Installation of cast iron heating radiators

The market for heating devices is striking in its diversity. But the familiar cast iron radiators are still popular due to their many advantages. They are durable, resistant to corrosion, unpretentious in operation and very durable. But even the most reliable device may one day require replacement. The question of how to hang a heating radiator on the brackets can be solved independently. The main thing is to have experience, the necessary materials and take into account some of the nuances of installation.

Modern cast iron radiators - an example of style

- Features of selection and installation

- Preliminary preparation

- The main stages of independent work

- Decorative design of radiators

Connection sequence

The most crucial moment in the installation of batteries is their connection to the heating circuit and subsequent check. In order for all the work to be carried out efficiently, it is necessary to follow the sequence of installation of a cast-iron radiator.

- The heating circuit is pre-switched off, the supply of the coolant to the apartment is stopped, followed by its draining from the pipes using a circulation pump.

- The battery is hung on brackets with checking its horizontal and vertical position with a building level.

- The plugs are unscrewed from the device.

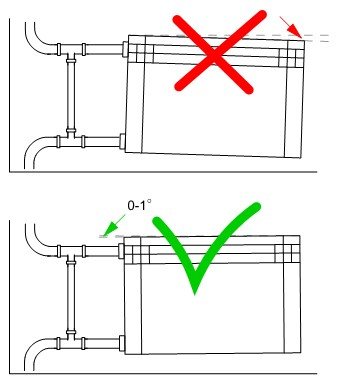

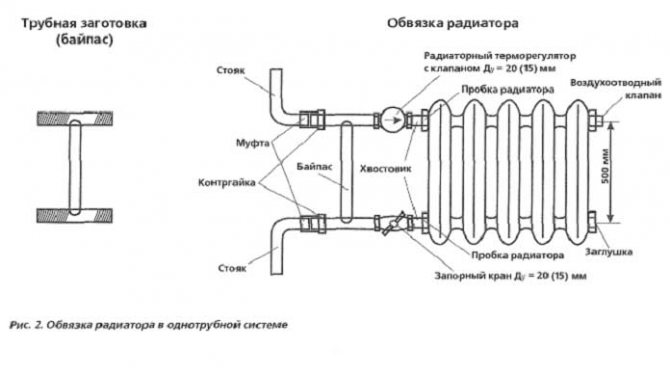

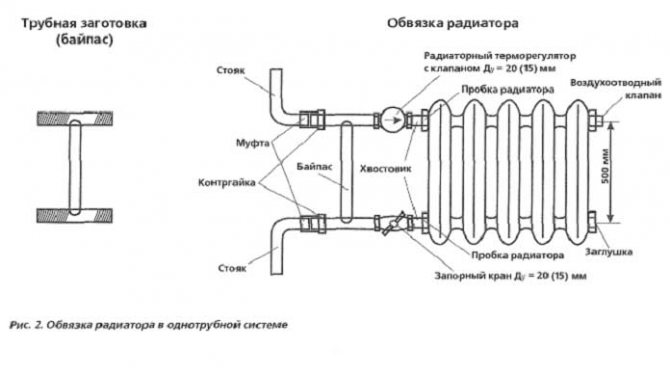

- In the event that the lateral connection diagram of cast-iron heating radiators is "introduced" into a one-pipe circuit, then a bypass with a valve must first be installed and connected. If the system is two-pipe, then squeegees with cranes are used.

At the last stage, he installs the Mayevsky crane on cast-iron radiators.

After connecting all heating elements, a trial check of the quality of work is carried out. It will show how securely the system is mounted. To do this, water is launched into it under pressure. If there is no leakage, no incomprehensible noises and knocks, then all circuit elements are connected correctly.

Is it worth changing cast iron batteries to bimetallic

If the old cast-iron radiators do not suit you in terms of heating quality, it makes sense to clean them - they can be silted up. Over time, dirt is deposited on the walls, which is a kind of heat insulator and does not allow the coolant to effectively give off heat.

If you live in your own home and have your own individual heating system, there will be no sudden changes in pressure and temperature. In this case, it makes sense to install cast iron batteries. They will be able to effectively retain heat if you forget to add fuel to the boiler and will produce soft, uniform heat.

It is better to install bimetallic radiators if you live in an apartment with a central heating system. They will withstand extreme temperatures and pressures in the event of an accident, will not silt and will last for a long time.

