What is a Compression Fitting

Installation of pipelines made of metal-plastic cannot be done by welding or gluing; for this, the method of mechanical crimping is used. There are two types of connections - one-piece and detachable.

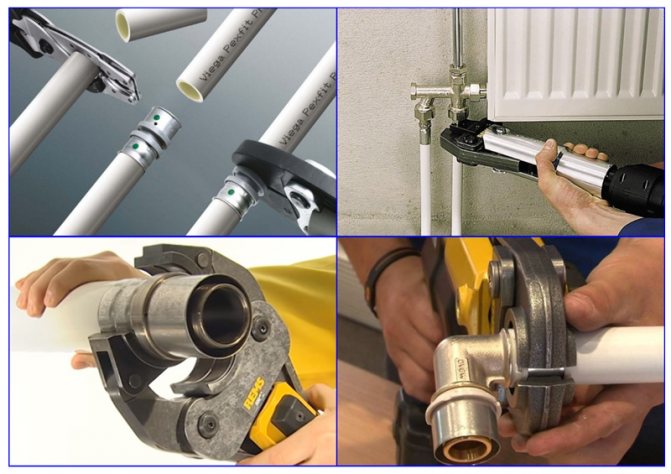

For the first type, press fittings are used. Permanent connections are made mainly in closed engineering networks, mounted under the floor or in the wall. They do not require periodic maintenance. They are carried out using a special tool called a press pliers.

Crimp, or compression, fittings are used for detachable connections, the most common today. Their execution does not require expensive tools, just a few wrenches.

Design features

Detachable connections are used, as a rule, for the installation of open pipelines, as well as for the connection of any working devices.

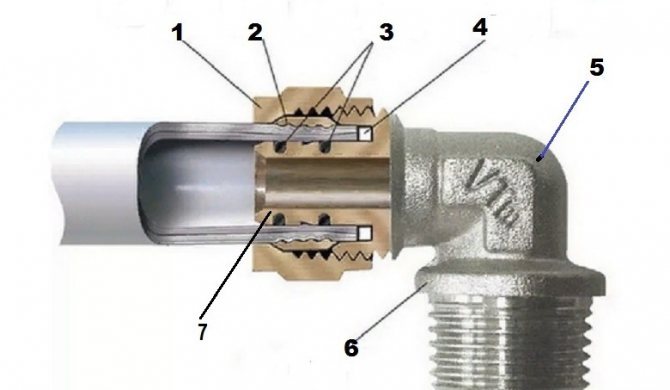

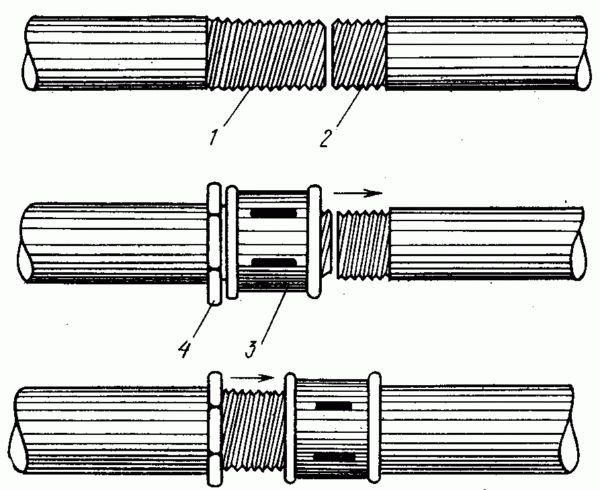

Compression fittings consist of the following parts:

- Union nut.

- Crimp ring (cracker, collet).

- O-rings made of E.P.D.M. (ethylene propylene diene rubber).

- Teflon dielectric gasket.

- Fitting body.

- Restrictive collar.

- Stock.

A suitably prepared metal-plastic pipe is put on the stock of the product. This is done all the way into the dielectric spacer, which is used to limit stray currents.

O-rings are used to enhance the tightness of the system under the influence of internal pressure. The union nut crimps the metal-plastic pipe on the rod with the help of a cracker.

The installation of crimp connectors does not require the use of expensive tools, only scissors, a calibrator, a beveller and a set of wrenches are needed. If necessary, the fittings can always be disassembled and connected to the pipes again. With proper installation and operation, compression connectors will last long enough.

The disadvantage of such parts is the need to constantly monitor their condition and periodically tighten.

Compression Fittings Prices

compression fitting

An example of a water supply system wiring

First, we draw a plan for the wiring of the water supply system. This can be done on a piece of paper, indicating the necessary fittings. Please note that for the installation of taps, a threaded end fitting must be installed. Taps are needed at outlets to household appliances and to plumbing fixtures, to heating radiators. This makes it possible to turn off the devices without overlapping the entire system. The type of thread and its size are selected depending on the type of valve used.

