Technical characteristics of cross-linked and heat-resistant polyethylene pipes

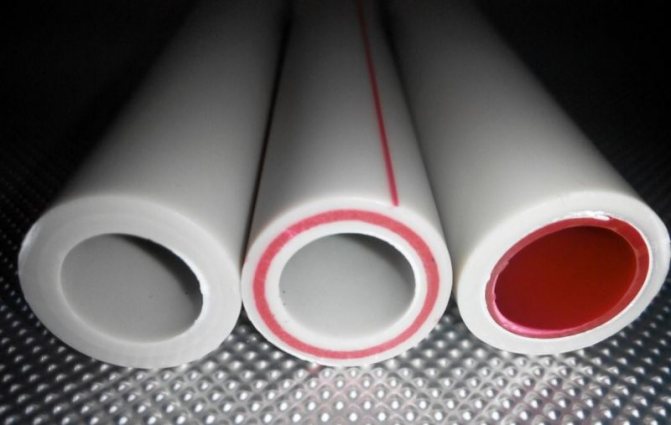

Polyethylene pipes are specially marked. They are divided into types:

- REX - sewn;

- PE-RT - heat resistant.

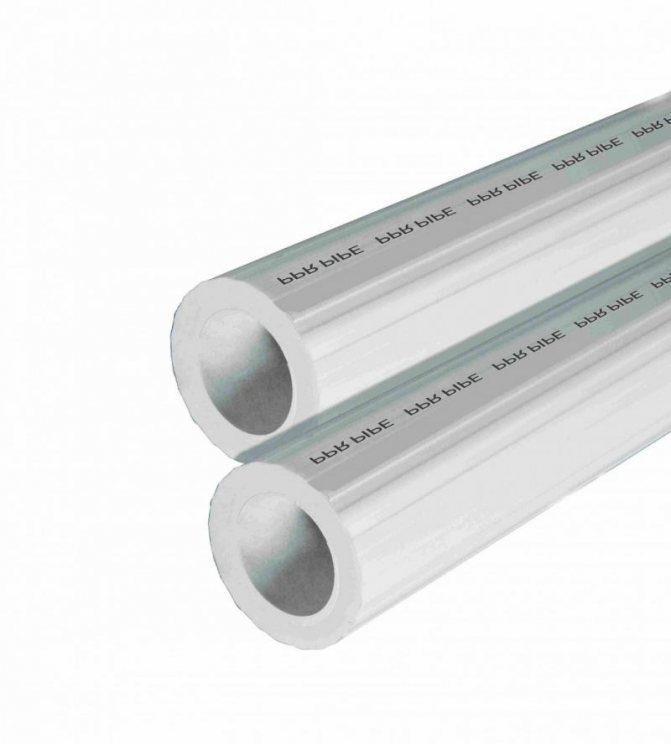

Photo 1. Crosslinked polyethylene pipe. Such products are often used in warm water floors.

Such materials use for heating and water supply. In this case, the polyethylene structure is improved by formulation modifications. Therefore, this substance is able to withstand high loads and elevated temperatures. XLPE applies in different situations. A substance has a number of characteristics that relate to its properties. Product by structure tolerates high temperatures well. The material becomes durable and does not lose its elasticity.

When polyethylene is heated, it tries to quickly restore the previous shapeif deformation occurs due to load. It is worth considering the level of stitching. When this figure is high, then there are more intermolecular bonds. This type is considered durable and of high quality.

All sewn pipe types apply special markings. If the material has initials REX, this means that the structure of the product has increased stability.

When finding PE-RT markings, which means heat resistance. In such a material, a change in the molecular structure occurs according to other processing methods. Heat-resistant products are suitable for heating systems. Moreover, the material has the following qualities:

- Tolerates increased temperature and internal pressure.

- The duration of use is 50 years.

- The PE-RT types are repairable and weldable.

Features of production

In the manufacture of polyethylene used in the form of granules. At high temperatures, the substance begins to melt.

Then it is pushed through the annular hole. This stage forms the required section. When the punching process takes place, the workers control the uniformity.

If the product is intended for a room or floor heating system, then the structure an oxygen barrier is created. The material is additionally covered with a film of ethylene vinyl alcohol, which dries quickly.

When stitching occurs, cheap manufacturing methods are used. For this they can use reagents. Otherwise, apply irradiation with electron beams. This production method is slow and expensive.

Benefits

The use of polyethylene pipes provides for the following selection criteria:

- heat resistance;

- strength;

- does not corrode;

- no layers appear inside the product;

- the form is restored on its own without installation;

- weigh little;

- easy to install;

- high technological capabilities;

- safe materials.

Polyethylene has the advantage of being able to retain its shape. Moreover, the material resistant to high temperatures... Such products are widely used for heating systems. This is considered to be the main difference between polypropylene and plain polyethylene.

Structure resistant to corrosion... Therefore, this material is more popular than copper. In polyethylene, the build-up from the inner wall does not form due to hard water.

Per long service life no decrease in flow rate occurs. Therefore, they are often used to replace steel ones, in which a passability delay occurs over time.

Polyethylene after deformation restores its previous shape... In some situations, expansion and contraction occurs. Other materials do not have this property. Therefore, polyethylene is not afraid of temperature changes and external influences. And also such products have a small mass. This makes it easy to install them according to any scheme. Polyethylene allows for convenient fitting manipulations, which connects pipes where welding, gluing and soldering are not required.

disadvantages

Polyethylene has disadvantages, which lie in the following properties:

- the material is afraid of light;

- internal or external insect damage;

- when installing or dismantling, do not use glue;

- has a negative impact on health.

Polyethylene attracts insects. Bugs are able to penetrate the structure and, as a result, holes are formed. This leads to water leakage. You cannot use glue on polyethylene. The substance has a destructive effect on the structure. In this case, the material can suffer from the adhesive for insulation.

Insulating materials for the heating system must be selected carefully. Otherwise, the service life will be reduced and the pipes will have to be replaced again.

Over time, polyethylene accumulates harmful substances... When water enters, these particles pass through the liquid into the body to the person. Therefore, the material is considered to have a negative impact.

Installation features

During installation, there are several installation methods. They are used with:

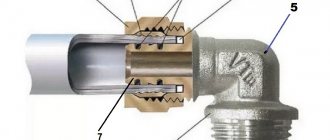

- Compression fittings.

- Press fittings.

When using compression fittings, the installation process is considered simple. First you need to direct the thread to the connector and put on the nut. After that, a split ring is used, which is pulled. The edge of this element must recede from the cut no more than 1 mm. Then the pipe is pushed onto the fitting spigot. To complete, tighten the nut. In this case, wrenches are used.

Installing pipes with press fittings will require pressing equipment. Installation by this method is carried out in the following stages:

- A continuous clamping sleeve is put on the pipe.

- A dilator is used, which is inserted all the way.

- Then you need to bring the handles of the expander. They should be held 10-20 seconds.

- You will need to insert into the fitting. This is done all the way.

- The press is used to press the sleeve onto the fitting.

Pipes sewn from polyethylene will be the best solution for a heating system. Such material and construction will be irreplaceable for a long time.