Installation procedure

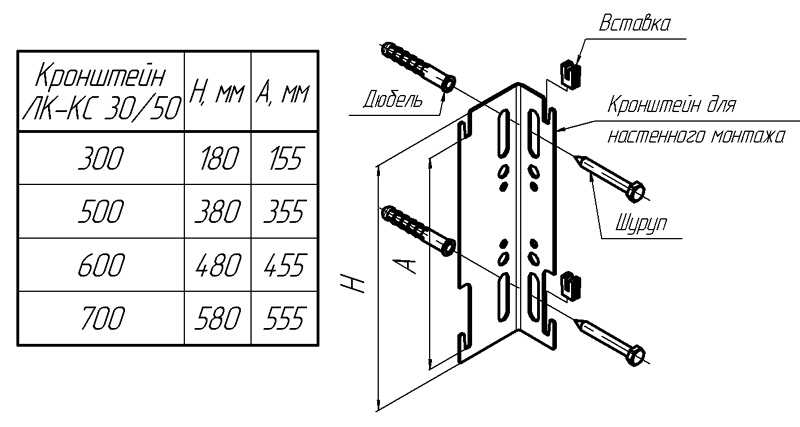

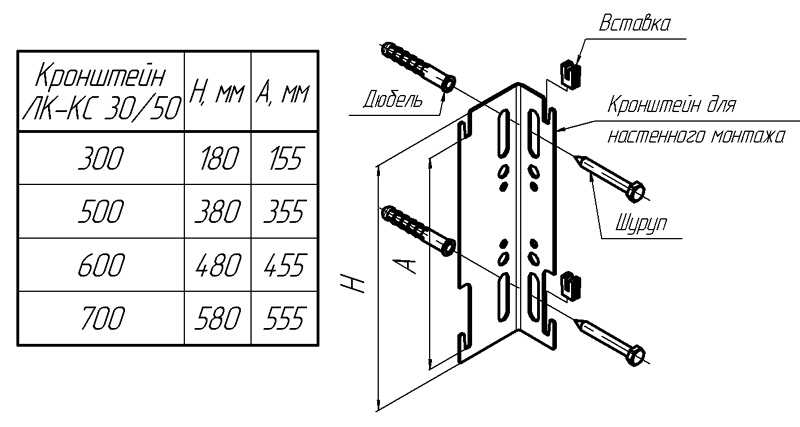

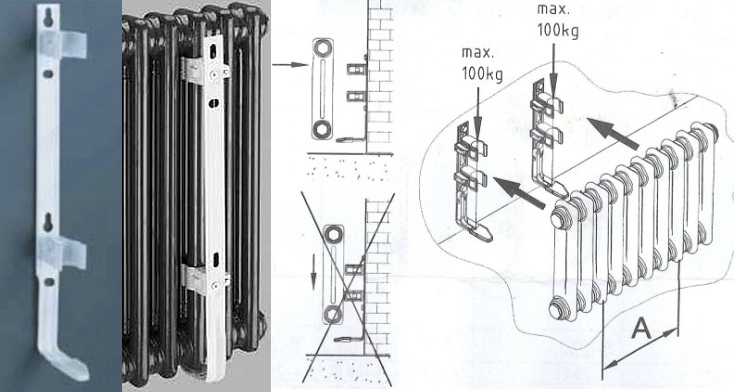

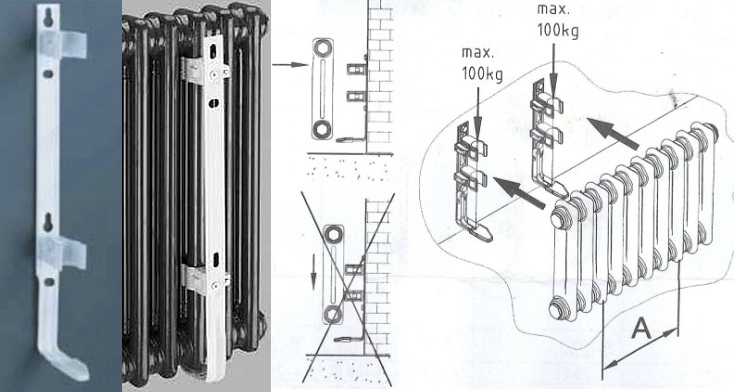

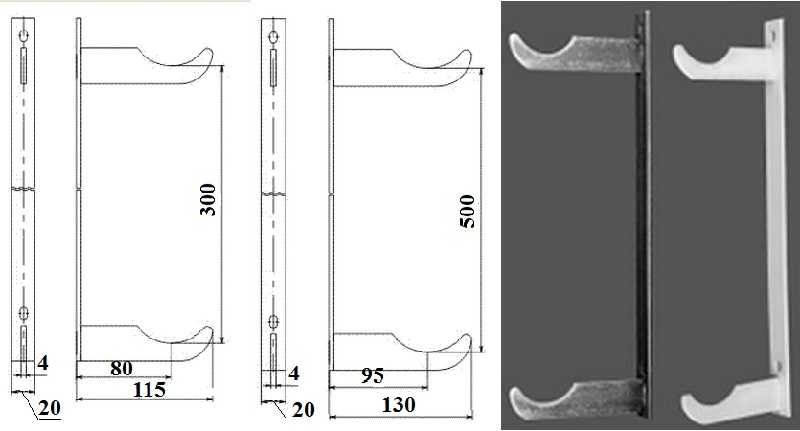

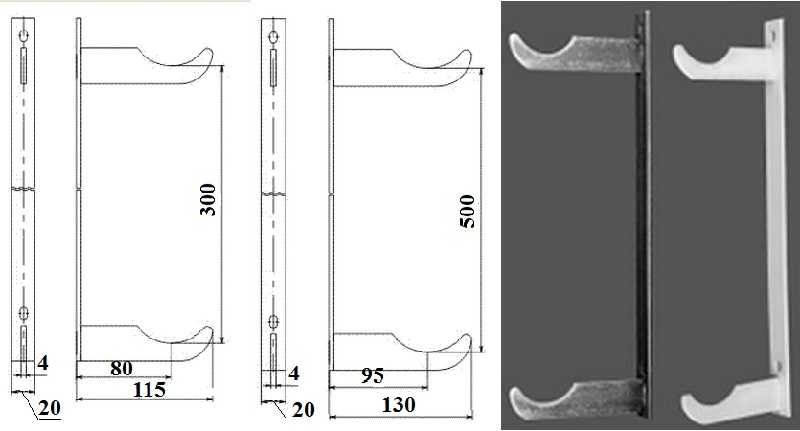

Mounting brackets for a cast iron battery

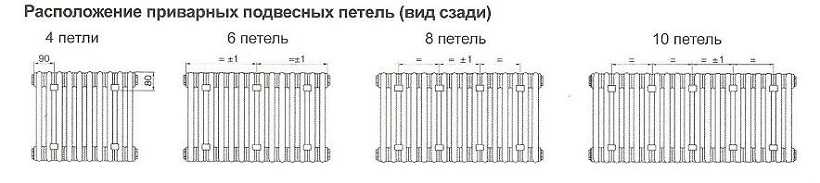

First you need to determine the required number of brackets. It depends on the area of the heater. For 1 sq.m. heating surface requires 1 bracket. Calculate the surface area of the radiator depending on the number of sections of the device and mark the wall for the installation of the brackets. After marking, check the calculations again, drill the holes, insert the dowels into them and screw in the fasteners.

Heating radiator installation

The heating circuit must be shut off and the water removed completely. The remaining heating medium can be pumped out with a pump. The battery is hung on supports, for a one-pipe system, a bypass is connected. Next, the radiator is connected to the system using threaded squeegees. All joints must be sealed.For this, any sealing materials are suitable, usually tow is used. If you know how to handle a welding machine, take the opportunity and weld the joints of the sleeves and the pipeline.

After installing the device, crimping is required. This procedure is performed by professionals with the appropriate equipment. If you have a device, do everything yourself, if not, then it is not advisable to buy an expensive device for the one-time installation of one or several radiators. After completing the installation, check the operation of the system.

Theoretically, there is nothing complicated in the installation of cast-iron heating radiators, but in practice, not everything is as easy as we would like. If you do not have the necessary experience or an assistant who has already done similar work, it is still better to hire a team of plumbers. Of course, paying for their work will significantly increase the cost of the heating system as a whole, but you will save time, effort and nerves. The final decision is only yours.

Minuses

- Great weight. Cast iron is a very heavy metal, the weight of one section of a cast iron radiator can reach several kilograms. On average, this is 2-3 times more than the weight of a bimetallic battery section, and 4-6 times more than the weight of an aluminum radiator. ...

