Plastic pipes for water supply

Plastic pipes can be used to pass cold or hot water, under pressure or not. Consider the types of plastic pipelines used for water supply networks.

Types of plastic pipes

Here are the types of plastic pipes for water supply:

- Made of polyvinyl chloride (PVC). Most common in plastic systems. The neat, beautiful appearance allows application with an open gasket. Easy to join with glue or rubber connectors. It is recommended to use cold water for plumbing.

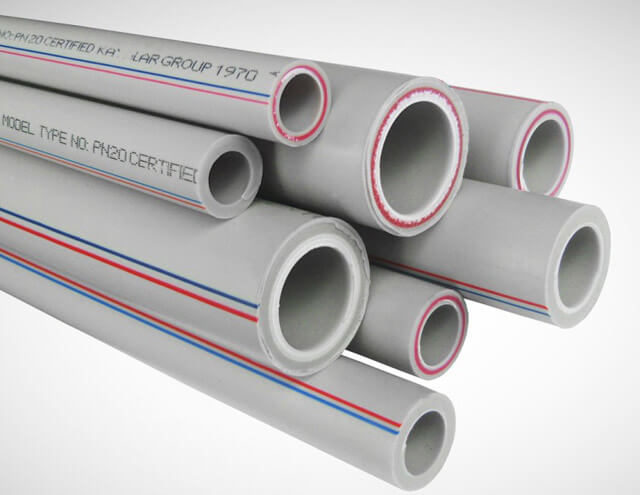

- Polypropylene (PP). Durable, lightweight, high temperature resistant. The plastic becomes soft at + 1400C, melts at + 1750C. It is supposed to be used for passing cold and hot water. Can be used in heating pipelines.

- Polyethylene (PE). Elastic, flexible, withstand shock loads, become soft when heated. There are high and low pressure. The low pressure version (LDPE) is designed for cold water pipelines.

- Made of cross-linked polyethylene (PEX). They have flexibility, high strength, are not afraid of high temperatures, do not crack in the cold. They are characterized by a long service life. Suitable for hot and cold water pipes.

- Reinforced plastic. They have a complex structure. The top layer is made of cross-linked polyethylene, then a layer of metal foil, inside - food grade polyethylene. Suitable for drinking systems. They are flexible, can be exposed to high pressure and temperature, physical exertion. Used for heating.

Which plastic pipes are best for plumbing

It is important to use pipelines that meet certain regulatory and hygienic requirements, because water used for food purposes will pass through them.

All 5 types of plastic pipes, which are described in the previous sections, can be used for water supply, it remains only to decide on their capabilities and the conditions in which they will be operated.

Reinforced-plastic pipelines are an excellent option for private houses, summer cottages. The multilayer structure gives them lightness and strength, corrosion resistance, durability. Their installation is quite simple. Used for hot and cold water supply. Their price is quite affordable.

An inconvenient moment when using them is the need to monitor the connecting fittings, tighten the threaded connections, which relax over time, and leaks may appear in the system.

Polyethylene, polypropylene and PVC versions are also used in plumbing systems. Here it is important to determine for what purposes they will be used. If this is an on-site irrigation system, then you can choose for a technical purpose, if it is an internal water supply for food purposes, the appropriate material is also chosen.

It would be ideal to use polypropylene pipes for water supply. Unreinforced structures are used for cold water. Reinforced polypropylene is used for hot water and heating. Fiberglass reinforcement reduces thermal deformation.

How to join PP pipe heating

Reinforced polypropylene is needed to transfer hot water, its maximum operating temperature is 120 degrees Celsius. The use of metal-plastic is recommended.

Products with a diameter of 26-40 mm are used, diameters of 20-26 mm are used to connect radiators.

The following types of connections are used for a sealed PVC pipe connection:

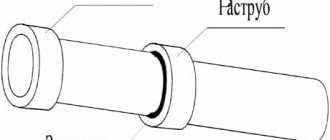

By socket welding:

- Applicable - with a diameter of 63 mm;

- a special tool is required;

- one edge expands, the other is inserted into it.

Socket welding:

- A special soldering iron is heated to a temperature of 270 ° C;

- at the same time the edge of the pipeline and a special coupling of a suitable diameter are heated;

- it is placed in a sleeve and fixed by slow cooling;

- the heating time of the products depends on their diameter.

For metal-plastic joints - compression fittings and press fittings are used.

For high-quality heating, it is necessary to strictly adhere to all fixing rules. In this case, the joints do not lose the reliability of fixation when they are repeatedly heated and cooled.

Advantages and Disadvantages of Plastic Water Pipes

Consider the advantages and disadvantages of plastic pipelines.

Benefits:

- durability;

- immunity to external influences;

- ease;

- not subject to corrosion;

- modern plastic does not affect the quality of water, does not emit harmful substances;

- low thermal conductivity, which keeps the temperature of the coolant;

- ease of installation;

- low cost.

Disadvantages:

- limitation in use for hot water supply;

- obtaining, under certain conditions, permanent connections.

