- Types of sewer pipes and their features

- Connection angle

- Preparing for the process

- We work with plastic pipes: the "in the socket" method

- How to join with an adhesive base or a weld

- How to connect a toilet

- Working with cast iron and ceramic pipes

- We connect a new toilet to a cast iron pipe

Sooner or later, any owner will have to replace the pipes. Since the procedure requires considerable costs, in order to save money, it can be carried out without the involvement of hired workers. But for this you need to know how to connect the sewer pipes.

Since types of pipes made of various materials are used in construction, in order to choose the correct connection method, it is necessary to take into account which of them the product belongs to.

Types of sewer pipes and their features

When installing, you need to take into account all the properties of the selected material in order to correctly choose the method of fastening and calculate your strength.

In modern construction, the following types are most common:

- Metallic. The most commonly used metals are steel or cast iron. The first option has a number of advantages, it is durable and is able to withstand rather high temperatures. Despite this, due to its increased tendency to corrosion, it is used less and less.

But cast iron is not inferior to positions. Being more expensive than steel products, cast iron pipes are undoubtedly better in service. Their ability to resist corrosion combined with their long service life is highly valued. But when assembling, you need to consider:

- installation is very difficult to do with your own hands;

- a large mass creates a lot of difficulties in work;

- the price category makes the purchase costly.

Ceramic pipes for sewerage

- Ceramic. Such materials are used in a wide variety of areas, including sewerage. Such products are mounted according to the same principle as the previous ones, but the lower weight makes it easier to carry out the work.

- Plastic. PVC products are quite versatile, since they have the following properties:

- strength;

- ease of installation work;

- affordable price category.

Products made from propylene have great advantages and increased strength, therefore it is preferable to use them. In addition, at home, the easiest way is to assemble the desired structure using a similar material.

What are plastic pipes

This is a generalized concept that contains polymer pipes, consisting of the following components:

- polyvinyl chloride,

- polyethylene,

- polybutylene,

- polypropylene.

The main property of these materials is the ability to become soft when heated to high temperatures, and then, when cooled, recreate their configuration and functionality.

Many inhabitants prefer plastic pipes when laying sewers.

Metal products are used much less often.

The performance characteristics and the unique properties of the material allowed these products to take a leading position in the market in terms of sales.

The indisputable advantage of the plastic pipeline:

- It is not corrosive. When laying pipes in the ground, no insulation work is required.

- Not susceptible to the harmful effects of chemical substances and environments that have a destructive effect.

- Moderate weight.

- High throughput of the structure, which is achieved due to the smooth surface from the inside of the product.

- Ease of installation... Through the use of fittings, you can create a pipeline of various configurations.

- Resistance to mechanical influences.

- Flawless pliability of the material.

- Long service life and the safe operation of the system for many years.

What do you know about deep well pumps? Their operating conditions, varieties and applications are described in a useful article.

Read about the electric hot water boiler here.

On the page: read about a children's outdoor plastic pool for a summer residence.

With all the above advantages, plastic has some disadvantages:

- thermoplastic materials are afraid of high temperatures and they have a rigid framework for the allowable working pressure.

Connection angle

Regardless of which option you prefer, some of the preparation steps will remain the same. First of all, keep in mind that it is recommended to lay the sewage system not in one horizontal line, but with a slight angle of inclination. So it will function better, therefore it is necessary that the angle of inclination of the installed system is at least 0.02.

If the amount of available wastewater is small, this indicator needs to be increased to 0.03. Basically, this means that for every meter, the difference between the level of the ends should be exactly 3 cm.But make sure not to make a too large angle, otherwise the water will drain, leaving dirt.

