Here you will find out:

- Features of using the device

- Error codes for the gas water heater "Oasis"

- The main causes of the malfunction and their elimination

- How to prevent breakdown of the Oasis gas water heater

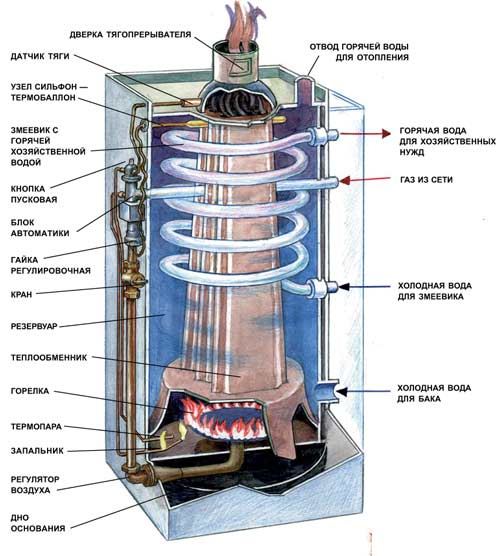

Before proceeding with the search for malfunctions of the Oasis gas column and choosing a way to eliminate them, you must clearly understand what type of device the device belongs to, know the device, the principle of its operation.

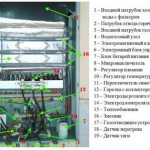

The layout of the Oasis gas column assemblies is typical for most models of Chinese-made flow columns

Above in the diagram, the device of a typical gas water heater is considered, which is also typical for Oasis columns. Let's consider further how the most common type of chimney flow-through model of the brand with automatic ignition works.

When the tap is opened, water is supplied through the inlet pipe to the water-gas unit, which turns on the ignition and gas supply. As soon as it ignites, a signal is sent from the flame sensor to the electronic unit to stop sparking.

Further, the water passes through a coil rigidly fixed to the heat exchanger, which is heated by the burning gas. The coil transfers heat to the outgoing running water.

When the tap closes, the water-gas unit cuts off the gas supply. Burning stops and the column goes into standby mode for opening the water tap.

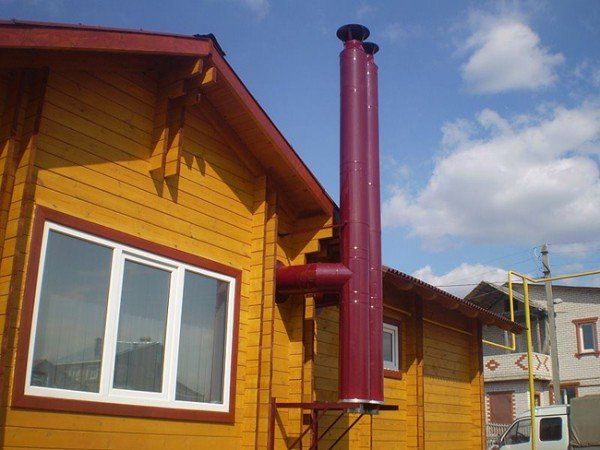

An important condition for the normal and safe operation of the column is the removal of combustion products through the ventilation chimney. If the hood is absent or insufficient, the draft sensor is triggered and the column turns off.

The overheating sensor is responsible for the timely shutdown of the column when the maximum temperature is reached. It is an essential element of the column to provide overheating protection.

Maintaining the required temperature is an equally important condition for fire safety and a long service life of the column. Overheating negatively affects the condition of all elements, especially the heat exchanger, which leads to their premature failure.

Features of using the device

So, in order for the Oasis gas water heater, the instruction manual of which is attached to the product, to work effectively, you need to follow certain rules for using the device:

- Use only the type of gas specified in the technical recommendations;

- It is necessary to monitor the charge of the batteries on which the device works;

- If you want to turn off the device, you must first turn off the water;

- If you are going to use the equipment for the first time, you need to take into account that air may be present in the gas supply pipes, so the device may not immediately ignite;

- The setting of the degree of water heating must be carried out by turning the handle of the tap or the gas regulator on the body of the device;

- If you are going to turn off the device for a long time, you must first turn off the hot water tap, the gas shut-off valve.

Now let's consider what should not be done while using equipment such as the "Oasis" gas water heater:

- You cannot turn on the device if there is no draft in the chimney.

- Do not leave the device unattended for a long time.

- No need to buy and install damaged or defective models.

- You should not unauthorizedly disassemble the device and repair it, as well as touch it during operation.

