Air vent valves (in a simple way, "air drains") are used in pressure water aeration systems to remove excess air from the aeration column.

For proper operation of the aeration column, high performance air vents are required that are resistant to contamination with iron hydroxide and light debris: such as:

- plastic shavings from HDPE and PP pipes,

- pieces of plumbing thread, fuma, flax,

- plant particles - leaves, roots

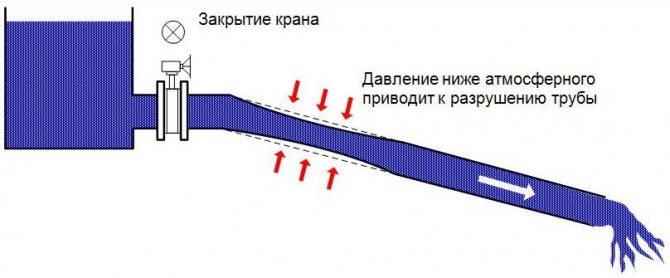

The air relief valve also acts as an air intake to the aeration system, compensating for negative pressure in cases of draining the water purification system.

The most famous brands on the Russian market: ARI, RACI, UNIRAIN

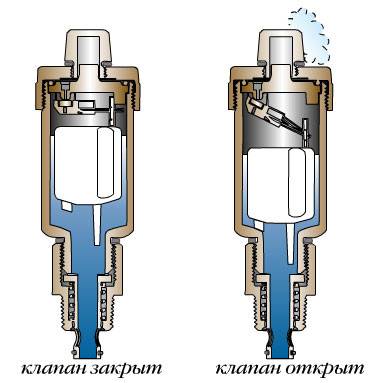

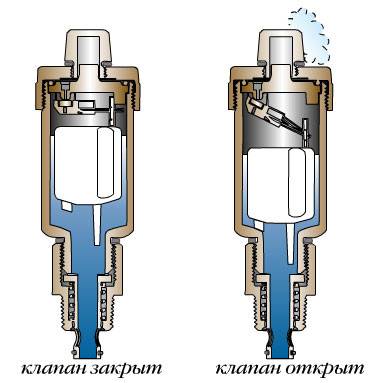

The air vent is automatic and operates on the principle of a float mechanism.