- Price. One section of a cast-iron radiator is noticeably more expensive than a section of a bimetallic or aluminum battery similar in size and heat transfer.

- Impossibility of installation in a system with automatic adjustment. The design features of the battery and the properties of the metal will prevent the sensors from receiving up-to-date information on the temperature of the coolant and surface. When choosing which is better to put heating batteries in an apartment, be sure to take this nuance into account.

- Low efficiency. Due to the thermal inertia, much more energy and coolant will be spent on heating a square meter of area than in the case of other types of batteries. This can be completely unimportant if your heating is centralized and you pay based on the square of the house. But if you have a gas boiler, you will have to spend more of your own money, and they will go mainly to heat the battery itself, and not to increase the temperature in the room.

- Unaesthetic appearance. Note that this applies only to old batteries, but if you have just such - they are unlikely to harmoniously fit into the modern environment. Cast iron batteries of the new model in this regard are no different from bimetallic or aluminum "brothers" - they look modern and stylish, they will perfectly fit into the interior of any apartment.

How to choose the right bracket

The main rule when buying a retainer: it must withstand the weight assigned to it. The maximum load is usually indicated in the attached instructions. The easiest way is to choose a bracket for an aluminum radiator, as it is lightweight and any type is suitable for it.

Use floor stands for very powerful batteries. But if the covering in the house is wooden, then you need to make sure that the clamps are equipped with additional fasteners to the wall. This is to reduce the load on the boards. For light heating elements that will be located in a deep niche under the window, it is better to buy a long bracket.

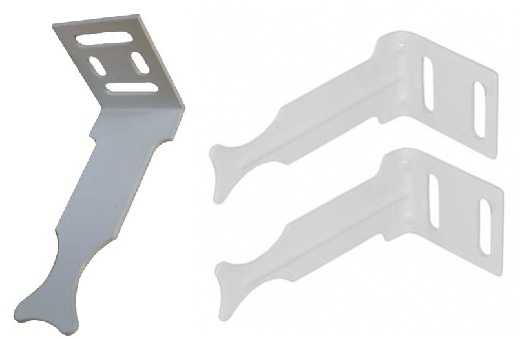

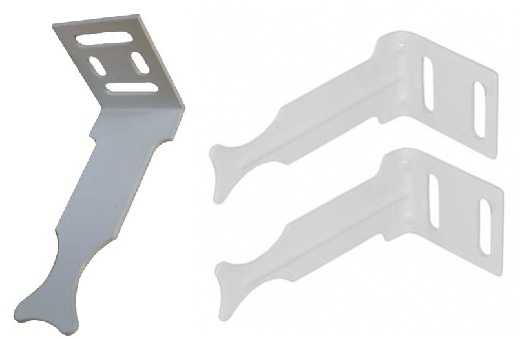

It is recommended for cast iron radiators to take holders with the ability to slightly change the height, otherwise difficulties with installation may arise. The price of an adjustable bracket is not so high as to give up the convenience of mounting.

It is important that the alloy contains no toxic substances released during heating. It is not worth buying parts hand-held, especially without the appropriate accompanying documents

Please note that the lightest - the corner bracket - is only for aluminum and copper radiators

Fasteners for steel radiators

There are two different types in this group: tubular and panel radiators. They have a different design, respectively, a different mount.

In panel radiators, brackets are welded on the rear wall, with which they are hung on the brackets. The shape of this type of fastener is different: it is designed specifically for staples.

In panel radiators, brackets are welded on the back wall

When installing panel radiators, it is necessary to strictly observe the vertical position of the brackets. High precision is required: four or six staples must fit the hooks precisely

It is also important here that the wall is perfectly flat and smooth. In general, using ordinary brackets, panel radiators are quite difficult to hang

Easier to work with other types of holders.

