Automatic and mechanical thermostats

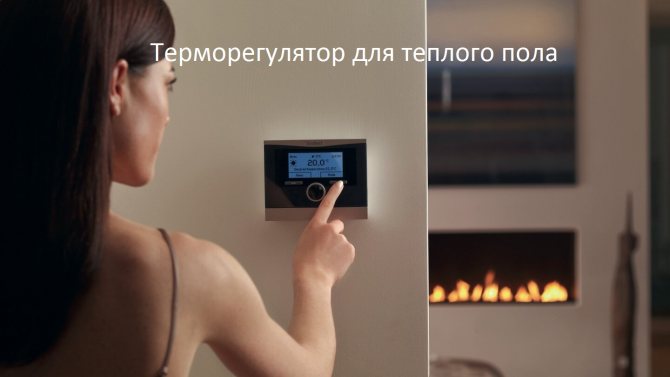

Thermostats for underfloor heating

There are several ways to control underfloor heating. All types of devices can be conditionally divided into two types: automation and mechanics. What is the fundamental difference between these devices?

- Automatic floor controllers are cheaper than automatic controllers for a water heating system. The average cost of a thermostat for an electric floor rarely exceeds 1000 rubles. Thus, automatic equipment for an electric floor rarely costs more than 3000–4000 rubles;

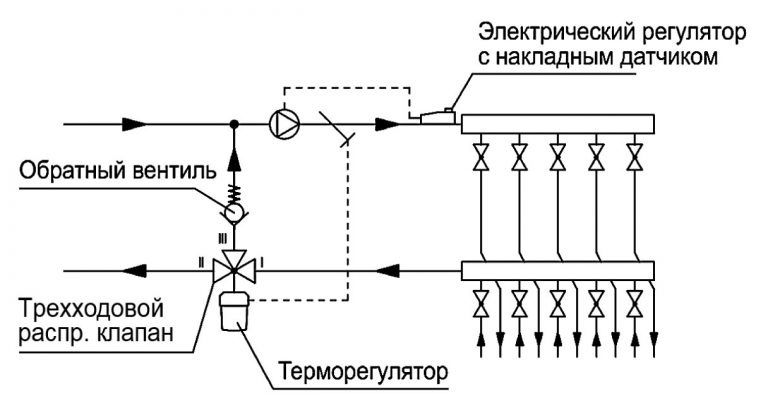

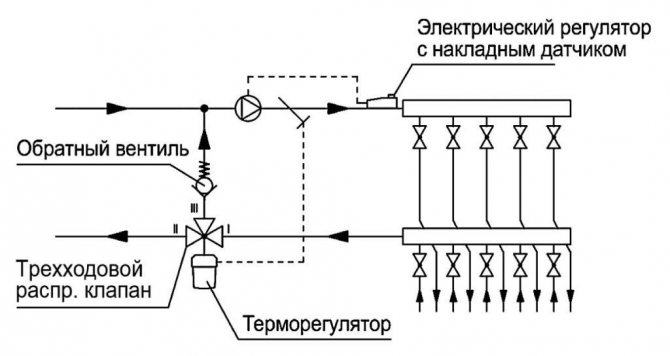

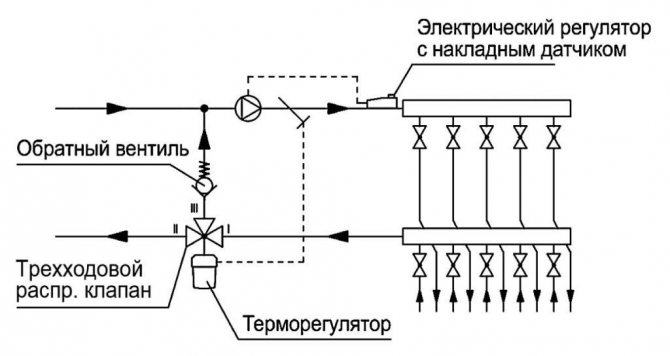

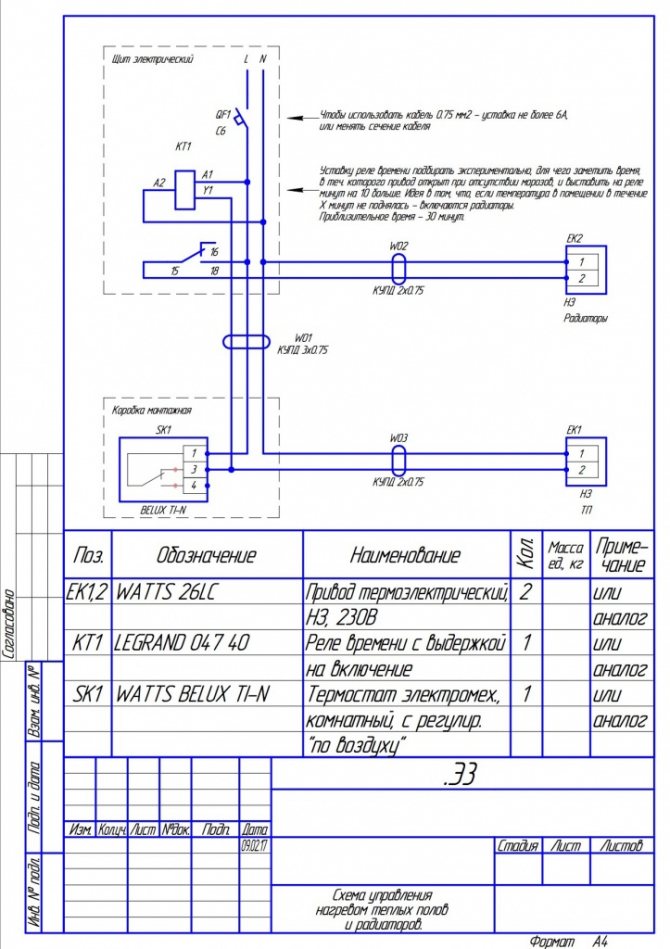

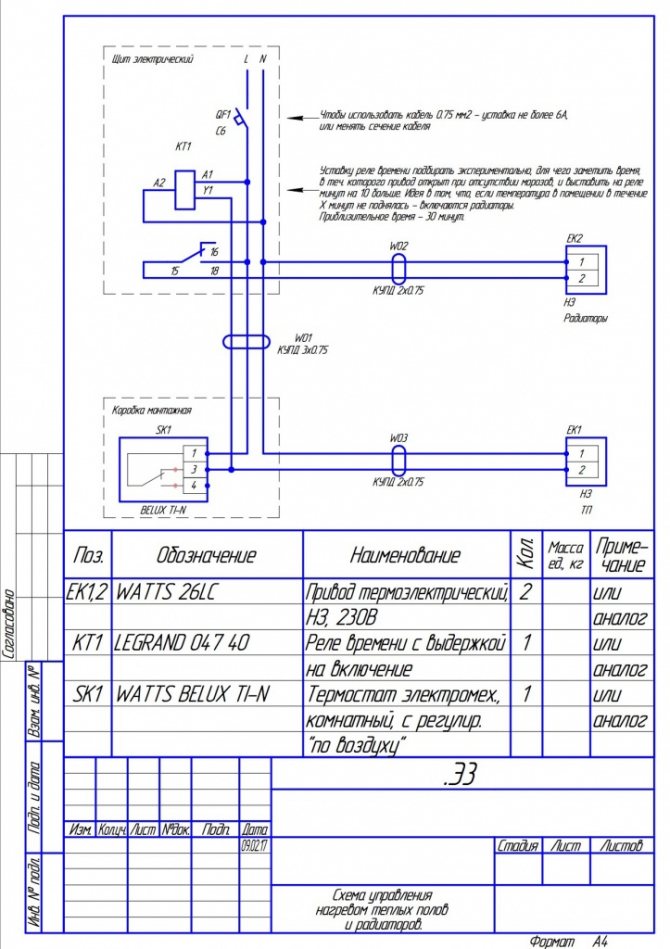

Scheme of operation of automation for electric underfloor heating - The automatic control system for a water-heated floor requires more complex technological solutions, the average cost of which often exceeds 20,000 rubles.

