Insulation is not visible under the facade cladding, but it plays a very important role The facade with a hinged ventilated system is a structure that protects the walls of the building from the influence of environmental factors, mechanical stress and destruction. The suspended ventilated facade system consists of an external cladding screen and a rigid frame subsystem. Hinged ventilation façade can be insulated and not insulated. In Russia, it is more preferable to install an insulated ventilation facade due to the harsh weather conditions in winter.

Insulation for ventilated facades must meet the relevant requirements:

- have high vapor permeability, which should not be inferior to the level of vapor permeability of the building wall;

- have a certain density (it directly depends on the material) and effectively soundproof the wall;

- to minimize the transfer of heat from the building wall to the surrounding space;

- do not absorb moisture and do not cake, as this leads to destruction of the material and deterioration of thermal insulation.

The service life of a ventilated facade is measured in decades, so the requirements for materials are very strict.

The thickness of the insulation is selected taking into account the heat loss of the building through the brackets

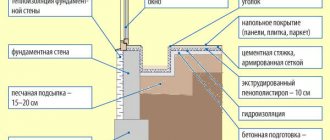

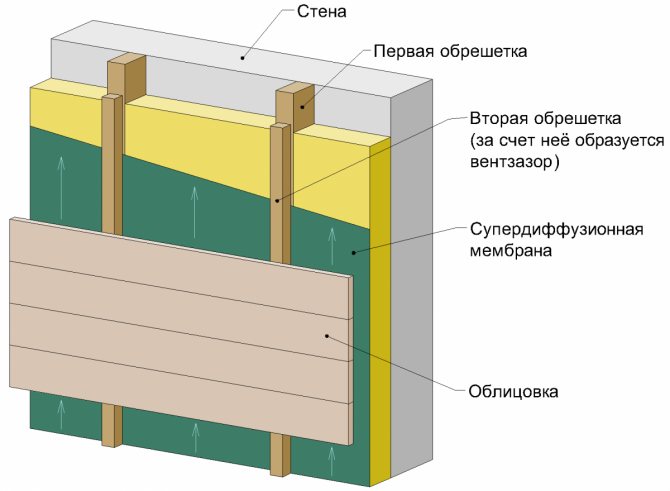

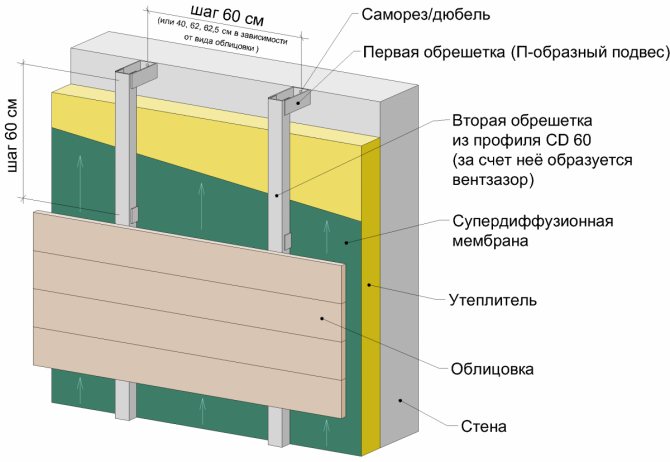

Ventilated facade layout

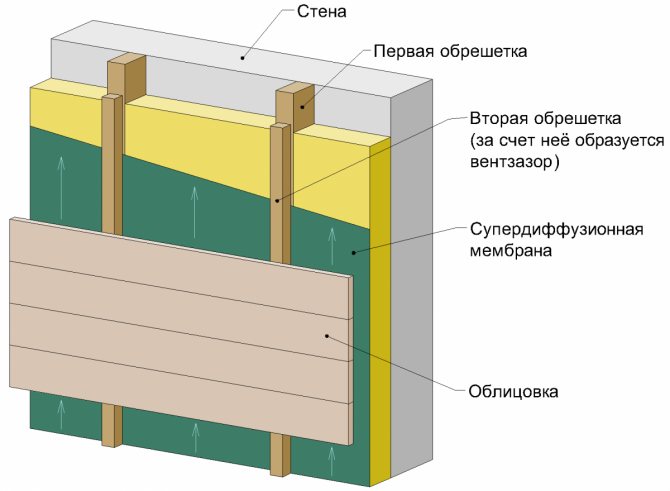

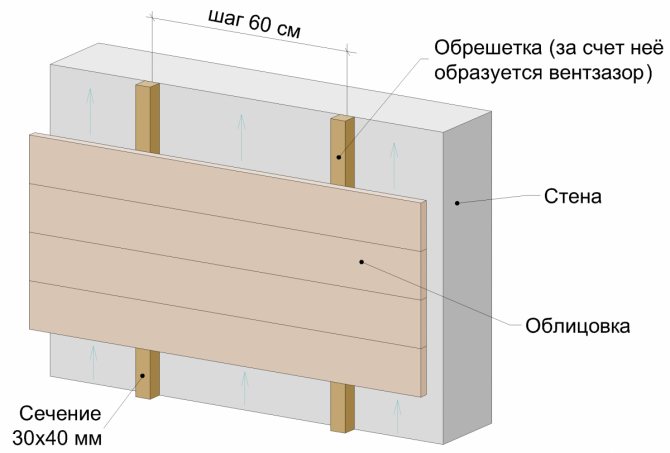

