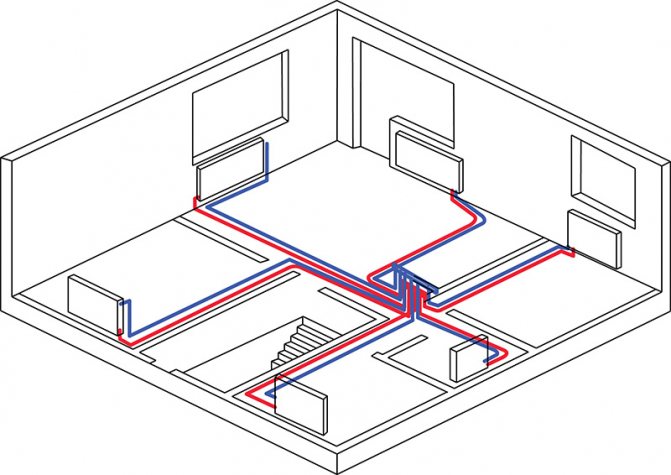

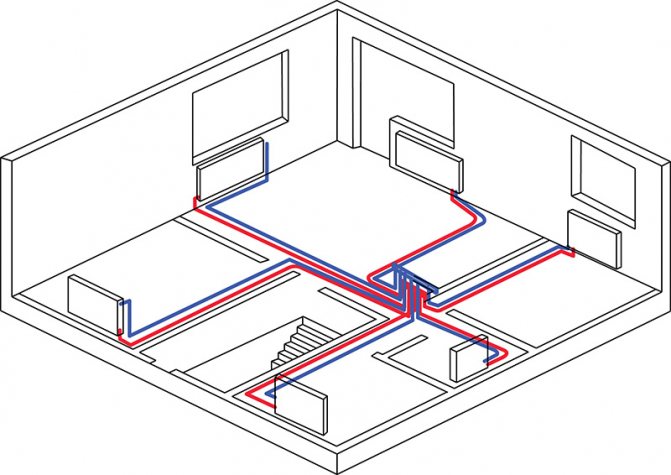

Collector (beam) heating circuit

It is called radial, because during its installation, the installation of a distribution manifold is provided for at each level. From this collector, like rays, pipes diverge to heating radiators. A feature of the beam system is the independent connection of each radiator or circuit, and, accordingly, the uniform distribution of the coolant over all devices. Such a heating system allows you to regulate the consumption of each radiator or circuit separately, achieving the correct distribution of temperature zones in the premises.

The main disadvantage of the beam layout is its high material consumption. This system requires a lot of materials. Moreover, not only pipes, but also valves, since each radiator will have to supply two lines at once - the supply of the coolant and the return. And each line must be equipped with valves - both at the inlet and at the outlet.

But, despite the high consumption of components, such a system makes it possible, in the event of an emergency, to quickly turn off any radiator, group, separate room or whole floor. The heating system can continue to operate during this time and heat the premises. In addition, with beam wiring, pipes are laid without joints.The pipe made of cross-linked polyethylene and laid under the floor eliminates the risk of leaks, and all repairs, if required, are carried out directly at the radiator connections or in the manifold.

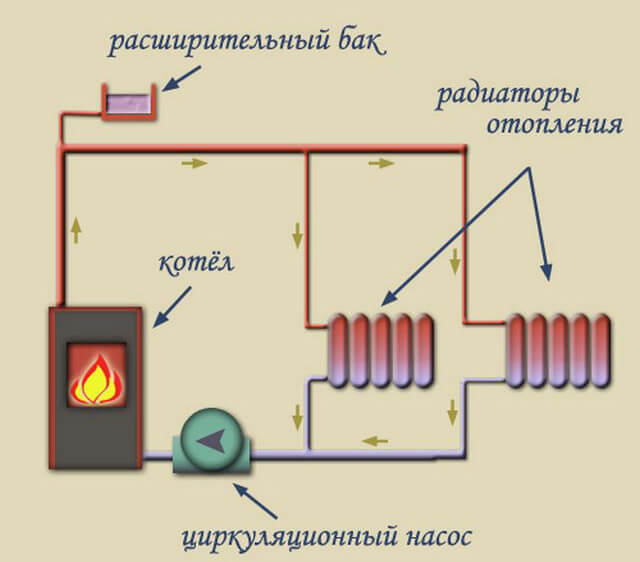

Gravitational (gravity) heating circuit

A heating system with natural circulation of the coolant is called gravity or gravity. Its work is based on the difference in the density of cold and hot water and the difference in height in the location of the heating devices and the boiler. Hot water has a much lower density, so the colder coolant coming from the radiators displaces it from the boiler and directs it up the riser. After the heat is transferred to the radiators, the cooled water moves towards the boiler under the influence of gravitational forces, and hotter water from the boiler flows in its place.