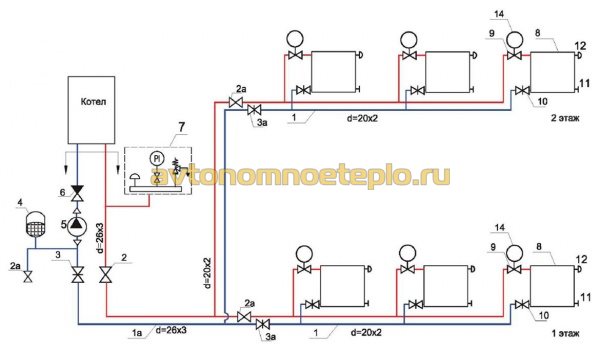

Types of gas boilers

- By appointment: only for heating (single-circuit) and for heating with hot water in boilers (double-circuit).

- According to the produced capacity: low-power - with one-stage power regulation,

- medium productivity - with two-stage power regulation,

- high-performance - with modulated power control.

- wall-mounted, with heat exchangers made of copper,

Benefits

their uses are as follows:

- They are environmentally friendly;

- Compact and quiet in operation;

- Easy to operate;

- They can be installed in a residential area.

But they have a significant drawback - explosiveness.

Error codes for the gas water heater "Oasis"

- Error E1: Ignition defective. Reasons: no gas supply, or gas pressure is too strong. Defective ignition control electrode.

- Error E2: The air pressure switch does not close. Causes: chimney clogging.

- Error E6: There is no flame. Reasons: air has accumulated in the system.

- Error E7: Low pressure. Reasons: there is little liquid in the hot water supply system.

- Error E9: It signals that the pump has broken down and that the system has an impermissibly low pressure.

Oasis boilers characteristics

The "Oasis" boiler is a gas boiler, but at the same time it will not be able to operate on liquefied gas. All models are designed only for natural gas - conversion to liquefied gas is not foreseen and impossible. Therefore, the boiler can only be used for buildings connected to the gas supply system.

With regard to the "average" structure, the boiler "Oasis" of various modifications is capable of heating areas (m 2):

- NZR 13 - up to 100;

- NZR 16 - up to 120;

- NZR 20 - up to 160 - 180;

- NZR 24 - up to 200 - 220.

The volume of the membrane (expansion) tank of the gas "Oasis" is 6 liters. This must be taken into account if the boiler is chosen for a private house. It may be necessary to install an additional tank (with a large volume of coolant).

All gas boilers "Oasis" are double-circuit, therefore, in addition to heating, they also provide hot water supply. Depending on the automatic settings, the water temperature can be from 36 to 60 0 C. The DHW circuit productivity - 10 l / min (for the NZR 24 model - 12 l / min) - is quite sufficient to meet all the household needs of a family of 5 - 7 people.

The main causes of the malfunction and their elimination

The designs of all gas water heaters are similar to each other. Why not summarize all the problems and describe the options for solving them? Because each brand has its own weak points. Then there are malfunctions characteristic of specific brands. We analyzed user reviews to collect reliable information for you.

In Oasis water heaters, factory defects are extremely rare.

External and internal factors can cause a breakdown:

- Incorrect installation and connection.

- Incorrect operation.

- Chimney and ventilation blockages.

- Problems with internal components: scale, corrosion.

We have described the ways to fix these problems below.

The column does not light up

There can be many reasons, we will help you figure it out. The main thing is to correctly determine the location of the breakdown.

If the device does not ignite at all, no spark is generated, then:

- The batteries are dead. Automatic ignition devices are battery operated. For replacement, take quality elements with a good charge. If you find a leak where they were installed, clean all contacts and install new batteries.

- Traction problems. For the normal operation of equipment, it is necessary to have a draft in the chimney. If not, inspect the ventilation hole for blockage. This could be a foreign object, soot, or debris from the street. Clean the hole if possible. Make sure that the outside of the chimney outlet is not blocked.

How do you know if there is cravings? Light the spike, bring it to the viewing window of the column. The flame deflects - there is a thrust, it burns evenly - no. You can also lean a piece of paper against the ventilation.In the presence of traction, the sheet will press against the terminal, otherwise it will fall.

- The water pressure regulator is set at the minimum level. A small pressure is created in the system to activate the diaphragm and open the gas valve. Set the knob to the maximum value.

- Low line pressure. Does a trickle flow when you turn on the tap? Contact the water utility and wait for the supply to be restored. If this happens frequently, it is recommended to install a circulation pump.

- The strainer is clogged. The part is located at the entrance to the water unit, retains small debris that enters with the flow of water. It is necessary to disassemble the unit, rinse the filter under running water.

- The membrane is stretched. The element is used to start the gas valve. With line pressure, the diaphragm expands, pushes the stem and opens the valve. It wears out over time, so it needs a replacement. You can read about it here: "Water column of the gas column".

- Broken microswitch. It cannot be repaired, so a replacement is needed.