Also, transition fittings are needed before and after the meter (water or heating depends on the type of system). Having drawn a detailed plan, put down dimensions in all areas. According to this drawing, consider how much and what you need. Fittings can be purchased strictly according to the list, and it is advisable to take pipes with some margin. Firstly, you could make a mistake when measuring, and secondly, in the absence of experience, you can spoil some piece - cut off less than required or compress it incorrectly, etc.

Agree on the possibility of an exchange

When buying everything you need, agree with the seller that, if necessary, you can change / return some fittings. Even professionals are often mistaken with them, and even those who decided to do the wiring of the plumbing or heating system from metal-plastic with their own hands and even more so. No one will take the remains of the pipe back from you, and the fittings are easy. But keep the receipt for sure.

When and how to get started

Arriving home, lay out the fittings, proceed: the installation of metal-plastic pipes in the summer can be done immediately, in the winter you need to wait some time (12 hours) until all the elements are heated to room temperature. Cut off one piece of pipe at a time to the desired length. It's a little longer, but you won't get confused that way. Further actions depending on the selected type of fittings.

After completing the installation of metal-plastic pipes, the pipeline is checked. If it is a water supply, it is enough to open the tap at the entrance. This should be done gradually and smoothly. The system will immediately begin to fill with water. If nothing has flowed anywhere, you did everything right. If any connections are leaking, they must either be redone - if press fittings were used, or tightened - if the assembly was on crimp connectors.

If a heating system was assembled from metal-plastic pipes, it must be pressurized before starting it - tested with increased pressure by pumping cold water into the system. If the test is successful, you can do a test run of the heating.

stroychik.ru

Fittings types

During operation, pipeline systems change the direction of movement, branch out, drown out, attach some devices or change the diameter. All these tasks are solved using assembly elements. Each such detail, depending on the purpose, has its own shape.

Fittings types:

- Taps. Change the direction of travel by 45, 90 or 120 degrees.

- Couplings. Connect two pipes of the same diameter.

- Plugs. Close the dead end.

- Tees, Crossings. Used to create branches.

- Fittings. Designed for connecting a flexible hose.

Reducing couplings are used for the installation of pipelines of different diameters. Elements connecting pipe sections with the same holes are called straight lines.

Purpose

Pressing tongs are recommended for the installation of metal-plastic structures of any complexity. There are many applications:

- series connection of water and heating units;

- collector type system, when connecting and disconnecting each node is possible separately, which allows even one room to be disconnected;

- installation of "warm floors";

- combined way of joining.

Airtightness is especially important in the last three versions, when the structure, after installation, is completely mounted into a wall or floor covering. Here, the value of the pliers connecting with the pressfitting is irreplaceable.

Watch the video

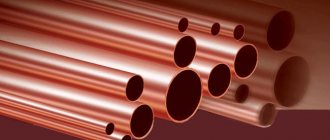

What materials are they made of

For the manufacture of assembly elements are used: cast iron, steel, copper, bronze, brass, plastic. It is believed that when installing utility networks, the materials of pipes and connecting elements must match each other.

To connect pipes made of carbon steel, cast iron and steel assemblies are used, copper - bronze and brass, polyethylene - plastic. Since metal-plastic pipelines are connected by mechanical crimping, the materials for the manufacture of parts must be plastic and durable.

Compression fittings for metal-plastic pipe products are made from:

- brass (an alloy of copper and zinc), plated with nickel or tin;

- of stainless steel.

Brass products have higher corrosion resistance, but they are also more expensive than stainless steel assemblies. The body and union nut of the assembly device are made of these materials. O-rings are made of synthetic rubber (EPDM). The crimp ring is made of stainless steel or Teflon.

When installing the collet, the outer layer of the pipeline sheath must not be damaged.

Tool functions

The water supply system is a system of pipes with numerous branches, connections.The complexity of the structure is influenced by the architecture of the building, the number of objects connected to it.

Docking of water pipes is carried out with special connecting devices - fittings. There are the following types:

- Transitional - mounted at the joints of steel and metal-plastic products;

- Collet (threaded) - used to connect cylindrical engineering structures. A crimp ring is applied to the joint, which is tightened with a nut;

- Press fittings - used when installing metal-plastic pipes. The design consists of a body with a fitting, sealing and insulating rings, a crimp sleeve.

Efficient operation of the water supply system is possible if the pipe connection is made reliably and tightly. With a threaded fitting, there is a high probability of an error, the need for constant further monitoring of the work done. Over time, the tightening of the nut weakens, it must be tightened, otherwise a leak will occur in the pipe.