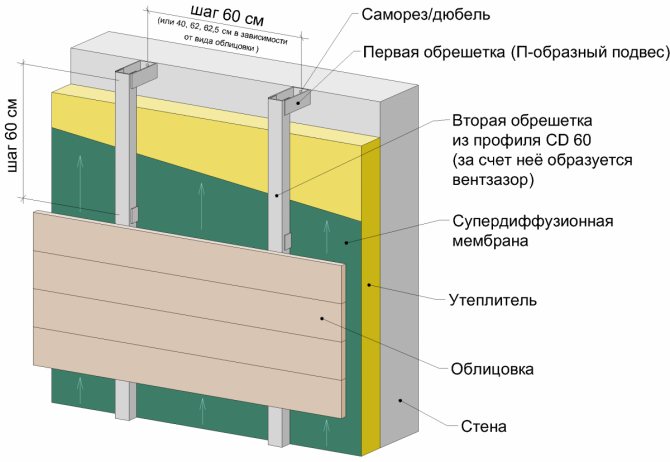

I will give a general diagram of a ventilated facade, Figure 1 (using the example of a ventilated facade with a wooden lathing).

The figure shows the first and second battens. This is a conventional name adopted in this article. This name does not depend on the material of the lathing. The first lathing is the one that is attached to the wall, the second lathing is attached to the first and the cladding is attached to the second lathing. The first crate can also be called "main".

I will describe what options we will consider and (briefly) when this or that option is applied.

- Arrangement of a ventilated facade with a wooden crate, for a non-insulated facade;

- Arrangement of a ventilated facade with a wooden crate, for an insulated facade with an insulation thickness of 50 mm;

- The device of a ventilated facade with a wooden lathing, for an insulated facade with an insulation thickness of 100 mm (despite the Note below, it is rare, but it is performed).

Note on the wooden lathing

Wooden lathing is mainly used for wooden sheathing, such as OSB, blockhouse, board. It is important to note this moment. Despite the fact that in Internet sources the option of a completely wooden lathing is given very often, and its device is simple, it is important to understand that the device of a completely wooden lathing is advisable for a ventilated facade without insulation and (sometimes) for a ventilated facade with insulation, if the insulation is no more 50 mm. Let me explain why.

