Step-by-step instructions for connecting bimetallic heating radiators

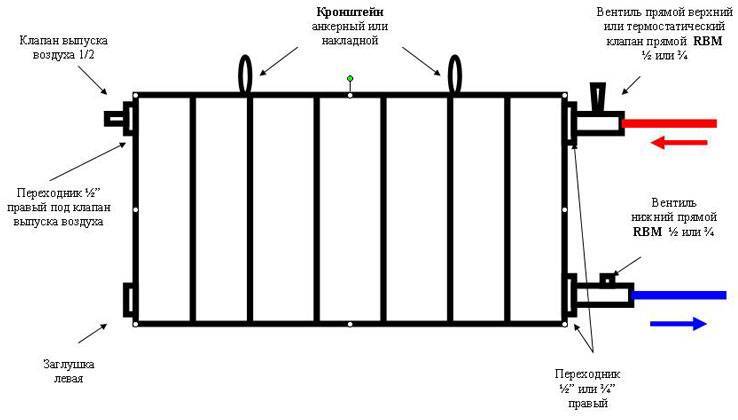

First of all, you need to calculate the diameter of the supply pipes and order a mounting kit of the appropriate size. Be sure to check the presence of the elements required to connect the radiators of your choice. For this you will need:

- air vent valve;

- 2 adapters;

- adapter for Mayevsky valve;

- bung;

- brackets;

- gaskets for the plug and adapter.

Before connecting bimetallic radiators, it is necessary to properly prepare the container. To do this, turn off the water and drain its residues from the heating system. Dismantle the old battery, while it is necessary to loosen the threaded connections of the outlet and supply pipes.

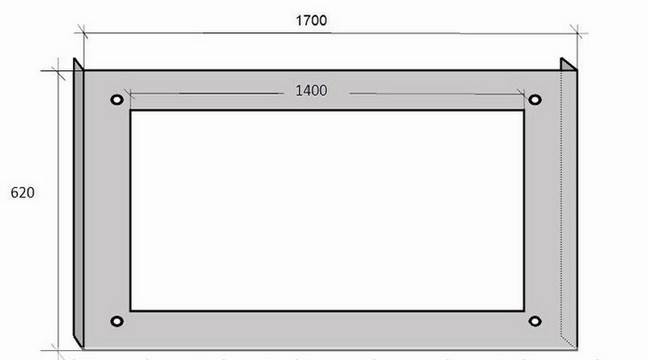

Drawing of a screen for a bimetallic radiator.

Mark the locations of the mounts. To do this, you must attach the heating radiator to the pipe connections. Check levelness with a building level. Next, mark the mounting holes with a pencil. For this it is necessary to attach the fasteners to the place of their installation.

In the previously marked places, it is necessary to make holes of the corresponding diameter. For this, a puncher is used. Fasteners are fixed with dowels. Consider the fact that for 8 or fewer sections of a bimetallic radiator, 3 fasteners are enough. If there are more sections, you need to use 4 fasteners.

Install the battery on the prepared mounts. It must be installed so that the horizontal collector is on the hooks. In addition, you should be aware that the main feature of connecting bimetallic batteries is that the heating unit should, as already mentioned, be stored in the package until it is fully installed and a performance test is performed.

Install the Mayevsky valve, which should be included in the delivery kit, on any battery. Always use a torque wrench when tightening the valve. This will allow you to stay within the allowable voltage. Install thermostatic and shut-off valves.

Finally, bimetallic radiators are connected to heat transfer heating systems. It is forbidden to clean the surfaces to be connected with emery paper or a file, because this can lead to leaks.

