Soldering flux for copper pipes

Few people know what soldering flux means. A flux is understood as a substance, consisting of chemical elements, which helps the solder to better fill the joint space. In addition, one of the functions of the flux is to remove dirt and products from the oxidation process, such as boric and hydrochloric acids. Apart from everything, it forms a layer of protective film against air oxygen... Taking into account these features, it is necessary to correctly choose the types of metal products that need to be connected and substances that will fill the connecting gap, as well as keep the indicators of the temperature heater under control.

Flux in the soldering process

Experienced welders who have been working in production for many years, of course, can do without the compositions in question.

However, if you are a second-class specialist or are just starting to use a welding machine, flux is your faithful friend, because its use simplifies the process and improves the quality of the products obtained.

Judge for yourself: even if you don't have much experience, submerged-arc soldering guarantees a much better result than arc welding.

This is due to the fact that in the first case, the seams are reliable and even, and the work itself takes much less of your time.

In addition, the soldering technique under consideration provides a deeper melting of the part due to the choice of a current with an increased density.

True, in this case, the temperature of exposure to the electrode also increases, as a result of which it may lose part of the coating, but this is not at all a cause for concern.

Moreover, the use of a special composition during brazing will allow avoiding the appearance of pores and, in the future, foreign bodies at the place of the weld seam, because in principle, pores are not formed when brazing with a torch under flux.

Types of flux

- The first type of chemical assistant includes substances that do an excellent job of preventing corrosive formations. This connective substance consists mainly of substances that dissolve liquid and an element such as phosphorus. As a result of their mutual work, an integral connecting substance is formed. When using this type, the need to use substances that are designed to clean up after the soldering process disappears. It is very profitable and not at all troublesome.

- The second type of flux is a substance consisting of salicylic acid, which is perfectly soluble in organic solvents. In addition to this component of the connecting substance, petroleum jelly, alcohol and gold derivatives can also serve as the basis. If you use this type of flux in use, you can achieve an excellent result in relation to the seams, in addition to cleanliness, they will acquire a neat appearance.

- The third type of soft connector is rosin and sodium boric acid. Sodium salt begins to melt at temperatures of 70 degrees Celsius. It is necessary to pay special attention to the fact that this substance and its melting products are absolutely not harmful to human life and health. You can create connecting substances yourself by mixing all the components into one whole.

Submerged-arc copper soldering

What is the difference between flux soldering?

First you need to understand its differences from conventional arc soldering. So, compared to hand welding, the flux soldering process becomes more efficient. The recoil level increases by about 4-5 times... And this is understandable, since the electric current passes through the electrode wire only at its exit. Therefore, the use of flux in the welding process of copper makes it possible to use a current with increased density. You do not even have to worry about the fact that the electrode will be exposed to prolonged exposure to high temperatures, which will lead to the detachment of the coating material.

Brazing materials for copper pipes

In addition, in the process of using high currents, the melting depth of the metal product rises to sufficiently high. Even because of this, the soldering process can be carried out without cutting the thickened edge. It is necessary to give credit for the fact that providing high protection of the metal in the molten state from contact with air currents, metal seams and joints are of high quality.

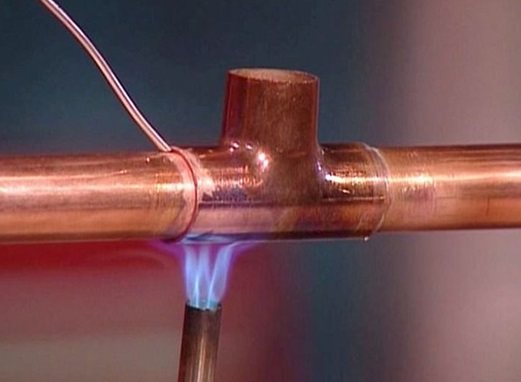

Soldering copper pipes with your own hands

The minimum amount of foreign inclusions is achieved by the absence of pores in the metal seams. There is an explanation for this, the rate of formation of metal crystals increases, since slag formations are present on the coating of the connecting seams.

The disadvantage of using soft connectors is that the molten metal becomes as liquid and fluid as possible.