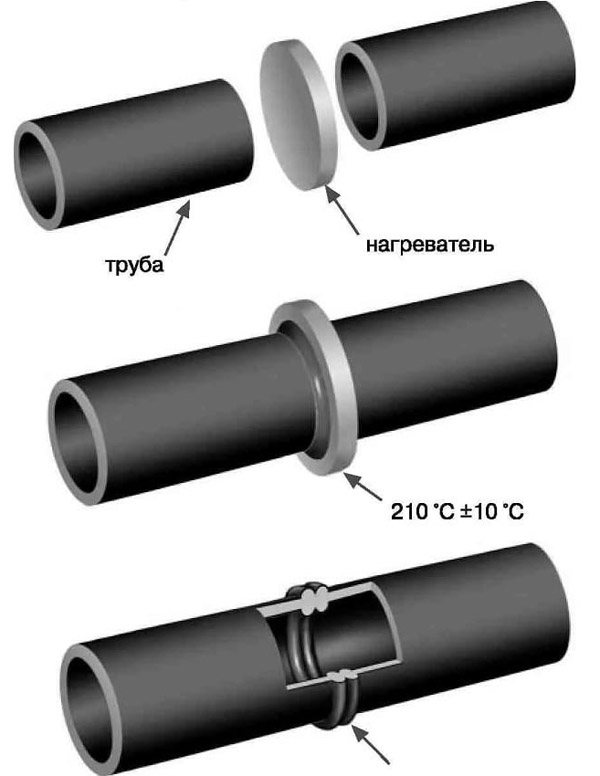

Features of the connection of polypropylene pipes

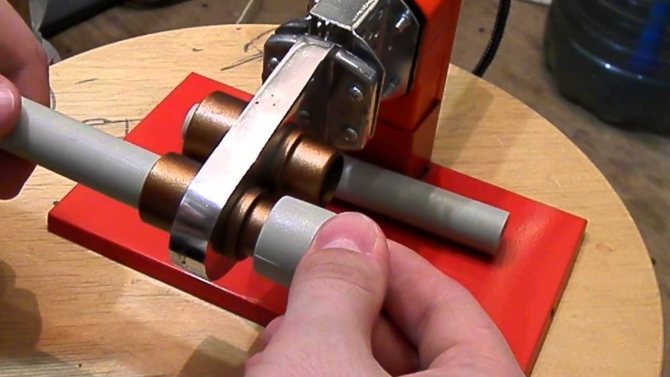

With our own hands, pipes with a diameter of up to 6.3 cm are mainly connected by a socket method or by socket welding. For pipes of large diameters, it is recommended to use butt welding. Welding of polypropylene pipes up to 4 cm in diameter can be carried out with a manual welding machine, more than 4 cm - with a device with a centering device. The heating element (nozzle) is a sleeve and mandrel, which melt the outer surface of the pipe and the inner part of the bell.

Polypropylene pipes are securely connected by hot welding

Standard Teflon nozzles have a diameter of 16-40 mm and are cleaned after each welding.

Important! The cold nozzle must not be cleaned of the plastic layer.

The welding machine with the necessary attachments is installed on a flat surface and fixed. Welding temperature of polypropylene pipes is about 260 degrees. Socket welding is performed in the following sequence:

- the pipe is cut at a right angle;

- the socket of the fitting and the end of the pipe are cleaned of dust and dirt;

- a mark is applied to the pipe at a distance of 2 mm more than the socket depth;

- a pipe is inserted into the sleeve, and a bell is put on the mandrel;

- withstand the required heating time, remove the parts and dock them.

Polypropylene pipes can be connected using compression fittings. No special equipment is required for installation.

Compression fittings are also an acceptable option for connecting PP pipes.

Preparing for the process

Before proceeding directly to the installation, pay attention to some of the nuances that the technology requires:

Sewage pipe

- make sure to purchase a sufficient amount of materials and related products;

- make a plan according to which you will place the sewer system;

- mark up and start cutting;

- the places where the cuts were made should be cleaned in order to facilitate further work, so clean them from burrs.

Get serious about making a plan, mistakes made will be difficult, and sometimes almost impossible to fix. Do not forget that in private construction and in multi-storey buildings, products of 50 or 110 mm Ø are usually used.At the same time, it is worth taking into account how much equipment you intend to connect.

Coupling connection

The design of a conventional coupling consists of a cast iron body, a pair of nuts, rubber gaskets, and four washers. When buying, you need to pay attention to its compliance with the diameters of the connected plastic pipes. For joining, pipes are inserted inward until the ends touch in the middle of the coupling, passing through washers and gaskets. Tighten the nuts just enough to compress the gaskets.

The tightness of the pipe connection with the coupling is one hundred percent, however, when they are laid close to the wall or floor, this method is unacceptable. Then the clamping couplings come to the rescue. Before joining, the end of the plastic pipe is cleaned and the coupling is unscrewed. Fasteners are put on the prepared place in the correct order. The sealing ring is placed at a distance of at least 10 mm from the end.

The clamping sleeve is inserted inside the plastic pipe and the previously worn parts are moved to it, the bolt is tightened. The degree of clamping is checked by light twitching of the body, if it is fed, continue pulling. A fitting with a union nut is screwed onto the thread on the opposite side, installed in the next section.

