General classification of tees

Tees can be classified according to several criteria:

- material of manufacture;

- manufacturing method;

- fastening method;

- operating principle.

The material of manufacture can be different: steel, stainless steel, brass, copper and plastic. So, stainless steel tees are needed to work with aggressive conditions - more often it is the chemical and oil and gas industry. Tees made of steel, brass, copper and plastic are installed in systems for transporting water (hot and cold), steam, for heating systems. Brass tees are used for metal-plastic pipelines.

Tees made of polymer (polyethylene and polypropylene) materials are well suited for cast iron structures. The tee can be used as a connector, branch or fitting.

According to the manufacturing method, tees are divided into welded and stamped. A stamped tee is a part that is hot stamped and machined. A welded tee is a welded nipple design. There can also be stamped-welded tees - i.e. using both welding and stamping.

There can be four fastening methods: coupling, flanged, welded and threaded. The choice of fastening depends on the function of the pipeline, operating conditions and requirements for strength and tightness. Of course, the material from which the tee is made also affects.

There are only two principles of operation - tees can be transitional and equal. Equal tees are elements with three identical holes that are needed to connect pipes of different diameters. The neck of such a part is located perpendicular to the body, there are tees with a different angle of the neck, but they are produced in limited quantities and are used in pipelines with low pressure.

Reducing tees are elements with one hole, which has a smaller diameter. They are used to branch pipes with different diameters and change the pressure in the system.

In metal-plastic pipelines, in addition to threaded and tees for a press sleeve, combined tees are also used, in which the ends are also formed by a crimp method.

Table 1. Technical parameters of tees depending on the manufacturing method

| Indicator | Alloy and carbon steel | Galvanized Tees | Stamped tees | Stainless steel tees |

| Operating pressure | Up to 16 MPa | Up to 10 MPa | Up to 16 MPa | Up to 16 MPa |

| Temperature | -70 to +450 degrees | -700 to +4500 ° C | -70 to +450 degrees | -70 to +450 degrees |

| Conformity | GOST 17376-2001 and GOST 17380-2001 TU 102-488-95 | |||

| Working diameter | 45-426 mm | 50-300 mm | Up to 462 mm | |

| Features of the | Often used in the Far North and in the oil and gas industry | 10% heavier than steel, resistant to chemicals and corrosion | — | For pipelines of critical areas |

| Material grade | Steel 10, 20, 09G2S, 10G2, 15x5m, 10x17n13m2t, 13khfa, etc. | |||

.

The most popular fittings: differences and features

Most often, when connecting plastic pipes, several types of similar products are used. Each of them has design features, advantages and disadvantages.

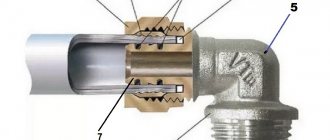

American

It is a one-piece, non-separable structure, which is designed to connect various plumbing parts to the water supply and connect a plastic pipe to a metal one. The part is sealed due to a special cone with either a silicone or a rubber seal ring.

With the help of an American pipe, the pipes are connected easily and reliably

American women are divided into two types:

- straight;

- corner.

The use of corner fittings will allow you to make a corner joint of a plastic pipeline without undue stress on the plastic pipe and plumbing part. There are two types of American women - with an external thread, and an internal thread.

Advice! The use of American women with different threads will allow you to mount the pipeline without attracting additional adapters.

Plugs

The plugs are represented by dead-end elements that are connected to the pipe by soldering or threading. Instead of sealing the hole, use a plug.

The purpose of the plugs for plastic and metal-plastic pipes is to protect pipes from the penetration of foreign objects and dirt into the system. Caps for plastic pipes can be installed with pipes or other fittings. The advantage of using plugs will allow for future pipeline upgrades. The plug is dismantled, and a new pipe section is attached instead. Depending on the need, the plugs can be soldered and screwed on.

The plug is needed if the pipeline is planned to be extended or modernized in the future.

Shut-off and control valves

This category of goods includes valves and taps. Shut-off and control valves are divided into two main types: manual valves and thermostatic valves.

The armature also differs in the type of its body, and it happens:

- polymeric;

- metal threaded.

The first ones are soldered into the system when mounting, while the second ones are always equipped with an American on the one hand, which allows you to mount the valve immediately, without disassembling the entire system before).

Advice! Shut-off valves designed for cold water should not be installed in the gas or hot water pipeline.

The main distinguishing feature of the crane is a high degree of tightness, which determines the area of use.

Taps are needed to shut off the water in the event of an accident or replace pipes

Taps are used when installing plastic piping, which is later used to supply cold / hot water or gas. They are also relevant when using hoses for water supply.

Crosses and tees

Plastic plumbing tees are connecting elements that play an important role in the installation of any pipeline. Plastic tees for hoses are used to create branches or connect several hoses, pipes. Depending on the needs, tees with straight (90 degrees) or sharp angles (35-40 degrees) are used.

Advice! Do not use connecting tees for other purposes. Otherwise, with a strong internal water pressure, the entire system will deform and disintegrate.