Before purchasing a flux for copper products, pay attention to its special features. First of all, in order to avoid the formation of a film of oxides, it is necessary to carry out some measures:

- Constantly keep under control the limits of the temperature indicators of the soft connector and solder, it is necessary to ensure that they are the same. When choosing a flux, focus on its performance, depending on the type of solder.

- In the case when an ideal coincidence of temperature indicators is achieved, it becomes possible to use it as a device for measuring temperature changes during the soldering process. Therefore, overheating of the elements during soldering is impossible.

Today, there are dry, pasty and liquid fluxes on sale. In most cases, connectors in a liquid state find their use in a liquid solder process. Dry flux is inconvenient to use. Pasty flux for copper products is quite convenient, since it does not require delay in its application. Particular attention should be paid to the quality of the flux in order to get a high-quality result of the work done.

Quality can be determined by the following features:

- the surface after soldering is completely covered with it;

- has a viscous base and high density, which ensures the availability of solder to the destination;

- protects from the formation of a film, qualitatively cleans it from it;

- has a homogeneous composition of chemicals;

- with its help, all seams are visible during the soldering process;

- using it, the possibility of working in an upright position comes off;

- well removable dirt.

To achieve a high-quality product, it is necessary to get rid of it after the soldering process with the help of solvents intended for this.

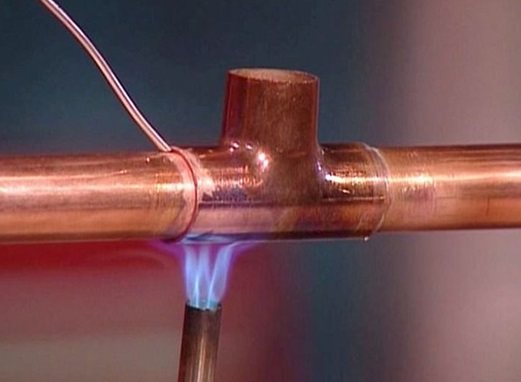

Types and features of gas burners

A gas torch is rightfully considered the most convenient device for welding any copper products. The device is lightweight and lightweight, easy to use and economical. The ability to adjust the flame power allows you to set the parameters for specific types of work.

The standard construction of a gas burner includes the following elements:

- Assembly for securing a container with fuel.

- Instrument head.

- Nozzle.

- Reducer.

- Flame intensity regulator.

In addition, manufacturers include additional elements in the design: adapters, tips, flame reflector, etc.

Devices are classified according to several parameters. So, according to the technical capabilities of the device there are:

- Household.Inexpensive devices with a minimum set of functions. The fire temperature is regulated in the range of 1000-1500 ° C.

- Professional. More expensive burners, designed for serious volumes of work. The flame has a temperature of 1500-2000 ° C.

Depending on the gas mixture used, burners are divided into several types:

- Propane. They are specialized or universal. They are considered the most common. The gas produces an even, intense flame.

- On MARP gas. They are characterized by a soft but energetic flame that gently acts on the pipe material, preventing damage to it.

- Acetylene. They are more often used when working on trunk facilities. They are powered by disposable cylinders, or are stationary. Gas gives a high flame temperature, which has a positive effect on economy, but often leads to overheating of parts and increases the likelihood of damage.

Gas burners with disposable cylinders are easy to use, do not depend on electricity sources, are compact and safe. The only drawback is the need for frequent replacement of cylinders.

Stationary installations are distinguished by a powerful flame torch, which allows soldering to be performed quickly and efficiently. In everyday life, they are used extremely rarely.