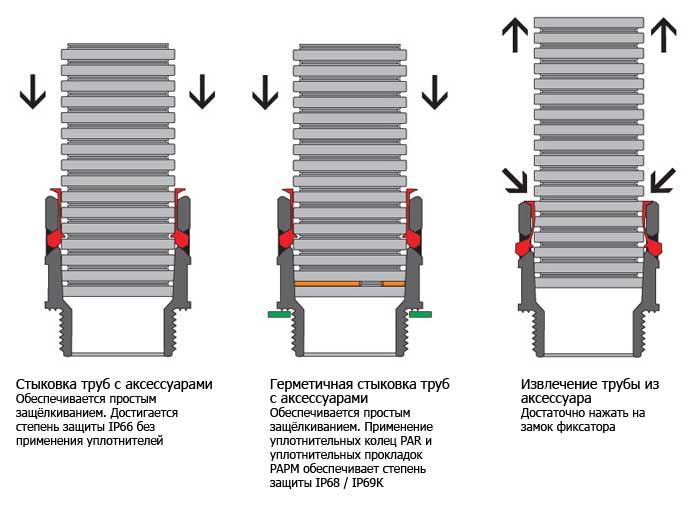

We work with plastic pipes: the "in the socket" method

If you are thinking about how to connect sewer plastic pipes, several methods will come in handy. The process is easy enough due to the properties of the material, but there are many ways to make connections.

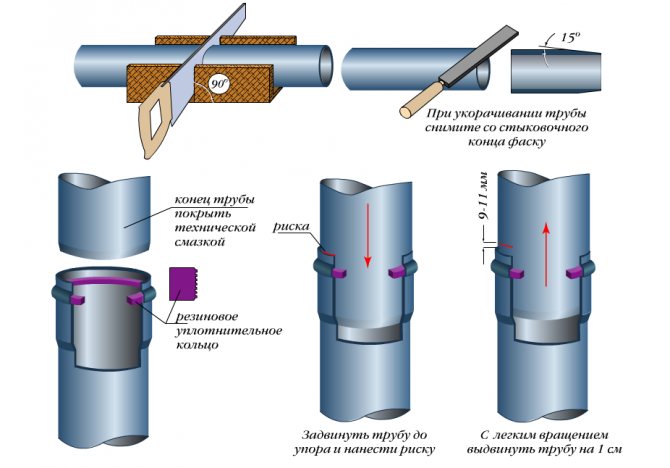

One of them is the flared version. A similar principle is used in children's construction sets. So you can easily assemble almost any equipment. The following instruction will come in handy:

- Clean both the bell end and the spigot end.

- Check for the presence of the seal. This rubber product is designed to ensure tightness.

- Take silicone grease. She needs to spread the smooth part.

- Insert the corresponding part into the socket.

Installation of a plastic pipe for sewage

- Make a mark to mark the injection level.

- Pull the pipe back and slide it out about 1 cm, making sure it goes through the existing seal.

Consider the direction of the future flow, the socket should be located along its course. This method is suitable only for the installation of certain networks, namely gravity.

Pay attention that there are no defects on the surfaces. Sometimes products have deep, large scratches that need to be carefully sanded down with a knife. If you are making a connection to a fitting, there is a possibility that it will have large solder seams. They also need to be removed, otherwise the connection will definitely be loose.

The hot method is sometimes used. For example, there is no socket on your material, and you need to make a connection. In this case, you can use a soldering machine and heat up the desired area by gently twisting it. Then connect the pipes in a smooth motion. Sometimes a construction hair dryer is also used. True, this method should not be used when you are mounting the system horizontally.

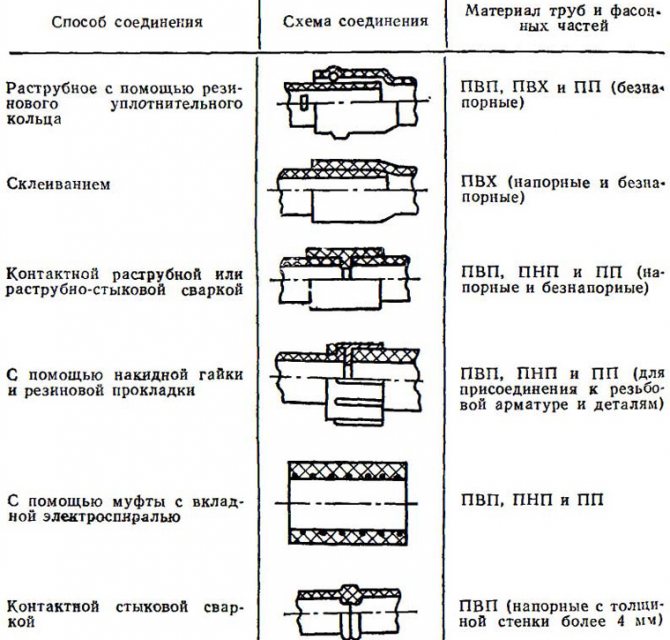

Connection types

When assembling the pipeline, detachable and one-piece assemblies can be performed.

