The old metal pipelines in heat supply systems are being replaced by products made from more practical and convenient materials. The most popular today are metal-plastic, polyethylene and polypropylene pipes with brass and bronze connecting elements.

Reinforced-plastic pipes for heating are characterized by excellent hygienic, hydraulic and temperature qualities. They excel in heating and water supply functions.

Composition and production

For household use, products are manufactured in accordance with GOST R 53630-2009.

The standard is intended for the manufacture of pressure multilayer pipes with a circular cross-section, which are intended for the transportation of water, including drinking water, and for the installation of water supply and heat supply.

MPT consists of several layers of plastic, metal and special glue:

- layer - inner, is in constant contact with liquid, plastic;

- adhesive layer;

- barrier layer, thin rolled aluminum or fiberglass;

- adhesive layer;

- layer - outer, exposed to environmental influences, plastic.

The adhesive composition consists of composites based on thermoplastic polymers with adhesion to layers and a melting point of 120 degrees. Plastic components for the inner layer produced on the basis of the following polymers:

- cross-linked polyethylene, with a strength of 8 MPa (which tool you need to buy for installing pipes);

- polyethylene with increased heat resistance and strength from 8 MPa;

- polypropylene with a strength of 8 MPa;

- polybutene with a strength of 12.5 MPa.

Do you know the installation height of the heated towel rail? Instructions on how to equip a bathroom with a year-round coolant are posted in a useful article.

About polypropylene or cross-linked polyethylene for heating is written on this page.

The metal layer is made of thin aluminum or fiberglass tape. The outer layer is made of polymers with low oxygen permeability.

The production of MPT is a complex high-tech process.

The molten polymers are uniformly fed into the molding mechanisms, where the layers are glued together. At the same time, pipes are molded along the outer and inner diameters.

At the exit, the product enters the cooling tanks, after which it is cut or wound into coils.

Application of polymers and metal made it possible to use the advantages of each material, achieving the combination of useful characteristics from the pipes.

Polymer layers protect the reinforcing aluminum layer from corrosive processes. Metal makes products flexible, increasing fracture toughness.

Thanks to this combination, the pipes can withstand the temperature of hot water without changing their technical characteristics (read about the use of cold welding for pipes under pressure in this article).

Characteristics and technical description

Tubular products have not only technical characteristics, but also operational characteristics.

By purchasing metal-plastic products, are determined with a choice for all characteristics.

Some technical details can tell a lot about plumbing pipes, but are incomprehensible to the average person.

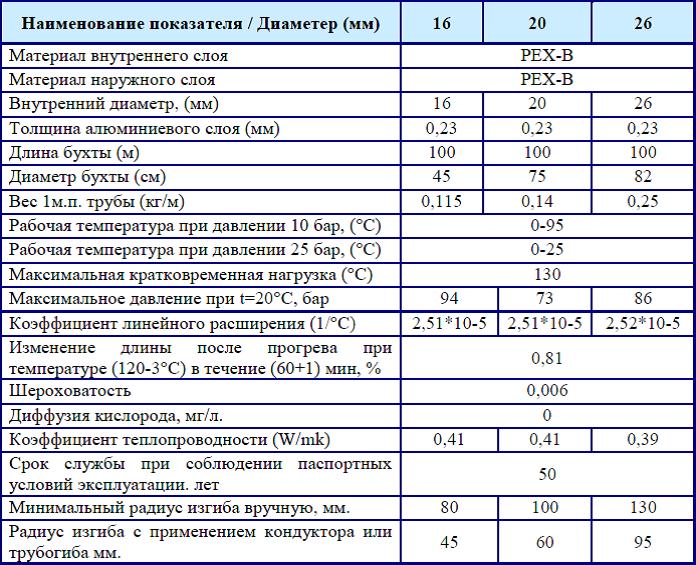

When choosing MPT, they are guided by the following technical parameters:

- external diameter, products with an indicator from 16 to 63 millimeters are produced;

- Wall thickness, produce pipes with a thickness of 2 and 3 millimeters;

- reinforcing layer thickness, depending on the purpose, is 0.19-0.3 millimeters;

- weight depends on length and diameter (find out about the weight of a steel, galvanized pipe on this page);

- operating pressure - up to 10 bar for hot water, up to 25 bar for cold water;

- short-term temperature impact up to 110 degrees.