A durable / reliable option for joining the elements of a metal-plastic water supply system is the use of a press fitting. Its installation is carried out with press tongs. They crimp the fitting at the junction of metal-plastic communications, to seal and seal it.

Advantages of crimping pliers:

- ability to withstand pressure up to 10 bar;

- 50-year operational period;

- no need for preventive maintenance.

Criteria for Selection of Compression Fittings

In order to buy compression fittings for metal-plastic pipes, you should go to a specialized store. When purchasing such parts, you must definitely pay attention to the presence of a quality certificate.

This document should reflect the following parameters:

- Manufacturer's warranty obligations.

- The maximum pressure and temperature for which the connectors are designed.

- Material and weight of the product.

The device markings must be clearly visible. The product should be checked for weight. If the part is too light, then another alloy was used instead of brass or steel, mainly based on aluminum.

Be sure to check online product reviews. Very often, manufacturers use cheaper raw materials, thereby reducing the cost of products, but at the same time the quality of products deteriorates. To obtain a reliable pipeline, you do not need to strive for excessive savings and always remember that high-quality products cannot be low-cost.

In practice, it has long been verified that metal-plastic pipe products and assembly elements must be from the same manufacturer. There are good reasons for this. Pipes and fittings from different manufacturers can differ in size literally by a millimeter. This is enough to reduce the reliability of the connection.

There is no common standard for all manufacturers on the shape and size of assembly elements. Each company has its own parameters for tubular products and assembly devices.

Watch a video on how to select a fitting.

Compression and self-locking type connectors

Copper pipe fittings classified as compression or self-locking are also called collet or crimp fittings. These connectors are a good alternative to fittings that are soldered to copper parts. A collet-type fitting is an element whose design consists of O-rings and gaskets, as well as a ferrule, which, when tightened, helps to achieve the tightness of the joint created. The material for the manufacture of compression or collet fittings can be not only copper, but also brass or metal-plastic.

Male Brass Collet Fitting

Collet crimp-type connectors are the best option for heating and water supply systems, for the installation of which copper pipes of different diameters or pipe products made of different materials are used. Recently, self-locking fittings are becoming more and more popular, which are distinguished by more preferable performance characteristics.

Self-locking fittings can completely replace soldering in terms of the speed of the connection and its reliability. The design of such fittings includes a whole set of rings, one of which is equipped with special teeth. The principle of operation of such connecting elements is based on the fact that when acting on a ring with teeth using a special assembly key, it is fixed in an adjacent element, thereby creating a reliable and strong connection of copper pipe sections. Unlike soldering, dismantling a connection made with such a fitting is as simple as obtaining it, using the same assembly wrench.

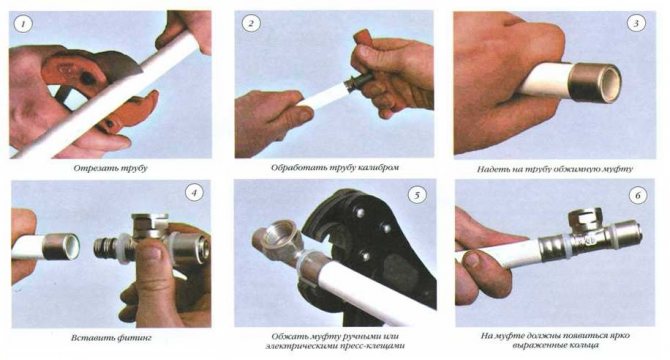

Step-by-step instructions for connecting a pipe to a fitting

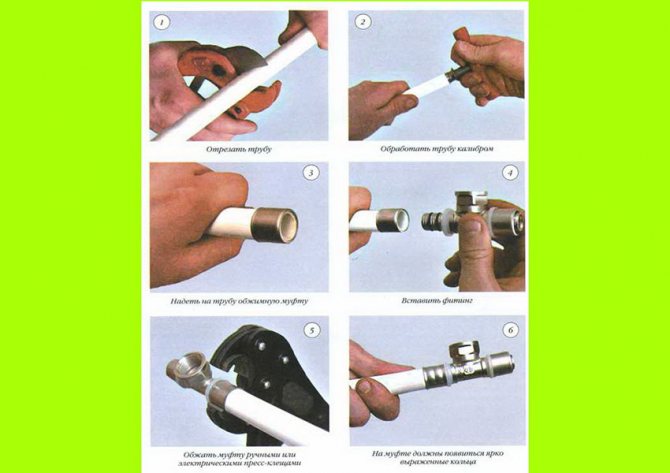

The installation of compression assembly elements can be carried out by any untrained person, subject to careful observance of the technology. To get the job done with tools, you need a pipe cutter, a calibrator, and two wrenches. Before starting the installation, it will be necessary to straighten the metal-plastic pipe.