Non-removable connections

When laying a section of a pipeline in ceilings, walls, floors and foundations, the nodes must be as reliable as possible, therefore they are made one-piece.

The following connections are one-piece:

- Butt-welded or shapeless. The ends of the pipes are heated to a temperature close to the melting point and pressed against each other. In this case, a burr forms along the seam - an influx of softened plastic outside and inside the pipe. Burr reduces the throughput of the knot, but removing it reduces the strength of the resulting joint.Therefore, butt welding is used only for mating products with an inner diameter of more than 50 mm, so that the formed burr does not significantly affect the throughput of the pipeline. To perform butt welding, special tools are required: a facing tool that ensures the accuracy of the joining, and a welding mirror for uniform and equal heating of the pipe ends.

- Electrofusion... This method also consists in soldering pipes, but using a special welded fitting - electrofusion. An electric welding machine and a coupling made of the same type of plastic as the pipes are used. On its inner surface, a heating element is laid in a spiral, the terminals from which are brought out. The coupling is put on the ends of the pipes to be connected and connected to the welding machine, when turned on, the heating element heats up the coupling itself and the nozzles of the pipeline parts to be connected. The plastic elements are welded together to form a strong, burr-free joint inside the assembly.

- Glue... In this way, pipes of different diameters or of the same diameter are connected, but with sockets. Silicone or other waterproof sealant is used. On the outer surface of the thinner pipe and the inner surface of the wider one, a thin layer of glue is evenly applied. The width of the adhesive is approximately the same as the diameter of the larger pipe or the depth of the socket. Then insert the smaller of the abutting elements into the larger one, rotate one of them relative to the other by about ¼ of a circle and hold it stationary for a minute. Apply another thick strip of sealant along the joint and allow it to harden. The resulting connection is reliable and does not require any special skills and tools. The only limitation is the difference in the diameter of the products to be joined - it should be no more than 1 cm.

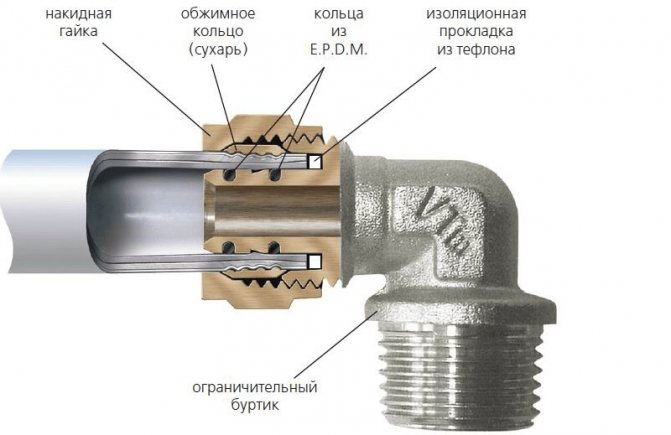

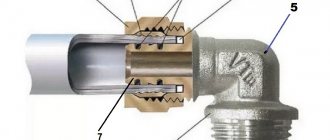

- Crimping... For connection, crimping pliers and a press fitting are used - a set of a fitting with a smooth or ribbed fitting and a ferrule. Typically, this method is used to mate plastic with metal, since the second branch pipe of the shaped element is threaded. The ring is put on the pipe and moves along it to the side, a fitting is inserted into the end. Then the ring is pulled in the opposite direction until it stops and tightened with pliers. The polymer squeezed during pressing tends to restore its previous shape and occupies all the available space between the parts of the press fitting: it tightly wraps around the nipple and fills the gaps in the ring.

Note! The crimping method is suitable only for soft polymer pipes with plasticizers that can recover their shape after slight deformation. For unplasticized polyvinyl chloride, the method is not applicable.