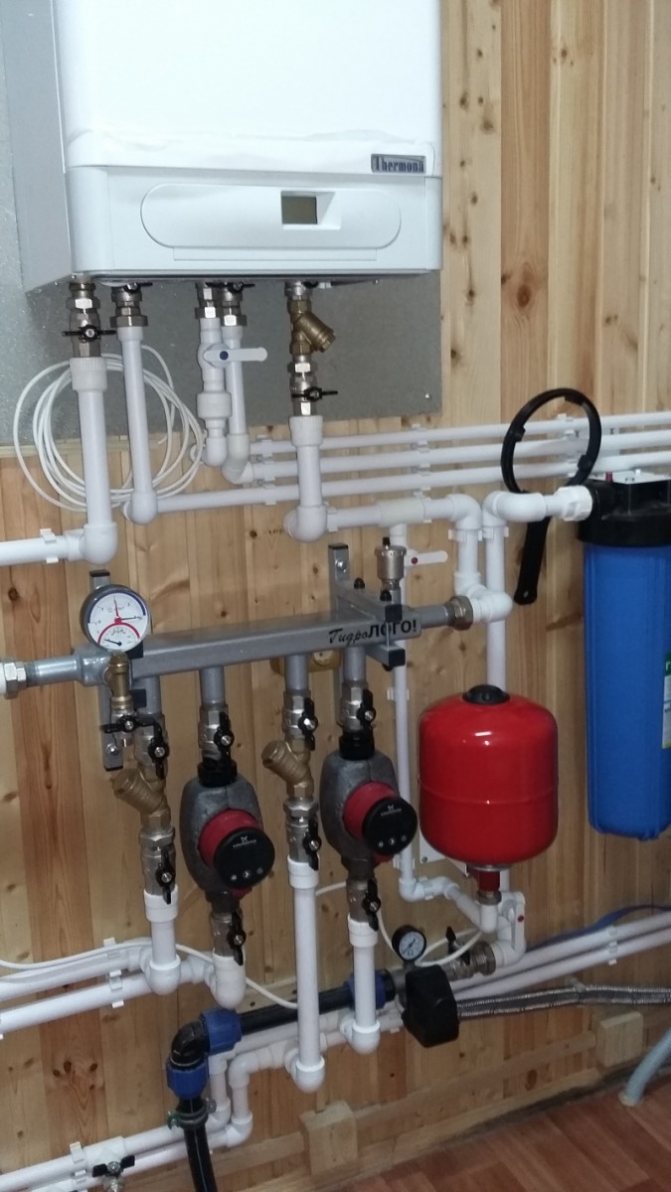

Foamed polyethylene insulation

Thermal insulation protects the pipes from freezing, as well as from heat loss... One of the best thermal insulation materials for pipes is polyethylene foam. Its feature is high resistance to heat transfer, which increases the heat-insulating properties.

Photo 2. Foamed polyethylene for thermal insulation of pipes. The material can be selected for any diameter of pipe products.

In addition, foamed polyethylene is eco-friendly material, it is resistant to aggressive environments, has increased strength, moisture resistance, durability.

Varieties and general characteristics of plastic pipes

Plastic pipes are a polymer-based material, the functionality of which depends on the characteristics of the base. Plastic pipes are used in heating systems, cold and hot water supply, sewage, ventilation, as sleeves and channels for electrical wiring. Each area of application has certain requirements for this material, so the characteristics of plastic pipes for heating are specific. But at the same time, there are general properties inherent in all types of polymer pipes.

Varieties of plastic pipes

Polyethylene pipes (PE, Russian abbreviation - PE) - are produced for the installation of high and low pressure pipelines (LDPE and HDPE pipes), are used for internal and external distribution of water supply, sewage and drainage systems; in heating systems, use is possible only as a supply pipeline for an expansion open-type heating system tank.

Pipes made of cross-linked polyethylene are a material made of polyethylene, in which molecular “cross-linking” is performed in one of four ways, increasing strength by creating additional cross-links between polymer molecules in the lattice. They are used for the installation of heating systems, as well as for wiring the circuits of cold and hot water supply.

Polypropylene pipes (PP, Russian designation - PP) - a group of several types of pipe material based on polypropylene, differing in the values of the main characteristics (operating temperature and pressure). They are widely used in heating systems, cold and hot water supply, sewerage and ventilation systems.

Polybutene pipes (PB, Russian abbreviation - PB) are a high-quality material that differs from polypropylene in increased flexibility, frost resistance and maximum working pressure.

Polyvinyl chloride (PVC) pipes are two types of material (unplasticized and chlorinated), obtained from vinyl chloride by polymerization.

Important! Due to the increased rigidity and the release of chlorine when in contact with a hot medium, PVC pipes for the installation of heating systems, as well as SGW, are not used.

Fiberglass pipes - the walls of this high-strength pipe material are made of fiberglass with a filler based on epoxy resins; these products have not found wide practical use in heating systems due to the time-consuming connection method.

Reinforced-plastic pipes are products with a multilayer wall structure, which provides the material with high technical characteristics and is widespread in heating systems, especially when installing underfloor heating.

General characteristics of plastic pipes

- Strength is the ability to withstand loads typical for pipeline operating conditions, including water hammer.

- Plasticity and elasticity - preservation of characteristics unchanged after deformations from exposure to temperature and pressure loads.

- Corrosion resistance - the neutrality of the pipe material to contact with moisture and dissolved compounds.

- Low coefficient of thermal conductivity - the material, along with external thermal insulation, participates in the process of reducing heat loss and the formation of condensate.

- Dielectric properties - no factors of static electricity and stray currents.

- Low coefficient of friction - reducing the load on the circulation pump when overcoming the friction of the fluid against the inner surface of the pipeline wall.

- Resistance to biological influences - they do not decompose and are inert to the presence of bacteria.

- Lack of calcareous formations on the inner walls.

- Durability - due to the characteristics listed above.

- High sound insulation properties - the movement of the medium in the pipeline is noiseless.

- Low specific gravity - low transportation costs.

- Simplicity of installation technologies.

Plastic pipes for heating must have all the properties listed above, and some of them (heat resistance, flexibility) - to a greater extent than, for example, polyethylene or PVC products that are not suitable for heating systems.

Thus, of the listed types of plastic pipes in heating systems, wiring is used only from the following materials:

- polypropylene;

- cross-linked polyethylene;

- high temperature resistant polyethylene;

- polybutene;

- metal-plastic.

To have an idea of which plastic pipes are better for heating, consider the products from this list of materials in more detail.

Variety

To begin with, manufacturers currently offer three main models of plastic pipes that are used in heating.

- Reinforced-plastic pipes.

- Polypropylene.

- Made of XLPE.

Reinforced plastic

Let's start with their positive characteristics.

- Like all types, metal-plastic pipes for heating do not corrode. Hence their long service life.

- Salt deposits are never formed inside them, which means that the diameter of the pipe does not change, which allows you to guarantee excellent permeability.

- Low roughness of the inner surface. This guarantees a minimum pressure loss of the heating medium.

- These pipes have minimal linear expansion. For heating systems, this is one of the most important indicators. Especially when it comes to hidden wiring.

- High frost resistance.

- Neither oxygen nor light passes through them.