- Wiring problems. Remove the cover, inspect all wires leading to the control box. If the insulation is broken, replace the loop.

- Defective solenoid valve in the gas unit. You need to inspect, check and install a new part.

The flame is lit and extinguished

This happens when the electronic unit does not receive an ignition signal, stops ignition and shuts off the gas. The reason may be a malfunction of the flame sensor or the formation of carbon deposits on the sensor.

Remedy: Lightly clean the sensor with a fine emery cloth (zero grade). In this case, one should not be too zealous so as not to damage the metal coating. If this procedure fails, the flame sensor needs to be replaced.

The column is leaking

Leaking is a serious malfunction, but you can cope with it yourself.

The stuffing box leaks through the stem. To verify this, remove the shroud and check where the water is coming from.

How to do a DIY repair:

- Remove the adjustment knobs by pulling them towards you.

- Unscrew the four screws securing the casing.

- Disconnect the display wiring.

- Remove the batteries from the unit and disassemble it by unscrewing the bolt from the bottom.

- Disconnect the water hoses.

- Unscrew the bolts of the water valve, remove it.

- You got to the stuffing box and its stem. When dismantling the old stem, the gasket may remain inside - this is not a problem. Simply remove the gasket from the new part and install.

- The assembly is carried out upside-down.

A more serious problem is radiator leakage. The new heat exchanger costs almost as much as the new Oasis Turbo model. How to save money? Close the fistulas by soldering. Read more in the article "How to solder a gas water heater".

The easiest way to repair a leak is if a hole has formed on the outside of the tube. Then you can use cold welding. Internal corrosion requires the use of a soldering iron or torch with a temperature of 170 degrees. A rosin or aspirin tablet is suitable as a gumboil.

Before starting work, prepare the radiator:

- Drain the pipes.

- Dry.

- Sand the soldered area with fine sandpaper.

- Wipe with a degreaser.

You can start repairing. To prevent the fistula from appearing, the thickness of the solder should be 2-3 mm. Examine the node for green spots - these are future fistulas. Better to take care of them right away.

The column goes out after a few minutes

Such a malfunction is often associated with poor traction or overheating.

Remedy: clean the chimney, reduce the water temperature by adjusting the flame and pressure, do not dilute hot water with a mixer.

Clogged heat exchanger

How to understand that the radiator is clogged:

- Long-term heating of water.

- The stream is not hot, but warm.

- Pieces of scale come out together with water.

These are indirect signs, so it is better to inspect the device.Scale on the heat exchanger plates and the coil appears from poor-quality water and high heating temperatures. It is recommended to set 55 ° С and do not mix flows on the mixer.

There are two ways to get rid of the blockage.

- Without removing the node from the column. You will need a dedicated pump with tubing. A reagent is poured into it, which can be bought in a store or made on the basis of hydrochloric acid. Connect the hoses to the coil and start bleeding until all scale comes out of the holes.

- With dismantling. This is a more budget option. A deep container is filled with water, a heat exchanger is lowered into it. A solution of citric acid (150 g / 750 ml) is poured into the coil through a watering can. The container is placed on the stove and boiled for 15 minutes. Then the radiator is rinsed under running water, dried and installed in place.

Reduced pressure and weak water heating

Signs of scale formation in the heat exchanger are a decrease in the flow of water at the outlet of the column and its weak heating. In this case, the column may not ignite well, and the radiator overheats due to poor heat exchange with water. This triggers the thermal protection sensor and turns off the column.

Clogged radiator fins also lead to overheating. When they become clogged with debris, scale, it becomes difficult for the combustion products to exit into the chimney, which can lead to burnout of the heat exchanger skirt.

Water hardness is the main reason for the deterioration of the pipeline capacity. The presence of calcium, magnesium and other impurities contributes to the formation of scale and reduces heat transfer. Heating greatly enhances this process.

Scale reduces efficiency, increases gas consumption to achieve the desired temperature. If you do not take measures to remove it, deposits will grow even faster, up to the complete blocking of the water flow.

It is impossible to use a column with heat exchanger tubes clogged with scale. This will lead to local overheating, cracks in the coil and the need to replace it.

Remedy: flush the heat exchanger with a special solution. There is a wide variety of reagents available for professional use. They do the best job of descaling without damaging the piping.

Most chemicals contain solutions of various acids. Their concentration and composition are selected in such a way as to effectively dissolve salt deposits, but to act as gently as possible on the inner surface of the pipeline. The choice of a suitable reagent should be based on the material of the heat exchanger.

For example, reagents intended for copper radiators cannot be used for pipelines made of galvanized and stainless steel and vice versa.

The highest quality flushing is carried out using special equipment (boosters). The effect is achieved through repeated circulation of the reagent, its heating, reverse, and the use of special formulations. The cost of such equipment, as well as services, is quite high. Buying boosters is more justified for professional use.