Today, this system is considered outdated and rarely used due to such shortcomings as high cost, low efficiency, lack of economy, since it requires high costs for materials (large pipe diameters) and work (it is difficult to comply with a number of stringent requirements for implementation). Effectively works in small low-rise buildings. In two-story houses, the efficiency is lower, it is difficult to achieve a balance of the upper and lower floors.

In conclusion, it is worth emphasizing two main advantages of this system - a high level of inertia and energy independence, that is, the absence of the need for electricity in the building, which is planned to be equipped with this heating system.

Open heating systems diagrams

In open-type heating systems, the coolant can circulate in two ways. In the first case, the movement is carried out in a natural way, its second name is gravitational circulation. In open-type heating with a pump, additional equipment forces the liquid to move, this option is called forced or artificial movement. You need to choose one or another method depending on the area of the room, the number of floors and the thermal regime used.

Types of dead-end heating systems

Depending on the organization of the piping, two types of dead-end heating systems are distinguished:

- horizontal;

- vertical (shoulder).

In the first case, the supply and return pipelines are located horizontally. For them, pipes of the same diameters and mounting components of common standard sizes are used. This greatly simplifies the installation of the heating system in a private house.

The horizontal circuit allows almost the same temperature to be maintained in all radiators. However, its disadvantage is the increased complexity of balancing individual radiators with a significant length of pipelines of the heating system.

The vertical system is used when it is necessary to heat a two-story house. In this case, the pipeline system is split into two branches. The first branch runs along the first floor of the building. The second branch leads to the second floor through a vertical riser. Dead-end heating systems of this type are more complex.

For their stable and stable operation, a number of conditions must be met:

- the number of heating devices on each floor should not exceed 10;

- an accurate calculation of the diameters of the pipelines must be carried out;

- balancing valves with automatic pressure control must be installed on each floor;

- when installing a vertical dead-end system, the movement of the coolant by gravity is excluded - a circulation pump must be used.

When installing a dead-end system of any type, not only accurate calculation and qualified performance of work, but also the correct choice of radiators and accessories is of key importance.

Ogint radiators are distinguished not only by their high thermal efficiency and reliability, but also by excellent hydraulic characteristics. Our company also offers functional assembly elements. This allows you to create efficient and stably working dead-end heating systems of horizontal and vertical type.

Gravitational circulation

In systems where the coolant circulates naturally, there are no mechanisms to facilitate the movement of fluid. The process is carried out due to the expansion of the heated coolant. In order for a scheme of this type to work effectively, a booster riser with a height of 3.5 meters or more is installed.

The pipeline in a heating system with natural circulation of liquid has some length restrictions, in particular, it should not exceed 30 meters. Consequently, such heat supply can be used in small buildings; in this case, houses with an area not exceeding 60 m2 are considered the best option. The height of the house and the number of floors are also of great importance when installing the booster riser. One more factor should be taken into account, in a heating system of a natural circulation type, the coolant must be heated to a certain temperature; in a low-temperature mode, the required pressure is not created.

A scheme with gravitational fluid motion has certain capabilities:

- Combination with underfloor heating systems. In this case, a circulation pump is installed on the water circuit leading to the heating elements. Otherwise, the operation is carried out as usual, without interruption even in the absence of power supply.

- Working with a boiler. The device is installed in the upper part of the system, but at a lower level than the expansion tank is located. In some cases, a pump is installed on the boiler so that it runs smoothly. However, it should be understood that in such a situation the system becomes forced, which makes it necessary to install a check valve to prevent liquid recirculation.