Automatic temperature control system for water heated floor

As for conventional mechanics, it is much cheaper and is designed for manual adjustment of the floor heating operation. The lack of a screen and thermometers is the main disadvantage of mechanical thermostats. With the help of devices of this type, you will not be able to adjust the operation of the warm floor to the desired mark on the thermometer. The regulation of such heating systems is carried out based on one's own feelings: hot means the tap must be screwed on, cold must be unscrewed.

Underfloor heating equipment

The mechanical controller is in low demand in the thermostat market, since it is significantly inferior in popularity to electric thermostats with a display. In addition, electrical automation is so simple that even children and the elderly can operate it.

Choosing a thermostat

When choosing the right thermostat for home use, you should pay attention to the following factors:

- First of all, you need to choose a system in which the power of the sensors fully matches the power of the floor. In the event that the sensor does not fully provide the floor, the room will not be heated to the desired temperature. If several sensors are connected in a large room at the same time, then their power may not be enough. For this reason, you will have to connect additional regulators.

- Another important factor is the type of device. There are two types: external and internal. The internal type of regulator is installed inside the wall. For this it is necessary to make a deepening. If there is no desire to spoil the wall, then it is worth installing an external temperature regulator. For this, a box is used.

- Everyone should choose the functioning of the regulator according to their taste. If a person often needs to leave the house for work, then it would be more rational to buy a programmable regulator that can be programmed for a long time and controlled remotely. In other cases, it is worth choosing those that are suitable both in price and at the request of the consumer.

- And the last thing is the appearance of the regulator. There are a large number of them. They differ from each other in shape, color and other parameters. But in most cases, they are similar to regular household outlets.

Many will doubt that they need a device such as a thermostat. And this is an erroneous opinion, because otherwise it is necessary to install a special cable that independently regulates the degree of self-heating. Such a warm floor is not durable and quickly deteriorates.

Automation capabilities

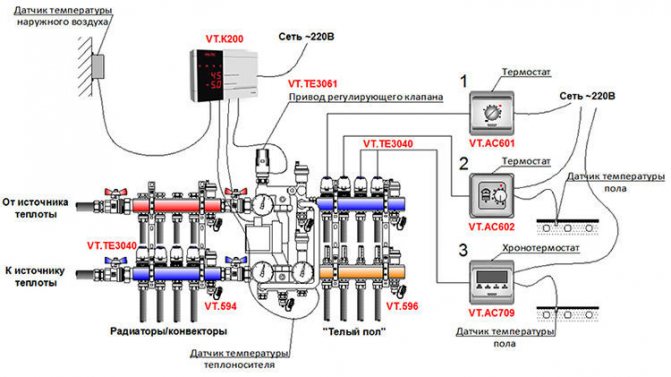

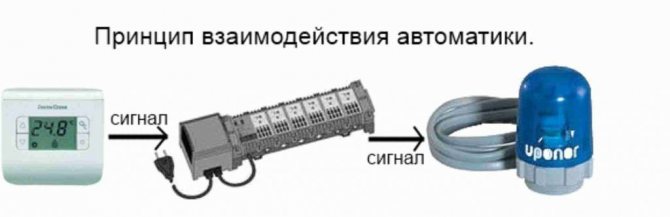

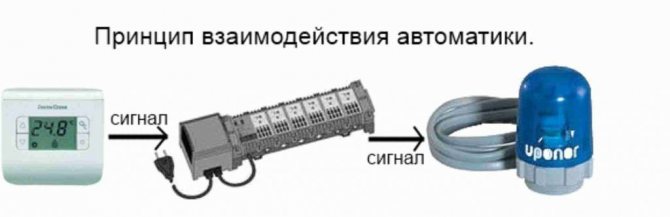

Automation takes part in the control of the following devices: circulation pump, thermostatic heads, servo drives, thermostatic valves or a gas burner.