The main stages of the work:

- Measure a section of the pipeline of the required size and cut it off with a pipe cutter or a hacksaw with fine teeth.

- Clean the cut area with a beveler or file.

- Use a calibrator to restore the ovality of the hole.

- First put the union nut on the pipe, and then the compression ring.

- Lubricate the fitting stem with silicone.

- Push the end of the pipe tightly against the dielectric ring until it stops on the stem of the connecting element.

- First screw on the union nut by hand, and then fix it by pressing with two keys.

Excessive force should be avoided when tightening the nut so as not to deform the threads or crush the O-rings. After the system is assembled, it is imperative to carry out testing by filling it with working fluid. In the event of a leak, re-tighten.

See how the pipeline is installed using collet fittings.

Connection of metal heating pipes without welding

The fastest way to connect without welding is a compression fitting. Nevertheless, we will consider other methods: threaded connection and installation of a repair and mounting clip. The latter is used both for joining and for eliminating leaks resulting from cracking of the metal.

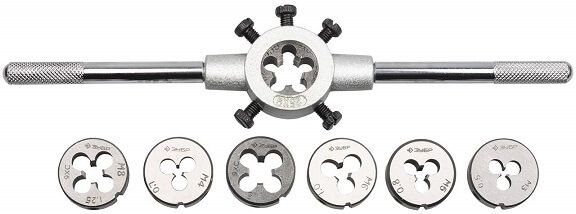

Thread

It will be possible to create a threaded connection only if there is free access to the pipe, i.e. at the stage of initial installation. In other cases, threading will be quite problematic or impossible. The procedure itself is carried out according to the following scheme:

- Remove paint and rust from the pipe. If there are metal beads after welding performed earlier, they should be cut down. The surface to be joined must be clean and smooth.

- Using a file, chamfer the end where the cut was made.

- Take a die of a suitable size, screw the handles into it. Coat the cutters with grease or lard.

Die - Place the tool on the pipe, make sure that it is strictly perpendicular.

- Perform half a turn of the die clockwise, then a quarter turn counterclockwise. Then repeat the movement until the thread is cut.

Now let's figure out how to crash into a heating pipe without welding. To do this, you will need to use a sleeve with a nut. It can have three branches to create a route. When creating a thread, it should be remembered that it should be 2 times longer on one pipe. Fastening the coupling:

- A nut is screwed onto a longer thread, then a coupling.

- A nut is screwed onto the second pipe.

- The parts are matched together, after which the coupling is twisted from the long thread and partially screwed onto the short one. The element should be approximately in the middle of the cut.

- It remains to screw the nuts on both sides, having previously wound the sealing material on the threads (fum tape, tow).

Such a connection is considered strong enough and can last more than one year.

Mounting the threaded coupling

Attention! On thin metal, threads can rot, causing rupture and risk of flooding.

Compression fittings for steel pipes

This type of connection allows heating without welding pipes and cutting threads. At the same time, experts note the high reliability of compression fittings, the production leader of which is the Gebo company. This often leads to confusion of concepts - many call these connectors after a popular manufacturer (a vivid analogy is the Xerox brand, which has become a household name for document copying works).

Compression fitting

Important! Compression fittings can only be used if the water in the heating system does not warm up above 80 degrees.

Among the advantages of this method of connection, one can single out the speed of work, and the absence of the need to use a special tool. All you need are two bladders to hold and clamp the fitting.

The method of work is as follows:

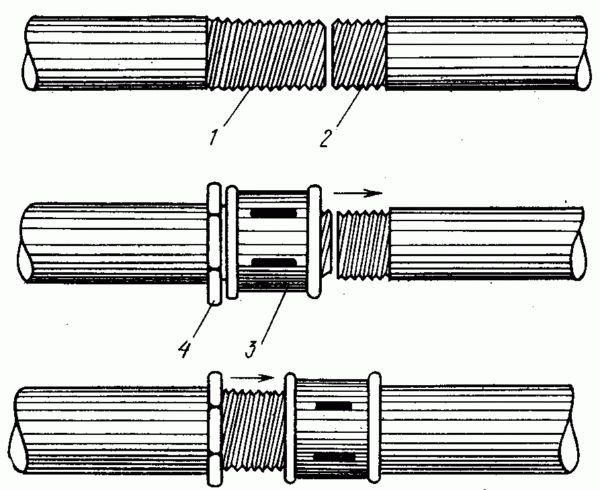

- Slide the fitting parts onto the pipe in the following sequence: nut, clamping ring, clamping ring, sealing ring.