DIY installation of plastic pipes for plumbing

Before laying water supply networks, it is necessary to determine the choice of material and its quantity, draw up a wiring diagram and determine the number of connecting and shut-off valves. When drawing up a diagram, the following rules must be taken into account:

- the length of the pipeline is made as short as possible;

- arrange the smallest number of connections to exclude possible leaks;

- take into account that turns at an angle of 900 reduce the pressure in the pipeline.

Installation of a water supply system from polypropylene pipes

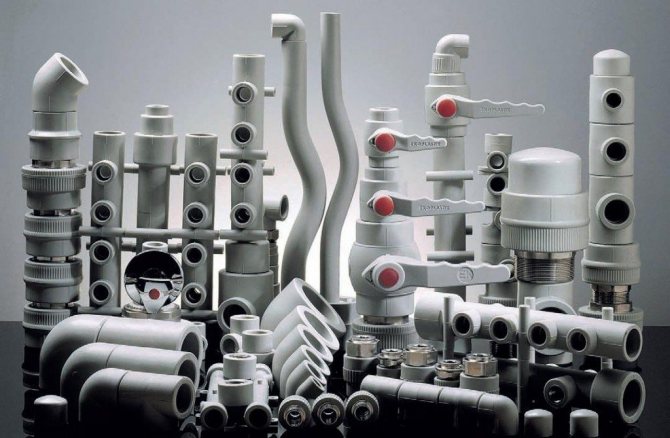

These materials are not flexible; they are cut into separate pieces to change direction. For the connection, special fittings are used:

- couplings are used to connect segments of the same diameter;

- adapters designed to connect different diameters;

- corners are needed to turn the pipe. They can have an angle of 45 or 900. In addition to a simple hole, the corners can be threaded, with the help of which a mixer or other sanitary equipment is installed;

- crosses and tees, they are installed at the branching points of pipelines.

To connect the elements of the polypropylene water supply system, a special soldering iron is used, which is equipped with nozzles for various diameters. Pipes and fittings are put on nozzles heated to 250-2700C and held for 5 to 10 seconds.

After heating, the pipeline elements are removed from the nozzles and the pipes and fittings are connected, avoiding twisting. Plastic elements freeze within half a minute. After complete cooling, a strong one-piece connection is obtained. Correct connection is indicated by an even shoulder around the connection point.

Installation of a water supply system from polyethylene pipes

To connect polyethylene pipelines, in addition to the methods used for polypropylene, electrofusion welding is used. This requires a special welding machine and a connecting sleeve, which is put on the ends of the elements to be connected and connected to an electrical device, the material of the sleeve softens and merges with the pipe. We get a single design.

Installation of a water supply system from metal-plastic pipes

For the device of such a pipeline, it is necessary to use metal fittings. These can be tees, bends, crosses, adapters made of metal.Consider the types of fittings and methods of their installation.

Push-in fittings consist of a body, ferrule, and rubber gasket. It is a reusable split design. They have a thread with which they are connected to consumer devices. During installation, nuts are put on the pipe, then the ring, then this structure is inserted into the fitting and the nut is clamped.

Compression fittings. It also uses a union nut and a compression ring, which are put on the end of the pipe, then a fitting is inserted into it, onto which the nut is then screwed and clamped. The connection is sealed with tow or thread.

Press fittings. This process is carried out using press tongs, a sealed one-piece joint is obtained. Before joining, the pipe must be calibrated and chamfered. Then the sleeve is put on and the fitting is inserted. The sleeve is clamped. This connection can be used in hidden wiring.

Nuances of calculating the diameter of pipes

To perform the calculation, you need the following data:

- general heat losses of the property;

- battery power in each room;

- the length of the contours;

- the way of wiring the heating system, which can be one- or two-pipe, with natural or forced movement of the working environment.

This means that before calculating the diameter of the pipe for heating, they calculate the heat loss, determine the performance of the boiler and the power of the batteries for each room in the household or apartment. In addition, you need to select a layout option. According to the results obtained, a diagram is drawn up and only then they begin to determine the desired value.

You need to know that for polypropylene and copper pipe products, manufacturers mark the outer diameter, and the inner diameter can be calculated by subtracting the wall thickness. In turn, for metal-plastic and steel products, the internal section is indicated. These nuances will help you make the right purchase.

Fast and high-quality assembly of plastic pipes

To get a high-quality plumbing system, you need to properly follow the technology of work. Start laying from the point of connection to the water consumption device. An adapter with a ball valve is installed here, with which you can turn off the water.

The pipe is fixed to the wall with special holders, 20 mm away from it. The holders are installed with a maximum step of 1.5 m, it is imperative to install the mount at bends and when cornering. Fittings are used for turns and corners.

Before connecting the internal water supply network to engineering systems, it is necessary to install shut-off valves to turn off the water supply. A counter is also installed here.

Types of docking of the sewer system

For sewage, a modern option is to use polypropylene and PVC pipes with a diameter of 80 mm. They are able to work at subzero temperatures Wells are of the following types:

- Rotary, which allow you to change the direction of movement of the fluid;

- overflow, allowing you to service a water supply system with places where its diameter changes;

- viewing, making it possible to serve flat areas with a length of more than 12 meters.

Plastic sewer pipes are connected using special fittings with rubber seals. This makes it possible to carry out installation work without the use of expensive equipment. Due to its simplicity, all work can be carried out on site.