1. If insulation is needed 100 mm, then the main (first) lathing should be with a section of 100x50 mm. And then there is the second lathing (for fastening the membrane and organizing the ventilation gap), with a section of 30x40 mm. This means that with a lathing step of 60 cm, the wood consumption per floor will be the same as for the construction of a frame house of the same area. And, as a rule, the owners are counting on a more economical option, they use an inexpensive finish, such as PVC siding, and the purchase of timber for the crate will reduce all savings to nothing.

2. Completely dry wood is rarely taken (it is harder to find and more expensive). A beam of 100x50 mm, if taken not completely dry, will lead a lot.And at the same time, this bar is powerful enough (in its cross-section) to "twist" along with itself the cladding itself (the PVC siding, which is popular for such a design, will twist it for sure). In addition to wooden lathing, the article will consider:

- Combined (first metal, second wooden) lathing for a non-insulated ventilated facade and an uneven load-bearing wall.

- Combined (the first metal, the second wooden) lathing for the insulated ventilated facade and an uneven load-bearing wall, with an insulation thickness of 50 mm.

- Metal lathing. For an even and uneven wall, for a non-insulated ventilated facade.

- Metal lathing for a heat-insulated ventilated facade, with an insulation thickness of 50 mm.

- Combined lathing made of a self-made fastener and a wooden bar for a heat-insulated ventilated facade with an insulation thickness of 100 mm.

- Arrangement of metal lathing for the insulated ventilated facade, if the insulation is 100 mm.

For each of the nine options for the crate listed above, the following points on the device will be considered:

- from what the first and second lathing is made in each case;

- how the first lathing is fixed to the wall;

- how the second crate is fixed to the first;

- how the insulation is attached (if any);

- how the superdiffusion membrane is attached (if any);

- due to which a ventilation gap is formed in each case.

Note. In this article, I deliberately do not give the details of the cladding fasteners to the second crate. The fact is that fasteners vary greatly depending on the cladding material. And for each type (for OSB, siding, etc.), you can make a separate article with installation details.

Manufacturers and brands

In the process of choosing a material, be sure to pay attention to the manufacturer of the insulation. If a company has been on the building materials market for a long time, then its products are of high quality and will last a long time.

But here there is a high probability of getting fake, so be sure to ask for quality certificates. Stores that value their customers are incapable of offering fake products. As for specific examples for mineral wool insulation:

- Rockwool.

- Isover.

- Ursa.

- Paroc.

- IZOVOL.

These companies always offer quality materials and have not dropped in the ratings for a long time.

Penoplex is most often used as a heater for the ventilation facade of buildings for various purposes in the form of expanded polystyrene. With a small thickness, the slabs perfectly retain heat and are not susceptible to the development of mold and mildew.

If polyurethane foam is chosen for insulation, then you should pay attention to such brands as:

- Baymer.

- Basf.

- Isolan.

- Huntsman-NMG.

Attention! Professionals recommend using material from one manufacturer, of the same thickness, and preferably from the same batch, to insulate one structure.

Wooden lathing (the first is not, the second is from a bar) for a non-insulated ventilated facade

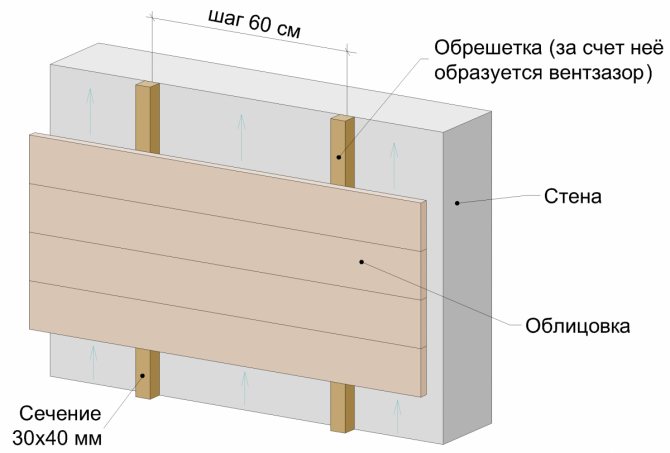

So, for a non-insulated ventilated facade, a 30x40 mm bar is needed for the lathing device. In fact, only the second crate is performed, the first (since there is no insulation) is not needed. The diagram of the device is shown in Figure 2 below.