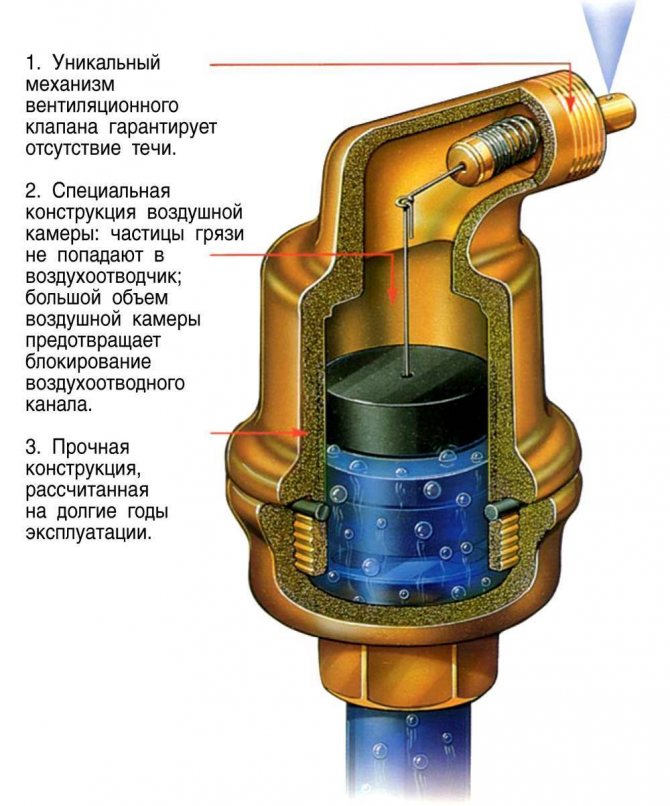

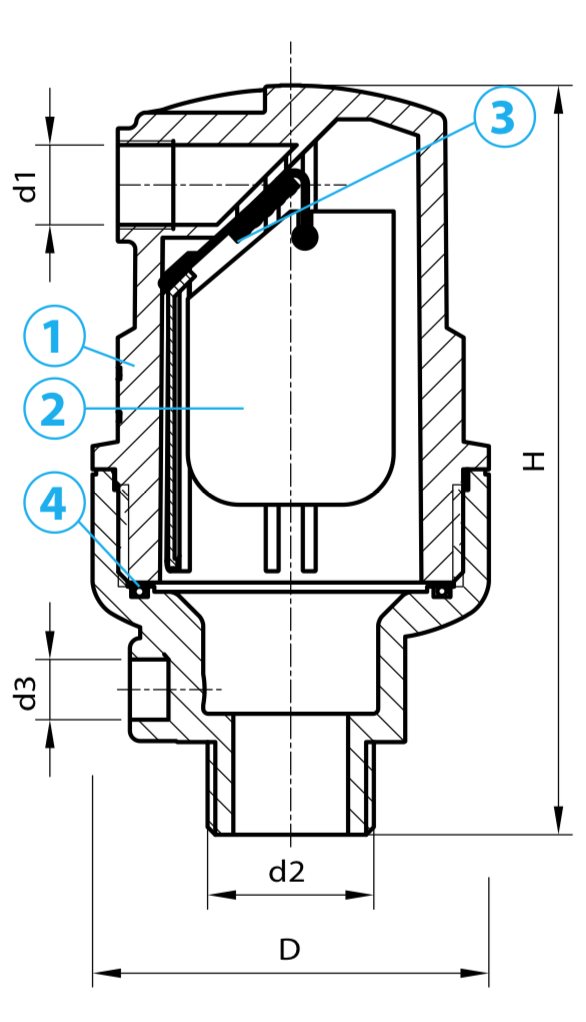

RACI air vent device diagram

Air vent RACIVENT

The diagram shows the RACI automatic air vent device from RACIVENT (Italy).

The valve body is made of fiberglass reinforced nylon. Very durable, withstands high pressure (up to 16 atm). Inside there is a polypropylene float and an E.P.D.M. rubber gasket.

Simple design and quality of parts guarantees durability of work with water of any chemical composition.

How an automatic air vent works

When the water supports the float from below, it pushes the rubber gasket and the pressure of the water pushes the gasket into the valve body. This closes the hole. When the water leaves, the float sinks and pulls the rubber gasket along with it, the hole for air inlet and outlet opens.

During operation, the automatic air vent spits water. Why is this happening? Because air bubbles hit the float mechanism from below rather sharply and this causes an impulse operation of the air vent. To prevent the air vent from splashing dirty water at its outlet, a thread with a diameter of 1/4 to 1/2 is provided (depending on the model of the air vent valve RACI, A.R.I., Unirain,

This video shows how the RACI air vent valve works

How to get rid of the traffic jam

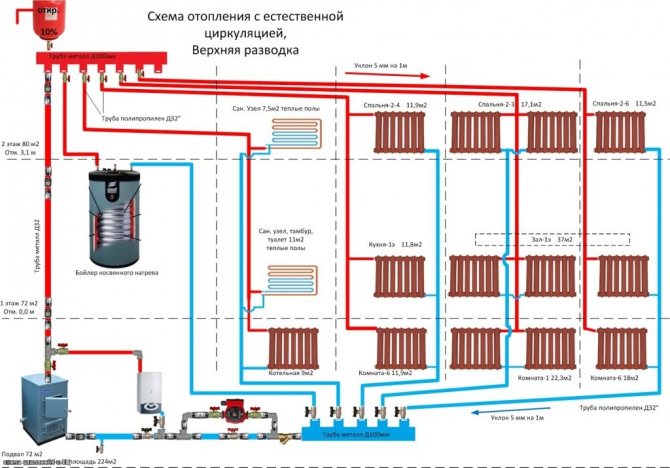

The choice of the method for venting air from the heating system circuit depends on its configuration and the characteristics of the organization of the coolant circulation - natural or forced.