Pastes for soft soldering of copper pipes in Moscow

The "Online Consultant" is available on the seller's website. To go to the site, click "To the store"

One click order is available on the seller's website. To go to the site, click "To the store"

The "Online Consultant" is available on the seller's website. To go to the site, click "To the store"

One click order is available on the seller's website. To go to the site, click "To the store"

A free number 8-800 is available on the seller's website. To go to the site, click "To the store"

The "Online Consultant" is available on the seller's website. To go to the site, click "To the store"

Brazing

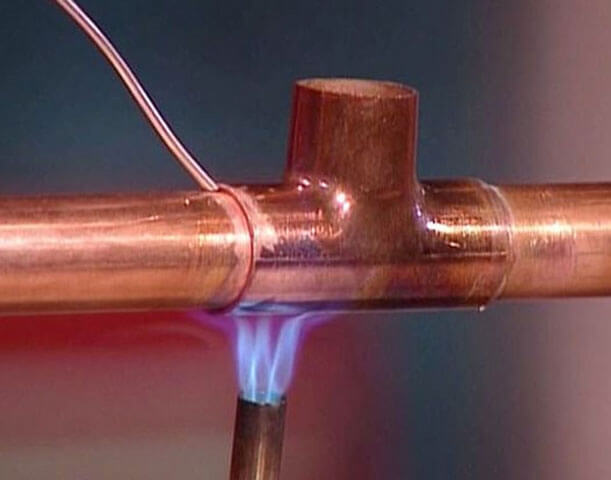

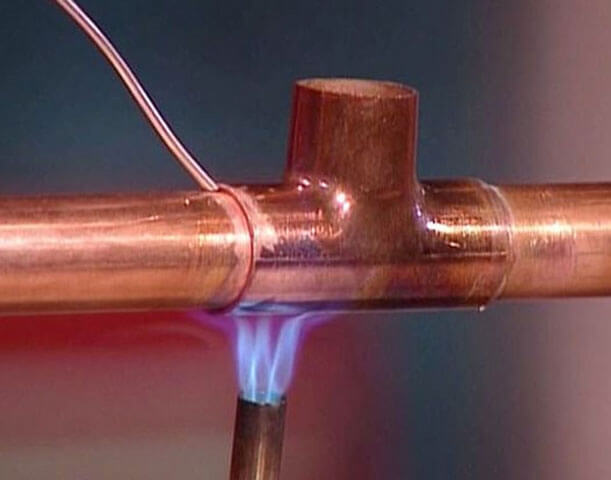

Do-it-yourself brazing of copper pipes using solid solder is carried out if the system is planned to be operated at a temperature above 110 ° C. The connection requires a temperature above 700 degrees, therefore, soldering is performed using a flame method.

Copper-phosphorus solder is available in the form of rods and is used for high-temperature brazing

Note! Brazing technology involves annealing the metal, which leads to softening of the copper.

The use of copper-phosphorus solder does not require flux. If you correctly ensure uniform heating of the ends of the products, then it will fill the gap. The readiness of the connection is checked with a solder bar - it should melt.

The soldering steps are as follows:

- The docking station is assembled and warmed up.

- Solder is injected at the junction of the socket and the pipe, which is softened by the torch.

- After the first adhesion, the pipe is turned and the softened solder is wound on the next section of the joint.

The advantages of brazing copper pipes technology are:

- good seam strength;

- the possibility of reducing the width of the connection;

- applicability in systems operating at high temperatures.

Since the correct brazing of copper pipes with solid solder should exclude overheating of products, which leads to ruptures, it is better to entrust the work to specialists.

Brazed pipes are used in heating systems

What kind of solder for brazing copper pipes is better to use, types and features of materials

Copper tubular products are used in a wide variety of industries. Gas, oil products, water and other media are transported through pipelines made of it. For the installation of the lines, solder is used for welding copper pipes.

The conditions in which such pipelines are operated can be different - they influence the choice of the type of solder for connecting structural elements.

Materials required for work

Brazing copper pipes can be done by yourself. For work you will need:

- solder;

- steel brush;

- flux;

- brush;

- soldering iron or gas torch.

The solder is in the form of a wire with a melting point lower than that of copper. This allows the products to be joined by heating. With the help of a steel brush, during the preparatory work, the inner surface of the fitting and the outer part of the pipe are cleaned.

Solder can be high-temperature, which is a thin copper wire with the addition of up to 6% phosphorus and has a melting point of 600-800 ° C, and low-temperature - from tin melting at 300-400 ° C.

Liquid flux is applied to the coupling and pipe prior to assembly of the connecting unit, solid flux is melted in the brazing zone. Paste flux is a thickened mixture that can be applied both before and after the docking process. The flux cleans the surface of the pipe from oxides, protects the soldered area from oxygen, promotes spreading of the solder and improves the adhesion of the parts to be joined.