You can choose MPT for a water supply system based on operational data.

They do not give numerical characteristics, but reflect the reaction of the material and product to certain influences.

The main performance characteristics are:

- no harmful effects on the environment;

- rust, scale, mineral deposits do not form on pipes;

- products restore their shape after bending;

- plasticity will allow you to bypass the elements of the premises and save on stainless steel fittings (described here);

- installation is in progress without the use of special tools (compression fittings);

- no waste after assembly;

- smooth inner surface facilitates water flow;

- MPT compatible with pipes from other materials;

- resistant to condensation and freezing;

- the composition of the water remains unchanged;

- used for re-assembly;

- do not require external paint coating.

What do you know about XLPE pipe fittings? Read on for a helpful article on how to mount innovative products.

What the diameters of ceramic pipes can be is written here.

On the page: it is written what is the name of the cable for cleaning the sewer.

The positive qualities of MPT are due to the design features and materials used.

The combination of the strength of metal and the flexibility of plastic makes the pipe plastic, with the ability to restore its original shape.

Rules for choosing metal-plastic pipes for heating

To prevent the network circuit from flowing in 2-3 years due to a violation of manufacturing technology, you need to choose the right materials.

The main nuances:

- Buy only from a reliable manufacturer who can give quality certificates. Counterfeiting such pipes is difficult, but possible. Reliable manufacturers always certify the goods, and if there are no documents, this is an obvious fake or a factory defect.

- Check the pipeline visually. There should be no defects in the form of chips, violation of the integrity of the plastic layer. The texture is smooth, without burrs, the diameter coincides with the size indicated in the technical data sheet of the products.

- If the letters of the marking are applied with errors, this is a fake.

- Inspect the cut - it will instantly identify counterfeit. Factory pipes show butt welding of aluminum, if the seam is overlapped, the quality is poor, as with different thicknesses of aluminum foil.

Important! For pipes of special shapes, you need to know the thickness of the external polymer spraying layer, be sure to check the compliance.

Disadvantages of MPT

Right choice takes into account both the negative aspects of operation and installation of pipe metal-plastic products.

There are few of them:

- concealed installation does not allow use collapsible connections;

- the polymers included in the pipes are destroyed by prolonged exposure to ultraviolet radiation;

- with prolonged exposure to low temperatures on a cold water supply system, pipes burst. Insulating materials must be used.

Pipes are delivered in coils... The length of the bay is 50-200 meters. When sold, products are cut by meter.

A leak appeared - minor repair

If after some time the pipe began to leak a little, do not panic - everything can be easily corrected. The pipes are monolithic, and only with mechanical damage can they become unusable, so pay attention to the connections. Find out the cause of the leak:

- If a section of the pipe is damaged, it can be easily replaced without damaging the entire water supply. There is another, simpler way.We pull a rubber rectangle - a bandage - over the leak, and fix it with a clamp.

- If the leak is small and only drops are leaking out, use a septic or epoxy adhesive - this is a temporary repair.

- If the connection is loose, just tighten it with a key.

- If a fitting bursts, replace it with a new one.

- Rubber seals could be damaged.

For the heating system, products are usually used with non-food polyethylene inside, and with technical plastic. Their cost is several times lower than usual, which captivates consumers. But the course of working with them is a little different. Special press fitting equipment will be required. It is very expensive, it is not advisable to buy such a machine for the sake of laying several pipes. Can be borrowed or rented. In many cities, the rental of tools and construction equipment is practiced.