Connection types

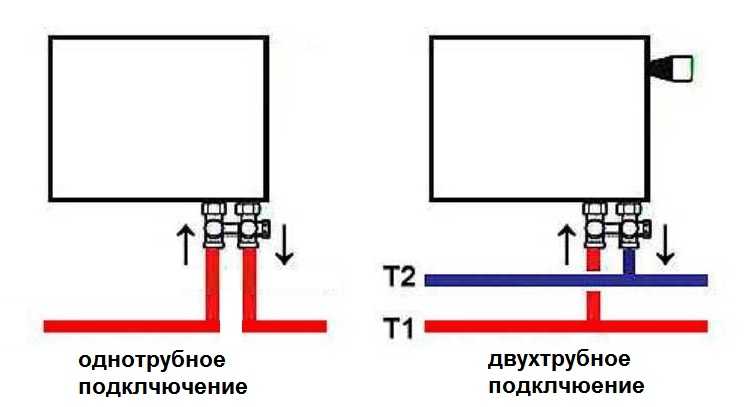

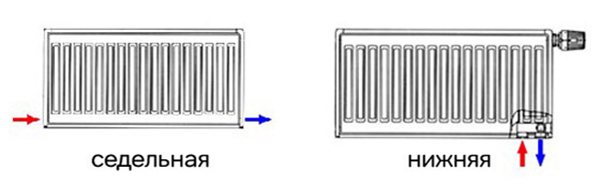

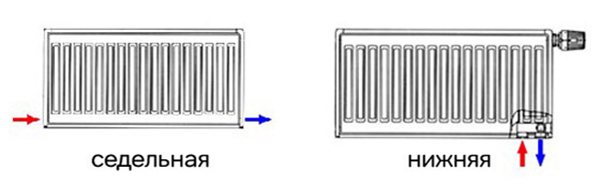

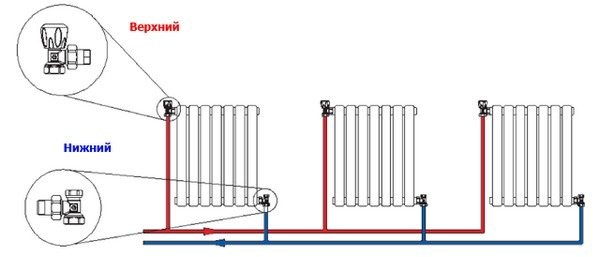

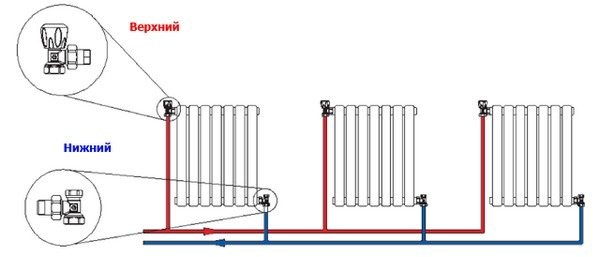

The bottom battery connection system is of two main types:

- One-sided - pipes exit on one side. Hot water enters through the upper part of the battery, under which there is a lower plug for cold water drainage.

- Versatile - here hot water comes from one end, and cold water is discharged from the opposite. This method is ideal for rooms with individual heating. The main advantage is in the way of supplying water to the battery, which can be carried out in all directions: top-down, bottom-up and bottom-down. The pipes for the supply and outflow of water are shorter.

Bottom Lead Battery Connection Types

Connecting bimetallic heating radiators

The connection of bimetallic heating radiators is carried out in a similar way to the insert of other types of batteries and is even somewhat simpler, due to the characteristics of the material. The steel core of the battery is more durable than cast iron and tougher than aluminum, so there is less chance of damage during operation. In addition, most of the components used for installation are steel, which prevents the "conflict" of materials.The lightness of the batteries allows them to be attached to any surface, without the need to reinforce the brackets.

Radiator connection diagrams:

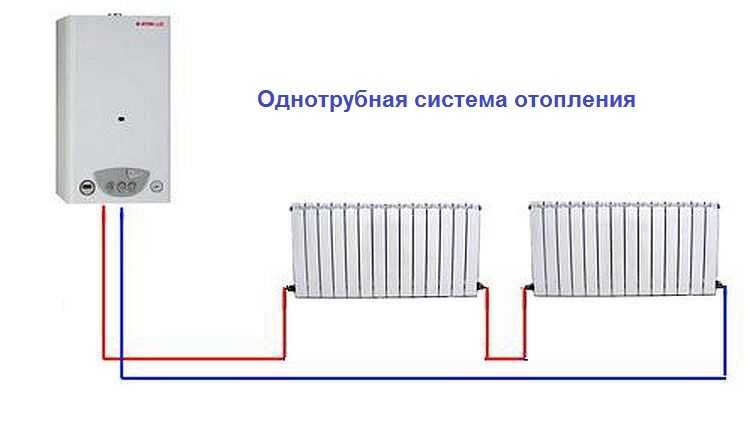

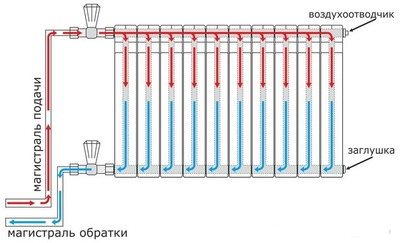

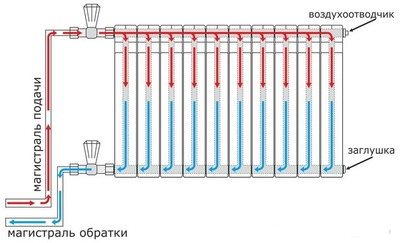

On bimetallic heating radiators, the connection diagram depends on the type of wiring.