Dismountable connections

In areas that remain accessible for maintenance, repair and replacement, connections are usually made detachable, these include:

- Compression... The principle of connection is similar to crimping, but the nipple of the fitting used is threaded, and a crimp nut is used instead of a ring. Compression plastic products can be connected both to each other and to parts made of metal alloys.

- Threaded... Shaped elements are threaded and for their use the branch pipes of the connected parts of the pipe network must also have a thread. For joining plastic pipes, threaded fittings are used in combination with pressure or compression fittings.

- Socket with a seal. The simplest and cheapest method, similar to glue joint, but instead of glue, a sealing element is inserted into the socket of one pipe: a silicone or rubber ring when joining polymer products, a corrugated rubber adapter when joining pipes from different materials, chasing - oiled natural threads - when forming a knot from cast iron. If necessary, the sealed unit is additionally reinforced with a waterproof sealant.The assembly turns out to be conditionally collapsible, since the seals are disposable and will have to be changed when the assembly is re-mated.

- Flanged... This method is used to connect large-sized pipes, but is almost never used for the installation of domestic sewers, since it is complicated in execution, and the resulting unit is unaesthetic, has a large weight and size. At the ends of the fittings used there are flanges - transverse round or square platforms with holes for bolts. The flanges of the parts to be joined are aligned and bolted together. The difficulty lies in the fact that the bolts must be tightened equally along the entire perimeter of the flange, otherwise the unit will not be sealed. Metal pipes with high throughput often have their own flanges at the ends, but polymer products do not have fastening pads. Therefore, for docking, adapters are used, consisting of a flange platform and a fitting, which is inserted into a polymer part.

Note! Any type of connection will be reliable only if two requirements are met: the contacting surfaces must be clean, smooth and degreased, and the cuts must be even, without distortions, waves and burrs.

How to join with an adhesive base or a weld

It is easy to make such an installation if you use the glue intended for this. Clean the surfaces to be connected in the same way, not forgetting to degrease. After that, apply glue, connect the pipes and hold for about 1 minute. This period of time will be enough for the glue used to set.

In conclusion, achieve complete tightness by applying an additional layer of glue for this purpose so that it covers your joint and forms a small bead on it.

Connection of plastic pipes

The weld seam method is often used. If you doubt how to connect PVC sewer pipes, but at the same time you have an apparatus that allows you to carry out welding work on such a material as plastic, the following method will come in handy:

- heat the ends until you notice that the ends are gradually melting (this usually takes a few seconds);

- press the ends and fix them in the desired position until the plastic is sufficiently cooled and set.

You will get the strongest connection, which, if done correctly, will be monolithic.

It should be noted that the purchase or rental of such a device is justified when you are constantly doing such work. In the case when you have to carry out only installation in your own apartment, it is better to give preference to fittings. Do not forget to also use rubber gaskets, and optionally - silicone.

Sewerage from cast iron and PVC pipes - let's connect everything!

Not all high-rise buildings and residential buildings have old cast-iron pipes replaced with plastic ones. In such situations, measures to create a high-quality sewage system become more complicated. The connection of cast iron pipes is made according to one and only method - socket. The technology for its implementation is identical to the operations performed during the assembly of PVC structures. You strip the ends of the pipes, insert the smooth end into the socket, and then proceed to seal the resulting joint. This is where the peculiarity lies. Products are pressed (minted) not with sealing rings, but with special ropes (oiled) made of organic fibers.

Connection of cast iron and PVC pipes

Sealing joints in such situations is carried out as follows:

- Insert the end of the cast-iron pipe into the socket, center it with metal or wooden stops. They should be driven directly into the gap between the tubing.

- Twist one turn of the rope around the joint and push the fibers into it. They are required to submerge approximately 75% of the socket depth.

- Make another turn of the cord.Repeat the procedure for deepening it into the socket.

- Then, one by one, wind the remaining turns according to the described scheme until the rope is on the joint surface.

The final work on sealing the connection of cast iron products is the application of a cement patch over the pressed fibers. Instead of cement, it is allowed to use a silicone-based sealant or bitumen mastic. The resulting connection will delight you with high reliability. True, after a while, the procedure for sealing the joint may have to be repeated. The socket method can also be used to connect PVC pipes with cast iron products. To do this, you need a special rubber adapter (cuff). You will need to first clean the cast-iron socket well from dirt.

Then seal the outside of the adapter with silicone sealant. Now you need to carefully place the cuff into the socket, and then insert a new plastic pipe into the adapter.