The batten is fixed to the wall with a side of 40 mm, and due to the side of 30 mm, a ventilation gap is formed. The lathing step is 60 cm.

Fastening the battens to the wall. If the wall is made of bricks or similar hard materials, then the lathing is attached to the wall with dowels.

If the wall is made of blocks (foam, gas, shell, etc.), then the crate is fastened with self-tapping screws for wood. The step of the fasteners is 50 cm. The lining is attached to the crate.

There is no insulation and superdiffusion membrane in this case.

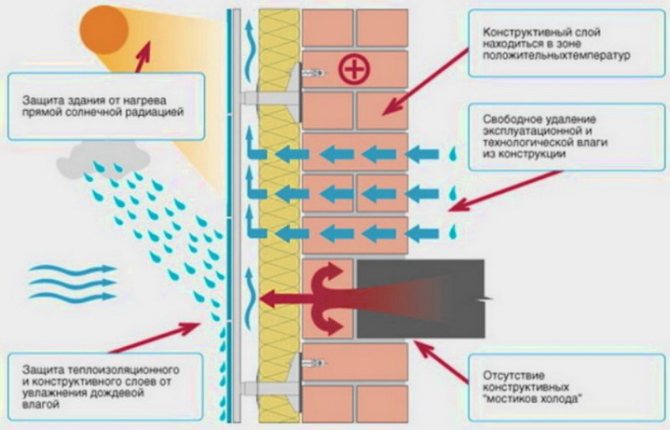

The ventilation gap is formed by a lathing bar, the size of the gap is 30 mm, this is enough for the free release of moisture from the wall.

Specifications and properties

Kermogranite is made from stone chips with the addition of clay, sand and dyes. Molds are poured, pressed, then the products are fired in a special oven to give them strength.

Facade facing porcelain stoneware does not absorb water at all, therefore will not be colored

in bulk over time. Facades are painted, for example, fiber cement, they absorb rusty smudges from metal slopes, dust. Porcelain stoneware surpasses fiber cement in this parameter.

Porcelain stoneware slabs are hard, durable, but fragile. For the installation of a hinged ventilated facade, everyone strives to use materials that surpass the parameters of porcelain stoneware in terms of strength.

After all, the facade is not only at a height, but the first floor and the entrance group are subjected to more severe exploitation. It is often necessary to replace a broken façade slab.

Porcelain stoneware for the installation of curtain walls can be used in all climatic regions of Russia. Because it has 100 freeze / thaw cycles.