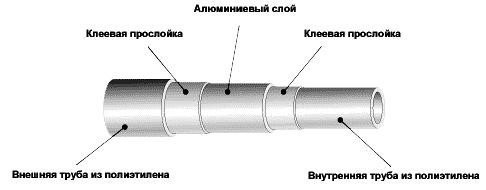

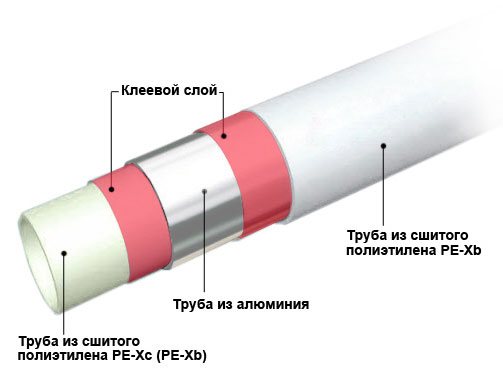

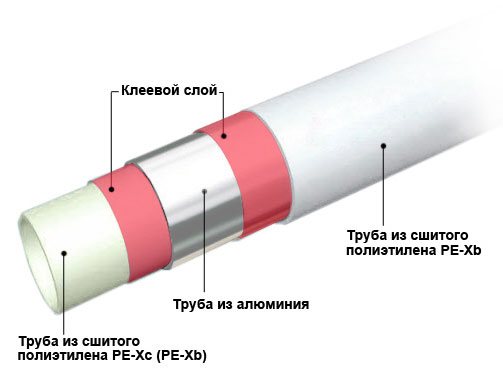

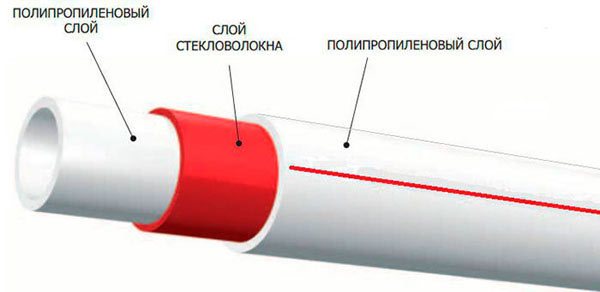

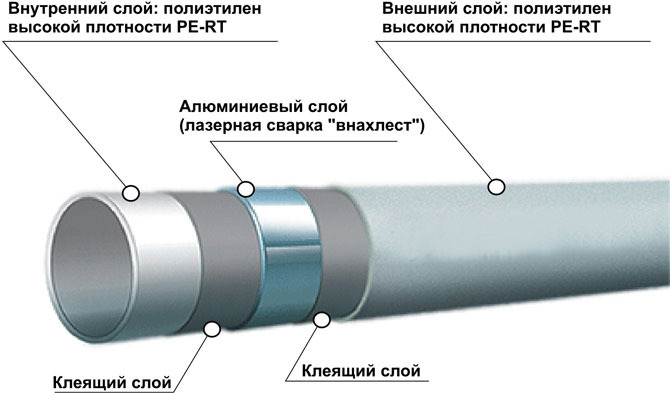

What do the reinforced-plastic pipes owe such high technical characteristics to? Its structure. It is multi-layered and contains several layers of different materials. Look at the photo below.

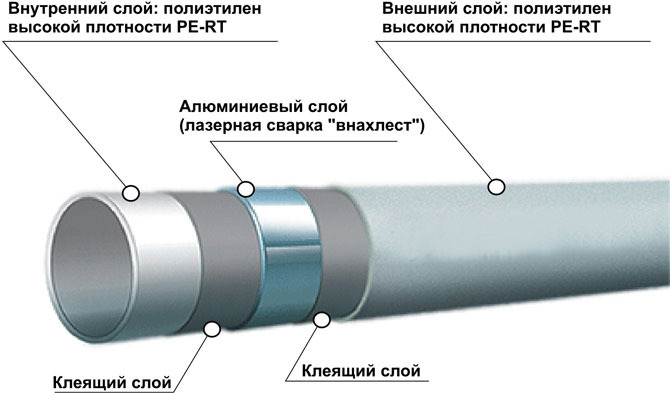

The structure of a metal-plastic pipe

There are five layers, where two layers are adhesive, two layers are polyethylene, and one layer is aluminum foil. The photo shows exactly in what sequence these layers are located. In fact, it turns out that these are polyethylene pipes for heating with a reinforcing frame that restrains the linear expansion of the polymer product. Without it, they cannot be used in heating and the hot water system, they will simply begin to change their dimensions, bend, fly off their mountings and break.

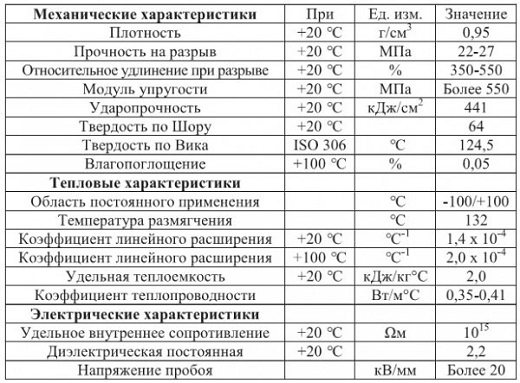

Specifications

We will simply list them so that you can compare them with other samples.

- The maximum operating temperature of the coolant is + 95 ° С.

- The maximum pressure at this temperature is 10 atm.

- If the temperature is lowered below + 25 ° C, then these pipes can withstand pressures up to 25 atm.

- Exposure to temperatures up to + 130 ° C is allowed, only in short-term mode.

If all these characteristics are strictly observed, then 50 years of trouble-free operation can be guaranteed.

Connection methods

This is a very important point on which the long-term operation of the heating network depends. Manufacturers offer four main methods:

- Welding.

- Sectional.

- Compression.

- Press.

Plastic fittings and valves

Nowadays, professionals refuse the welding method of joining, because it is very laborious and not the most reliable. In this case, the pipe has to be cleaned of the aluminum layer so that it does not interfere with the soldering. Therefore, we discard this option.

All other options are related to the use of fittings. Of these, the most expensive is the installation of detachable fittings. At any time, the joint can be disassembled, the pipe can be moved to another place where the installation can be carried out again. By their design, detachable elements are threaded fittings.

The compression option is a kind of intermediate device, which seems to be disassembled if you correctly change the crimp ring. But on the other hand, it is not recommended to touch the connection, the quality of the joint decreases. But press fittings, installed once, can no longer be disassembled.

Attention! It is not recommended to brick the detachable parts of the pipeline into walls or into the floor, this will negatively affect the repair work.

Pipe welding

Polypropylene

Let's start again with the advantages and specifications.

- These are the cheapest pipes in the "plastic" category.

- They bend well, taking on a new shape.

- Long enough service life, up to 50 years.

- Withstand temperatures up to + 95 ° С.

- High frost resistance.

- Quite a large coefficient of thermal conductivity.

By the way, currently manufacturers offer different polypropylene pipes with different technical characteristics. Below is a table in which all the available models with their qualities are collected.

| Model | Temperature, C | Pressure, atm. |

| PN 10 | 45 | 10 |

| PN 16 | 60 | 16 |

| PN 20 | 95 | 20 |

| PN 25 | 95 | 25 |

Not all polypropylene products can be used in heating systems. And only the last two models are suitable for the operating conditions. Let's talk about them.