Standard bracket for panel radiator

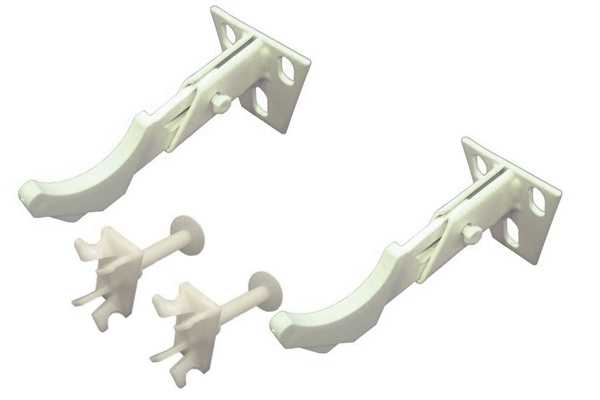

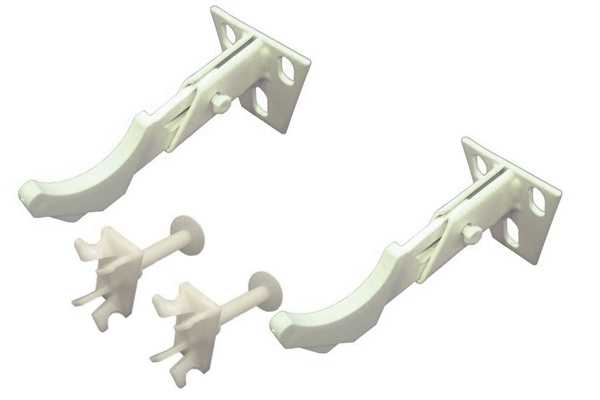

Since the mass of the heater is small, it is enough to fix it on the upper brackets, install stops at the bottom that will give it a direction in the horizontal plane. They are not attached to the wall, but cling to the bracket with hooks and simply abut against the wall. For reliability, the part that faces the wall is widened.

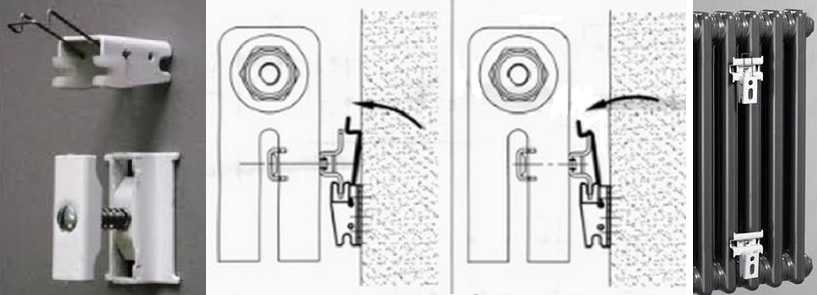

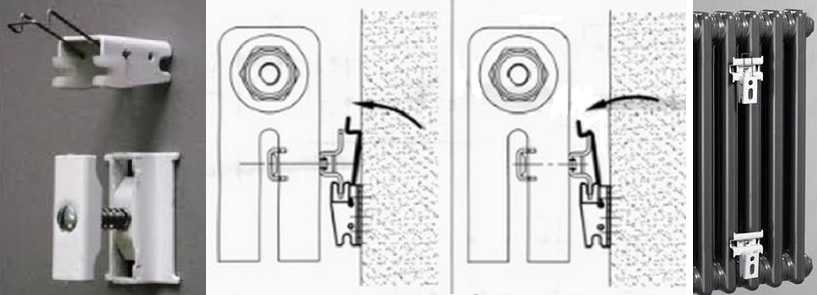

This is how a set of brackets for tubular steel batteries looks like: the upper collector is hung on the hooks, and plastic stops are placed below

There are also special mounting plates for easy installation. They are a strip of metal with plastic clips at the top and bottom. The brackets on the rear panel are not required when using this fastener. The strips are fixed on the wall, a radiator is inserted into them, which is held by plastic hooks.

Bar for quick mounting of panel batteries

Fasteners for tubular radiators are similar to sectional ones: the same hooks, only of a different size, often equipped with plastic pads.

There are also special fasteners with grips for SMB tubes. This is a strip of steel with plastic clips and a shelf on the bottom that serves as a support for the radiator. This mounting plate can be used if the weight of the device filled with water does not exceed 100 kg. Installation is simple: place the battery on the shelf, bring the upper edge closer to the clips. They clasp the nearest tube, a click is heard. The radiator is installed, supply pipes can be connected.

Rail for quick installation of tubular radiator with shelf and clamps

There is a second option for quick installation: SVD fasteners. It has two parts. One is attached to the radiator, the second to the wall. Then they are connected to each other and fixed with a steel loop.

Another type of holders for tubular models: two parts, one is mounted on the wall, the other is fixed to the pipe. They are pulled together with a wire retainer.

Floor mount for tubular radiators can be of several types: tubular stops, which are welded at the factory, or posts with hooks. Radiators are hung on such racks, and the racks themselves are attached to the floor.