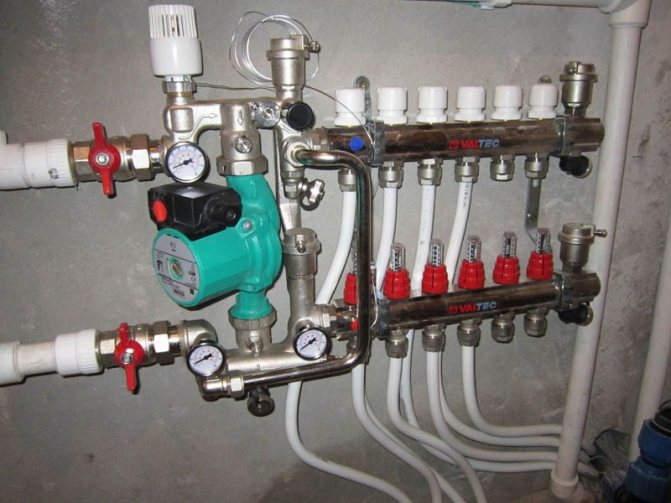

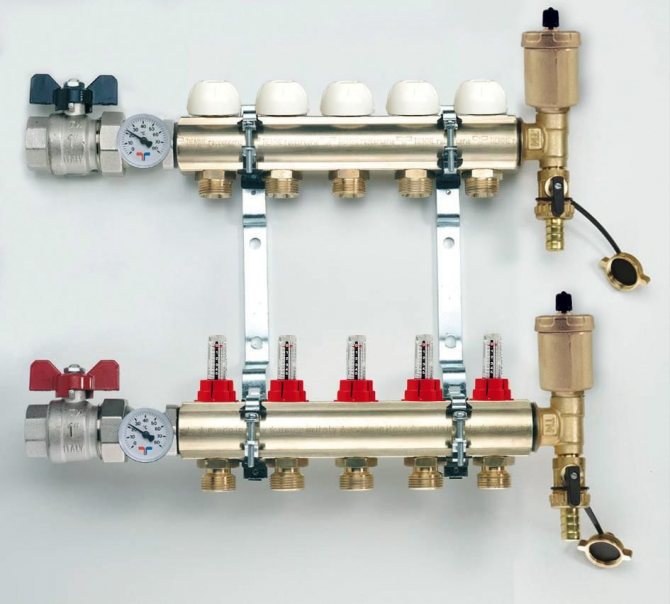

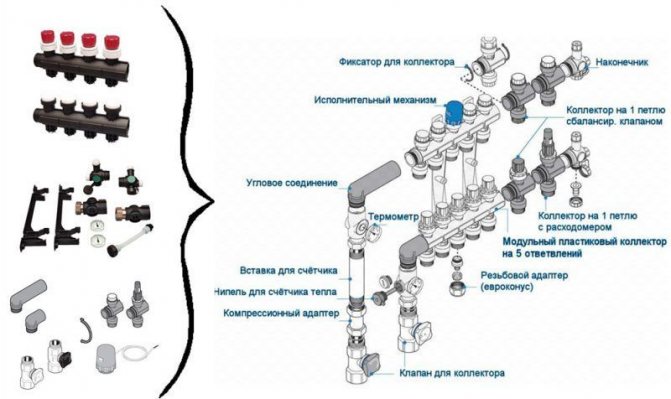

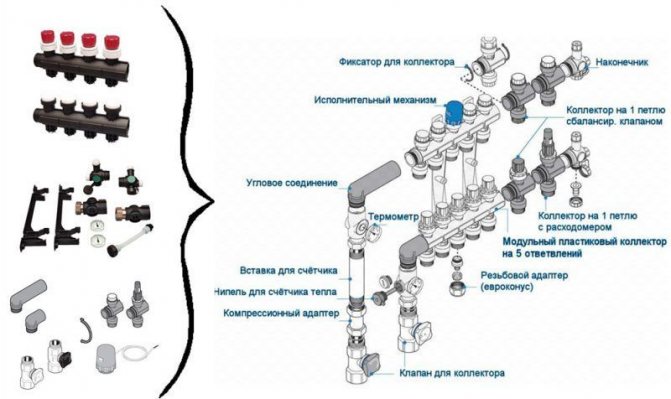

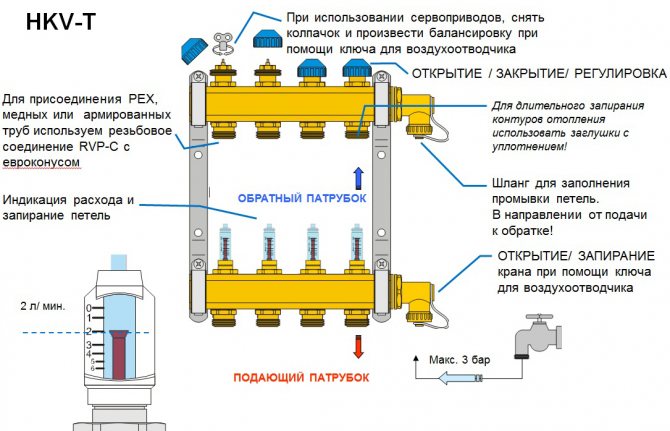

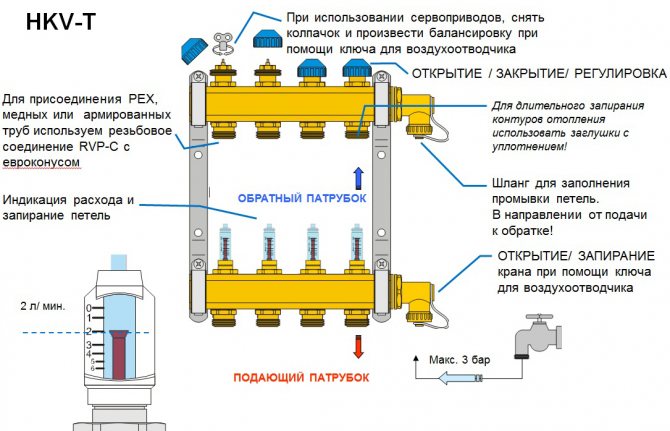

Collector device for underfloor heating on automation

- Circulation pump control is the easiest way to control the operation of a water floor. The device allows you to turn on / off the pump depending on the temperature of the water in the pipes. This control method is not suitable for a house where there is one common pump, since the system turns off the heating in the entire room. But this method of controlling the temperature in the house is ideal for rooms where there are several pumps;

- Thermal head control is a semi-automatic control system that allows heating to be turned off under certain conditions. For example, the thermal head closes the three-way valve as soon as it detects a high temperature of the water in the pipes. Low temperature of the coolant triggers a reverse reaction - the system opens the valve of the hot water pipe;

Mixing unit for underfloor heating Valtec for 2-4 circuits - Servo control. In this case, a servo drive is mounted on the collector, with the help of which the coolant supply to different circuits is adjusted. This type of controller is excellent for temperature control in several rooms at the same time;

- The weather controller adjusts the floor temperature depending on the weather conditions. The system consists of a complex set of sensors and controllers, some of which are installed on the street, and others - in the apartment. This method allows you to save up to 20-30% of gas consumption or 15% of firewood for space heating.

As for private houses with 2-3 rooms, it is not necessary for them to install expensive and complex automatic systems. For effective control, automation for a circulation pump or a conventional mechanical valve is sufficient.

Servos for manifold

For underfloor heating, the pipeline is connected to a manifold. The equipment has outlets for hot coolant and for chilled liquid that is pumped into the boiler. The number of outputs in the manifold corresponds to the number of water heating circuits. A coolant of a certain temperature is supplied to the line. Servos are designed to regulate it by means of valves located on the manifold.

We recommend: How to assemble a collector for an underfloor heating?

The underfloor heating control unit has the following components:

- spring made of nichrome; an electric current passes through it;

- container with thermal fluid; it is heated by means of a nichrome spring;

- the stem to which the cold circuit valves are attached;

- thermal sensor; the device is installed on the underfloor heating liquid circuit;

- thermostat; it is programmed for a certain mode; a temperature sensor and a servo cable are connected to it.

A certain heating mode is set on the thermostat. If the floor temperature exceeds the set parameter, the thermostat closes the servo circuit. The spring, which is in the thermal fluid, begins to heat up.

The fluid expands and presses on the stem, which opens the valve for the cold circuit. In the mixing chamber, the hot coolant and chilled water are mixed. Warm liquid enters the floor line.

When the set temperature drops, the thermostat opens the servo circuit. The spring begins to cool down, the thermal fluid cools down and narrows. The stem rises and closes the cold circuit outlet. The underfloor heating system is installed in Moscow for heating country cottages.

When using a servo drive, the thermal fluid heats up and cools down quickly. The system changes the operating mode in 1-3 minutes. The thermal head on the mixing unit turns off the heating system for 15 minutes. The machine for the warm floor can be controlled remotely by means of servo drives using electronic gadgets.

Individual and group heating controllers

Devices of this type belong to a separate category, since they allow you to regulate the temperature of the water supplied to several collectors. They operate on a voltage of 24-50 V and can be used even in rooms with a high level of humidity - baths or saunas.

Water underfloor heating control on the outside temperature

How does it work? Complex regulation combines group and zone automation. The complex type controller usually takes into account the specifications, combinations and layouts of films or pipes.

Underfloor heating room thermostat, underfloor heating controller and servo drive

The signal from the group manifold is fed to the servo which drives the flow control valve. Thus, group regulation is the control of the temperature of the water in the pipes, which is realized due to:

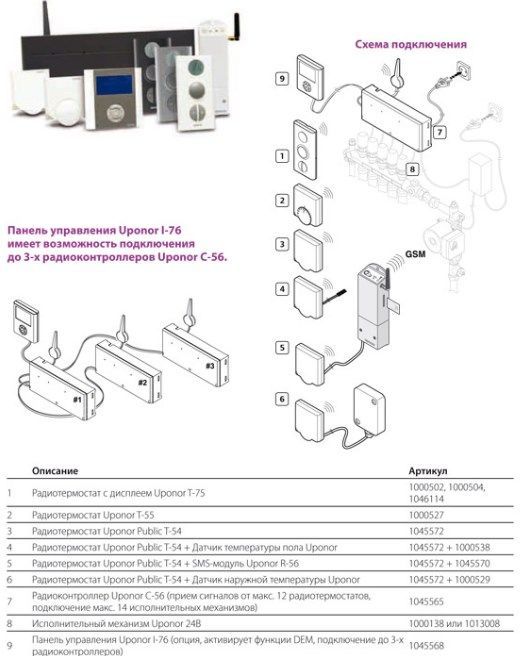

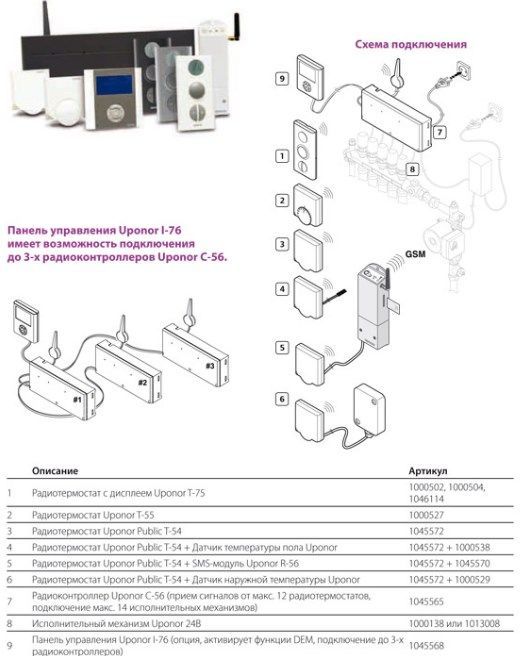

Uponor wireless underfloor heating system DEM

- Grouping of mixing units, which allows you to adjust the parameters of the water circulating in the pipes in several zones or collectors at once;

- Connections of individual mixing units, due to which branching of the group connection occurs - individual adjustment points are created for underfloor heating. Branching into individual mixing units allows you to control the underfloor heating through one unit;

- Maintaining a constant temperature in all rooms. Implemented with a thermostatic head mounted on a two- or three-way valve;

- Climate control. In this case, a complex system of several sensors is used to maintain the temperature of the coolant according to the specified parameters.