A gas torch is required to heat metal and solder

A distinction is made between gas burners with a stationary cylinder or a disposable one. There is a separate type of burners - acetylene-oxygen, which differ in their design. The choice of the power of the apparatus for soldering is carried out according to the melting temperature of the solder. Professional tools are used to braze copper pipes with hard solder, semi-professional - hard and soft solder.

What is soldering and soldering?

Solder is an alloy or metal that is used to join separate metal parts in order to equip a single system. The technology of joining two parts into a one-piece structure is usually called soldering.

Since solders are used in many industries, they are produced in a variety of forms - this can be wire, rods, foil, etc. The chemical composition of the solder for brazing copper pipes directly depends on the temperature of melting, on the type of elements used, on their parameters and other nuances.

The basis of the solder is the following chemical elements:

For solder, the melting temperature should be lower than for the metals from which the butted parts are made, which are slightly heated during the soldering process and cannot be deformed. Soldering is considered to be a more profitable connection method compared to welding.

Solders in accordance with the melting point are of several types:

- Fusible - from 150 to 450 degrees.

- Medium melting - no higher than 1100 degrees.

- High melting point - up to 1850 degrees.

The first type of solders is used for soft soldering, and the second and third - for hard soldering.

What do you need to solder copper pipes? When joining products, in addition to solder, flux is required. It is necessary to protect the bonded surfaces from oxidation. To make the connection strong, you must choose the right solder and flux. The purpose of using solders is to obtain a reliable seam. It is often impossible to do without it when joining pipes for different purposes, including copper products.

Reasons for defective solder joints

As a result of soldering, a reliable connection is obtained.

At the end of our article, we will touch on the sad topic of unsuccessful attempts to solder pipes. Indeed, from the first time, this process will not work for all home craftsmen.

Typical cases of defects in soldered seams occur due to the following reasons:

- Insufficient heating of the pipe or solder. As a result, copper or tin solder wire simply does not soften and sticks to the flux in places. In this case, the seam will flow at the first attempt to use the pipeline for its intended purpose. This drawback is easily eliminated - just hold the pipe or solder in the torch flame until the color of the entire flux layer changes.

- Errors in the imposition of the flux layer.Sometimes the master makes a mistake and misses a section of the pipe without lubricating it with flux. As a result, the solder does not stick to the pipe or falls off after hardening. This error can be corrected by carefully examining the pipe after applying the flux.

- Overheating of the pipe. In this case, the flux will simply burn out, and the solder will fall off immediately after cooling. Therefore, you should not overexpose the pipe in the burner flame.

In addition, it is very important to adhere to safety rules during the soldering process. After all, this technology is associated with the use of an open flame (burner) and chemically active reagents (flux). Therefore, when working with a burner, solder and flux, you need to use personal protective equipment: gloves, glasses, aprons, and so on.

Brazing copper pipes

Due to the fact that copper is weakly susceptible to corrosive processes, it is easy to solder. Tin, silver, other alloys and metals are the best in contact with it during the docking process.

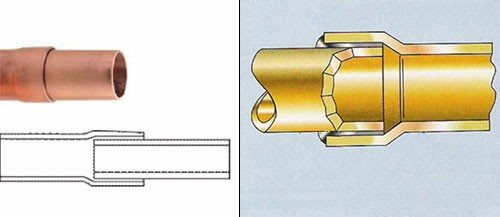

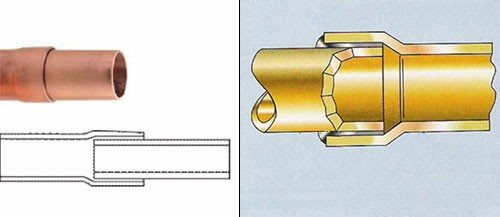

Capillary soldering is used to connect copper products. It is based on the ability of a liquid, due to adhesion, to move along narrow channels, including against the direction of gravity. Due to the phenomenon of capillarity, the solder is able to uniformly fill the gaps, regardless of how the pipes are positioned.