Crosses with tees for plastic pipes are:

- transitional - the neck and through-holes of the tee have different diameters;

- equal bore - the neck and bore of the tee have the same holes.

Tee fittings are connected to pipes using soldering or threading. Reducing tees are also common, allowing you to switch from one type of connection to another (from thread to soldering, and vice versa).

Using a reducing tee, pipes of different diameters can be connected

Swivel joints

Swivel joints or angles allow the pipeline to be rotated during installation. The corners are joined to the pipes both by soldering and by tightening a nut. Angles vary in dimension, but 90 degree angles are most common.

Couplings

Couplings are designed to create a high-quality connection of parts absolutely identical in their diameter.

There are the following types of couplings:

- couplings for plastic pipes, used for soldering plastic pipes and made of the same material as the pipes;

- couplings used to mount elements that are made of various materials (when, on the one hand, it is necessary to use soldering, on the other, a nut);

- couplings that are used to move from rigid pipe sections to corrugated sections (they are actively used when installing a sewer pipeline);

- couplings - adapters.

A coupling for plastic pipes is relevant when joining long sections or when joining several pieces.

The coupling will help to securely connect two pipe sections

Supports and bends

Bypass fittings include connecting elements that can significantly simplify the installation of a plumbing pipeline at the intersection of several routes or to resolve some structural obstacles - when it is necessary to lay a pipeline near an already installed system.

Plastic supports are intended for rigid fastening of pipes. They are only relevant if it is prescribed by the instructions when installing the heating system and the pipeline for supplying hot water. The use of supports will allow you to securely fix the entire structure at pre-planned points.

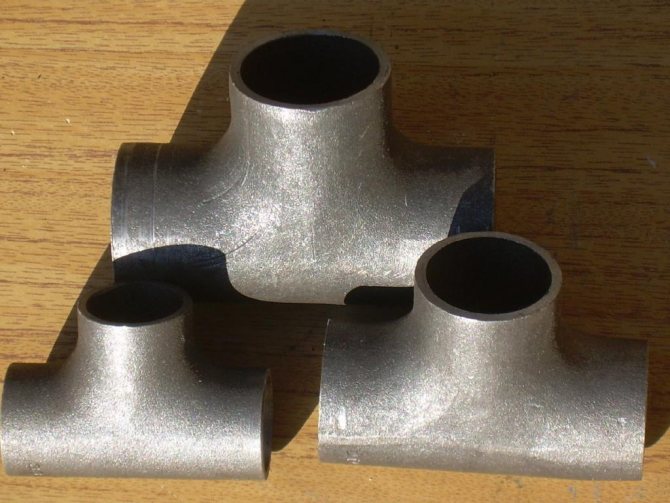

Equal Tee Classification

Equal tees are divided into the following types:

- simple mortise without reinforcement - needed in systems with pressures up to 2.5 MPa, if the pressure is higher than 2.5 MPa, then the pipes must be of small diameter;

- Tees with reinforcement - used in systems with high pressures up to 4 MPa, where structural reinforcement is required. Such tees are divided into subspecies - with a thickened fitting, with a saddle and with linings.

By the type of manufacture, equal tees are divided into:

- welded - made by welding two parts of the pipe (neck and body). The body is the part that connects the two elements of the main pipe, and the neck is the part of the tee that connects to the branch pipe. Of all welded elements, the most economical simple mortise;

- stamped - made by extrusion on presses. They are distinguished by high strength due to the smooth transition from the body to the neck;

- stamped-welded - in this way tees with a large diameter are made. First, the body and the neck are stamped separately, and only then they are welded together.

Equal tees are made primarily of low alloy or carbon steel. They are used for transportation of neutral liquids, and if they are corrosive or food media, they are made of stainless steel.

You can find out the range of tees and their prices in your city here:

- Astana;

- Almaty;

- Karaganda.

Operational areas, design and production technology

Today, steel products can be used in pipeline structures that transport various working media. Consider the main substances that move along such communications:

- water;

- steam;

- gas;

- petroleum products.

Consider the structural elements that make up this part:

- welded product;

- three nozzles.

Note! The branch pipes are usually covered with a special heat-insulating material to protect the tee in harsh climatic conditions.

There are several ways in which you can complete this part:

- hot stamping;

- water stamping;

- welded method.

The most common way to manufacture these products is by stamping from a solid sheet. This is due to the fact that this method requires a minimum of financial costs. Hot stamping is useful for mass production of these connectors.

Tees differ in manufacturing method - stamped parts are most common

These connecting devices are regulated by state standards (GOST). Steel tees are described in GOST 17376. Such parts are made of carbon or alloy steel, and are used when laying industrial-type communications. There are products that are regulated by another regulatory document - GOST 17376-2001. These steel fixtures are made from carbon steel and low alloy steel.

The operational areas of this type of steel fittings do not end with industrial pipelines. They are also used for other structures:

- heating piping systems;

- water pipes;

- gas pipelines.

With a tee, you can easily connect to the main line, which is why this product is so popular and used in almost all industries. The most widely used device today is a welded product. And for pipes with large cross-sectional indicators, flanged tees are used.