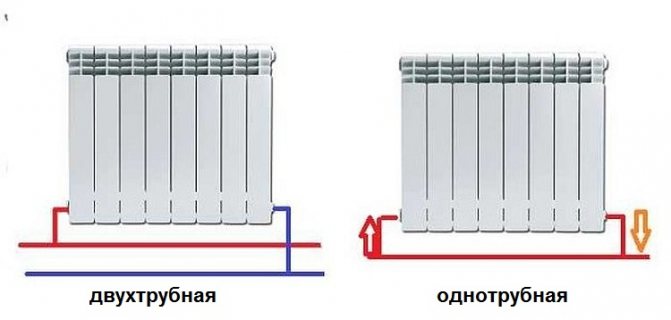

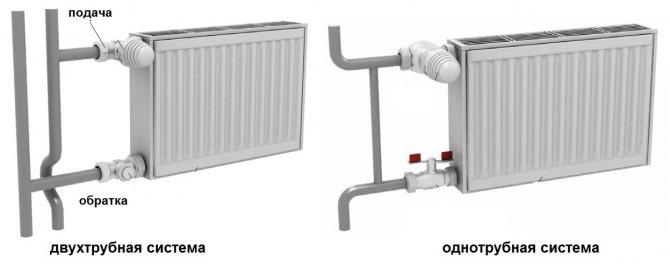

- One-pipe wiring involves a series connection of heating radiators. The supply pipe is connected to the first radiator, the coolant passes through all the interconnected radiators, gradually cooling down, and an outlet goes from the last battery, through which the coolant is sent back to the boiler. Such a wiring assumes uneven heating, which can be regulated by installing more powerful radiators at the end of the line.

- Two-pipe wiring involves parallel connection of radiators. The inlet and outlet pipes are independent and communicate only in the boiler. A more efficient type of wiring that allows you to control the heat exchange of each radiator.

Each radiator has 4 outputs, so there are several connection schemes for the system.

- Diagonal - coolant inlet from the top of one side, outlet from the bottom of the opposite side. This connection is used for two-pipe interconnections, and provides 100% efficiency.

- One-sided (lateral) - used in one-pipe wiring, the supply pipe is connected from the top, the outgoing pipe is from the bottom. This connection option gives 98% efficiency.

- Bottom - both input and output are mounted on the bottom of the battery. The lower efficiency is 93%, but when used in an autonomous heating network, the losses are insignificant, due to the short length of the line.

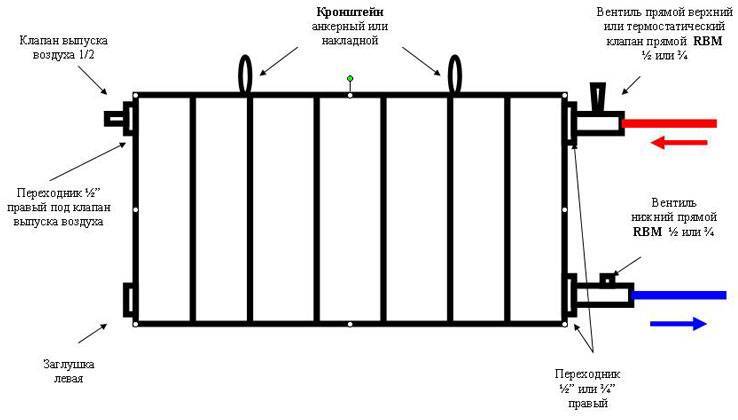

Radiator connection accessories

The heating radiator connection kit consists of the following mandatory elements.

- Adapters - 4 pieces.

- Fasteners - pin or corner brackets, with a large number of sections, it is justified to increase the standard 4 mounting points to 6 or more.

- Plugs and gaskets.

- "Mayevsky" crane or automatic air vent.

In addition to the main elements, regulating and shut-off valves and additional adapters to them, usually "American", are purchased. Installation of shut-off valves, on the inlet and outlet pipes, will further simplify the replacement of the radiator at any time, without draining the coolant from the line. The radiator can be equipped with a thermostat to control heating.

The nuances of installing radiators:

The correct connection of heating radiators is carried out with respect to the distances:

- from the edge of the window sill to the surface of the battery - 100 mm;

- from floor to battery - 90 - 120 mm;

- between the wall and the radiator - at least 20 mm.

This arrangement of sections will provide efficient heat exchange and will allow the equipment to operate at full capacity. In addition to observing the distance, a prerequisite is the horizontal position of the battery. When marking the fasteners, it is necessary to use a level to avoid slopes, otherwise there will be problems with air locks that even the built-in air vents will not fix. When installing a new equipment system, before starting, a check is carried out with special equipment - a pressure operator. The device creates an increased pressure in the system (by about 25%), which allows you to check the tightness and reliability of all connections.