Brackets for radiators are of different types and types: for wall and floor installation. The standard ones that come with the kit are reliable, but they are more difficult to work with. Planks and quick-fit devices save time, but cost a lot.

Fasteners for cast-iron, sectional, panel radiators

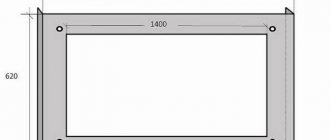

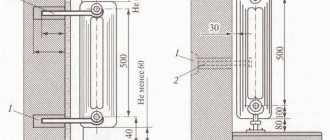

The order of installation of radiators does not depend on their type: the rules remain the same, only the fasteners change. If it is supposed to be installed under a window, the following distances must be observed: from the floor must be at least 80-120 mm, to the window sill at least 60-100 mm, to the wall - 30-50 mm. It is also necessary to determine the number and location of the fasteners.

The number of brackets (hooks) per battery depends on its length. If there are few sections - up to 8-10 pieces, then two holders are required at the top, and at least one more at the bottom. If there are more than 10 sections, three supports are installed on top, and two on the bottom.For each next five to seven sections of cast-iron radiators and ten tubular and aluminum, the number of fasteners increases: one holder is added at the top and one at the bottom.

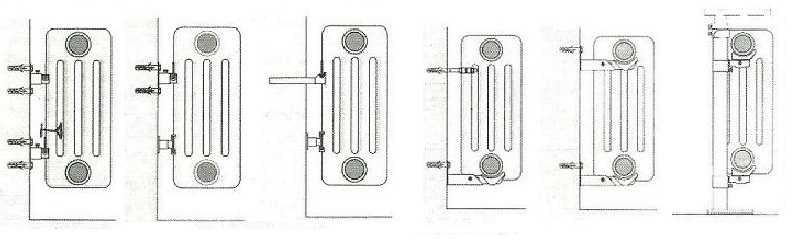

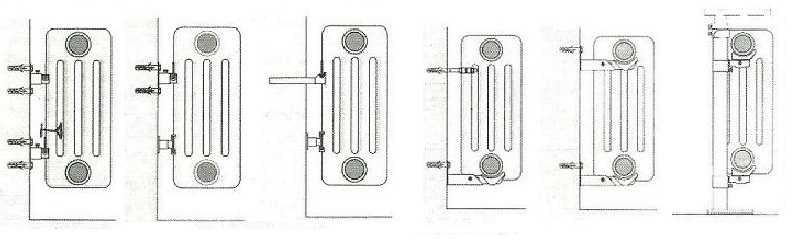

Ways to use different kinds of fasteners for sectional radiators

Replacing radiators (cast iron batteries) according to the rules

- The replacement begins with the fact that we completely shut off the heating.

- We drain all the water from the system.

- We install any supporting objects under the old batteries, and install water tanks on the floor.

- We cut off the cast iron radiators and remove them from the hinges.

- We cut metal pipes into equal lengths, make a thread.

- We install tees, on which the bypass and batteries will be installed in the future.

- If it is cold outside and you need to turn on the heating as soon as possible, then it is recommended to first assemble the bypass. Then you can turn on the heating.

- Then we mount the ball valves on the tees to shut off the supply to the battery.

- "American women" are screwed to the cranes.

- The batteries are hung on the walls.

- We measure the length from the American to the radiator, cut off the metal-plastic.

- A plug is screwed into the holes in the battery from below, and an automatic air vent (or a regular barrel) is screwed on top.

- We connect the bimetallic battery, open the taps, close the bypass.

- When the battery is filled with water, you need to press down on the air vent with a paper clip to release excess air from the inside.

Fasteners for cast iron batteries

Since these are the heaviest heating devices, the holders for them are the most massive: they must hold considerable weight for years. These can be single or curved pins fixed to the bar. In any case, thicker metal is used in the manufacture of fasteners for cast iron batteries. In the price lists, it usually comes with the addition of "reinforced". Can be painted (standard color is white) or not. Some manufacturers paint on request in the desired color (when ordering a radiator, specify the type of fastener and its color).

Mount for a cast-iron battery and make it reinforced: from a thicker metal

When buying, you will need to take into account the dimensions: fastening for sections of different depths is done on purpose, since it is necessary to ensure a distance to the wall of at least 3-5 cm.