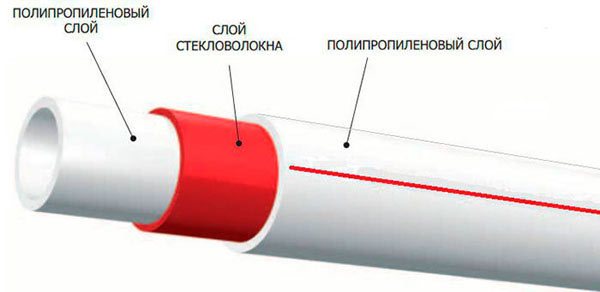

To begin with, the high temperature of the pipes helps to contain the reinforcement layer. So today manufacturers offer five main types of pipes of this type, which differ from each other precisely by the reinforcement cage.

- In the first form, a solid aluminum sheet is used. It is applied to a pipe made of a thick polypropylene layer, and on top it is covered with the same material, but with a thinner layer.

- The same, only with a perforated aluminum layer. By the way, here it is in the picture below.

- A tube with a solid aluminum sheet, where two thick layers of polymer are used.

- Everything is the same, only fiberglass is used instead of aluminum.

- Exactly the same construction in which a composite material (fiberglass + polypropylene) is used as a frame.

With perforated aluminum layer

And now the important question is, which polypropylene pipe is better? Based on the experience of specialists, we can say that the fifth model is ideal for heating. And the worst one is with a perforated frame. It's all about the density of the layer, in its strength characteristics. And although the perforated aluminum sheet is a fairly strong base that can withstand heavy loads, and linear expansion too. It has one drawback - oxygen seeps into the coolant through the holes in the aluminum, which negatively affects the metal devices of the system.

By the way, pay attention to the photo below. On it you will see all the consequences of the wrong choice of plastic (PVC) pipes for heating.

Poor quality plastic pipes

XLPE pipes

Polyethylene itself is a soft and pliable material when exposed to high temperatures. A pipe made from it is clearly not suitable for heating. It's all about its structure. A polymer consists of long chains of longitudinal monomolecules. But scientists have found ways to make it more durable. There are several options in which longitudinal molecules begin to appear in the polymer structure. Crosslinking of the molecular network occurs in all directions. Hence the name of the new material - cross-linked polyethylene. By the way, it has two names: Russian (PE-S) and English (PE-X).

A few words about the technical characteristics.

- The maximum temperature of the coolant is + 95 ° С, while the withstanding pressure will be 7 atm.

- When the temperature drops to + 70 ° C, the pressure increases to 11 atm.

XLPE pipe coil

Under such loads, the product will work faithfully for 50 years. I would like to note the high flexibility of the pipe. It can be rotated with a bend radius equal to six diameters of the pipe itself. This is the highest degree of flexibility of all plastic pipes. In addition, manufacturers produce a product in the form of a hose with a sufficiently long coil length (most often up to 200 m). This allows the construction of a heating system with virtually no joints. Reduces the possibility of leaks at the joints. This is a big plus. And it will be appreciated by those who are trying to build a heating system in their own house with their own hands, because the complexity of the installation process is also reduced.

As for the size range, for example, we can cite the products of the famous German brand "Gabo Systemtechnik".So the company produces pipes with an outer diameter of 10 to 260 mm. Moreover, in the first case, the wall thickness is 1.3 mm, and in the second 3.4 cm. This is the range. I would like to add that even German standards allow deviations in dimensional indicators, but only upwards.

The bottom photo offers several purely technical items that determine the quality of the pipe material.

Helpful information

Polypropylene pipes

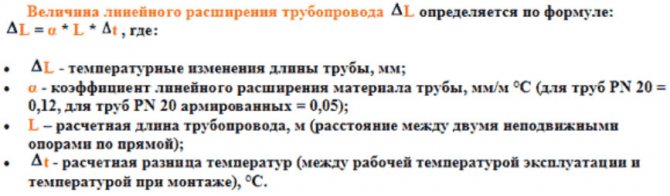

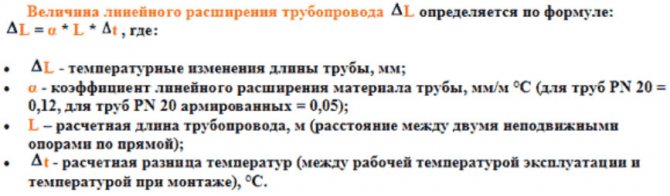

Polypropylene is a flexible and tear-resistant material, which makes it widely used in the construction of pipelines. Products made from this material, produced in diameters from 16 to 110 mm, bear the Latin PP mark. The high quality of the polypropylene pipe material was not achieved immediately. The melting point of polypropylene is 175 degrees at a value of 90 operating temperature. Even a short-term operation of a polypropylene pipeline at a coolant temperature of 110 degrees is permissible, from which it follows that the material is quite suitable for installing heating systems. But polypropylene has a high value of the coefficient of thermal expansion, which means that ordinary polypropylene pipes at the installation site will significantly increase in length when heated from the passage of a hot coolant through them. In addition, the diameter of such a pipeline will also increase when heated, which will limit the use - the facing tiles of the finishing of warm floors can crack or peel off from the base when the heat pipes expand under it.

The solution to the problem was found in the reinforcement of polypropylene pipes, which significantly reduced the thermal expansion of PP-material products. Thus, polypropylene pipe products began to be produced in two main types:

Reinforcement of polypropylene pipes

PP-pipe fittings are made of aluminum or fiberglass, the location of which in the pipe wall can be different. Reinforcement with aluminum is also called stabilization, and PP-pipes reinforced with foil are called stabilized, therefore the word Stabi is present in the marking of such products.

As a result of the reinforcement, the walls of PP-pipes are already multi-layer structures, differing not only in the material of the layers, but also in their layout.

The version of the reinforcement of polypropylene pipe products can be as follows:

- an aluminum layer in the thickness of the wall closer to the outer surface - when welding such products, the aluminum shell must be removed together with the outer layer of polypropylene;

- a layer of aluminum foil in the middle of the wall section - the foil is not removed during welding, no thickenings are formed on pipes of this section;

- reinforcement with an interlayer of fiberglass fabric - pipes with a slightly higher coefficient of thermal expansion than aluminum, but a simplified soldering process.

The layer of aluminum foil has a thickness of 0.1 to 0.5 mm - the thicker the foil, the higher the working pressure of the pipe. The aluminum shell, which not only increases the strength of the PP-pipe, but also serves as an oxygen barrier, can be either continuous or uniformly perforated.

Polypropylene tends to pass oxygen through its mass, including oxygen contained in the air. Consequently, oxygen will flow through the walls of the pipeline into the coolant. This is a negative factor if antifreeze is used as a heat carrier in the heating system - some of its types, in interaction with oxygen, form compounds that harm the boiler and the circulation pump. For such a heating system, the pipeline should be installed from PP-pipes with solid aluminum reinforcement.

If water is used as a heat carrier, then it is better to use pipes with a perforated shell for the heating pipeline.Perforation of aluminum, which is carried out through or embossed, allows you to bond adjacent PP-layers without the use of glue. Such polypropylene pipes are minimally subject to thermal expansion and do not form thickenings due to temperature and pressure changes.