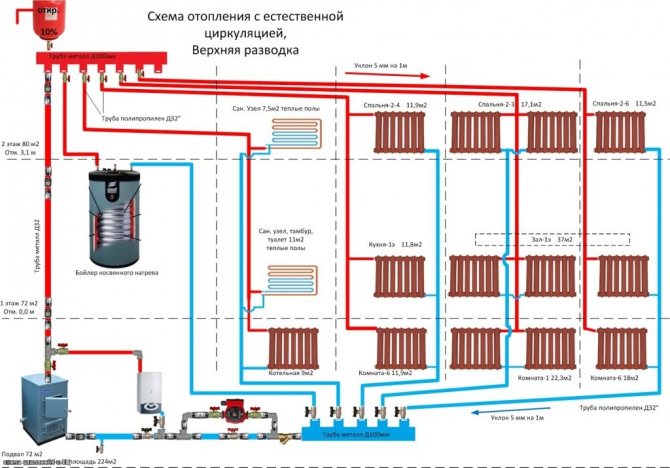

With natural circulation, air is discharged through the expansion tank installed at the highest point. This is possible only if air moves freely through the pipes to the location of the expansion tank. For this, the system must provide for a slope of the pipelines, and a ball or electromagnetic check valve is mounted at the outlet of the boiler heat exchanger.

Systems with forced circulation mode and the presence of a bottom wiring are equipped with an air collector at the highest point. The rise of the coolant occurs in the supply line in the direction of its movement.

The return pipeline in the same direction has a slope, which makes it possible to quickly drain the liquid during repair work and after the end of the heating season.

In addition, such systems are equipped with air vent valves (air valves), which are installed at points where there is the greatest risk of air congestion.

To release air from batteries equipped with a manual valve, you must:

- turn the screw of the locking unit by half a turn, until a hissing sound appears;

- leave the tap open until the hissing stops and a uniform stream of coolant appears from the drain hole;

- screw the locking screw back to its original position.

If necessary, the procedure is repeated once more, draining 200 - 500 ml of water.

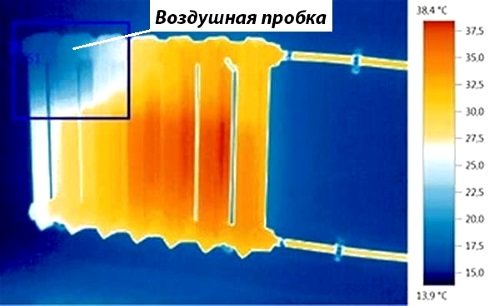

With regard to aluminum radiators, it is a little more difficult to deal with air in them. Air appears in them much more often due to the properties of this material to increase gas formation and requires regular descent.

Cleaning the vent valve

- Turn off the valve separating the air vent valve from the column

- Holding the lower part of the valve with one adjustable wrench and the second wrench, carefully unscrew the upper part of the valve body counterclockwise

- Remove the float, rubber gasket and plastic plate

- Clean all parts with citric or oxalic acid

- Lubricate all parts with water treatment silicone

- Assemble the valve in the reverse order, tightening the cover with your hands with a little effort (if it flows, you tighten it).

For the convenience of disassembling and cleaning the air exhaust valves, it is recommended to cut a service key out of the plywood.

Types of air vents

Automatic air vents differ in the type of installation, dimensions, thread diameters. according to the location of the nozzles, they are:

- Vertical;

- Radiator;

- Corner.

The angle automatic air vent is convenient for installation on the radiator. In the place where the heating pipe enters it. With such an installation, it will help to catch the air and gases formed in the radiator itself.

The vertical automatic air vent is best installed at the entrance to the heating system. When positioned this way, it will prevent air from entering the system.

The second option for installing a vertical model is at the top of the heating system. It is there that gases accumulate and interfere with the effective circulation of water or coolant.

Radiator air vents are installed instead of a plug or a Mayevsky valve in radiators. They are convenient, but it is advisable to install them on each radiator.

Range

We offer to buy air vents for water purification as part of aeration kit. To order, write to the mail or call.