Good results can be achieved in less costly ways using available tools and reagents.

The most popular and proven heat exchanger flushing agents are citric acid, vinegar, decalcifier and other acid cleaners. It is important to observe the dosage - exceeding the concentration of the active substance can damage the pipeline

For descaling, usually 10 - 20% solutions are used. For 1 liter of water, 100 g - 200 g of antiscale or citric acid or 9% vinegar are taken. The greatest effect is achieved when the solution is heated to 80 - 100 degrees.

Flushing can be done in two ways:

- without dismantling the radiator;

- with the removal of the heat exchanger.

To flush the radiator without removing it, a number of steps have to be performed. First, turn off the water by substituting a container for draining. Disconnect the outlet pipe, open the tap.Then unscrew the nut connecting the coil to the water block. Connect the funnel from the cut plastic bottle to the coil inlet with a flexible hose.

Then fix the funnel above the heat exchanger. Pour the working solution into the funnel in small portions until foam appears at the other end of the coil. The procedure will have to be carried out for 4-6 hours - until the end of the chemical reaction, guided by the released foam, or using acidity indicators.

With the dismantling of the heat exchanger, flushing is performed as follows: first, the column is disassembled, the radiator and burner are removed. Then the plate is cleaned from soot and soot. After that, the radiator is placed in a large metal container with water, the reagent is poured into the pipeline and the container is heated. At the end, the heat exchanger must be rinsed with cold water and a 10% soda solution.

Gas smell when turned on

This is a serious and dangerous problem. Shut off the gas supply immediately! Contact the gas service.

The oil seal is probably worn out. Replacement in case of gas leaks must be carried out by a specialist. How to disassemble the gas-water unit and get to the oil seal, we have described above.

When starting to operate the equipment, read the instructions. It is recommended to carry out a routine inspection of all units of the water heater once a year. Now you know what to do. And if you are confused, cut off the fuel supply and contact the service center.

How to clean a heat exchanger

The heat exchanger is cleaned at the end of the heating season. To carry out the work, it is enough to have a standard set of tools available. Before starting work, it is necessary to disconnect the boiler unit from the gas network (main or local) and electricity.

Consider how to clean a floor standing gas boiler

:

- the first step is to dismantle the burner device;

- all wires must be disconnected from the gas valve;

- a thermocouple is removed from the combustion chamber, which is connected to the gas valve by a capillary tube;

- the fuel supply pipe is disconnected;

- bolts or nuts (4 pcs) that fix the plate with the burner are unscrewed, the assembly is removed outward.

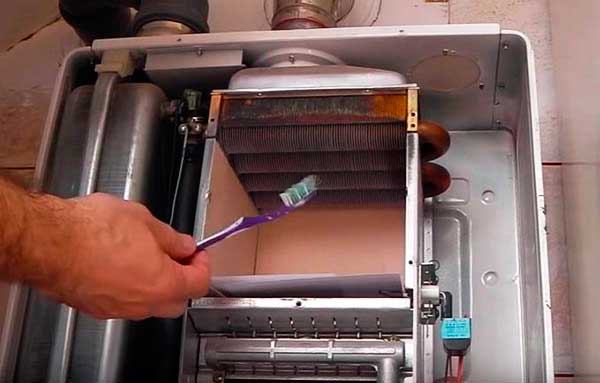

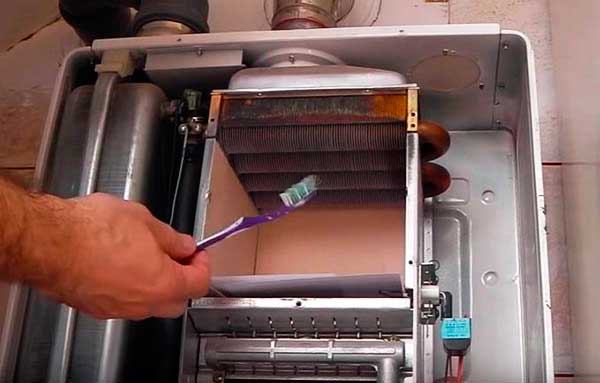

It is convenient to clean the gas boiler burner with an old toothbrush. Soot must also be removed from the flame control sensor, igniter, piezoelectric device for automatic ignition.

To get to the boiler heat exchanger, remove the top cover of the unit, disconnect the draft sensor and chimney, remove the insulation, dismantle the casing fasteners and the casing itself. Having gained access to the heat exchanger, it is necessary to remove the turbulators from it.

A soft metal brush is suitable for cleaning the turbulators, and the heat exchanger itself is freed from soot deposits with a miniature scraper made of thin metal. A long-handled brush is also used. First of all, the smoke tubes are cleaned and swept, then the soot that has crumbled on the bottom should be removed.