In addition to brackets for cast-iron radiators, hooks are also produced. They are sold together with wall plugs. They are installed as standard: a hole is drilled, a dowel is inserted into it, and a hook is screwed into the dowel (there is a thread on one side of it).

There are mounting plates for cast iron radiators that make installation easier.

In addition to the wall mount, there are feet for floor installation. They are height-adjustable or not. The upper arcs are also different, fixing the section on the stop: there is an arc made of steel wire, and there is a chain of movably connected links. In both cases, the batteries are fixed to the support using these arcs and bolts.

Stands for floor installation of sectional radiators - any wall-mounted battery can be installed on the floor

How are bimetallic batteries different from cast iron radiators?

Replacing radiators is a serious matter, approach it with special care.

Everyone knows that the replacement of heating radiators belongs to the category of dangerous repair operations, therefore it is recommended either to study all the specifics of the work well, or to entrust this matter to the master.

In the meantime, let's figure out the qualities of certain types of radiators.

Cast iron radiators are the most durable and durable. They can easily serve you for 50-60 years. Such batteries can heat air and objects using infrared radiation, even if the temperature of the water inside reaches only 50-55 ° C. The weight of cast iron radiators reaches 8 kg, which indicates their high thermal inertia.

Bimetallic radiators are relatively new radiators in Russia.They have high heat dissipation, have a beautiful and presentable appearance, have great strength and are easy to install, while they are lightweight, and automatic systems make it easy to use such radiators.

If cast-iron radiators are already installed in your apartment, then choose bimetallic ones for replacement, due to the poor quality of water purification.

If the coolant is constantly cold, then only cast iron batteries are suitable for you, but if on the contrary, then feel free to install bimetallic radiators. The result will be noticeable with the onset of the first cold weather.

If convectors are installed in your house and water of acceptable quality is installed, then replacement with bimetallic radiators is possible.

More about materials:

- Battery Mounting Kit (Bimetal): includes 1 plug, 1 tap and 4 feet, all sold as a set.

- Batteries.

- Dowels and hooks that will hold the battery.

- Cranes, angles, tees and other small parts. In order not to forget anything, first make a drawing in which you break the system into parts.

- Reinforced plastic pipes.

- Tools: drill, pliers, grinder, carving machine, adjustable and gas wrenches.

- Heating shutoff valves.

Most of us have cast iron batteries, old, installed about 3-4 decades ago. It is important to take into account the fact that heating used to work on the principle of thermosiphon water circulation. Then they switched to a closed one, and the heating system received forced circulation. Cast iron radiators quickly get dirty from the inside, which leads to poor heating quality. This fact is the most important impetus: then it is necessary to replace cast-iron radiators with more modern ones. Cast iron batteries are very heavy compared to their current aluminum counterparts, as they are also called bimetallic.

Cast iron batteries lead to a constantly cold floor in remote rooms, and at the ceiling level, the temperature is more or less normal.