The most popular in Russia are three models of air vents:

- A.R.I. S-050 made in the USA by A.R.I. Flow control Accessories LTD is the oldest player on the Russian market and the most expensive (such a valve costs about $ 100). At the same time, it clogs up more often than others, but never breaks. Serves for a very long time. Requires periodic cleaning. The kit includes an already swiveling drainage bracket with an undefined diameter female thread. From our experience, we do not recommend extracting it from its seat. Then the connection may leak slightly. The range includes valves with connection sizes 1/2 ", 3/4" and 1 ". You can screw the 3/8 tube heated by a lighter directly into the air outlet fitting. After the plastic has solidified, a thread of the desired size is formed on it. You can wind a couple of fuma skeins on it and screw it in again. A reliable connection is obtained. Cost around $ 100

- RACI 5361 made in Italy by RACIVENT not so long ago on the Russian market as ARI, however, has proven itself very well over the years. Most contamination-resistant valve. There is only 1 ″ connection size. Outlet 3/8 female thread. Requires an additional fitting for the discharge tube. The valves are very high quality, the cost is around $ 70

- UNIRAIN ARV-1 ″ A manufactured in Spain by UNIRAIN is the most budgetary valve for air exhaust, while good quality, resistance to pollution is a good working option. The cost is about $ 45.

- There is a Chinese analogue of the Raci valve on the market - they are the same in shape, but without a label on the plastic. They only work at high pressure.

Air vent valves operate reliably only at pressures of 2 atmospheres and above

tell friends

Installation rules

An overpressure relief valve should be installed as close to the compressor as possible. On low-power mobile units, the installation site is provided by the manufacturer. When installing distributed stationary systems, the distance from the compressor outlet to the gate should not exceed 1.5 meters. It is unacceptable to install an emergency relief device after the shut-off valves. If the valve is closed for any reason, the valve will not be able to fulfill its protective function, and the increased pressure can seriously damage the equipment or even cause an accident with a threat to the life and health of people working nearby.

Before installing or replacing the valve, it is necessary to completely depressurize the system and disconnect the compressor motor from power. The threaded connection should be wrapped with FUM tape or plumbing thread. At first, the threaded connection is tightened by hand, and only after making sure that the thread has entered evenly, it is possible to apply significant physical effort to tighten it with a wrench.

After installing the valve, it is necessary to test it by increasing the pressure in the system to the threshold value. It should trigger and reset. If this does not happen, the installation is unacceptable until the cause of the failure is clarified and eliminated. If the valve is adjustable, it is necessary to set its operating reset value using an adjusting hex key, using a pressure gauge built into the compressor control unit.

How the device works

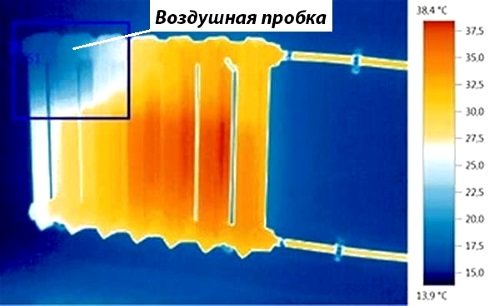

An air valve (or several) is installed in the heating system, in places most likely for the accumulation of air bubbles. This prevents the formation of a large congestion, the heating works smoothly.

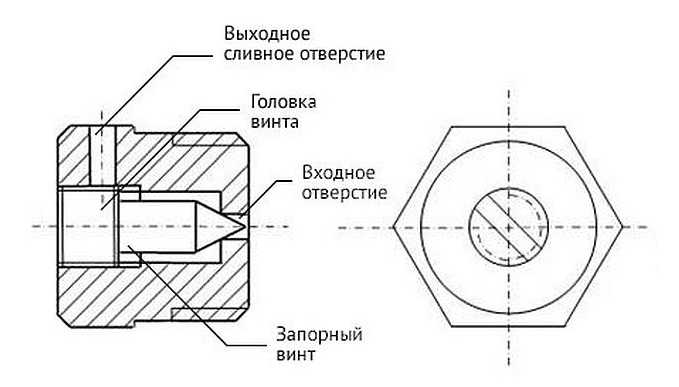

Mayevsky crane

Such devices were named after the name of their developer. The Mayevsky crane has a thread and dimensions for a pipe with a diameter of 15 mm or 20 mm. It is arranged simply:

- In the body of the valve body, 2 through holes are made, which, in the open position of the Mayevsky crane, are connected to the heating system.