The wall-mounted boiler is cleaned with a toothbrush

Cleaning the wall-mounted heat generator. After turning off the gas supply, it is necessary to dismantle the front panel of the boiler. Then the front cover is unscrewed, which closes the combustion chamber. It is recommended to cover the nozzles with a sheet of heavy paper to prevent the burner from clogging up with falling soot. Do-it-yourself cleaning of the heat exchanger of a double-circuit boiler is performed using an old toothbrush or a brush with metal bristles. After cleaning is complete, brush around the heat exchanger and carefully remove the paper containing the collected soot. How the procedure is performed, see the video below.

Flushing of a single-circuit and double-circuit gas boiler

Flushing the heat exchanger of a gas boiler is necessary to remove internal deposits that can disrupt the normal circulation of the coolant in the heating system and cause problems with the supply of hot water to the local DHW system. Also, the sediments may contain substances that destroy the metal.

How often this action is required to be performed depends on the type of coolant. If purified water circulates in the system, it is enough to do prophylaxis every four years, removing deposits. The system with antifreeze should be flushed every two years and the coolant should be changed regularly - under the influence of high temperatures, it changes its properties over time and can become dangerous for the metal elements of the system.

How to prevent breakdown of the Oasis gas water heater

In order to prevent a situation when it is necessary to repair the Oasis gas column, it is necessary to properly care for the gas equipment and operate it correctly. It is these recommendations that can be read in the instructions for gas water heaters. Here are some tips for use:

- It is necessary to monitor the charge of the batteries.

- When turning off the unit, you must first turn off the water.

- If the unit is shut down for a long time, then it is necessary to shut off the supply of bitter water.

- Descale the column periodically.

- Use only the gas recommended by the manufacturer.

- Do not turn on the column if there is no traction.

- Do not repair yourself.

Features of using batteries

Of all the parts, batteries require the most frequent replacement. For gas water heaters, you should choose only alkaline batteries made according to the Alkalin power technology of standard size "D" and the first letter "L" in the designation - LR20. Their capacity and service life are five times longer than that of saline ones: from 1 to 1.5 years.

It is better not to buy items that are too cheap, they may turn out to be fake. It is possible to install NiMH or Li-Ion batteries, but their price with a charger is higher

Quality batteries start at $ 1.2. There is a radical way to reduce the cost of replacing batteries - converting the speaker to power from the mains.

To do this, you can buy a special power supply unit for 3 V, or use a charger for a mobile phone, for 5 V, with an additional stabilizer. The main requirement is that its power is sufficient for ignition, which occurs at a supply voltage of 3 V and a current of 350 mA.

In cases of power outages, you can always keep batteries in stock, fortunately, alkaline batteries have a shelf life of 5 years and more.

Column heat exchanger quality

When choosing a column, you should pay special attention to the quality of the heat exchanger. The type of metal and its quality have a large impact on the life of the radiator. They are made of galvanized steel, stainless steel, copper.

The most durable stainless steel, but inferior in thermal conductivity to copper. Accordingly, they are less economical and have lower efficiency. Copper ones are the most efficient in terms of heat transfer, but also the most expensive.

When replacing the heat exchanger with a new one, pay attention to the thickness of the metal and the weight of the radiator. Quality shouldn't be too light

The factor of the high cost of copper leads to the fact that manufacturers save as much as possible on the thickness of the heat exchanger wall, bringing it down to 0.5 mm, which significantly reduces the service life. For the same reason, other metals are added to copper. The alloy obtained in this way can have unpredictable properties. As a result, such a heat exchanger cannot even be soldered.

System water quality

If the water in the system is subjected to frequent chlorination, this will adversely affect the condition of the copper heat exchanger. Combined with thinner pipe walls, this can quickly lead to corrosion and fistula formation.

Increased water hardness in combination with heating is no less problematic. Scale deposits require periodic flushing.

You can improve water quality with aquafilters and magnetic softeners.

Internal structure of Oasis boilers

One of the characteristic features of the modifications is the presence of a closed combustion chamber. Air intake is carried out from the street using a coaxial chimney. The combustion products are also removed through the pipe. This makes the operation of boilers as safe as possible. In addition, due to the closed firebox, the gas consumption is significantly reduced.

Separately, we can note the presence of two heat exchangers. This solution increases the speed of heating water for hot water supply, and also allows the device to start in summer mode, which increases its efficiency.

All wall-mounted double-circuit gas heating boilers Oasis have a high degree of autonomy, achieved thanks to the internal device, including:

- Burner - pressurized device is used. The connected burner is automatically controlled. Electric ignition is provided. The burner is equipped with photo sensors that monitor the presence of gas. After a power outage, the gas supply to the burner is blocked. A coaxial chimney is used for the boiler. Through it, air is simultaneously taken in and combustion products are removed. Not included in the basic package.