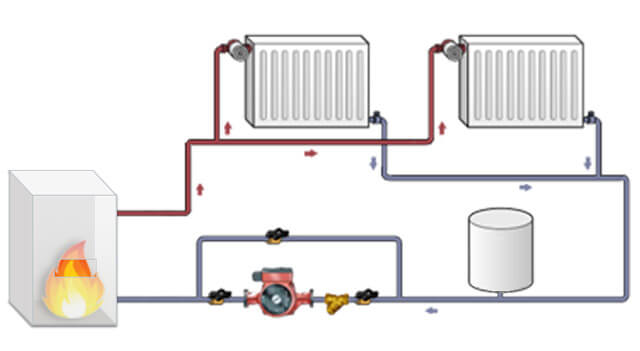

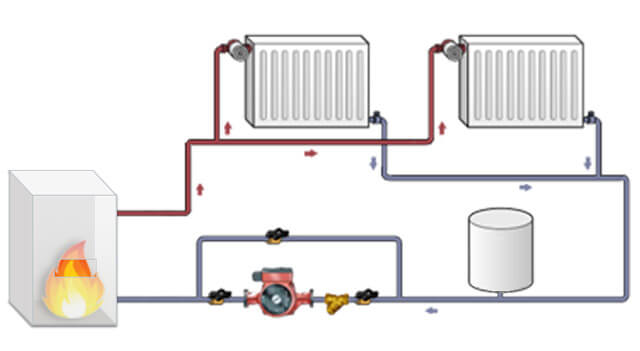

Systems with artificial induction of the movement of the coolant

Diagrams of an open heating system with a pump in any case imply the use of an appropriate device. This allows you to increase the speed of movement of the liquid and reduce the time for heating the house. The coolant flow in this case moves at a speed of about 0.7 m / s, so heat transfer becomes more efficient and all sections of the heat supply system are heated equally.

In the process of installing an open-type heating system with a pump, several features should be taken into account:

- The presence of a built-in circulation pump requires connection to the power supply system. For uninterrupted operation in the event of an emergency power outage, the pump is recommended to be installed on the bypass.

- The pumping equipment must stand on the return pipe in front of the boiler inlet, at a distance of up to 1.5 meters from it.

- The pump cuts into the pipeline, taking into account the direction of movement of the coolant.

The installation of the pump also has its own characteristics, it is located on the bypass pipe between two shut-off valves. If there is electricity in the network, which is necessary for the operation of the pumping equipment, then the taps are shut off. In this case, the coolant passes through a bypass elbow with a circulation pump. In the absence of voltage, the valves are opened, allowing the system to operate in gravity mode.

Single pipe or double pipe?

Single pipe heating systems have become widespread, primarily in high-rise buildings, in old central heating systems, as well as in systems with natural circulation. Despite the lower metal consumption (length of pipelines), the system often consists of disadvantages:

- With the sequential movement of the coolant of the first radiator to the next, a significant drop in temperature occurs, so the heat transfer surface should increase with distance from the hot water supply.

- There is no possibility of individual regulation of the heat transfer of each radiator.

- The presence of a bypass on the radiators generally averages the temperature in the heating system riser, but also preserves the impossibility of regulation.

Two-pipe heating systems are the most common option and adapt to almost any piping layout in the building (dead-end, associated or collector). Heat is supplied to and removed from radiators through different pipelines. The system is more stable from the hydraulic side and is subject to both qualitative and quantitative regulation. See the section with the classification of heating systems in the direction of flow of the heating medium.

One-pipe and two-pipe heating systems

In any heat supply system, water is heated in the boiler, then enters the heating devices, after which it returns to the boiler through the return pipe. However, such a movement of the coolant can be carried out in different ways.

A single-pipe system assumes the movement of liquid through one large-diameter pipe, and all heating devices are located on the same line.

A single-pipe heating system with natural movement of the coolant has several advantages:

- Use of a minimum amount of consumables.

- Simple assembly of all elements and their connection.

- The minimum number of pipes in the room.

Of the disadvantages of such a pipe layout, attention should be paid to the uneven heating of the batteries. With a distance from the gas boiler for an open heating system, the batteries heat up less, respectively, their heat transfer decreases.

The two-pipe system is gaining popularity. Due to the fact that the heating devices are connected to both the supply and return pipes, the system forms a kind of closed ring.

Among the advantages of this scheme are the following:

- Uniform heating of all heating devices.

- An individual temperature can be set for each radiator.

- High reliability of the heating system.

Of the minuses of a two-pipe heating system, a more complex installation of communication branches inside the room and significant investments and labor costs stand out.