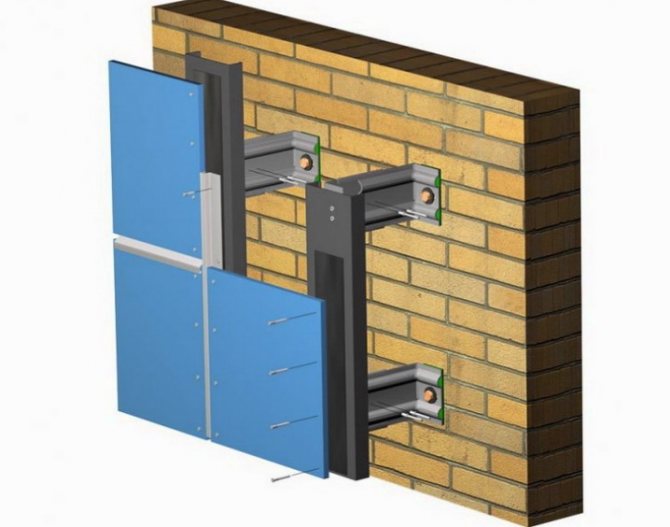

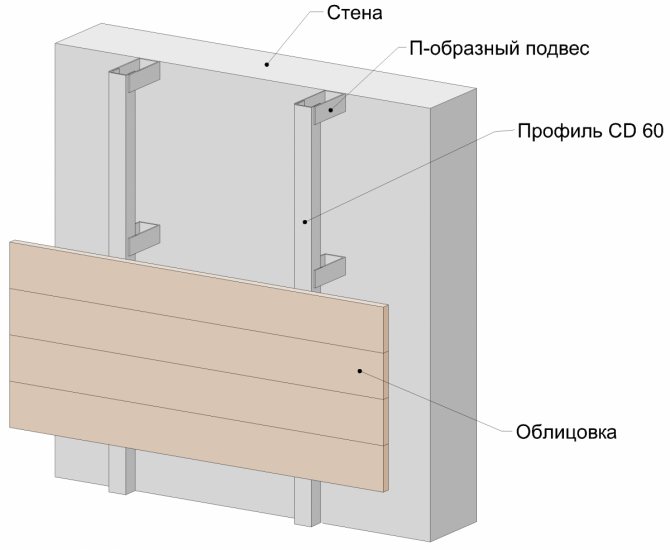

Metal lathing. For a smooth and uneven wall, for a non-insulated ventilated facade

As mentioned above, U-shaped hangers are used to level the plane without plastering the original wall (if it is uneven).

The first lathing made of U-shaped suspensions. U-shaped hangers are attached to the wall with dowels (if the wall is brick or concrete) and self-tapping screws (if the wall is a block), 2 fasteners (self-tapping screw or dowel, depending on the wall material) for each suspension. The step of the suspensions vertically is 60 cm, horizontally - depending on the type of cladding (62.5 or 62 - OSB, LSU, 60 or 40 - blockhouse and siding).

The second lathing is made from the CD 60 profile.

The second crate is attached to the U-shaped suspension as follows: for each suspension there are 2 self-tapping screws (1 self-tapping screw for one "ear" and 1 self-tapping screw for the other "ear"). Self-tapping screw with a diameter of 3.5 mm and a length of 9 mm (popularly called "nines", "fleas"). They are black and galvanized, galvanized is preferable.

Important points when fastening (namely metal to metal):

- In the U-shaped suspension itself there are ready-made holes, we fix the screws not in them, but in solid metal. No need to make your work easier, fixing to the finished hole will not work. The self-tapping screw cuts the threads in the metal and if it is fastened not in solid metal, but in a finished hole, then it will not cut the thread, accordingly, it will not hold properly. Will scroll.

- It is better to fix it with a screwdriver, not with a drill. The drill is high-speed, it does not have a stopper when pressing a self-tapping screw, in addition, it is heavier, does not sit well in the hand. But if there is no screwdriver, then you need to have a magnetic attachment on the drill, plus watch out for each self-tapping screw: if after fixing it scrolls, then attach another self-tapping screw to this "ear" of the suspension. If he scrolled, then attach another one. All in solid metal. As a result, on some "ears" of suspensions there may be 2 or even 3 self-tapping screws. But only the self-tapping screw that does not scroll will hold.

There is no insulation and superdiffusion membrane in this version. The ventilation gap is formed due to the length of the “ears of the U-shaped suspension and due to the CD 60 profile. The size of the gap is adjustable (the profile can be placed closer and further to the wall). It is optimal to make the size of the gap 30-40 mm.

Features of the installation of some materials

When using some materials, it is necessary to know in advance about the features of the installation of insulation. When using polyurethane foam, there is no need to clean the surfaces and carry out any work. This determines the insulation itself. But when installing mineral wool and expanded polystyrene, a certain plan should be followed.