Zonal (individual) regulation is implemented due to:

Floor heating automation

- Room automation installations, the sensor block of which allows you to regulate the air temperature in a single room according to the specified parameters;

- Zone automatic floor heating is used to automatically control the temperature in the room. The zone control unit is installed in rooms, the functioning of which is impossible without maintaining the temperature at a constant level (swimming pools, saunas, greenhouses).

Zone regulation is carried out as follows - the user sets the required parameters for the thermostat. A deviation of the temperature regime up or down entails a corresponding reaction - the device turns on or off the heating using a warm floor.

Scheme of zonal regulation of water underfloor heating

Watts water underfloor heating made easy

The author of the article is Ustalov D.S. Chief Service Specialist

Do not take the title of the article as a call to refuse the services of specialists. For the design of heating systems, at least knowledge of heating technology and hydraulics is required. And specially trained engineers should do this. Our goal is to make you a competent consumer - a person “in the know”, who knows exactly what he wants and what equipment he needs. Fortunately, WATTS INDUSTRIES manufactures the entire line of equipment for "warm floors". And if you have an inquiring mind and skillful hands - the information given will be enough for self-production of the "warm floor" system in your home.

What is good about "warm floor water and electric"

The key word is comfort. This is the main advantage of the "warm floor". A room with such a heating system warms up evenly, there are no "cold" and "hot" zones. It is pleasant to walk on such a floor even with bare feet, especially on frosty days. For older people, this is a big plus. Didn't your grandmother go around the house in felt boots? And in woolen socks? With a "warm floor" she would not have such a need.

The second big plus is the "invisibility" of the underfloor heating system.Most citizens tend to hide heating devices behind various decorative screens, in building structures, etc. Forgetting that the heat transfer of the device decreases, often at times. With underfloor heating, such a problem does not exist, and the designer's imagination is not limited by anything.

What's wrong with the "warm water floor"?

The main disadvantage of "warm floor" is high inertia. External conditions are constantly changing: the air temperature on the street changes, the sun appears / hides, there is no one in the room, then there are many people, household appliances and lighting are turned on / off. At the same time, we want the room temperature to remain constant. Underfloor heating is a large amount of concrete that cools slowly and heats up slowly. In a room with a "warm floor" the temperature will "walk" up and down more than in a room with radiators, and you will have to put up with this. Part of the problem is solved by "smart" regulators for underfloor heating, which take into account this thermal inertia. We'll talk about regulators below.

Another drawback is that the power of "warm floors" is limited. We cannot heat the floor to high temperatures - we will not be comfortable. Building codes limit the surface temperature of the floor to 26 degrees for rooms with a permanent stay of people and up to 31 degrees for bathrooms and other rooms with a temporary stay. At this temperature, the heat transfer (roughly) will be from 55 to 112 watts per square meter.

In modern buildings, this heat transfer is sufficient to heat most rooms. But if your room has high ceilings, or a large glazing area, or several outer walls, the heat transfer may not be enough, and you will have to install additional heating devices. In this case, it is better to contact a specialist to carry out a heat engineering calculation "according to all the rules."

Warm floors myths

Over the past few years, we have seen aggressive advertising from manufacturers of electrical heating systems, especially thin film systems. It is always pleasant to listen to stories about rivers of milk and jelly banks, just do not forget the economic side of the issue. If you use electric heating, you will consume exactly as much electrical energy as your house (or apartment) will lose heat. The amount of this heat, or heat loss, is determined by indoor and outdoor temperatures, as well as by the structure of your building (walls, windows, ceilings), nothing else.

Obviously, heat loss practically does not depend on what kind of heating system you have - water or electric. The automation of the electric "warm floor" does not functionally differ from the automation of the water one, so there is no room for savings here either. But the cost of one kW * h of electric energy is 5-10 times higher than the cost of gas required to obtain the same amount of heat. In general, electrical energy is the most expensive form of energy, albeit the most convenient. Choosing an electric "warm floor", you save on the cost of equipment, but your monthly payments will be several times higher than any other option.

How it's done? Do-it-yourself water heated floors. Laying a water heat-insulated floor.

Pipes

The best solution for water-heated floors is polyethylene pipes. Regular polyethylene is not suitable here, it is necessary to use cross-linked polyethylene (PE-X) or heat-resistant polyethylene (PE-RT). There is no difference between these pipes, choose any.

| We produce both types of pipes in a wide range: 12, 15, 16, 17, 18, 20 mm (outer diameter). A wide assortment is convenient for specialists - you can choose the pipe that is optimal for hydraulics. | |

| WATTS PE-RT DD (EVOH) | WATTS INTERSOL PE-X B |

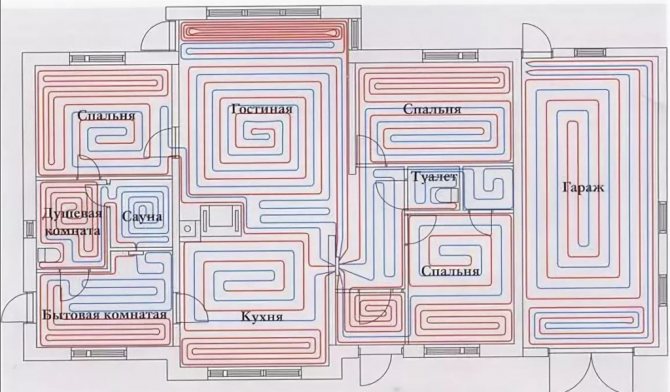

If you make a "warm floor" with your own hands, without calculations, choose between 16 and 20 pipes. With the "sixteenth" pipe you can "roll up" the area up to 20 m2, with the "twentieth" - up to 40 m2.If your floor is more than 40 m2, you need to split it into several parts, each of which should not exceed 40 m2. The longest side of your underfloor heating should not exceed 8 meters. Exceeds - Divide again. The laying step when using the 16th pipe will be 200 mm, the 20th - 250 mm.

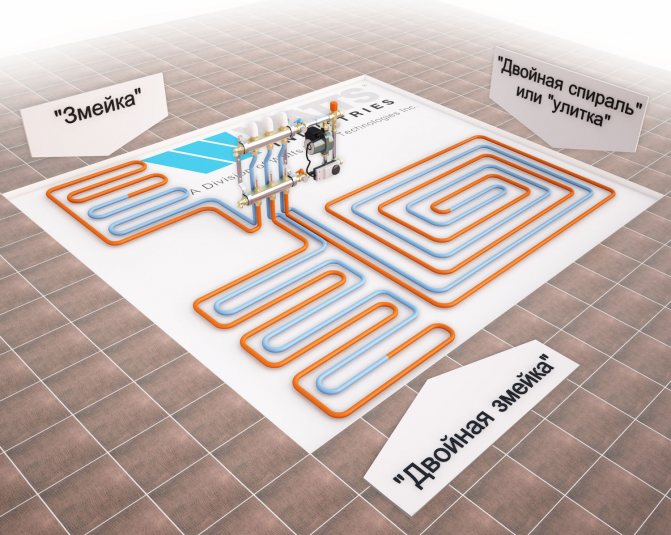

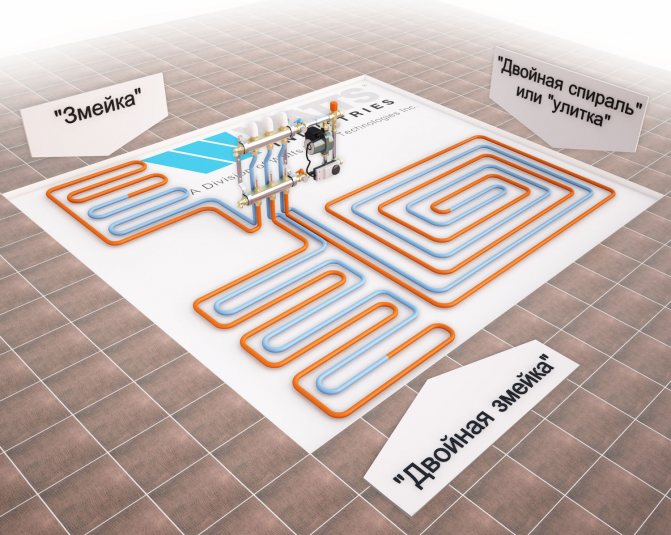

The pipe should be wound in a "double helix". You can also wind it with a "snake", but the heating of the floor will be less uniform, and the leg will feel it - we see no reason in such a winding.