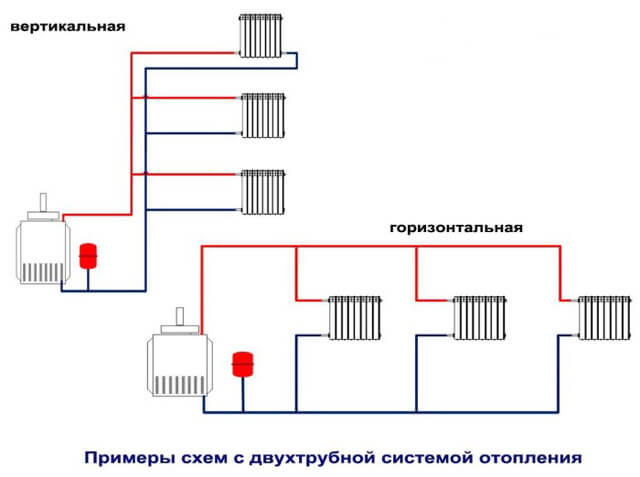

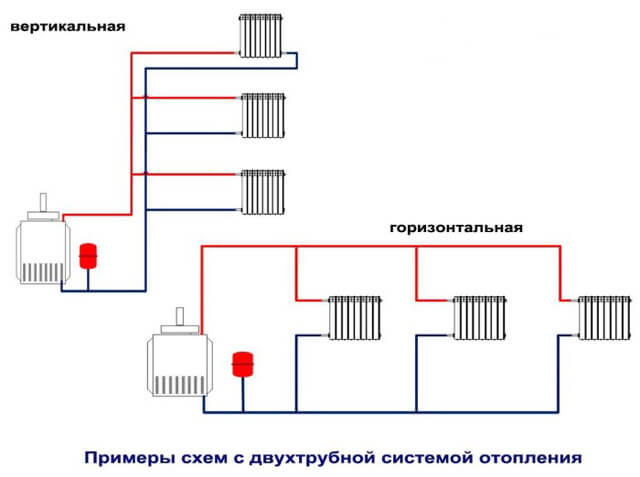

Pipeline arrangement options

There are two types of two-pipe routing: vertical and horizontal. Vertical pipelines are usually located in multi-storey buildings. This scheme allows you to provide heating to each apartment, but there is a large consumption of materials.

A positive property of such a wiring is the natural outlet of air from the pipes, as it rises upward. The horizontal scheme is used in one-story and two-story construction. Air from the pipelines is removed using Mayevsky taps installed on each radiator.

Top and bottom routing

Coolant distribution carried out according to the upper or lower principle... With top routing, the supply pipe runs under the ceiling and down to the radiator. The return pipe runs along the floor.

With this design, the natural circulation of the coolant occurs well, due to the height difference, it manages to gain speed. But such a layout was not widely used due to its external unattractiveness.

The scheme of a two-pipe heating system with a lower wiring is much more common. In it, the pipes are placed at the bottom, but the supply, as a rule, passes a little higher than the return. Moreover, pipelines are sometimes run under the floor or in the basement, which is a great advantage of such a system.

This arrangement is suitable for schemes with forced movement of the coolant, since during natural circulation, the boiler must be at least 0.5 m lower than the radiators.Therefore, it is very difficult to install it.

Oncoming and passing movement of the coolant

A two-pipe heating scheme, in which hot water moves in different directions, is called counter or dead-end. When the movement of the coolant is carried out along both pipelines in the same direction, it is called a passing system.

The associated circuit is easier to adjust and adjust, especially in main pipelines. If the number of sections of the radiators is the same, then there is no need for balancing in the passing scheme.

In such heating, often when installing pipes, they resort to the principle of a telescope, which facilitates adjustment. That is, when assembling the pipeline, pipe sections are laid sequentially, gradually reducing their diameter. With the oncoming movement of the coolant, there must be thermal valves and needle valves for adjustment.

Fan connection diagram

The fan, or beam, scheme is used in multi-storey buildings to connect each apartment with the possibility of installing meters. To do this, a collector is installed on each floor with a pipe outlet to each apartment.

And for wiring only solid pipe sections are used, that is, without joints. Thermal metering devices are installed on the pipelines. This allows each owner to control his own heat consumption. When building a private house, such a scheme is used for floor-by-floor piping.

To do this, a comb is installed in the boiler piping, from which each radiator is connected separately. This allows you to evenly distribute the coolant between the devices and reduce its losses from the heating system.

Coolant supply methods

The hot fluid line can be positioned in several ways. Depending on this, the eyeliner is divided into upper and lower.

The upper distribution implies the supply of hot coolant through the main riser and distribution to the radiators through the distribution pipes. This system is best used in private residential buildings and cottages one or two stories high.