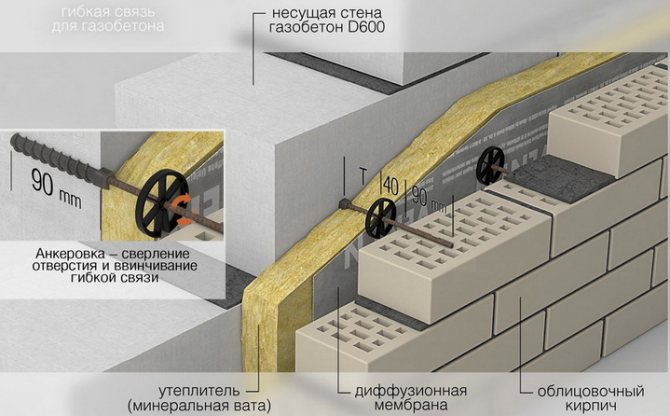

Installation of mineral wool

Before installing the mineral, you need to take care of the frame for it. The lattice should be made already of the insulation itself to install the material in the spacer.Also, mineral wool is attached to the frame using dowels with plastic washers at the end. It is also necessary to take care of additional waterproofing of the insulation so that in the future it does not become damp and mold. After applying waterproofing, a windscreen must be installed. The windproof film is fastened with an overlap of up to 10 cm. After applying additional protection, the insulation boards must be fastened with a facing material. If you follow all the rules for installing mineral wool, you can achieve an excellent, and most importantly, durable material.

Styrofoam installation

As a rule, this type of insulation does not require an additional frame and lattice. Foam plates can be fixed with glue by first cleaning the mounting surface. But if you decide to use ready-made polystyrene foam plates, then it is still worth working on the frame. Dowels with wide heads are driven into the seam between the plates, thus securing the material in place. Plates must be fastened at a short distance from each other. Since when the temperature rises, the foam tends to expand.

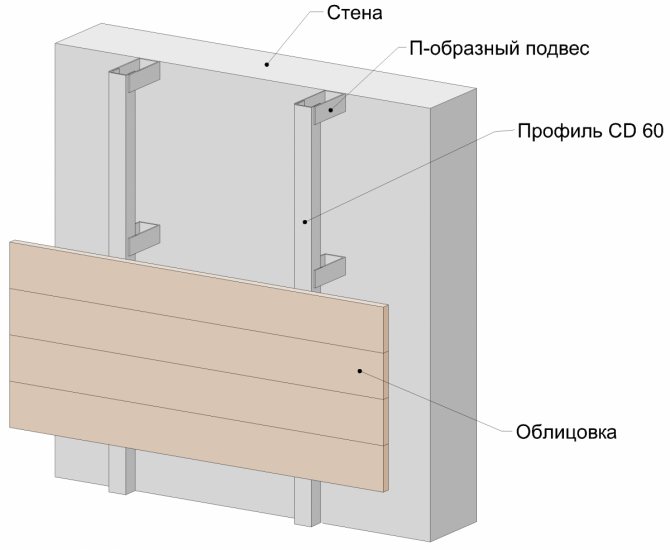

Metal lathing for a heat-insulated ventilated facade, with an insulation thickness of 50 mm

The first lathing made of U-shaped suspensions. U-shaped hangers are attached to the wall with dowels (if the wall is brick or concrete) and self-tapping screws (if the wall is a block), 2 fasteners (self-tapping screw or dowel, depending on the wall material) for each suspension. The step of the suspensions vertically is 60 cm, horizontally - depending on the type of cladding (62.5 or 62 - OSB, LSU, 60 or 40 - blockhouse and siding).

The second lathing is made from the CD 60 profile.

The insulation is put on the suspensions of the first sheathing. A membrane is put on top of the insulation (it is also pierced by a suspension), and then the second crate from the CD 60 profile is attached.

The second crate is attached to the U-shaped suspension as follows: for each suspension there are 2 self-tapping screws (1 self-tapping screw for one "ear" and 1 self-tapping screw for the other "ear"). Self-tapping screw with a diameter of 3.5 mm and a length of 9 mm. For the finer points of fasteners, see the item “Metal crate. For a smooth and uneven wall, for a non-insulated facade ", above.