Another important point - there are pipes with oxygen protection (with the addition of EVOH in the name), there are no protection. If you have a cast iron boiler, or there are steel radiators in the heating system, you need a pipe with protection. If the boiler is wall-mounted, with a copper or stainless steel heat exchanger, and heating devices without steel elements, use a pipe without protection.

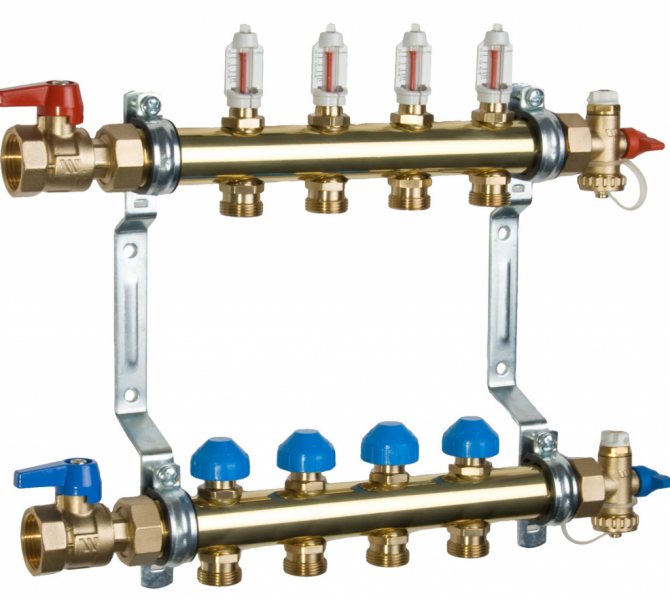

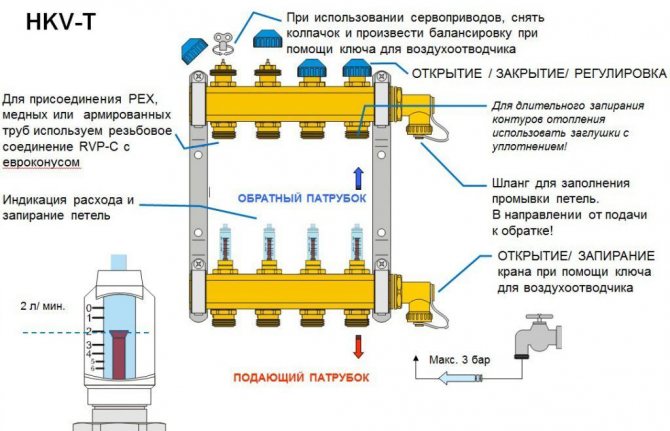

Collector for underfloor heating

| |

| Brass manifold HKV2013 A MS | Stainless steel manifold HKV2013 VA |

Each room with a "warm floor" is at least one circuit (one pipe loop). All these circuits must somehow be combined into one and connected to a boiler or other heat source. This is where collectors come to our rescue. We produce a wide range of collectors for underfloor heating, but the choice, as in the case of pipes, is quite simple. Let's start with the material. The collectors are made of brass or stainless steel. There is no functional difference, but aesthetically, stainless steel manifolds look better.

Now about the filling. Collectors designed for a warm floor must perform three mandatory functions: shut-off (the ability to turn off a separate loop of the "warm floor"), regulating (the ability to change the amount of coolant flowing through the loop of the "warm floor", depending on the air temperature in the room or the surface temperature floor) and balancing (the ability to adjust the hydraulic resistance of each loop of the "warm floor"). Our collectors have it all. On the “supply” there are shut-off valves (manually operated), on the return there are shut-off and control valves for the installation of servo drives (they are controlled by automatic equipment, and the adjustment is done manually with a special key).

We also have manifolds with flow meters, which are liked not only by installers (easy to set up), but also convenient for you to control later. It's clear that extra convenience comes with extra money. All of our manifolds have a different number of "outlets" - from two to twelve. That's all, the choice is yours.

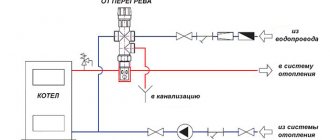

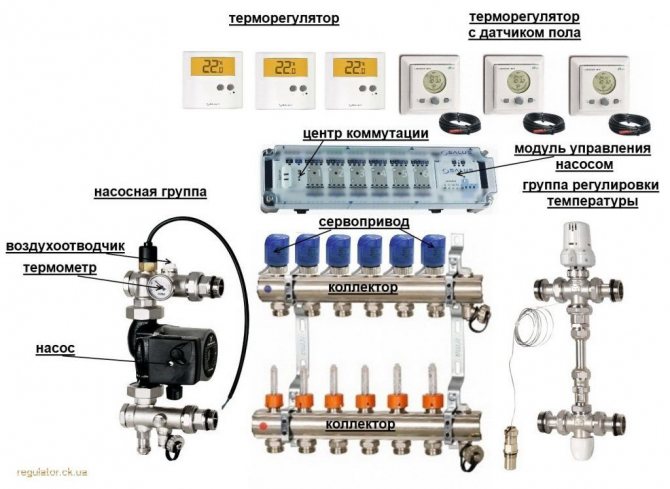

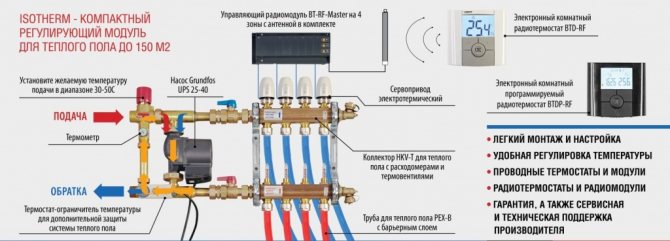

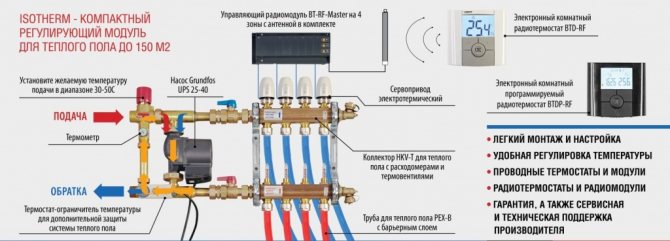

Pump and mixing modules. Mixing unit for underfloor heating.

The temperature of the coolant that you supply to the "warm floor" should not exceed 55 degrees. These are considerations of comfort (so that the floor does not overheat), and all kinds of engineering considerations (uniformity of heating, hydraulics, concrete dehydration at elevated temperatures, thermal expansion of structures, etc.).

Most often, the "warm floor" works in the 45/35 mode or close to this. If your house is heated only by “warm floors” and you have a condensing boiler installed, you do not need a mixing module. In all other cases, it is simply necessary. The function of the module is to lower the temperature coming from the heat source by mixing in the "return" coming from the "warm floors". And to ensure the circulation of the coolant through the loops of the "warm floors".

The module also has a protective function - if the control valve fails for any reason, and an overheated coolant goes into the floors, the circulation pump will stop and nothing threatens your floors.

This module connects directly to the collectors that you selected in the previous step. We offer four pump-mixing modules for your choice.

| FRG 3005F | FRG 3015F | ISOTHERM | FRG 3015W2 |

For small heating systems (up to 50 m2) we offer the FRG 3005F module. If your system is larger, use the FRG 3015F or ISOTHERM modules, they can serve up to 150 m2.

Between themselves, these modules differ in the location of the pipes for connecting the heat source, in the first case they "look" vertically down, in the second - horizontally, coaxially with the collectors. All of the aforementioned modules maintain the same temperature that you set on the module's regulating valve. If you want to implement temperature control according to a time schedule (night temperature decrease), or "weather-dependent" regulation - the FRG 3015W2 module is for you. The temperature is controlled by an external controller.