Recently, basalt fiber, known for its high heat resistance and low coefficient of thermal expansion, has been used to stabilize polypropylene pipe products. An example is the EKOPLASTIK polypropylene pipes made in the Czech Republic, reinforced with basalt fiber fused into plastic, which reduces the coefficient of thermal expansion by three times.

According to the value of the permissible pressure and temperature, PP-pipes are divided into the following groups:

- PN 10 - thin-walled material for installation of cold water supply systems with operating temperatures up to + 20 ° С and floors with heating agent heating up to + 45 ° С, operating pressure 1 MPa (10.0 kg / cm²);

- PN 16 - pipe material for cold and hot water supply circuits with ambient temperatures up to + 60 ° С, operating pressure 1.6 MPa (16.0 kg / cm²);

- PN 20 - products for universal use, including for SGW with temperatures up to + 80 ° С, working pressure 2 MPa (20.0 kg / cm²);

- PN 25 - aluminum-reinforced pipe products for hot water and heating systems with operating temperatures up to + 95 ° C, pressure up to 2.5 MPa (25.0 kg / cm²).

The value of the nominal pressure is included in the marking of the products, for example PN10, PN16, PN20, PN25.

For the installation of heating systems, the most common PP-pipes of the following sizes:

- 20 mm - for internal wiring of the water supply network and the heating system circuit;

- 25 mm - for the manufacture of risers in low-rise buildings, for connecting heating radiators and floor heating systems;

- 32 mm - for the manufacture of risers and supply pipes in high-rise apartment buildings (6 floors and above).

Connection of polypropylene pipes for heating systems

PP-pipe connections are made of the following types:

- one-piece - by welding;

- detachable - threaded connections.

When installing hot water and heating systems, you usually have to use both methods, since the connection of the fragments of the pipeline to each other is done by welding, and the tie-in into the riser and the connection of radiators is done with a threaded connection.

Welding is carried out using a special tool - a welded soldering iron, which, when used correctly, creates a strong sealed connection based on the penetration of the molecules of the contact surfaces into each other.

The process of welding PP-pipes is simple - skills are acquired after several trial connections of unnecessary scraps and a pair of elbows.

For threaded connections, fittings are used that are pre-welded with a soldering iron to the prepared cut of the PP-pipe.

Disadvantages of polypropylene pipes

What is called a disadvantage is often a feature of this material. The same is the case with PP-pipes. If you call their flammability a disadvantage, because furniture also burns, especially from natural wood, but its naturalness is not qualified as a disadvantage.

Basically, one has to deal not with the shortcomings of polypropylene pipe products, but with the low quality of products from a certain manufacturer, the wrong choice of material for the existing operating conditions and installation errors that cause claims to the PP material.

We list the features of polypropylene pipes:

- when installing horizontal sections on brackets, in order to avoid sagging spans, the step of the supports should be performed, depending on the diameter of the pipeline, in the amount of 0.5 - 1.0 m;

- preparation of material joints before welding must be carried out carefully - cleaning from foil, facing;

- when welding PP-pipes, it is necessary to accurately maintain the heating time of the welded joints;

- lack of flexibility is neutralized by using the necessary fittings (lines, half-bends);

- when buying material for installing a heating system, it is better to purchase pipes and fittings from one manufacturer;

- PP pipes of dubious quality should be avoided, for example, even with barely visible external defects.

Criteria for choosing pipes for heating

So, the differences between heating and plumbing systems are obvious. Accordingly, pipes for their construction must meet a set of certain criteria. It would be wrong to select pipe material solely for economic reasons in this case.

In a standard heating system, pipes must have the following characteristics:

- The pipeline must withstand prolonged exposure to high coolant temperatures. In central heating networks, this value is regulated and does not exceed 70-75 ° С. In private networks, it is more difficult to control the temperature of the carrier, so the safety margin of the pipes should be even higher.

- Pipes must withstand an increase in the pressure of the working medium and the associated possible negative processes, one of the most dangerous among which is a water hammer - a sharp short-term increase in fluid pressure.

- The design of the pipe should have a smooth inner surface that prevents the formation of blockages, as well as the accumulation of deposits. All types of plastic pipes satisfy this condition.

- The material from which the pipe is made must have a low coefficient of thermal expansion. This will avoid deformation (in the worst case - mechanical damage) of the pipeline during operation.

- The material must provide resistance to corrosion and aggressive chemical environments.

- The pipes must have a durability comparable to or exceeding the service life of other elements of the heating system.

- The circulation of the coolant should be as quiet as possible. In plastic products, this, as a rule, does not cause problems, but in metal pipelines, fluid swirls are often created, accompanied by strong noise.

- Aesthetic component. The pipeline must organically fit into the interior of the room.

Modern industry produces several types of polymer pipes that fully meet these criteria.

XLPE pipes

To improve the characteristics of polyethylene (conventional, low pressure - HDPE),

there is a special technology for changing its molecular structure called crosslinking, which creates additional bonds between molecules with an increase in the strength and heat-resistant properties of the polymer. Cross-linked polyethylene pipes have the PEX designation and have a solid wall of a solid or multi-layer section - one or two shells are made of the base material, and between them or outside there is a reinforcing layer that also serves as an oxygen barrier.

The material is successfully used in many areas, including the wiring of hot water and heating systems, conventional and high-temperature.

The connection of plastic heating pipes made of PEX material is carried out in one of three methods:

- crimp (compression) - collapsible joint;

- pressing - conditionally dismountable connection;

- electric welding - non-separable installation.

Each of the installation methods corresponds to a specific tool and fittings.

There are 4 methods for cross-linking polyethylene, after using which pipe products are made from the resulting material, having the corresponding designation in the marking:

Characteristics of PEX pipes by crosslinking technology

PEX-a pipe material has uniform crosslinking and a good percentage. PEX products have the greatest flexibility of all sewn pipes and have good molecular memory - the ability to recover their shape after deformation.This allows you to easily correct configuration defects and creases formed during the installation of the circuit using a conventional construction hair dryer.

PEX-a is a long-used cross-linking method that allows to obtain material with a wide range of operating temperatures, retaining its strength characteristics even with peak short-term fluctuations from -100 to +100 degrees. The production of peroxide-crosslinked polyethylene is a costly process, but the high cost is justified by the quality of the finished product. PEX-a pipes are successfully used for the installation of heating and hot water supply systems, retaining their characteristics for many years.

With these advantages, PEX pipes have two significant disadvantages. During operation, this material is subject to intensive washing out of chemicals by the coolant, which adversely affect heating equipment and automation. In addition, the cost of this type of cross-linked pipes, as well as fittings for it, is much higher than PEX-b and PEX-c materials. As a result, taking into account the cost of work, the total cost of equipping a heating system made of PEX-a cross-linked polyethylene may turn out to be several times higher than when using products made of polyethylene of another type of cross-linking.

PEX-b cross-linked polyethylene pipes began to be produced later than the previous type, but 40 years of presence on the market is also enough time to evaluate the characteristics of the material. Products from PEX-b are in wide demand due to the successful combination of affordability and quality - high tensile strength.