Connection methods

Possible ways of connecting aluminum radiators - side and bottom, depending on whether to which part the supply and discharge pipes go.

Unilateral

In this case, the pipelines are located on one side of the appliance.

Inlet pipe from above, outlet from below.

Option prevails in high-rise buildings, because it is convenient for a standard passage of the riser to the side of the radiator.

This connection is usually used when the number of battery sections is not more than 10, otherwise its far edge does not heat well.

Important!

With a larger number of sections, it is possible to install

tube - flow extension... It will supply the coolant to the middle of the radiator.

Diagonal

This option considered a reference and is taken as a sample when testing heating systems. The coolant flows to the upper inlet on one side of the radiator, while the outlet is located at the bottom on the opposite side.

Photo 2. Two-pipe diagram with diagonal connection of radiators. The top and bottom taps are shown.

In this case, the diagonal passage of the coolant through the entire battery and its uniform heating is ensured. With the number of sections in the radiator about 15, the system works optimally.

Attention! The reverse version of the side connection (entry from the bottom, exit from the top) will be a serious mistake and will critically reduce efficiency.

Lower

Both the supply and return pipes are connected at the bottom. The pipes in this case are hidden in the floor, which makes it the most aesthetic option in terms of appearance. Disadvantage: the radiator may not fully warm up, heat loss reaches 15%.

Varieties of devices

There are 3 types of heating devices, the design of which allows the implementation of the bottom connection:

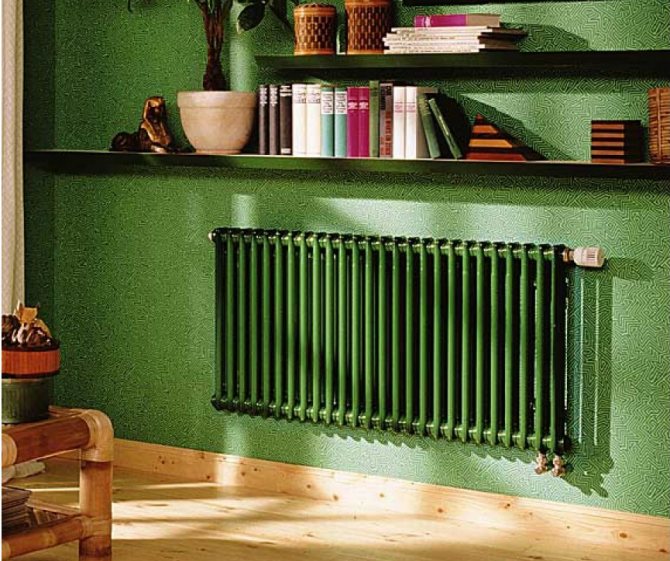

- Bimetallic sectional radiators equipped with convection fins. The devices are versatile in use, as they are equipped with 4 connection points. For example, the parameters of Kermi batteries allow you to connect them in 4 different ways. Heat loss in the worst case will be 15% maximum. The problem of power decay is easily solved by adjusting the thermostat.

Bimetallic radiator with bottom connection

- Smooth or corrugated panel batteries are distinguished by a lower connection scheme without the possibility of diagonal or top connection. The required devices with connecting elements are supplied separately.

Panel radiator with bottom connection

- Tubular steel batteries are found to be very efficient in function as they have high heat transfer characteristics. The most expensive of this type are high (can reach 2.5 m) batteries made in Germany or Italy with the possibility of one-way connection, that is, the elements for the supply and outflow of water are located next to each other.

Tubular steel batteries with bottom connection

Advantages and disadvantages

Indoor installation of a radiator with bottom connection allows achieving symmetry and harmony in the lines of the interior. The pipes hidden under the flooring will not attract attention and spoil the atmosphere with their unsightly appearance.

Batteries with bottom connection in the interior

This type of connection also has its drawbacks. As already noted, for the sake of aesthetics, the pipes are hidden under the baseboard or mounted in the floor. However, in the event of an accident, such a decision is fraught with serious trouble.

Note! To get to the emergency pipe, you will have to dismantle the floor covering, and this process will be long and time consuming. As a result - additional financial costs, since in addition to the pipe, you will have to deal with the restoration of the floor.

Installation of radiators with bottom connection.

Many experts point out that the bottom liner is not very effective in terms of good heat transfer. Here, the advantage will be with batteries with a side connection type, which are often installed in new buildings. Due to the location of both pipes (for water supply and outflow) on one side of the radiator, maximum heating of the coolant is ensured. The lower type of connection is not very effective for multi-section radiators - they may not completely warm up. The problem will have to be solved with a duct extension. Most often, batteries with a bottom connection are chosen by owners of private houses.

Steel radiator with bottom connection