But what if you have not just a house, but a palace, and the area of warm floors is more than 150 m2? The answer is simple - use multiple modules.

It also always makes sense to separate the warm floors of bathrooms and bathrooms into a separate circuit, with its own mixing module. In these rooms, the temperature of the floor surface is higher, therefore, the temperature of the coolant must be higher.

Electrothermal Servo Drives

We laid the pipes, attached them to the collectors, screwed the mixing module, what next? It's time to talk about temperature management. Let's start with devices called "executive" devices. With servos. They are installed on the manifold control valves, and at the command of some external device they control the valves. Those. fulfill someone else's will, and therefore "executive".

The servo drive works as a switch - it completely closes the control valve, and the movement of the coolant through the loop of the "warm floor" completely stops. The room has warmed up - the “warm floor” has completely turned off and is slowly cooling down. The room has cooled down by half a degree - the "warm floor" has switched on "at full" and raises the temperature back. That is, if the required temperature in the room is 20 degrees, the real temperature will "float" in the range from 19 to 21 degrees. This is a completely normal and comfortable regulation mode. The accuracy of maintaining the temperature depends on the very external device that gives commands to the servo drive, and which will be discussed below.

| Electrothermal actuator 22CX | Electrothermal actuator 26LC |

We produce two types of servos: 22CX (New) and 26LC. The first is more compact, the second is more beautiful, and with an LED signaling the current state. There are modifications for 230V, there are for 24V. There are normally open ones, and there are normally closed ones. Series 26LC normally closed only. Let's talk about this in more detail.

| If the actuator is normally open - in the disconnected state (no power supply), the control valve will be open. If the drive is faulty, or the device giving it commands is faulty, the "warm floor" will work and the room will not cool down. This is a plus. But the air temperature in the room will be clearly higher than normal, and you will pay more money. This is a minus. Choose for yourself what you don’t like anymore. The zealous Europeans prefer not to overpay, and their choice is normally closed drives. In Russia, as a rule, they choose comfort and normally open drives. Or they simply “don’t bother” and take the ones that are available. |

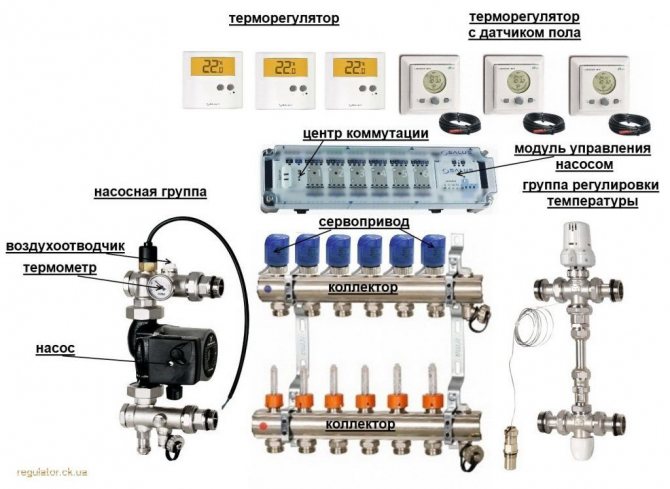

Automation and regulation principles. Room thermostat for temperature control.

So we got to the "brain" of the heating system with "warm floors" - to the automation. First, let's talk a little about the principles of regulation. First of all, the air temperature is important to us - it is it that determines our feeling of comfort. The temperature of the floor surface is also important to us - the legs want to feel warm. These two temperatures are tightly coupled. You need to understand that the floor will be perceptibly warm only for a part of the heating period, for a significant part of the time it will be colder than you want.

Perhaps in autumn or spring, when heat loss is minimal, you will even want to wear slippers. For most people, the air temperature is more important than slippers, and they control the "warm floor" according to the air temperature in the room.Is the feeling of warmth under your feet more important to you? Then you must set a comfortable floor surface temperature for yourself, and the air temperature is what you get.

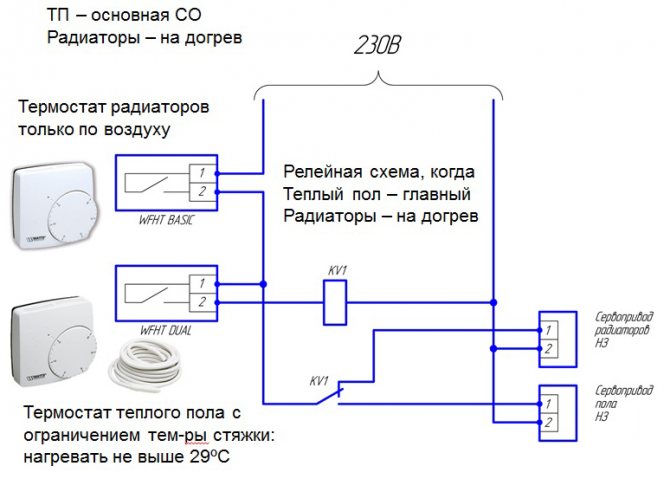

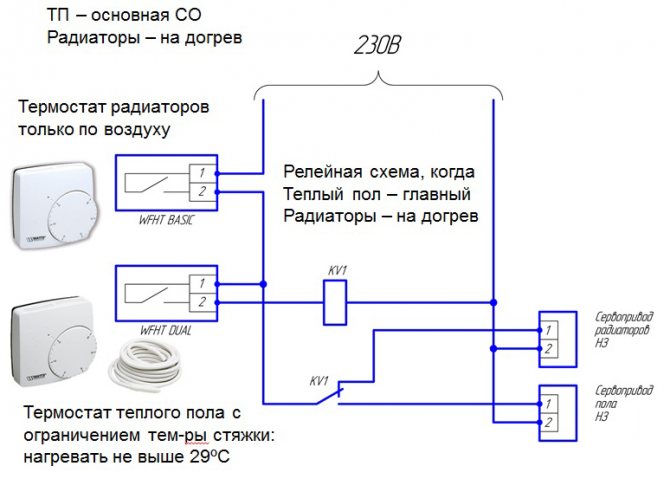

A more difficult case is not only a warm floor in the room, but also radiators. If these two systems do not have a common control system, there will be a mess. Suppose you have "thermal heads" installed on your radiators, and the "warm floor" is controlled by the air temperature. In this case, most of the heating period, the "warm floor" will be turned off, since the power of the radiators will be sufficient to maintain the required air temperature. Isn't that what you wanted?

It is possible to adjust the floor according to the surface temperature. At low temperatures "overboard" everything will be correct - the radiators will turn on only when there is insufficient heat transfer from the floors. And in those moments when the heat transfer of the floor is higher than the need for heat, it will become hot in the room. Not good either. We believe that the optimal control algorithm should be as follows: the floors are controlled according to the air temperature as long as their heat transfer is sufficient. As soon as it becomes insufficient, the floor temperature is fixed, and the radiators are immediately switched on, which are controlled by the air temperature.

We have the necessary equipment to implement all these algorithms.

Thermostats

Devices that maintain a stable temperature of something are called thermostats. We offer you many different thermostats. Let's consider them in more detail.