- Security group - 2-circuit hinged gas heating boiler Oasis has multi-level protection that prevents spontaneous combustion and the occurrence of explosive situations. Provided: water flow sensor - controls the pressure of the water supply and the heating system, blocks operation in the event of a drop to critical values. Dump valves are installed to help in case of overheating of the coolant. When the room temperature drops, the anti-freeze system is activated, which maintains the minimum heating of the heating system.

Oasis boilers passed certification and received permission for operation by Rostekhnadzor. This made it possible to operate the equipment of the Chinese manufacturer throughout the territory of the Russian Federation.

What to focus on operation

Boiler piping - there is a circulation pump and an expansion tank in the internal structure of the boiler. During installation, you will need to additionally install a filtration system. Automation is sensitive to voltage drops, which is one of the main disadvantages of the Oasis boiler. To eliminate the possible failure of the control board, it is necessary to connect the UPS. Big noise - The blower burner is making a lot of noise. Noisiness requires installing the boiler in a separate room. The technical characteristics declared by the manufacturer are somewhat different in this respect from what actually happens.

Especially noisy when DHW is turned on.

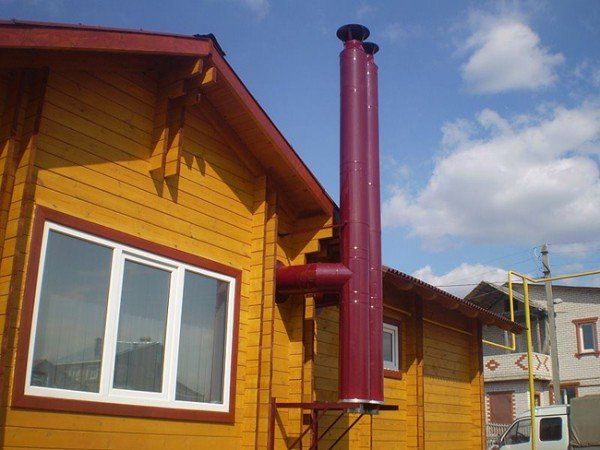

Coaxial chimney - it is extremely important to comply with the installation requirements, strictly adhere to the maximum height, angle of inclination and other parameters. Productivity and efficiency ultimately depend on a quality installation.

Chinese doesn't mean bad

All components from the closed combustion chamber to the temperature sensor are checked for quality and compliance with standards. The only condition for trouble-free operation is the installation and operation of the boiler in accordance with all the rules and in accordance with the manufacturer's recommendations.

Removing the column lining

Such a do-it-yourself gas water heater repair, like replacing batteries, is the only way to troubleshoot problems that does not require removing the external casing of the unit. To repair geysers Vector, Oasis and any other in case of other malfunctions, it will be necessary to open the device. To start removing the casing from the water heater, it is necessary to shut off all the water and gas supply valves, and then do the following (for example, the Neva 5611 water heater is taken, which we will disassemble on the table).

Power problems

For normal operation of most of the components inside the unit, a stable power supply is required.Therefore, if malfunctions of the gas column appear in the form of failures, which are characterized by the fact that the flame does not ignite or goes out during the operation of the apparatus, then a possible cause of such a malfunction may be lack of current power

supplied from batteries.

This does not apply to units without electronic components in the design. For example, you will not find it in the Neva 3208 unit, which you want to repair, or when repairing an old model Astra gas water heater.

Often, when repairing the Oasis gas water heater, as well as the Junkers gas water heater, users are often misled by the fact that the LCD display glows and there seems to be no power supply problem. But it should be borne in mind that for ignition, a sufficient charge is required in order for a spark to form in the glow plug. In addition, the electronic unit also needs power to transmit it to the solenoid valve in order to keep it in the "open" state. Therefore, if the batteries are already dead, then there may not be enough power to ensure the operation of these modules.

In the instructions for the water heater, the manufacturer indicates the operating time of one set of batteries. As you might guess, this value is approximate, and it depends on the quality of the batteries used. When buying batteries, you should pay attention to the markings applied to them. For long-term operation of the gas column, it is recommended to choose batteries marked LR20

... This means that they are alkaline, that is, alkaline.

Cheaper ones, labeled R20, fail very quickly and cannot cope with constant load. Lithium CR20 batteries are ideal. Their main difference from alkaline ones is their high capacity, stable generated current, long-term operation, which is several times longer than the service life of LR20 batteries. The only drawback of CR20 batteries is their high price

... So buying LR20 alkaline batteries will be the right choice in terms of economy and cost effectiveness.