Among the disadvantages of this type of PEX pipes, it should be noted the rigidity and low degree of molecular memory - it is rather difficult to give the coils of the coiled implementation material the desired configuration.

Crosslinking by the PEX-c (radiation) method is performed by irradiating polyethylene with a stream of charged particles, in which part of the existing bonds is destroyed with the formation of new ones. The method is characterized by the inevitable unevenness of crosslinking, which causes a high degree of risk of cracking, but this technology does not require large costs, and PEX-c pipes are still produced for systems with low requirements for the strength and heat-resistant characteristics of heat pipelines.

PEX-d pipes (nitrogen structure of the material) - the production technology is complex and costly, while the high cost of the material is not justified by the characteristics of the material, so the demand for products is not high.

Types of polymer pipes for heating pipelines

Today on the market you can find 3 types of plastic pipes for heating systems. Products are made from various polymers.

- XLPE pipes.

- Polypropylene pipes.

- Metal-plastic products.

Each of the types of pipes can be used to install a reliable and durable heating system. However, the features of each material will determine some of the specifics of the operation of such heating networks.

XLPE pipes

Pipes made of polyethylene, as well as connecting elements to them, are more expensive than analogues made of polypropylene. In addition, such products are easier to install, since no special tools are required. Polyethylene pipes are easy to bend, especially when heated.

Note! The term "sewn" does not imply the presence of seams or joints on the pipes. This refers rather to the internal structure of the substance from which the pipe is made, namely to the arrangement of the molecules in a certain order.

This type of plastic pipe shows the best resistance to repeated freezing of the carrier. Corridor of working temperatures from -50 to 100 ° С. Provided that these parameters are observed, the service life of a pipeline based on XLPE pipes reaches 50 years.

Among the disadvantages of polyethylene pipes, we note the vulnerability of the material to ultraviolet radiation. However, many modern products are manufactured with a protective shell that minimizes this negative impact.

Polypropylene pipes

The main advantage of polypropylene pipes is their low cost.

The ease of installation, which you often hear about, is quite relative. Firstly, installation will require the use of a special welding machine. The device has a considerable cost, and requires certain operating skills.

Secondly, in polypropylene it is almost impossible to check the quality of the welded joint, which, meanwhile, depends on many parameters. From the qualifications of the master, the state of the welding machine, the correct heating temperature, the holding time.

Note! Insufficient holding time can lead to leaks over time, and excessive heating can melt the inner plastic layer and reduce the throughput of the pipeline.

Another disadvantage of a polypropylene pipeline is linear elongation. Even reinforced products are able to noticeably lengthen when heated, which often leads to a change in the configuration of the pipeline.

We recommend that you familiarize yourself with: Varieties of PVC pipes and how to choose the right quality product

For this reason, polypropylene is not recommended for use in screed pipe projects.

It is worth remembering that not every type of polypropylene pipes is suitable for a heating system:

- First type. PP-H marking. Not intended for networks with high media temperatures. It is mainly used in ventilation and cold water supply systems.

- Second type. PP-B (PP-2) marking. It is often used in networks with low media temperatures, for example, underfloor heating systems.

- Third type. PPRC marking (PPR, PP-3). Resistant to compression impacts and high temperatures. Ideally suited for the construction of heating systems.

Metal-plastic products

The most common type of pipes for heating systems. The multilayer structure of the pipe (two layers of cross-linked polyethylene, two layers of glue and an aluminum insert placed between them) makes it resistant to high temperatures and makes it easy to bend products without special tools. Good flexibility will help to significantly reduce the number of connectors.

Reinforced plastic has excellent soundproofing qualities and does not form condensation. Pipes are produced in coils and sold in linear meters. This minimizes waste.

The connection of pipeline sections is made by means of fittings, which, by the way, are considered the weakest point of such heating systems:

- Threaded connections are easy to install, but are not considered reliable and durable. In addition, the cost of such fittings is unreasonably high.

- Press fittings are considered more reliable, but special crimping pliers are required for their installation. Such a connection is obtained non-separable.

High temperature resistant polyethylene

The material labeled PE-RT was created as a better alternative to cross-linked polyethylene and is a thermoplastic with no cross-linking in the manufacturing chain, which significantly increases equipment productivity. At the same time, in terms of strength characteristics, PERT pipes are superior to products made of PEX polymer, as well as in terms of ease of connection - their joints can be welded. This is the reason for the popularity of this material, which, by definition, is suitable for the installation of any hot water supply and heating systems.

Polybutene pipes

Polybutene tubular products (PB, Russian abbreviation PB) are a modern high-quality material that combines the advantages of polypropylene and cross-linked polyethylene.In hot water supply and heating systems, polybutene pipelines have been used relatively recently, but have already proven themselves to be a material that surpasses products that are identical in application in terms of technical characteristics.

Advantages of polybutene pipes:

- preservation of strength characteristics at critical temperatures;

- a high degree of flexibility remains even at low temperatures;

- low coefficient of thermal expansion;

- the possibility of installation using welding joints;

- low thermal conductivity;

- resistance to chemicals.

Polybutene tubular products are manufactured in coils and rods of both conventional and pre-insulated design. High technical characteristics determine not only the widespread use of polybutene in heating and hot water supply systems, but also their high cost today.

The choice of pipes for heating or which pipes are better?

There are several types of material. The most common type is called Green Line Type One.

It can be used in systems with media temperatures up to eighty degrees. More often this type is used in the arrangement of air conditioning systems and refrigeration units.

The type of material under consideration begins to undergo deformation already at a temperature of ninety-five degrees. Therefore, you need to use it with extreme caution.

In the heating circuit from it, the temperature of the medium must not exceed the above limit.

The table below shows the technical characteristics of CPVC and PVC.

| Properties | Chlorinated PVC | Plain PVC |

| Linear expansion coefficient | 0,62 | 1,2 – 1,4 |

| Density (g / cm2) | 1,57 | 0,95 |

| Thermal conductivity (W / Mk) | 0,14 | 0,22 |

| Tensile yield strength (MPa) | 50 to 55 | 18 to 26 |

| Design strength (MPa) | 10 | 6,3 |

| Oxygen permeability (when reaching +70 in the system) | Less than 1 | 13 |

| Elastic modulus (MPa) | 2400 | 550 to 800 |

Based on the above information, we can conclude that the chlorinated version of the material is characterized by a lower thermal conductivity. This property can significantly reduce heat losses in the system. The structures will not get very hot. The likelihood of condensation will be minimal. These properties allow the construction of a heating circuit without arranging an additional heat-insulating layer.

Pipes made of the material in question are suitable for arranging a central water circuit and floor heating. They can be used in systems based on gas and solid fuel boilers.

Products made from other types of plastics are also suitable for this task. But they also have their own pros and cons. For example, polypropylene (PP) structures are less rigid, which reduces the number of fittings required when installing the system. However, they do not have sufficient resistance to high temperatures.

Reinforced plastic pipes

Reinforced plastic pipe products are a material with a high-strength wall, consisting of 5 layers: an aluminum pipe with an outer and inner shell made of cross-linked polyethylene, bonded with a high-quality binder.

The design of the outer and inner shells may differ in the method of stitching or be made of polyethylene of increased heat resistance.