A heating system with a lower wiring is considered more efficient and practical. In this case, the supply and return pipes are located side by side, and the coolant moves from bottom to top. Hot water flows through the heaters and returns to the boiler for the open heating system through a return pipe. To prevent air accumulation in the heating system, a Mayevsky crane is installed on each radiator.

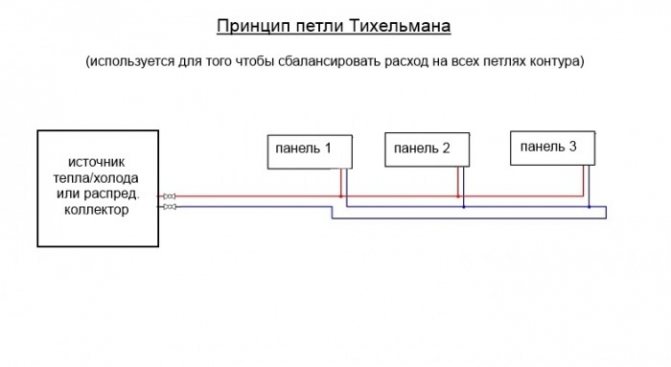

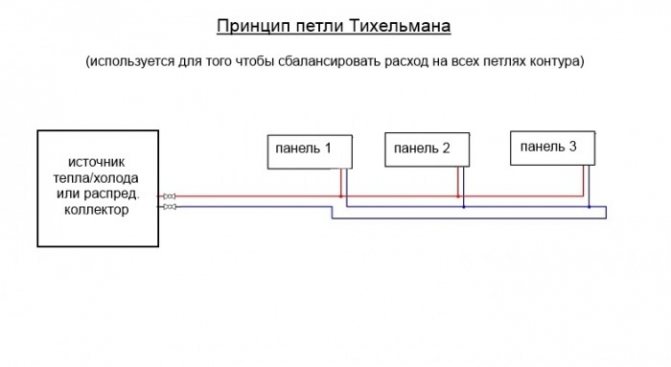

How Tichelmann Loop Works

The most common in household networks is a dead-end scheme for the movement of the coolant. Its principle of operation is that heated water from the boiler through the supply line enters each radiator

, and at the outlet from the heater circuit, it is immediately directed to the boiler through the return line. Thus, the flows of water in the "supply" and "return" move towards each other. In this case, the supply line runs from the boiler to the last device, and the return line runs in the opposite direction, starting from the last battery to the boiler.

A fundamental feature of a passing system is that both in the supply and return pipes the coolant moves in the same direction

... Typically this is used in networks with lower wiring. In this case, it is planned to lay not two, but three pipes:

- supply pipeline;

- return pipeline;

- pipeline for returning the coolant from the return line to the boiler.

In this case, the "supply" also runs from the boiler to the last heater.The return pipe runs from the first to the last heater. Thus, the coolant moves along it in the same direction as through the pressure pipeline. From the last heater, it returns back to the boiler through a separate pipe.

Main risers

Depending on the location of the main risers, the wiring can be vertical or horizontal.

In the first case, radiators on each floor are connected to a vertical riser. Such a system has its own characteristics:

- No air pockets are formed.

- Effective heating of buildings several storeys high.

- The ability to connect heating radiators on each floor.

- more complex installation of heat meters in apartments in multi-storey buildings.

With horizontal wiring, all floor radiators are connected to a single riser. The main advantage of such a scheme is the use of fewer materials for installation and, accordingly, a lower cost of the system.

Modern shut-off equipment for temperature control

Heating systems are the veins of modern houses that carry heat and heat them. Modern heating systems imply the use of the latest solutions and schemes, together with various types of equipment, which make it possible to automate the supply of heat throughout the networks.

Such elements can control the heating of houses even without human intervention and regulate the temperature within specified limits, depending on the time of day.

One-pipe heating can be significantly upgraded with new types of shut-off valves. Modern heating systems can imply installation on the flow pipe and bypass instead of two valves - one.

Such an element is called a three-way valve. Depending on the position of the closing damper, the three-way valve can open the path for the coolant to the radiator and close the supply to the bypass, and vice versa - it closes the bypass and opens the flow of the mixture to the battery.

Such cranes can be equipped with an electric drive, which is connected to a special device - a controller. This controller measures the air temperature in the room, or the degree of heating of the coolant mixture and gives commands to the three-way valve, thereby increasing or decreasing the supply of the coolant to the radiators. The rest of the hot heat flow is discharged into the bypass.