The ventilation gap is made due to the length of the “ears of the U-shaped suspension” and due to the CD 60 profile. The size of the gap is 30-40 mm.

Now let's consider whether this scheme can be applied to a ventilated facade with 100 mm insulation.

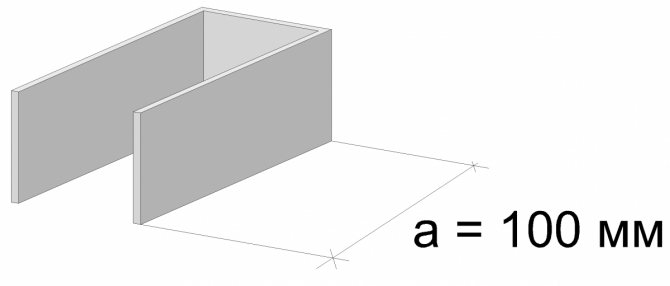

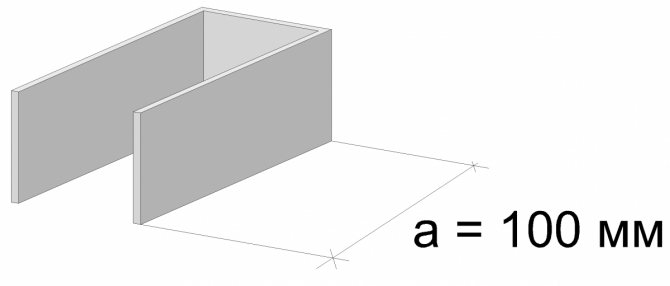

For a facade with insulation of 100 mm, this type of facade is difficult to perform, since the U-shaped suspension (see Figure 9) has a dimension "a" equal to 100 mm.

This means that if you put 100 mm cotton wool on it, it will be difficult to create an air gap. You will need either a 125 mm suspension, but it is more expensive. (A regular one costs about UAH 0.8, and 125 mm - about UAH 1.20). If the version with a suspension with a size of 125 (instead of 100 mm) is suitable, then this option can be used for a ventilated facade with 100 mm insulation.

Note. The use of a 125 mm hanger gives a 25 mm ventilation gap. This, in our opinion, is not enough. Therefore, we recommend for a ventilated facade with insulation of 100 mm, the solution with a self-made fastener, described below.