The technology for the production of pipes from metal-plastic is complex, but the cost is justified by the high technical characteristics of the final product, which is produced with an outer diameter of 16 to 40 mm and a wall thickness of 2-3.5 mm, the form of implementation is footage, coils.

The scope of metal-plastic pipes is industrial and domestic heating and hot water supply systems.

Advantages of the material:

- anti-corrosion;

- internal and external resistance to chemicals;

- low thermal conductivity;

- low coefficient of friction of the inner surface;

- small values of the radius of curvature during assembly bending;

- antistatic;

- dielectric properties;

- reliability of butt joints;

- durability.

Disadvantages:

- a significant amount of thermal expansion (the need to install expansion joints);

- lack of resistance to mechanical damage;

- the need to tighten compression fittings;

- low temperature resistance relative to steel pipes;

- high cost of valves and fittings.

The main technical characteristics of metal-plastic pipes are present in the marking of the material, applied for convenience to each running meter.

Performance characteristics of metal-plastic pipes:

Important! At a coolant temperature above 140 ° C, the inner polymer shell melts with stratification of the rest of the pipe structure.

Installation of metal-plastic pipes is carried out using fittings and special tools. If you have certain skills in the production of installation work, it is possible to install a heating system or SVG from this material on your own.

Types of plastic pipes for heating

Polypropylene belongs to thermoplastics. Transforms its physical characteristics under changing ambient temperatures.

When operating the heating circuit (at 140 degrees Celsius above zero), the pipe softens. At 175 degrees above zero, the structure will melt. Therefore, manufacturers have set operational limits at which heating elements are used.

PVC material has a high coefficient of thermal expansion. After reviewing the typical calculations, it can be seen that during the operation of the system - from 20 to 90 degrees Celsius above zero, the polyvinyl chloride structure lengthens on average by 3 centimeters.

It is better not to use in northern regions where there are extremely low temperatures outside. After all, the coolant in the heating system heats up above the boiling point. And this should not be allowed.

There are varieties on the market:

- polyvinyl chloride;

- polypropylene;

- polyethylene;

- made of cross-linked polyethylene.

Polyvinyl chloride affordable material, because many buyers choose it. Products made from these raw materials are of a high degree of rigidity, therefore, structures can be connected using specialized fittings purchased in plumbing stores.

There is no need to use expensive devices in this situation, and there is no need to purchase imported adhesive solutions, which are also expensive. Polypropylene components for the heating system can withstand the heat carrier temperature up to 90 degrees Celsius. This type is somewhat more expensive than polyvinyl chloride.

Polyethylene components are suitable for heating installation, as they are resistant: to high temperatures, aggressive environments, adverse external influences.

Polyethylene elements are renowned for their durability and reliability. The stitched polyethylene undergoes additional processing. In the course of exposure to high temperature on PVC raw materials, at the exit, the material becomes strong, as it acquires additional molecular bonds.

There are products on the shelves:

- unreinforced;

- with foil;

- fiberglass reinforced.

Each subspecies has its own characteristics:

- Unreinforced structures - technological plastic, for example, sheet.

- With foil have 3 layers glued together.

- Reinforced - resistant to thermal expansion. Reinforcement plays the role of a stabilizer, reducing deformation on the walls when exposed to high temperatures of the coolant.

- Fiberglass reinforced the most successful subspecies. The advantages of such structural elements are that they can be simply welded together, and after the work carried out, there is no need to perform any cleaning of the PVC surface.

The presented options are suitable for heating a house, cottage, apartment.But the user should remember that no reinforcement, even strong, will prevent the expansion of the plastic walls if the temperature of the coolant fluctuates within extreme limits.

Difference from metal-plastic

Reinforced-plastic structures are more complex in structure. They are manufactured:

- made of plastic;

- special glue;

- foil.

Linear elongation during operation of such products is unlikely. Structures are used even in those rooms that have complex geometry. But soldering is by no means used to connect the segments, some other methods:

- press fittings (detachable connections);

- threaded materials;

- compression (conditionally detachable).

Unlike polypropylene, metal-plastic structures are afraid of sunlight and mechanical stress. To mount metal-plastic, experience in this direction is desirable (heating installation). In addition, the fittings are overgrown with silt, rust (due to the poor quality of the coolant). This is not uncommon when operating a heating system in a city.

If the pipe is squeezed, a rupture of the monolithic structure will occur. The cost of such products is higher than polypropylene ones, therefore the second (PVC) option wins, and buyers prefer products with low cost and easy installation.

Main types

If we consider plastic pipes for heating from our point of view, then they can be divided into just two categories:

- Unreinforced, that is, it is ordinary plastic, the same as, for example, sheet.

- Reinforced pipes. Reinforcement is a way to deal with the main disadvantage of the material (thermal expansion). For this, a material is used whose expansion rate is lower than that of plastic. It acts as a stabilizer, reducing thermal expansion to an impressive 0.03 millimeters per m * C. Reinforcement is done in two ways:

- Foil. It turns out a kind of sandwich, with three glued layers of plastic, between which there is a thin ball of aluminum foil. This kind of pipes are good enough, but only if they are properly manufactured. If the latter is violated, then they will soon stratify.

- Fiberglass reinforcement gives us already monolithic pipes, since the fiber in them is placed directly in the plastic layer. The advantage of such pipes is that, firstly, they do not delaminate, and secondly, if two segments need to be welded together, then no stripping of the reinforcement is required.

Note that both options are great for heating systems. But it must be remembered that even reinforcement does not prevent the expansion of the material at high temperatures, it only reduces it.

So that you can understand the general picture of the expansion of polypropylene in comparison with other materials, we have given a table below. Basic values: the length of the pipe is one hundred meters, the temperature is fifty degrees.

| № | Material | Elongation, cm |

| 1. | Cast iron | 5.2 |

| 2. | Steel | 5.5 to 5.8 |

| 3. | Copper | 8.5 |

| 4. | Brass | 9.5 |

| 5. | Aluminum | 11.5 |

| 6. | Polypropylene with other materials | 15 to 31 |

| 7. | Polypropylene | 65 |

| 8. | PEX | 100 |

As we can see from the table, the expansion of our material is perhaps the largest, except that PEX "overtook" it.

Pros and cons

Pros:

- long-term operation (50 years);

- installation method: open or hidden;

- elements are not subject to corrosion;

- installation takes place quickly, without encumbrances and difficulties;

- products are environmentally friendly and safe for humans and the environment;

- PVC materials conduct heat poorly and weigh little.

Disadvantages:

- the inability to use structural elements in fire protection systems;

- there are some restrictions during operation;

- each type is a unique installation technology.

Advantages and disadvantages

Plastic pipes for heating have their pros and cons. Their advantages, in principle, are the same for plastic and for polypropylene in particular:

- They will last up to fifty years, which is five times more than steel pipes.

- They can be installed both open and hidden.

- Such pipes are not subject to corrosion.

- It's easy to mount them (we'll talk about this later).

- They are environmentally friendly.

- The water flow in them practically does not make noise.

- They do not conduct heat well and are lightweight.

There are not so many disadvantages, only three:

- Each type of pipe has its own unique installation technology.

- They cannot be used in fire protection systems (although we are, in fact, not interested in this).