Compression fitting installation diagram - Put on the coupling, make sure that all elements are positioned correctly and without distortions.

- Tighten the nut. One thread should remain visible. If, after supplying the coolant, a small leak appears, the nut can be tightened.

- Proceed in the same way for the other side of the fitting.

You can learn more about compression fittings by watching the video:

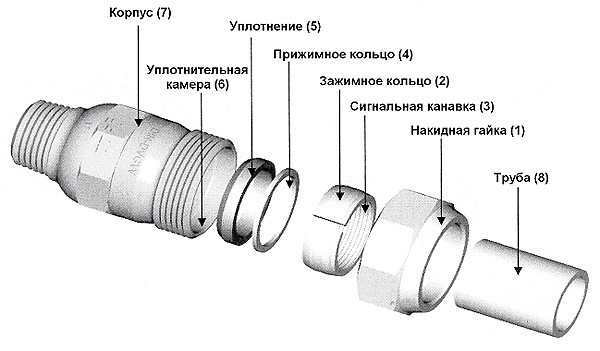

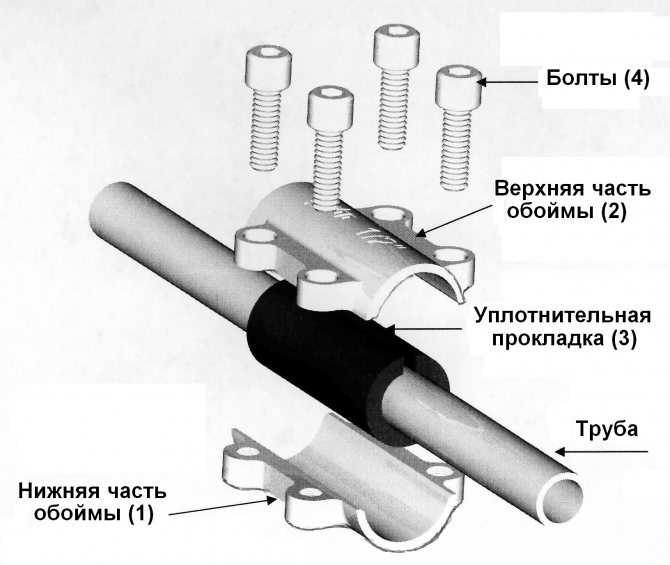

Repair and assembly clip

When operating old systems or exceeding pressure, the question often arises of how to seal the heating pipe without welding. For these purposes, a repair and assembly clip is used. It can be made in the form of a coupling or a tee. The outer part of the part is metal with clamping bolts, the inside is a rubber gasket.

Repair and assembly clip

The element is often used for emergency repair of leaks, but it can also be used as a permanent option for connecting water supply pipes. Instructions for use:

- Clean the joints of the pipe from paint and other deposits that may affect future tightness.

- Apply a rubber seal to the joint. Make sure that its cut does not hit the place where the upper and lower parts of the cage dock.

- Coat the incision with sealant and, if possible, allow some time to dry.

- Install the cage parts, fasten with bolts.

Installation diagram of the repair and assembly cage

These are all options for creating a strong connection between metal pipes without using a welding machine. Now we will describe several methods when working with metal-plastic parts.

The cost of crimp fittings from different manufacturers

The prices of compression fitting connectors depend on the type of material and weight, technical conditions, as well as on the manufacturer. Today, the market offers products from both domestic and foreign manufacturers who offer various prices for their products. The cost can also fluctuate depending on the seller and the region.

In order to choose quality products at an affordable price, you need to carefully study their parameters.The characteristics of the connecting elements and information about their cost should be looked for in the catalogs of manufacturers and sellers of sanitary products.

For comparison: parameters and prices of compression fittings for metal-plastic pipes from various manufacturers.

| Manufacturing firm | Parameters | |||||

| Material | Diameter, mm | Maximum pressure, bar | Maximum temperature, ° C | Manufacturer's warranty, years | price, rub. | |

| Valtec, Russia-Italy | Brass, stainless steel | 16–32 | 25 | 115 | 10 | from 93 |

| ProAqua, Germany | Brass, Teflon | 16–32 | 10 | 95 | 10 | from 61 |

| Uponor, Finland | Brass, polyamide | 16–25 | 10 | 95 | 10 | from 66 |

| Ape, Italy | Brass | 16–32 | 10 | 95 | 10 | from 106 |

| Rehau, Germany | Brass, stainless steel | 16–40 | 10 | 80 | 1 | from 312 |