In this case, the soldering process can take place using light-, medium- and high-melting alloys. Due to the first type, low-temperature brazing is performed, and the other two - high-temperature. The choice of solder is based on the conditions in which the finished pipeline will be used.

The low-melting type, also called soft solder for brazing copper pipes, includes tin and its alloys: tin-copper, tin-silver, tin-copper-silver. Solders, the main component of which is lead, belong to the same type, but they are toxic and for this reason they cannot be used when laying pipelines for supplying drinking water.

Now Technology: Nine Steps and Some Tips

Brazing technology for copper pipes is not complicated at all.

Here are the steps you can divide the process into:

- Cutting & Sewing: Cut the metal to length with a pipe cutter. Make the cutting area even, keep the cutter perpendicular to the surface.

- Cleaning workpieces with a metal brush, removing burrs from the ends. Emery cloth should not be used at this stage due to the risk of the formation of fine sand, which will interfere with the adhesion of the drink.

- Expansion of the edge of one of the pipes so that the end of the other pipe fits easily into the first with minimal clearance.

- Thorough cleaning of the ends with a wire brush after expansion.

- Application of the flux mixture to the end of the pipe in the most uniform thin layer.

- Insert the ends of the pipes into each other, warm up well until the color of the flux on the pipe turns silver.

- Solder is brought to the joint, which immediately melts and fills the joint gap between the pipes. The process ends when the gap is filled with solder.

- After warming up, the sealed pipe must be allowed to cool down thoroughly - in no case should it be touched at this time.

- Wipe clean, remove flux residues.

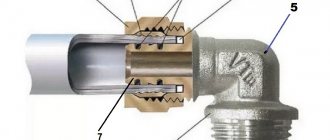

Pipe connection method.

Soldering copper pipes using solder is based on a physical phenomenon - the capillary effect. The fact is that the molten solder fills the gap between the pipes due to the forces of surface tension. After solidification, the solder in the gap turns into a strong monolithic seam.

If suddenly a defect occurs in the form of a fistula or damage to the joint, the product can be quickly and easily repaired. To do this, it is enough to heat it up and dismantle it. After removing defects, reheat and re-solder.

Pure butt joints of copper products cannot be made - they are not viable, and you will surely have a flood - all the soldering will collapse. It is better to make couplings by expanding the end of one of the pipes.

Now about bending.Only soft annealed pipes can be bent using a pipe bender. If not annealed, braze copper fittings are used. The angle can be 90 ° or less.

How to choose a solder

Despite the fact that soft solders are considered not strong enough, when using capillary welding, a high-quality sanitary structure can be obtained. Low-melting solders are used for joining copper pipe products with a diameter of 6-180 millimeters. They are preferred because they work at low temperatures. The fact is that copper at high temperatures is capable of losing strength.

All solders belonging to the medium and high melting type are of the solid type. For high-temperature brazing of copper products, solders based on copper, silver and other metals are used. Thanks to their use, a seam is obtained that is durable and resistant to high pressure and high temperatures.

Among them, the most in demand:

- copper-phosphorus;

- copper-silver-phosphorus;

- silver.

In the latter case, not only solder is required, but also a flux paste for brazing copper pipes.

What kind of solder to solder copper pipes?

There are a huge variety of solders for connecting individual elements of copper piping using soldering. All of them are divided into two types by consistency:

- solid (refractory);

- soft (fusible).

Low-temperature solders are the most popular for these purposes. They allow copper pipes to be joined at low temperatures, as a result of which the possibility of their deformation is excluded. But it is worth noting that the seams after such a solder have rather low mechanical properties.

High-temperature brazing alloys, in contrast to low-temperature ones, allow making the most durable pipe joints.

Important! It is recommended to use high-temperature solders only for experienced professionals who know all the intricacies of brazing copper products. An inexperienced person can simply burn through a copper pipe.

In low-temperature brazing, which is very popular when installing copper pipelines in a domestic environment, lead-free solders are most often used. Lead-free solders provide a mechanically stable bond. Lead-free solders include: tin alloys with bismuth, antimony, silver, etc. Tin in such solders contains about 95%, the remaining 5% is accounted for by additional elements.