Types of transition tees

Reducing tees are divided into:

- tees that have a crimp nut and a press sleeve;

- tees that have both a compression nut and a threaded end;

- a tee with fastening, their body is fixed to the support using cast brackets, into which self-tapping screws can be inserted. The ends are designed for threaded or crimp connections.

It should be noted that the press sleeves are made of stainless steel, and the seals are made of polymers. For the body, brass is used as the material. Threaded ends are made using taps and dies. To connect metal-plastic pipes using transition tees, both crimping and pressing methods can be used. In the case of a crimp fitting, a collet fitting is taken, in the case of a press fitting, a press fitting.

Selection of fittings for the water supply system

Fitting installation

Before purchasing accessories for water supply, you should familiarize yourself with some of the recommendations of experts:

- For joining polymer pipes, compression fittings are used: couplings, tees, adapters.

- When installing threaded fittings on polymer pipes, it is necessary to provide easy access to them to quickly eliminate the leakage.

- Threaded fittings for plastic pipes should be selected so that they fit on the pipes with some effort, which will prevent the system from leaking.

- If it is not possible to avoid threaded connections in plastic pipes, it is better to use American fittings for reliability.

- It is better to fasten metal-polymer pipes with metal or press fittings and reinforced combined threaded fittings.

- Metal-polymer pipes are produced, the installation of which is carried out by welding. This improves the reliability of the connection and increases the system's resistance to load.

- Metal pipes are connected with threaded metal fittings made of similar materials (see Steel water pipes: varieties, classification, installation nuances). However, there are exceptions. For example, brass fittings can be used on steel or cast iron pipes - they are quite durable and will not deform or corrode. For copper pipes, only copper fittings should be used - the system elements are connected by soldering.

Plastic tees: types and applications

Plastic tees are used for sewer pipes. There are several common types:

- sewer PVC tee 87 or 90 degrees - for connecting vertical risers with horizontal pipes;

- sewer tee made of PVC at 45 degrees - for fastening plastic pipes in a horizontal branch;

- PVC revision is a sleeve with an additional third hole screwed with a special cap. It is needed so that blockages can be dealt with in certain parts of the pipes.

PVC tee design

Externally, a tee is a part of a pipe with a side outlet, to which it is easy to attach an additional pipe and create the desired branching.

The T-piece can also be used for a regular connection without connecting another trunk, but taking into account the fact that in the future it may be necessary. For example, if it is planned to bring out another pipe after some time, then the tee can be installed in advance, and the additional outlet can be closed with a plug for now. Installing a branch pipe when the time comes will be a fairly simple operation: you just need to remove the plug and connect the pipe.

We recommend that you familiarize yourself with: The use of an American crane in pipelines of various types

The use of tees in the sewer system

Plastic tees are very convenient to use in the sewage system. Most often they are installed with a horizontal system. Installation and dismantling can be done by hand, because all parts have a coupling at their ends. Pipes can be both internal and external connections. In addition, when using tees and other plumbing parts made of plastic, you can forget about the problems of clogging channels lime or other organic substances, which ultimately lead to the formation of mold and mildew.

There are also plastic tees such as revision ones. In some cases, you simply cannot do without them, because they allow you to quickly clear blockages that may arise in sewer systems.

The service life of the entire sewer system will depend on the choice of material, type of connection and, naturally, the model of the tee. They can greatly simplify the work of installing the sewerage system in private houses or apartments.

Tee installation rules: general recommendations

Installation of tees on a plastic pipeline

The process of installing tees with a pressure or free-flow pipeline should be subject to a certain set of rules. Otherwise, this connecting element will turn from a fully functional part of the pipeline into a source of big trouble for its owner.

And in order for such a transformation not to occur, you need to adhere to the following recommendations:

- Use rectangular tees only in pressure systems. Free-flow lines should be equipped with 45-degree connection fittings.

- When assembling a free-flow network on the sockets, observe the orientation of the connecting element - the tee for pvc pipes should be oriented with the socket in the direction of fluid movement. To put it simply, the funnel first goes along the flow path, and then the smooth end. Otherwise, the joints will leak, which, you see, is very unpleasant (especially in the case of sewers).

- When mounting the tee on glue, try to select the position of the pipe relative to the connecting element within the first couple of seconds after installing the end of the pipeline into the fitting. It is strongly discouraged to rotate or displace the pipe after that. If you are not confident in your abilities, use the guides.

- When connecting a polymeric tee and the same pipe for welding, make a mark on the pipe body indicating the immersion depth. Otherwise, the tee for connecting PP or PE pipes will simply "clog" with excess plastic, which will affect the throughput of the pipeline.

- When assembling metal piping, take care of sealing the threaded ends or squeegees. Do not save on FUM and always use a locknut, before tightening it, wind up a couple of turns of the seal between the nut and the end of the tee.

Use detachable connections (threaded, collet) only in easily accessible places. When installing metal or plastic pipe tees in hard-to-reach places, give preference to welding or, in extreme cases, press fittings.