Wired thermostats

The most affordable option is wired thermostats. The thermostat itself is located in the room, the collector with a servo drive can be located either in the same room or anywhere (in a boiler room, for example). These devices are interconnected by thin cables (3x0.5 mm2 is sufficient in most cases).

| We recommend the use of WFHC switching control modules for switching thermostats and actuators. In addition to increasing the reliability of the entire control system, they can additionally control the boiler and pump. One thermostat can control several servos, i.e. if you have a large room, and there are several loops of the "warm floor" - you still only need one thermostat. |

| Switching module WFHC for 6 thermostats |

All thermostats have an indication of the current state ("heating" or "not heating"). The temperature control range is 5 ... 30 ° C. Accuracy of temperature maintenance +/- 0.5 ° C. There are versions for both open (the thermostat is installed on the wall surface) and for concealed installation (the thermostat is mounted in an installation box, similar to sockets and switches).

| WFHT-BASIC is the simplest model. This thermostat is able to maintain one air temperature value around the clock. The sensor is built into the thermostat housing |

| WFHT-BASIC + looks similar, and is able to maintain two air temperatures (day / night mode). The daytime temperature is set on the handle. The night temperature is 4 degrees lower than the day temperature. Switching between modes by signal of the external timer WFHC-TIMER, which is purchased separately. One timer controls all thermostats in the house. |

WFHT-DUAL is similar to the previous one, and looks the same, but it has the ability to connect a floor surface temperature sensor (setting 10 ... 40 degrees C). You can choose one of three control modes:

|

| The WFHT-LCD is functionally similar to the WFHT-DUAL, but instead of a dial with a dial and switches, it has a display and buttons. On the display you can see the current value of the measured temperatures - "the very thing" for the curious. |

These were all mains powered electronic thermostats. There are also battery-operated thermostats of the BT series. They look more glamorous. Servos are not controlled directly - a switching module is required (located near the servos).The batteries are "enough" for two years. Due to the fact that high voltage is not supplied to the thermostat, they can be installed in rooms with high humidity. These thermostats have a slightly wider range of adjustable air temperatures (5 ... 35 ° C).

| The BT-A thermostat is similar to the WFHT-DUAL model, but it can only work "over the air" or "over the surface". And only supports one temperature mode. |

| A more advanced version is the BTD thermostat. It is capable of supporting 4 temperature settings (day / night / frost protection / vacation). Each mode has its own temperature. Switching between modes is carried out manually - with control buttons. There is also a timer mode - "Maintain the set temperature for so many hours or days." |

| The most sophisticated thermostat is BTDP. It has everything that BTD has, plus a built-in programmable timer, i.e. you can configure which days of the week and at what time which mode to activate. The timer has 9 factory time programs and 4 user ones. Factory programs like "Morning, evening and weekend". It looks the same as BTD. |

Wireless thermostats (radio thermostats)

These thermostats do not need wires - the communication between the thermostat and the servo is done by radio. An excellent solution in the case when the finish has already been done, and there is no way to lay the wires.

All radio thermostats have an antenna pictogram on their body and operate "on batteries". And some thermostats come with a stand for installation on a horizontal surface.

The servo drive cannot independently receive the radio signal - therefore, a receiving radio module is installed next to the collector, which receives the signal from the thermostat and, in turn, controls the servos.

For a single thermostat - EHRFR 868 MHz single zone radio for WFHT series or 868 MHz BTR for BT series.

If there are several thermostats, we use the WFHC-RF MASTER receiving radio module, which is available for 4 or 6 radio thermostats with the possibility of expanding to 8, 10 or 12 zones.

A timer is built into the radio module, which makes it possible to switch between day / night mode even on the simplest radio thermostat.

Radio thermostats, like wired ones, are available in two lines: WFHT and BT. And visually they look the same. There are fewer models in the lines.

WFHT-RF BASIC is similar to WFHT-BASIC. Thanks to the timer in the radio module, it is able to work in day and night mode. The temperature in the night mode is 4 degrees lower than the daytime.

WFHT-LCD-RF is a complete analogue of WFHT-LCD. There is nothing more to add.

| BT series radio thermostats: BTA-RF, BTD-RF and BTDP-RF completely repeat their wired counterparts, only operate at a frequency of 868MHz and have a signal transmission range of up to 100m. The photo shows the radio thermostat BTA-RF. |

| To organize one temperature zone, we use one BT series radio thermostat and one BTR single-zone receiving radio module. |

Once again about the joint work with radiators

Now you know how our thermostats work. Let's try to solve the problem mentioned above: the room is heated with a warm floor and radiators at the same time, you need to choose automation. Can you yourself? Come on, we will tell you how we would do it, and you will check yourself. Let me remind you that we want to maintain a constant air temperature. While the power of the warm floor is sufficient, the radiators must be turned off. And, as soon as it became insufficient, they would immediately turn on. We are not going to overheat the floor surface either, and our automation should not allow it to heat up above 29 degrees (value for an example).

First of all, we will screw the servos on the radiators and on the collector with warm floors. We look at the thermostats - we cannot do with one thermostat, since it has one output, and it will not work out to control the two systems differently. We take two thermostats: "WFHT-BASIC +" and "WFHT-DUAL". We hang them side by side in our room, mount the DUAL thermal sensor in a screed.The DUAL thermostat will be controlled by the temperature of the floor surface. At the time when the BASIC thermostat will give us a signal that the air is colder than necessary. WFHT-DUAL will report that the floor surface is cold. Next, we assemble a simple relay circuit that:

- will disconnect both the floor and the radiators, if the air temperature is normal;

- will turn on floor heating if its surface temperature is below the maximum, and the air temperature is below normal;

- will turn on the heating of radiators if the temperature of the floor surface is at its maximum and the air temperature is below normal.

Simply put, BASIC turns on heating, and DUAL works as a switch between floor only and floor + radiators. This scheme is quite simple. If you are not on a "short leg" with an electrician - contact our specialists, they will draw you a diagram and explain everything in detail. Of course, a similar circuit can be assembled on other thermostats, including radio thermostats.

.