- When heating, there are some restrictions for them.

But I would like to add that all these shortcomings and shortcomings, in fact, are not, but the features of the material. The fact is that the standard in this case is galvanized iron pipes, and everything that does not fall on them is considered a deviation, that is, disadvantages.

Installation of plastic pipes

In order to install plastic pipes for heating, first of all, it is necessary to make a wiring, where all the details would be indicated. This is the location of each of the radiators, and the points at which the pipes will be attached. Do not forget about taking into account the thermal expansion that is a little boring to you.

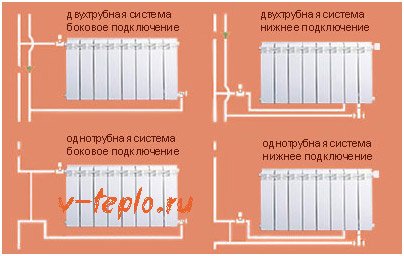

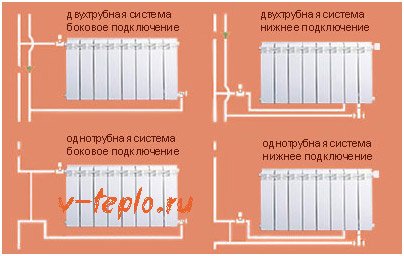

Important! Plastic pipes can be attached to the radiators from the bottom and from the side, in one and two-pipe way.

We will need the following components for the construction of the mains of their plastic pipes:

- Ball Valves.

- Adapters of different sizes required for connecting pipes.

- Clamps.

- Couplings for connecting pipe sections of the same diameter.

- Plugs.

- Nipple bends. Needed in order to switch to other diameters.

- Crosspieces.

- Tees.

- Several threaded couplings.

Before proceeding with the installation, you should first connect the main components of the pipeline - plumbing, batteries, boilers. After that, we mark the main lines where the pipes will pass, according to the drawn up diagram. We attach fastening clips along the lines and only after that all the parts of our line are connected together. If there are hard-to-reach (for installation) places in the house, then the pipes should be installed in them separately, using special couplings for this.

See also the instructions for replacing the heating radiator

And about the notorious thermal expansion. Because of this, it is recommended to use a flexible mount to compensate for expansion when laying the pipeline. Water can be put into the pipes only after at least an hour after the end of work, and we can talk about any hydraulic tests only after twenty-four hours.

Soldering pipes video

Welding

Plastic pipes for heating are welded in several stages.

Stage 1. We cut the pipes to the length we need using a marker. After that, we cut it off with a special tool called a pipe cutter. The incision site is carefully cleaned.

Stage 2. Welding using a soldering iron. There are different nozzles for it, but we need a "sleeve" directly for pipes and a "mandrel" necessary for the fitting.

After turning on the device, you should wait until its temperature reaches 260 degrees. We start welding, while moving all the way. On average, heating the material takes 10 to 15 seconds. For some time, hot parts remain plastic, so they should be fixed before they cool down, so that the surface does not deform. As a result, if everything is done correctly, you should get a monolithic part.

Average cost of polypropylene pipes

Such pipes cost an average of 35 rubles per meter, this is when it comes to conventional pipes. If they are reinforced (with fiberglass or foil), then the cost is already slightly higher - starting from 50-60 rubles per meter. But the maximum cost can hit, it all depends on the type of reinforcement.

As a conclusion

As a result, I would like to note three things:

- Plastic pipes for heating are undesirable in areas where there are very severe frosts in winter.If the temperature is even minus 25, then you should forget about plastic and pick up some stainless steel pipes.

- During the installation of polypropylene pipes, they cannot be placed close to the surfaces of the walls or ceiling, a certain gap must always remain. And what did you want - thermal expansion!

- Only reinforced pipes are suitable for heating. And the installation of such pipes is simple.

Characteristics of plastic pipes for heating

The coolant temperature should not be higher than one hundred and twenty degrees, otherwise the structural elements will fail. Plastic structural elements have a high thermal expansion rate (approximately 0.15 millimeters per m * C). Therefore, in order to avoid elongation of the plastic wall, the standard operating temperature is observed.

High-tech plastic pipes can withstand up to - 15 degrees Celsius. This indicator is important if the scheme is installed in a country cottage and freezing is possible under force majeure circumstances.

At -5, -10, -12 degrees Celsius, the system will never fail during defrosting and will function as efficiently as before.

The technical characteristics of the plastic components indicate that they have a low density (about 0.91 kilograms per square centimeter). PVC material is difficult to wear out during operation, it is quite hard.

Therefore, you should not be afraid that the elements will fail due to small particles (rust flakes circulating with the coolant). The inner surface of the product will not be mechanically scratched, the elements will not be damaged, so you should not be afraid of leaks.

Sizes of plastic pipes for heating systems: how to choose the right one

How successfully the system will function depends on the correct choice of the diameter. When calculating the cross-section of pipes, it is necessary to consider:

- wiring diagram;

- the speed of movement of the coolant;

- diameters of the pressure head and return pipes of the boiler;

- the calculated decrease in the temperature of the liquid in the batteries;

- the value of the resistance coefficient.

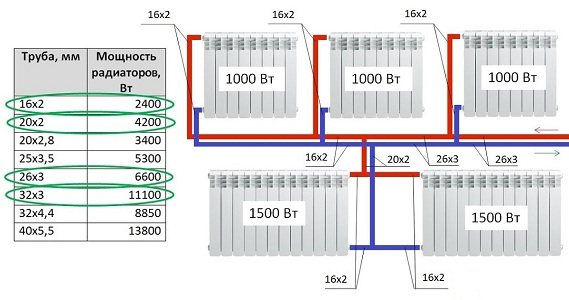

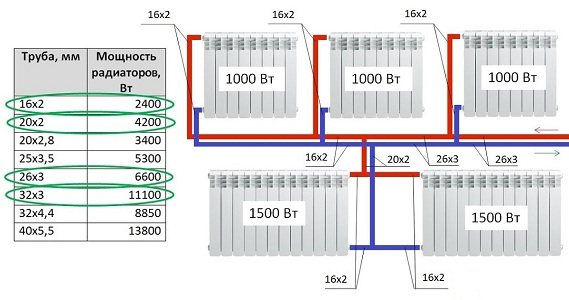

However, with a complex wiring diagram, especially when, in addition to radiators, a warm floor is also planned, standard calculation methods are not suitable. Then, to determine the diameter of the pipes, you will have to contact a specialist or consult with neighbors who have a similar system. If you plan to install heating with forced water circulation, it is preferable to choose options with a smaller section. This will facilitate installation, reduce the volume of heated water. However, you should not get carried away with minimizing the diameter, as this will cause a decrease in heat transfer due to an increase in water speed and the appearance of noise. The optimal speed value varies from 0.2 to 1.5 m / s.

To independently determine the diameter of plastic pipes, one should proceed from the fact that to heat 1 m² of a room up to 3 m high, 100 W of thermal energy is required. This means that for a room with one or two batteries of 20 m², 2 kW plus 20% of the reserve is needed, as a result 2.4 kW. The table indicates that pipes with a diameter of 8 and 10 mm are suitable for transmitting such power. The result is approximate, but it will help determine the cost of purchasing pipes.