In domestic conditions, soft solder is most often used, which contains a large amount of tin.

For soldering at low temperatures, solder can be used, which is an alloy of tin and lead, however, such a material is not recommended for installation of a plumbing structure. This is because lead is a toxic material and can harm the health of the occupants.

For brazing copper pipes, a special gas burner is used, which allows you to achieve maximum strength and reliability of the connection.

Pros and cons of different types of solders

An important advantage that brazing alloys have is directly related to the strength of the resulting seams and their resistance to high temperatures. Using high-temperature brazing, copper pipes with a diameter of 6 to 159 millimeters are joined. When laying water supply lines, the cross-section of pipe products connected by this type of soldering cannot be less than 28 millimeters.

As practice shows, of the soft solders for joining copper pipes, tin-copper is the most popular, and among hard solders, copper-phosphorus is often used. Different companies have different manufacturing technology and the percentage of components.

Before starting to create a copper pipeline, you should make sure that there are no defects on the surface, which can often be found when cutting pipes. The reliability of the seams largely depends on the cleanliness of the products that are used in the working process. For products with a diameter of 6-108 millimeters, the width of the joint can be 7-50 millimeters.

How to use solder

In order for the seam after soldering to be strong and airtight, it is necessary:

- carefully prepare the pipes before brazing. To do this, the ends of the pipes are cleaned of oxides and other types of contamination with a metal brush, and the burrs formed after cutting the pipes are removed using a special device - a bevel cutter;

Preparing a copper pipe for brazing

- extend the end of one pipe by a few millimeters so that the pipes can easily be joined together. If soldering is carried out using fittings (special elements designed for assembling a pipeline of various configurations), then the diameter of the fitting increases, and not the pipe;

Increasing the pipe diameter

- process the pipe soldering points with flux;

Fluxing the pipe before brazing

Since the flux is a toxic compound, when working with it, you must strictly follow the safety rules: work should be done with gloves and in a ventilated area.

- prepare a gas burner (equipment designed for brazing pipes made of copper) and slightly heat the areas to be brazed;

- carefully apply solder along the entire perimeter of the pipe, which, during the heating process, will gradually pass from a solid state to a liquid, thereby filling all the empty space;

Soldering with solder

- allow the solder to cool completely while stationary. For complete cooling, depending on the type of solder, an average of 3-5 minutes is required.

The process of soldering copper pipes using solder is presented in the video.

When choosing a solder and flux, it is necessary to take into account all the main characteristics of the substances, that is, if high-temperature solder is used for brazing, then the flux should also be designed for high-temperature brazing. Correctly selected and matching materials contribute to obtaining not only a tight seam, but also the most durable connection.

Copper soldering flux

Copper is recognized as the most reliable metal product and is used in many industries. At the same time, there are obvious drawbacks to the operation of copper, despite the high mechanical and technical characteristics and flux for brazing copper will help eliminate the problems of malfunction of the same copper plumbing system. The main task of using paste for soldering copper is the formation of a protective film against environmental influences, in particular oxygen.

Types of pipes

Despite the high performance characteristics, copper pipes are not the most popular product on the domestic market. High cost constraint, although, subject to the connection technology, the duration of the operating period will be much higher than that of similar materials.

There are two types of copper pipes.

- Annealed... After manufacturing, the pipes are subjected to heat treatment at a temperature of 650-700 Cº. The procedure gives the product plasticity, with some loss of strength. In addition, the cost of production increases.

- Unrecognized... They are characterized by high strength. The only drawback is low elasticity. When installing the pipeline, bends are made using couplings, since such pipes are almost impossible to bend.

Regardless of the type of product, special requirements are placed on the purity of the material. According to GOST 859-2001, the mass fraction of copper should not be lower than 99%.

Features of copper flux soldering

In many Western European countries, copper pipes have long been used as the main components of the water supply and heating systems. Damage to a copper pipe is an unpleasant little thing, but a flux for soldering copper wires will help get rid of the root cause of the malfunction. Let's try to figure out what types of flux are available in practice:

- The first and main category of the copper soldering flux group includes those components that perfectly cope with the manifestation of corrosion. This group includes all components that dissolve in a liquid, as well as in phosphorus. As a result, a whole substance is formed, which ultimately provides for an exception to the rules for cleaning the surface of the product after the soldering process. In most cases, this copper soldering flux is the least expensive and most cost effective option.