It should be remembered: never buy batteries from street kiosks, and even more so from trays in the market. This recommendation especially applies to the winter period, since the batteries lose their charge from the cold.

Common problems

Let's look at what breakdowns occur in household gas instantaneous water heaters. These breakdowns are typical for water heaters Neva, Oasis, etc.

If the water heater does not ignite

Don't sound the alarm right away. Some of the problems are not very serious. With these malfunctions, the water heater can produce cotton when switched on.

Lack of traction

There is no draft in the exhaust duct. Maybe something got there that blocked the exhaust duct.

Or maybe there are a lot of combustion products in this channel - soot and it is clogged. The circuit breaker was triggered and the column stopped working. It is necessary to check the presence of traction. Bring a match to the ventilation, if there is a draft, the flame will be directed towards the channel. If there is no draft, then you need to call a chimney sweep and clean the channel.

You may not be able to do it by cleaning one channel. Part of the soot accumulates on the column itself, in order to remove it, you can vacuum the column.

In the absence of the necessary draft, the water heater can turn on, work a little and go out. Try opening the vent to increase the amount of air.

Old batteries

Another reason why the water heater does not turn on is that the batteries have expired, the batteries in the electronic device have simply run out. Change them and the problem will be fixed.

Weak water pressure

There may be insufficient cold water flow. This is easy to check by turning on the water tap. If the pressure of cold water is small, you need to call the management company and find out the reason.

Clogged shower

There may be such a reason: the pressure of hot water in the tap goes on, when you switch to the shower, it stops going. Check if the shower itself is clogged.

The water heater does not heat or does not heat the water well

This is most likely a water unit problem. There is a rubber membrane, which, for some reason, stops responding to the pressure of water, which, in turn, leads to the shutdown of the gas supply. There may be a crack in the membrane, salt deposits may accumulate due to hard water, or simply clogged.

The unit must be disassembled, the membrane must be cleaned or replaced, it is better to replace it with a silicone one. The coarse filter installed in the water unit may also be clogged.

Column blockage

The water may not heat well due to a blockage in the column itself. This is indicated by the soot that forms above it and the changed color of the gas.

Repairs

Low power

Perhaps your column has low power, so carefully read the characteristics of your unit.

Weak gas pressure

Water will not heat well at low gas pressure. In this case, call the gas service.

The water is very hot

This is not a breakdown of your unit. You just need to reduce the gas supply, turn the valve, which is located on the gas pipe in front of the column.

Gas smell

If you suddenly smell of gas, then you should not deal with this problem yourself. Call the gas service urgently. There should be no gas smell. Also, if when the column was turned on, the characteristic sound of gas turning on did not follow, that is, gas does not flow, you should contact specialists, gas workers.

A little background

So we became "happy" owners of one of these. Literally right after the purchase, the heat exchanger leaked, as it turned out, we were given a refurbished return. With great difficulty, it was possible to make an exchange after written claims for a pre-trial settlement to the store. According to the rules of the store, the exchange is not possible, but where is it spelled out in the law. It is not so easy to even give it to the service: first you need to call the gas workers so that they draw up a breakdown report, assure it with seals and signatures; submit the act to the warranty service along with the column, where a decision on repair will be made within three days. And we have to sit without hot water all this time!

If the seller tells you that the gas equipment cannot be returned or exchanged, remember, this is a lie. In the event that you purchased a product with a factory defect, you are obliged to replace it with a new one at your request or return the money in the absence of a similar product.

After several months of operation of the second unit, a malfunction appeared: the gas column does not ignite. Immediately I remembered the procedure that must be passed for repair under warranty. Therefore, it was decided to repair the gas water heater with our own hands, or at least try.

Malfunction of the water unit

Most often, gas water heaters are repaired due to a malfunction of the water block. Its work consists in the fact that under the influence of liquid pressure, the membrane inside it, bending, transfers movement to the rod, and it already moves the pusher of the gas unit. As a result, the spring valve opens and the power supply to the control unit is turned on. Therefore, if the water unit is faulty, the device will not start.

The breakdown of the water block can be identified by outward signs

.

If you notice at least one sign, then the node will need to be removed and repaired. The water unit can only be removed together with the gas module, since they are a single structure. This can be done in the following way:

- after you have made sure that the gas valve on the pipe is turned into a closed state, you can disconnect the supply hose (a);

- similarly, with the water supply turned off, the nut on the pipe of the water block (b) is unscrewed;

- then, using a wrench, it is necessary to unscrew the nut that connects the water block to the heat exchanger (c);

- disconnect the connector block (d) on the conductors connecting the solenoid valve to the control module;

- in the same way, the wires (d) going to the switch are disconnected;

- using a screwdriver, unscrew the 2 screws (e) securing the branch pipe to the water-gas unit, through which the fuel is supplied to the burner manifold;

- after unscrewing the fasteners, the entire unit can be easily removed from the device.