Necessary calculations

It is very important to correctly perform hydraulic calculations; on their basis, the pipe diameter is selected for an open-type heating circuit with a pump.

To calculate the circulating pressure, the following parameters should be considered:

- Distance from the central axis of the boiler to the center of the heater. The larger this value, the more stable the coolant circulates.

- Water pressure at the outlet of the boiler and at the inlet to it. The circulating head is determined by the difference in fluid temperature.

The diameter of the pipeline largely depends on the material from which they are made. Steel pipes for the heating system must have a cross section of at least 5 cm. After wiring, pipes of a smaller diameter can be used, but the wiring, on the contrary, should expand.

The parameters of the expansion tank are also of great importance. For efficient operation of the system, a reservoir should be used that has a volume of about 5% of the volume of all fluid in the system. Failure to do so may result in pipes bursting or excess water splashing out.

Advantages and disadvantages

Among the main advantages are:

- ease of installation, which does not require large labor costs;

- low cost;

- aesthetic appearance, because one pipe runs through the house.

The disadvantages include:

- uneven distribution of the coolant over the radiators, as a result of which additional devices have to be installed;

- in two-story or more houses, for the effective operation of the system, it is necessary to create an increased pressure of the coolant by installing a circulation pump;

- when using metal pipes, it is much more difficult to dismantle and replace radiators.

System complete set

Open-type heating in a private house requires the installation of a boiler that runs on solid fuel or fuel oil. The fact is that this type of heating is characterized by the periodic formation of air jams, which can cause an accident when using electric and gas boilers.

The power of a heating boiler can be calculated according to the standard scheme, according to which 1 kW of energy plus 10-30% is required to heat 10 m2 of the area of the room, plus 10-30%, depending on the quality of thermal insulation.

You should not use polymers as a material for the expansion tank; steel is the best option in this case. The volume of the tank depends on the area of the heated room, for example, in the heating system of a small building with a height of one floor, an expansion tank of 8-15 liters can be used.

As for the pipes for the heating system diagram with a circulation pump, in this case the following materials can be used:

- Steel... Such a pipeline is characterized by high thermal conductivity and resistance to high pressure. However, the installation has some difficulties and requires the use of welding equipment.

- Polypropylene... Such a system is notable for easy installation, strength and tightness, it is able to withstand temperature fluctuations. Polypropylene pipes have been characterized by flawless operation for a quarter of a century.

- Metal-plastic... Pipes made of this material are resistant to corrosion, deposits do not form on their inner walls that impede the natural movement of the coolant. However, the cost of such a system is quite high, and its service life is only 15 years.

- Copper... A copper pipeline is considered the most expensive, but it perfectly tolerates high temperatures, up to +500 degrees, and is characterized by maximum heat transfer.

Heating devices in an open heating system must be sufficiently durable, therefore, metals with similar properties should be chosen. The most popular are steel radiators, which is explained by the optimal combination of the appearance of the models, their price and thermal power.

Classification

- Heating system type based on the created differential:

- Gravity heating system (with natural circulation);

- Pumped (mechanical) forced circulation heating system.

- Scheme of supplying the coolant to heating devices:

- standard or dead-end;

- passing;

- beam or collector.

- By the method of supplying and removing the coolant:

- one-pipe;

- two-pipe.

- By the method of installation of pipelines:

- open strip;

- concealed installation.

- By the type of material used for pipelines and connecting fittings:

- Steel pipelines;

- Copper piping;

- Reinforced-plastic pipes;

- Polypropylene pipelines;

Sequence of actions for self-installation of the system

Arrangement of an open-type heating system implies the sequential performance of the following work:

- Heating boiler installation. Depending on the size, the equipment is securely and firmly fixed to the floor or fixed to the wall.

- Pipe routing. The pipeline is installed in accordance with the previously drawn up project and the selected scheme. At this stage, we must not forget about the recommended slope along the entire contour.

- Installation of heating devices and their connection to a common pipeline.

- Installation of the expansion tank and its thermal insulation (if necessary).

- Connection of system elements.

- Test run, during which places of loose connection are identified.

- Heating system start-up.

It is recommended to install a temperature sensor at the outlet of the boiler, with the help of which the efficiency of the open-type heat supply system is monitored.