- The second group of components of fluxes for brazing copper pipes is presented as a substance where salicylic acid is used in the composition, which is dissolved in organic compounds. In addition, this group includes substances and materials that are components or derivatives of petroleum jelly, alcohol and even gold material. Using this type of flux for soldering copper with our own hands, we can achieve an ideal indicator of the condition of the seams, as well as the cleanliness and neat appearance of the treated surface.

- The third and perhaps the most popular group contains rosin or sodium boric acid. The last chemical component begins to undergo melting, starting from a temperature of +70 C. In this case, both rosin and boric acid do not pose a specific threat to human life and health.

What is needed for brazing copper pipes

Soldering copper pipes, which is not difficult to do with your own hands, does not require expensive equipment and any special materials. In order to correctly implement it, you will need the following tools.

- A burner, due to which the solder and the pipe section will be heated, where they will be connected. Such a torch is supplied, as a rule, with propane gas, the pressure of which is regulated by means of a welding reducer.

- Special device for cutting copper pipes. Since products made of this metal are very soft, they should be cut gently enough so as not to wrinkle the walls. In the modern market, pipe cutters of various models are offered, differing both in their functionality and technical capabilities. The design of individual models of such devices, which is important, allows them to be used even for work in hard-to-reach places.

- A pipe expander is a device that allows you to expand the diameter of a copper pipe, which is necessary in order to better perform soldering. In various systems mounted from copper pipes, elements of the same section are used, and in order to connect them qualitatively, it is necessary to slightly increase the diameter of one of the elements to be connected. This is exactly the task that such a device as a pipe expander solves.

- A device for chamfering from the ends of copper pipes. After trimming, burrs remain at the ends of the parts, which can interfere with obtaining a high-quality and reliable connection. To remove them and give the ends of the pipes the required configuration, a beveler is used just before brazing. There are two main types of chamfering devices on the market today: enclosed in a round case and made in the form of a pencil. More convenient in operation, but also more expensive are round devices that can handle soft copper pipes with a diameter of no more than 36 mm.

- To properly prepare copper pipes for brazing, it is necessary to remove all impurities and oxides from their surface.For these purposes, brushes and brushes are used, the bristles of which are made of steel wire.

- Typically brazing of copper pipes is performed, which can be high and low temperature. High-temperature solder is a copper wire containing about 6% phosphorus. Such a wire melts at a temperature of 700 degrees, while for its low-temperature type (tin wire), 350 degrees is enough.

- The technology of brazing copper pipes involves the use of special fluxes and pastes that perform a protective function. Such fluxes not only protect the formed seam from the formation of air bubbles in it, but also significantly improve the adhesion of the solder to the pipe material.

Copper pipe flaring kit

In addition to flux, solder and other basic elements, additional tools will be needed to solder copper pipes, which can be found in every workshop or garage. To solder or cook copper products, additionally prepare:

- regular marker;

- roulette;

- building level;

- a small brush with stiff bristles;

- a hammer.

Before starting work, it is also important to decide how to solder the copper pipes. The main options can be two: brazing copper (used less often) and the use of soft type solder. When solving this issue, it is important to proceed from the fact that there are requirements for the use of one or another type of solder. Thus, solid-type solders are used for brazing elements of refrigeration units and air conditioners. In all other cases (water supply systems, heating systems, etc.), tin wire can be used. But whichever technology is chosen, it should be remembered that the flux is necessary in any case.

Brushes for cleaning the inner surface of a copper pipe before brazing

What should a copper pipe soldering flux look like?

As you can see from the above, in order to choose a flux for brazing copper, it is necessary to study in detail the specification of each component, and at the same time, it will be necessary to follow some precautions and general rules of application:

- Flux paste for soldering copper should ensure the uniformity of the area of the processed surface of the product.