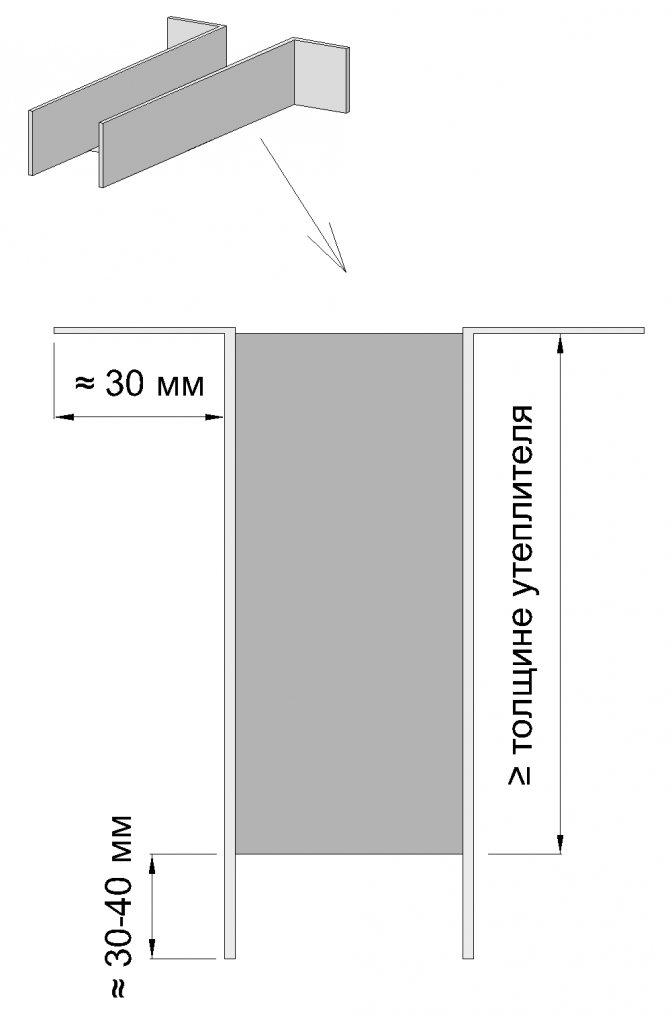

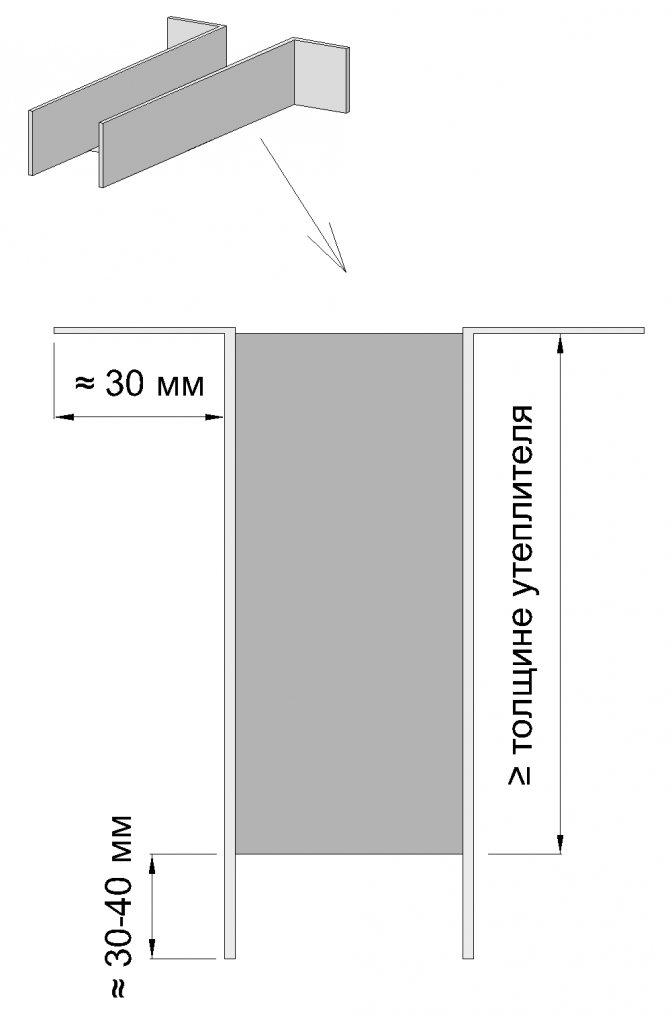

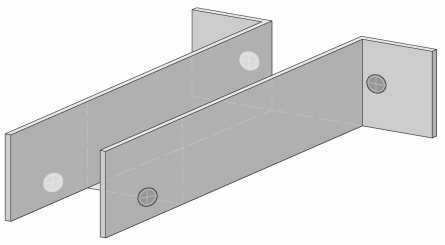

Construction of a self-made fastener from a cut CD 60 profile

An element like this looks like this:

Figure 10 shows the dimensions of the “ears” of the fastener. The upper, curved "ears", approximately 30 mm long, are attached to the wall. Lower, straight "ears", 30-40 mm long, on which the second lathing is attached (or a wooden block, or a metal profile). The size of the lower "ears" is adjustable for the thickness of the bar (if the bar is 30 mm, then the size is 30 mm, if the bar is 40 mm, then 40).

Fig 11. The location of the self-tapping screws for fastening a homemade fastener

We fasten the self-tapping screw closer to the edge (that is, at the end - closer to the place where the middle was cut, and from the side where we fasten the fastening element to the wall - closer to the place where the "ears" bend).