In cases where a cast iron product does not have a socket, the technology for connecting a plastic pipe to it will be slightly different. You need to cut off a piece of cast iron pipe with a grinder. It is very important here to perform the operation so that the edge of the cut product is as even and smooth as possible. After that, you need to pull the rubber adapter onto the cast-iron pipe. Be sure to seal the edges of the latter with a sealant. Now you put one more adapter on the mounted structure. This element is already made of plastic. It also needs to be covered with a layer of sealant. And then boldly insert the PVC product into the adapter and enjoy the tightness of the resulting connection of two pipes made of completely different materials.

How to connect a toilet

During the installation of PVC pipes, difficulties often arise when it becomes necessary to connect the toilet. In fact, you can do it yourself without the help of a pro.

First of all, the location of the drain should be noted. In the case when you are making a replacement, it is preferable to choose the same type of plumbing, but there is no guarantee that you will be able to easily get into the drain pipe. A cuff will help to cope with the problem: corrugated or eccentric. It is very simple to make the connection, since the cuff is essentially 2 nozzles with centers that are offset relative to each other.

Methods for connecting plastic water pipes, depending on the material of manufacture

To independently install a water supply system from plastic pipes, you do not need a lot of knowledge and experience, since this process is not difficult. However, in order to improve the quality of the work performed, it is necessary to familiarize yourself with the technology and some of the nuances of connecting pipe elements of this type. It is also important to learn a few lessons describing how to connect different types of plastic pipe and the main points of this process.

Methods for connecting plastic pipes

Firstly, it is worth noting that plastic pipes include products made of the following materials:

Each material has certain properties, therefore, the connection of products is performed in different ways, including soldering polypropylene pipes without a soldering iron (about

Work with cast iron and ceramic pipes

Since the methods of working with these types of pipes are not very different, it is reasonable to study them together.

It is not as easy to carry out such work as in the previous case, but sometimes it is preferable to opt for this material. For example, if you do not plan to completely replace the system, it is not always possible to connect a PVC product to old pipes made of metal.

Such pipes are also equipped with sockets, so they are simply inserted into each other. The junction is loose, and the gaps should be eliminated using ordinary tow.After that, you should use any waterproofing agent: silicone sealant, mastic or cement.

Most often, it is cement that is used, due to its cheapness. It is preferable to take a building material marked 400. To prevent cracking at the joint, you need to wet a rag and tie it over your joint, and then moisten. Since the cement, while drying, absorbs liquid, a similar procedure is necessary.

Connection of polyethylene pipes

The most reliable ways to connect polyethylene pipes with your own hands are butt and thermistor welding. Non-pressure structures can be glued together. For butt welding, the ends of the pipes to be joined are installed in the centralizer of the machine. The ends are fixed, leveled, cleaned and machined with a facing tool.

Further, the surfaces to be joined are heated with a special tool, which is removed after the surfaces to be welded are melted. The connection is formed by closing the ends of the plastic pipes with the required force. The contact pressure gradually increases to the required value. For some time, the joint cools down and the joint is ready for use.

Butt welding is applicable for pipes with a diameter greater than 63 mm. Polyethylene pipes can be connected using a coupling with embedded electrically heated elements. Such a joint is designed for a pressure of 16 atm.

One of the methods of installing polyethylene pipes is butt welding

Detachable joints of polyethylene pipes of small diameter (up to 50 mm) can be obtained using fittings. The push-in crimp connection is designed for a pressure of 25 atm. Thanks to the rubber sealing ring, the joint is sealed, and the plunging of the teeth of the plastic sleeve into the pipe is resistant to mechanical stress.

We connect a new toilet to a cast iron pipe

All details of the process will depend on how the drains are displayed:

- Vertical release. Installation is elementary, the main difficulties are in choosing a toilet model suitable for your conditions. The connection must be carefully sealed to prevent the spread of odor. For this purpose, it is optimal to use a rubber cuff.

- Horizontal release. For the most part, a similar design is found in imported toilet bowls. It is most appropriate to purchase these models in case of complete replacement of systems or their installation "from scratch". The connection is not difficult - you only need a corrugated hose.

- Oblique release

In this case, the outlet pipe of the toilet to be connected is connected to the inlet pipe. Pay particular attention to sealing and sealing.

Having carefully studied the nuances, you will learn how to properly connect sewer pipes made of various materials. Since their installation will not be difficult, even not the most experienced home craftsman will master it, which will significantly reduce the upcoming costs.