The service life of metal-plastic heating pipes is more than 50 years. That is why this type of system is very common. To do everything with your own hands you will need:

- Bending spring, scissors;

- Calibrator;

- Press;

- Spanners.

We start by measuring. You can draw a heating wiring diagram on paper, so it will be easier to calculate the required amount of material.

- Cut off the desired piece with scissors for cutting metal;

- Calibrate the pipe making the edges even. You can use a file;

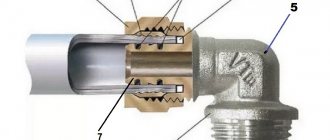

- Install the O-ring on the fitting;

- Pull the nut and clamping clamp onto the pipe;

- Armed with a calibrator, flare the end of the branch and put it on the fitting;

- We align and clamp the clamp;

- We tighten the nut, not strongly, hearing a crack, it is clear that the nut has pressed the clamp. This is done using a manual or electric press, the connection is reliable and of high quality;

- We are testing the system, the pressure is one and a half times higher.

Areas of use

The spread of metal-plastic pipe products is explained by a range of technical features:

- internal cold and hot water supply;

- space heating (how to remove air from the system in a private house);

- floor heating structures, playgrounds, swimming pools;

- movement of liquids and gases, including chemically active ones, in enterprises and in agriculture;

- compressed air supply;

- air conditioning pipelines;

- protective frame for electricians;

- production of ships and wagons;

- water supply for irrigation, irrigation measures, drainage of water from water pumps.

Such a pipe replaces plastic and alloy products.... The reason is the long service life.

Operating rules

During installation and operation, the technical and operational characteristics of metal-plastic pipes are taken into account.

This made it possible to reduce the harmful effects for products and use the pipeline for the prescribed period.

- In places where the pipeline is laid there should be no mechanical and high-temperature effects on the pipes.

Direct exposure to ultraviolet rays is excluded.The pipes are mounted on holders, which are located at a distance of 50 centimeters from each other.

The holes in the walls are equipped with sleeves through which the pipes are mounted.

- Heating installation determines the service life of MPT... In a private house, a two-pipe system with a collector is used.

The use of "Leningrad" is undesirable.With a small number of branches, a tee is used.

- Operating pressureexceeding 10 bar destroys the pipeline structure.

In your home, where the pressure does not exceed 7-8 bar, the pipes are operated normally.In apartment buildings, at the time of pressure testing, the pressure rises to 25 bar.

In such systems, a pressure reducer is installed.

- Polymers and metal have different coefficients of expansion when exposed to heat.

Pipes that are used to supply cold water cannot transport hot water.In this case, stratification of the product begins, leaks appear.

During installation, use connecting elements made of appropriate materials.

Hot and cold pipelines passing nearby are not closer than 30 centimeters.

- Installation of structures made of MPT is carried out at an ambient temperature of at least plus ten degrees.

IMPORTANT! Do not use metal-plastic pipes for installing underfloor heating in a cold room.

Outdoor use of MPT and outbuildings are recommended only in warm weather. For the winter period, water from such pipelines is drained.

The service life of half a century and the ratio of price and quality allow metal-plastic pipes to successfully replace products from other materials.

In what condition are the metal-plastic pipes after 7 years of operation, see the proposed video.

Subscribe to updates by E-Mail:

Reliability

Reinforced-plastic pipes are able to withstand a constant operating temperature of 95º, a short-term temperature of 110º.

Reinforced-plastic pipes can withstand a pressure of 10 bar, at an operating temperature of the transported substances of 95º; pressure of 25 bar, at a working temperature of the transported substances of 25º.

Reinforced-plastic pipes can be used when installing closed-type systems, i.e. brick up, but subject to access to the detachable elements of the pipeline. For example, it is possible to install a system of "warm floors" from metal-plastic pipes under a concrete screed.

The connection of metal-plastic pipes is carried out only by means of compression or press fittings.