conclusions

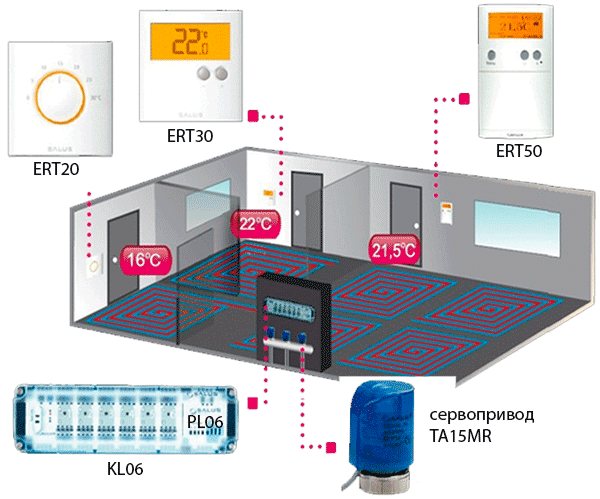

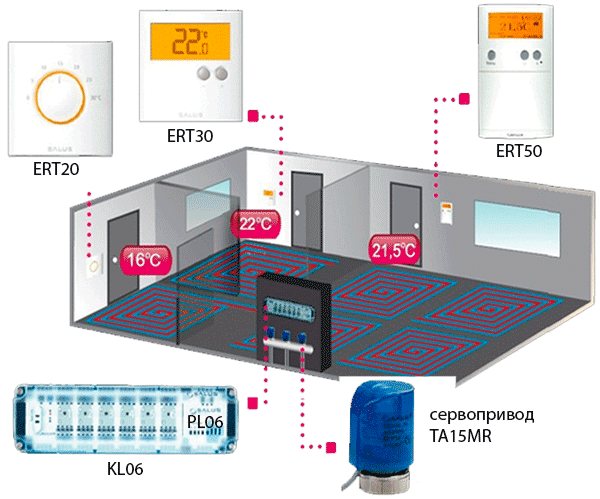

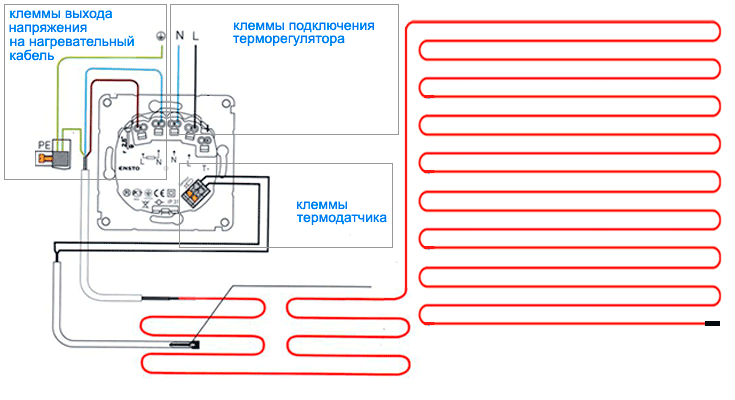

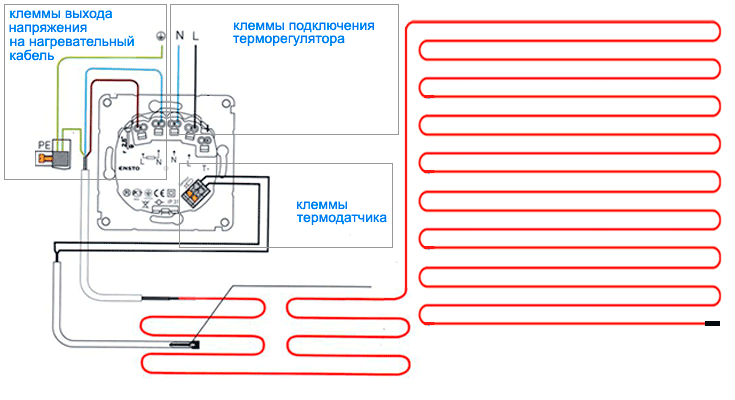

As a conclusion, we suggest you look at the figure below. There you can see all the devices listed in the article and their connection diagram. It's simple, isn't it?

When reprinting the materials of the article, a link to the site www.wattsindustries.ru is obligatory!

Wired and wireless thermostats

Room thermostats are only used for zone heating control in a room. By the type of connection, devices of this type are divided into two categories: wired and wireless thermostats.

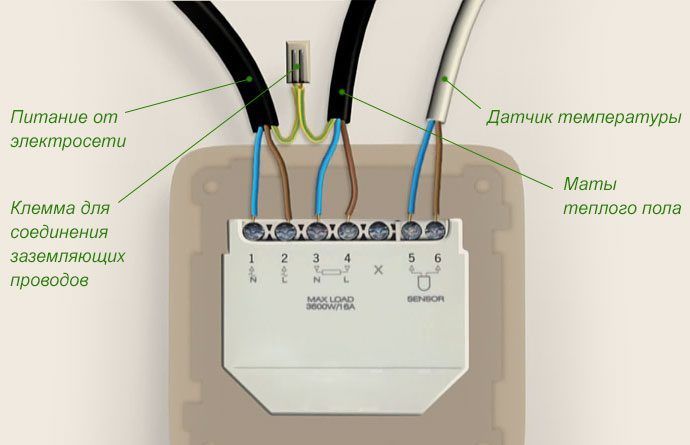

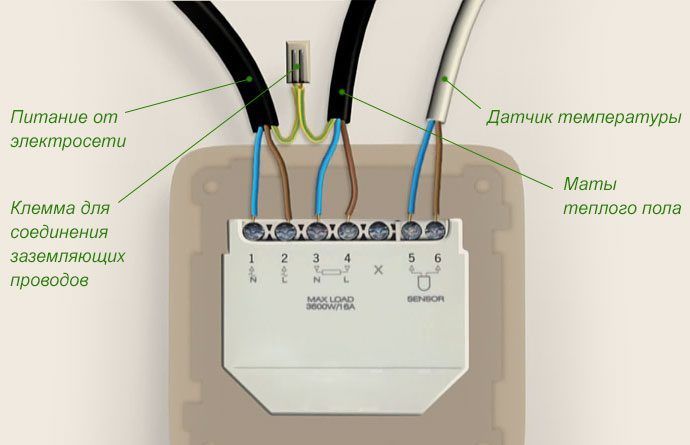

Room thermostat connection

The wired controller is installed inside rooms at a height of 1–1.5 m above the floor - in a place where you can most accurately set the actual room temperature. Experts do not recommend installing thermostats from the outside of the house or in an area where direct sunlight falls, as well as near working appliances - refrigerators, washing machines, stoves, etc.

Connecting a wired controller for underfloor heating

Practice has shown that for a zonal control scheme, one thermostat installed on the supply manifold is sufficient.

The wireless controller for the water floor is an indispensable device for apartments in which the renovation has already ended, and the owners do not want to lay a cable to the boiler. Wireless models are placed in the immediate vicinity of a boiler (electric or gas) or other regulated heating systems.

Wireless thermostats for water floor heating

The thermostat is controlled via a radio frequency channel. The device is powered by 2 AA batteries, and the receiver is powered by 220 V.

Electric floor heating control

Electric underfloor heating, due to their design features, is much easier to control using various remote systems. For an electric underfloor heating, only a 220 V network and a control device are needed. The easiest way to control an electric underfloor heating is realized through a "smart" socket using "on-off" commands from any mobile device.

The underfloor heating thermostat is a more advanced solution that allows you to set the temperature in a specific room.

Regulators are available in several different designs:

- Electromechanical

- Digital

- Programmable

Electromechanical regulators allow you to regulate the heating of the warm floor in manual mode. There is a temperature regulator on the body of the device, which can be set to the required value. Such a device is very reliable and inexpensive, and in case of breakdown it is easily repaired. The digital regulator performs the same functions, but is made on a modern element base and has touch buttons.

The most versatile device is programmable thermostat... This is a full-fledged multifunctional device that can be integrated into an integrated Smart Home control system. Temperature sensors are connected to such a device, and the built-in controller controls the underfloor heating using a dimmer. The system allows you to maintain the set temperature in one room.

To control electric underfloor heating in several rooms, you will have to purchase several thermostats.

Thermostat MCS 350

The thermostat MCS 350 can be considered a good solution for domestic use. The Teplolux Premium system is used to control various heating systems. Underfloor heating can be controlled from a touch-sensitive wall panel and from any mobile device on which the corresponding application is installed. The device works on a Wi-Fi network through a home router.

Home network allows you to connect up to 32 regulators, which will provide a comfortable temperature for all rooms of a large house. The delivery set includes two temperature sensors, one of which is located on the wall, and the other sensor has direct contact with the heated floor. This connection scheme provides two-way temperature control. The use of the MCS 350 thermostat, due to the rational temperature control, saves energy.

Useful video for setting up a thermostat

About the role of the sensor

It should be remembered that in setting up a warm floor there is one irreplaceable part - this is the sensor. The control unit adjusts the floor heating and saves electricity. The biggest savings come from programmable devices, but they are expensive.

The ability to adjust the warm floor as needed saves energy and, consequently, money.

The effect lies in the matching of the electrical power of the floor and the meter. Heating the floor to the required temperature is only possible with sufficient power. Therefore, when buying, you need to be interested in the characteristics of the product.

In some cases, in rooms with a large area, it is necessary to connect more than one regulator.

An important point is the type of setting. You should find a way for yourself so as not to make holes in the wall, but limit yourself to a box for a thermostat. Do not deviate from the recommendations in the instructions.

Both functionality and appearance are all significant factors. You can consult with specialists. Particular care must be taken when installing the insulated floor in rooms subject to moisture (bathroom).

The control unit must never be installed inside, you need to pass the cable to the heaters through the hole in the wall and place the sensor in the corridor.

We recommend: How to install a warm floor?

Electronic tuning equipment is able to serve different operating modes of floor heating with a high degree of energy savings. But this is an expensive technique.

- Similar posts

- How is the warm floor in the bathroom installed under the tiles?

- What is National Comfort underfloor heating?

- How to install a warm floor with a snail?

- Features of the Korean underfloor heating

- How are pipes for underfloor heating carried out?

- How is carbon floor heating installed?

Preparation and commissioning

When setting up underfloor heating, a thermal head is used in the form of a conventional tap, which is installed for water supply and reverse flow. Such a system is not assessed unambiguously:

- firstly, saving finances for the installation of the circuit is a plus;

- secondly, complications in operation, that is, frequent use of the thermal head disables it, an early replacement is required.

We recommend: What mats are there for a warm water floor?

A convenient device is called a flow meter (or rotameter), which is installed near the collector at the circuit holes. Adjustment in this situation is the control of device readings (0.3 ... 0.5 liters).

The first start, done correctly, reveals weak points, malfunctions, possible malfunctions in the floor heating system.

Every year, with the onset of a cold snap, heating is started.