Features of systems with forced circulation of the coolant

For high-quality and efficient operation of the forced circuit of an open-type heating system with a pump, the installation of appropriate equipment is required. In this case, it is necessary to correctly select the pump and the place for its installation.

Pump selection rules

The device is chosen according to two main characteristics: power and head. These parameters directly depend on the area of the heated building. In most cases, the following values are taken as a reference point:

- For a system heating an area of 250 m2, a pump with a capacity of 3.5 m3 / h and a pressure of 0.4 atmospheres is required.

- For an area up to 350 m2, it is better to choose equipment with a capacity of 4.5 m3 / h and a pressure of 0.6 atm.

- If the building has a large area, up to 800 m2, then it is recommended to use a pump with a capacity of 11 m3 / h with a pressure of more than 0.8 atmospheres.

If you more carefully approach the choice of pumping equipment, then additional parameters are taken into account:

- Pipeline length.

- The type of heating devices and their number.

- The diameter of the pipes and the material from which they are made.

- Heating boiler type.

Pump connection to the heating circuit

It is recommended to install the circulation pump on the return pipe, in this case, the already cooled liquid will pass through the device. However, when using more modern models, which are made of heat-resistant materials, a tie-in to the supply line is not excluded. In any case, the installed equipment should not disturb the circulation of the coolant.

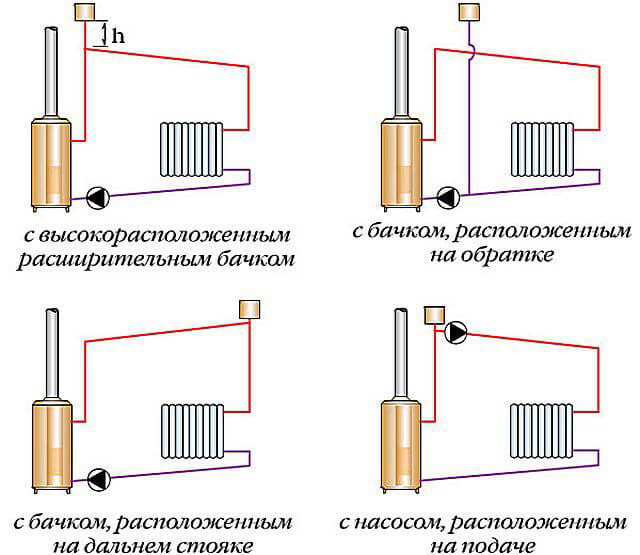

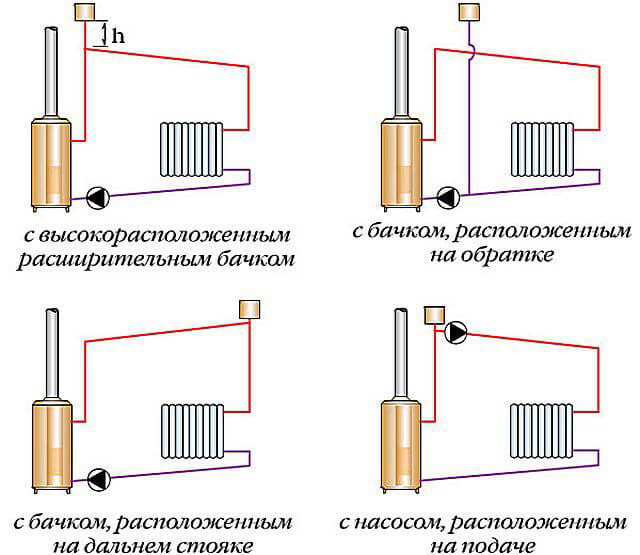

There are several options for changing the gravitational scheme to a forced option:

- Installing the expansion tank at a higher level. This option can be called the simplest, but this will require a high attic space.

- The expansion tank is transferred to the distant riser. If you use this method to reconstruct an old system, it will take a lot of time and effort. If you equip a new system according to this scheme, then it will not justify itself.

- Placing the riser of the expansion tank in close proximity to the elbow on which the pump is located. In this case, the pipe with the reservoir is cut from the supply line and cut into the return pipe behind the pump.

- Pump connection into the supply line. This method is considered the best option for the reconstruction of the heating circuit. Keep in mind, however, that not every appliance can withstand high temperatures.

In order for the heating system with an open expansion tank and pump to work efficiently, it is important to choose the right circuit, calculate the parameters of all constituent elements, select the appropriate equipment and carry out the installation work in sequence.