- The viscosity index of any component of the flux should be much lower than that of the solder, that is, the preparation should melt earlier than the solder and ensure uniform filling of the entire space of the workpiece. Complete replaceability is the main criterion for the indicator of the interaction of flux and solder.

- The oxide film must completely dissolve and protect the metal from the secondary oxidation process.

- The seam processed with copper solder paste must have a presentable appearance and not create inconveniences for further operation.

- Chemical stability of the substance. During the heating process, the flux should not decompose in any way.

- At the end of the technological work, the sludge residues must be removed.

- It is allowed to use paste for soldering copper pipes in a vertical position.

Flux options for copper materials

The industry today produces several options for fluxes that are used for specific industrial operations. As a rule, these are 3 main groups:

- Liquid category. It is used in special tubes, together with soft solders.

- Powder category. They are stored in special containers, used in conjunction with medium and reinforced group solders.

- Flux in the form of a pasty substance. This is a ready-made version of the flux that is used as a solder, and as a means of processing and applying solder to the surface.

Next, we take into account the intended purpose of the component for a specific category of production work, in particular:

- Preparations with anti-corrosion properties. The component of the drug includes solvents, as well as the composition of phosphorus. During the heating procedure, a kind of connection occurs, where organic components are formed.At the end of technological work, it is necessary to remove sludge without using special technologies, that is, in the usual way.

- Drugs with high frequency characteristics. As a component, gold or other materials of the noble group are used - ethanol, petrolatum, and salicylic acid. As a result, a smooth and perfect seam is formed, which does not require additional processing.

- Activated group fluxes. This category includes substances of the most popular groups - borax, as well as rosin. Borax already at a temperature of +70 C begins to melt, without emitting dangerous secretions.

For the latter group, it makes simple requirements, in particular, it is recommended to prepare preparations directly at the site of technological operations. So, rosin must be mixed in portions with salicylic acid or anhydride (the use of diethylamide and aniline is allowed).

Soldering process what you need to know

In the process of soldering, you need to remember the following.

The supplied current will move only at the departure, this will increase labor productivity by at least 5 times in comparison with manual arc welding. "

The use of welding currents in this case, which have a high density, will not cause the so-called peeling of the coating, and, consequently, overheating of the working electrodes in the final process of departure. If we use thick metal blanks, then it will not be necessary to carry out the section of the existing edges, since the penetration will be carried out completely to the depth.

For copper pipes, the following requirements must be observed during the brazing process:

- It is desirable that the flux was originally a derivative of the solder. In this case, it will be possible to achieve maximum uniformity of melting of all components of the flux and solder. This factor allows the specialist to fully control the heating workflow, and thereby regulate the production cycle of welding.

- If you use solder and flux that match in terms of melting temperature, then the last parameter is used to control the temperature of the soldering process. Here we will be able to minimize the loss of the brazing process, as well as possible damage to workpieces and other components.

The best option, albeit an expensive one, will be the use of a flux paste, which is at the same time a propoyem and a material for processing the preliminary soldering of the product surface.

There is one more important point, the formation of slag, which accompanies this process. In this case, the surface of the weld will increase crystallization, which in turn will significantly reduce the number of visible voids, as well as the appearance of deposited particles in the deposited substance. The disadvantage of this process is the increased fluidity. But despite this, the speed and quality of surface treatment will cover all possible disadvantages of soldering copper blanks.

A little about copper

Copper is a soft metal alloy, which in ancient times was used with pleasure by chasers for their work. Today copper is no less in demand. Pipes made of such an alloy are an integral part of heating and air conditioning systems. Plumbing can also be arranged using copper elements.

For the installation of the line, the soldering method is used, in the process of which the copper elements are connected to the solder. This soft metal material melts when exposed to specific temperatures to form a single sealed joint.

Important: soldering copper pipes with your own hands is not a difficult task. The main thing is to choose the right solder and determine the soldering temperature. At the same time, it is worth knowing that, at its high cost, copper pipes do not require additional connecting elements.That is, copper can be connected into a single line and at the same time save on the purchase of fittings, couplings, etc.

How to solder copper pipes, and how to do it correctly at home, in our material below with a detailed video instruction.