- These holes are sealed with a taper threaded screw.

- Air is discharged through a small (2 mm) opening directed upwards.

In order to bleed air from the system, unscrew the screw 1.5-2 turns. Air blows out with a whistle as communications are under pressure. The end of the airlock outlet is characterized by a drop in pressure and the appearance of water.

On the market, you can find several varieties of the Mayevsky crane, which are the same in design, but differ in the way of adjusting the locking screw. There are:

- with a comfortable handle for unscrewing by hand;

- with a regular head for a flat screwdriver;

- with a square head for a special key.

For an adult, the principle of unscrewing the locking screw does not matter. However, in a home with children, it is safer to use devices that must be unscrewed with a special device. Having unscrewed the usual tap with a comfortable handle, the child can scald with boiling water.

Automatic faucet

The automatic air relief valve is based on the principle of a float chamber, the design includes:

- vertical case with a diameter of 15 mm;

- float inside the body;

- a spring-loaded valve with a cover, which is connected and regulated by a float.

The automatic air valve for the heating system works without human intervention. Normally, when there is no air in the system, the float is pressed against the valve cover by the pressure of the liquid filler. At the same time, the lid is tightly closed.

As air accumulates in the valve body, the float goes down. As soon as it drops to the critical level, the spring-loaded valve opens and bleeds out the air. Under the pressure of the carrier in the system, the space is again filled with liquid.The float rises to close the spring valve cover.

When there is no coolant in the communications, the float lies at the bottom of the valve. As the system fills, air leaves the tap in a continuous flow until the coolant reaches the float.

A distinction is made between the following configurations of automatic air valves for heating:

- with vertical air discharge;

- with lateral air discharge (through a special jet);

- with bottom connection;

- with corner connection.

For the layman, the design features of an automatic crane do not matter. However, for a professional, there is a difference in choosing between devices.

It's believed that:

- a device with a nozzle and a side hole is more reliable in operation than an automatic valve with a vertical air discharge;

- The bottom-connected valve is more effective at trapping air bubbles than the side-mounted valve.

If the design of the Mayevsky crane has not undergone changes for many years, then the device of automatic valves is constantly being improved and supplemented.

Manufacturers offer automatic valves with additional devices:

- with a membrane to protect against water hammer;

- with a shut-off valve, for the convenience of dismantling the device during the heating season;

- mini valves.

Automatic air valves for heating need frequent inspection and cleaning. The undoubted advantages of these devices include the ability to install them in hard-to-reach places.

Reasons for the appearance of air and air congestion

Airing of the heating system can occur for several reasons:

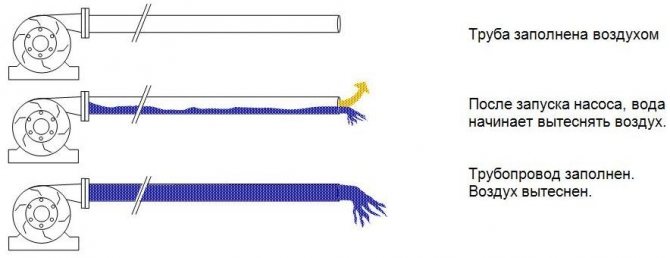

- Pipes fill up with heating medium too quickly. Due to the increased speed, the water does not have time to displace the air naturally from the line. The heating medium must begin to flow from the lowest point so that the air goes up through the open hole.

- No preparatory work was carried out before starting the heating system. As a result, the heat carrier contains an increased amount of soluble gases. During the heating of the water, they separate and accumulate in the pipes, forming a plug.

- Repair work was carried out to replace individual parts of the pipeline, but the water was not completely drained.

- Corrosion started in the pipes. When the metal comes into contact with oxygen, hydrogen is released, which gradually accumulates in the heating system.

- The tightness in the heating main is broken.

Installing an air vent will help avoid problems due to the accumulation of air masses in the pipeline. Thanks to the device, you can improve the quality of heating and extend the life of the radiators.