Repair of the gas water heater Neva 3208 regarding the “frog” malfunction is similar and intuitive, although the internal view of the unit is slightly different. The Neva 4511 gas water heater is also disassembled, repairing it with your own hands is quite feasible.

When is the repair done? chinese gas water heater

, the size of the water node is always surprising. It is rather small in size, and to disassemble the “frog”, you will need to unscrew only 4 screws.

Modernization of AGV boilers by the manufacturer

The manufacturer of boilers AGV was in no hurry to remove them from production due to the obvious advantages.

However, taking into account the fact that this equipment needed a thorough modernization, the following design changes were made:

- Fragile glass thermometers were replaced with more reliable Italian-made devices;

- The new systems were equipped with automatic equipment from the American company Honeywell;

- To turn on the device with a handle, a piezo ignition system was used;

- The new coating technology made it possible to improve the aesthetic appearance of the unit.

Boiler diagram AOGV - 23

Heating system handling rules

Install the unit in a separate room. It is advisable that this room be soundproofed, since a rather loud bang occurs when the boiler burner is turned on.

In some new modifications (AOGV-23.2-1-U), this drawback is largely eliminated, since when the water overheats, the automation does not turn off the burner completely, but switches it to a mode in which the flame is minimal.

The chimney (diameter from 140 mm) for combustion products is installed outside the living quarters. Below the junction of the pipe from the heating tank with the chimney, there is a garbage container - a "pocket" for foreign objects and waste that accidentally fell into the channel.

Chimney execution option for AGV in a private house

Note! Do not connect the unit yourself. It should be carried out by employees of the gas service

In this case, the device is registered.

For the unit, a room should be allocated at the bottom of the building. The ascending pipeline needs to be insulated. The return line should not be insulated.

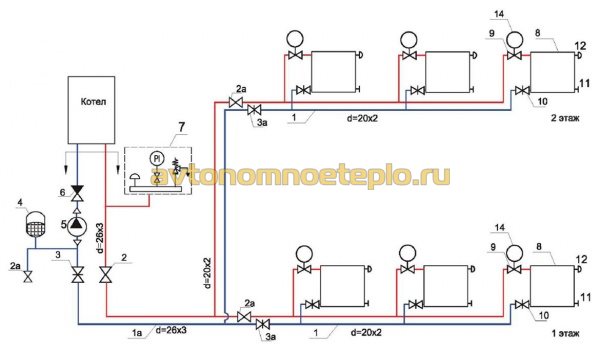

Installation instructions for heat transfer devices (radiators, convectors and heating panels) provide for their installation at the highest possible height from the unit itself. To circulate layers of air, such devices should be installed under windows. The return line is laid under the floor of the room.

If the return line is laid over the door frames, the system may become air-tight.

General view of a fragment of the piping of the heating system with AGV

Two-inch network pipes do not look very aesthetically pleasing, however, when replacing them with pipes of a smaller diameter, it is necessary to take into account that with a decrease in the pipe diameter, hydrodynamic resistance increases, which weakens the water pressure in the system. This, of course, can seriously impair the efficiency of such a unit.

AOGV connection: rear view

During installation, pipelines are installed with a slope of 1 cm for each meter of pipe length. This avoids air pockets in the system, facilitates water circulation and allows water to be drained from the system.

This addresses some of the practical issues of installing AGV in a private house:

Some caveats

- When the temperature of the water in the system drops below 55-50 ° C, condensation begins to evolve abundantly. If accumulated, it can extinguish the burners;

- Combustion products, mixing with condensate, form nitric and sulfuric acids, which cause corrosion of equipment;

- If the water temperature in the system drops below 50 °, then its circulation in the system almost completely stops;

- If the room is not heated in winter, the water from the system must be drained, but in this case, corrosion increases significantly;

- To get hot water without heating the entire system, you can use a tap that shuts off the circulation in the heating system. And if you connect the direct and return lines, you can save the turnover.

https://otoplenie-gid.ru

How to clean a heat exchanger

Cleaning the heat exchanger depends on its design and on what kind of water is used in the system: prepared - with special additives - or untreated.

By design, the heat exchanger can be of one of three types:

Lamellar are subdivided into two more types - primary and secondary (for heating water). The fire-tube heat exchanger is installed in floor-standing boilers, and the bithermal heat exchanger is installed in compact wall-mounted or floor-standing models.

Cleaning can be done in the following ways:

- mechanical;

- chemical;

- electric discharge;

- hydrodynamic,

Maintenance of gas equipment, including boilers, must be performed by specialists with appropriate education. If you do not have enough technical skills, it is better to invite a master.