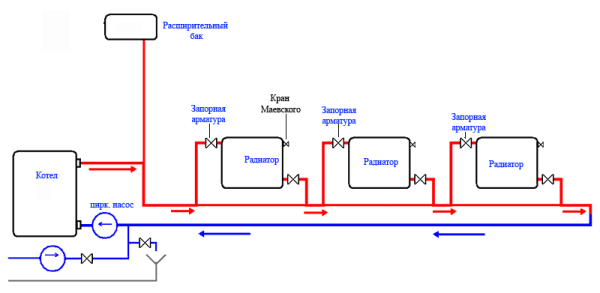

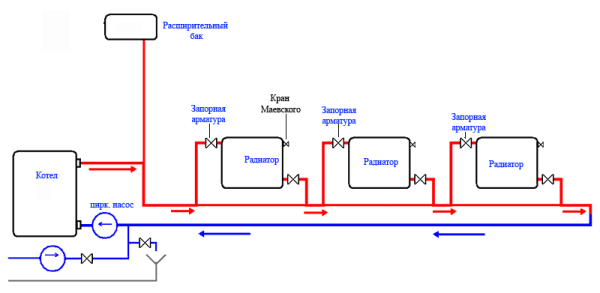

Connection diagrams

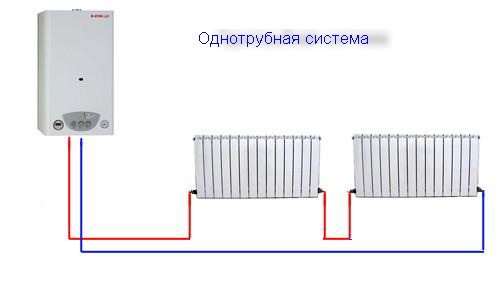

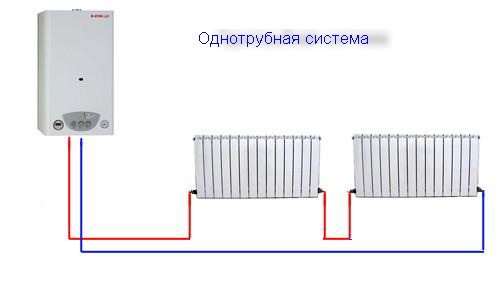

The most fail-safe circuit for connecting heating radiators in a private house with a bottling and a boiler is a single-pipe Leningrad. Heating devices are connected in parallel with the filling, which is laid along the perimeter of the room.

Somewhat cheaper in installation, but much more problematic in operation is a circuit using a series connection of batteries. Suffice it to say that their independent adjustment is impossible in this case.

Single-pipe version with series connection.

Finally, a two-pipe system involves connecting each radiator as a jumper between the supply and return lines. It is inconvenient in that it requires the already mentioned balancing - limiting the passage of heating devices closest to the boiler.

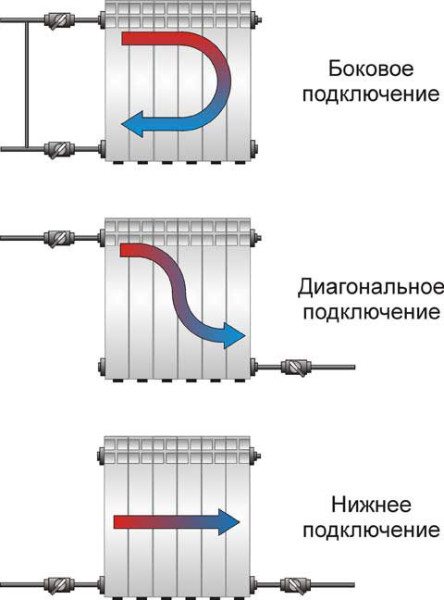

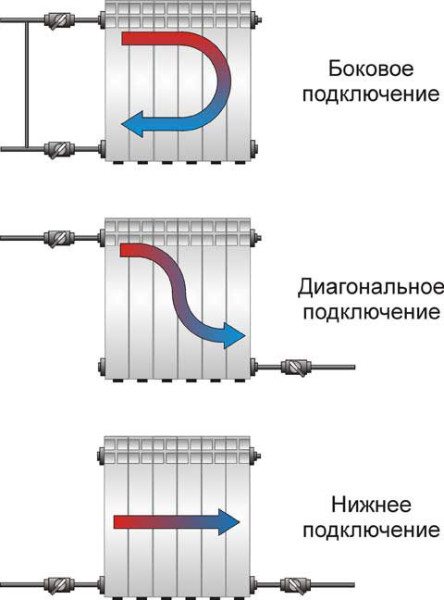

What can be the diagrams for connecting heating radiators to the supply line?

- One-sided. connections are connected to the upper and lower radiator plugs on the right or left. It is compact, but makes the heating of the device uneven: the last sections will always be colder than the first.

- From bottom to bottom. In this case, the battery must be equipped with an air vent. The advantages of the solution are that the radiator, with such a connection, does not require flushing and always heats up along its entire length.

- Diagonal. Heating of the sections is even more uniform; however, the bottom corner of an instrument with a blind plug will gradually silt up.

Connection options for connections.

Required tools and materials

Technology for unscrewing and assembling cast iron batteries: a - nipples capture the thread of the sections (2-3 threads); b - tighten the nipples, dock the sections; c - mount the third section; d - group two radiators.

Replacing or installing various cast iron radiators can take place in several stages and in completely different ways. To complete this installation, you will need:

- gloves;

- protective glasses;

- gas welding;

- assembly keys;

- rubber gaskets;

- screwdrivers;

- radiator keys (short and long).

If you decide to install or replace yourself, then be very careful and follow the rules of safety and security. Welding work can be harmful.

Mounting methods for aluminum and bimetallic radiators

The products are very similar in shape. Only they are made of thinner metal. In general, brackets for sectional radiators of any type are very similar. There are universal angle brackets for aluminum and bimetallic radiators. They have a recess at the top and bottom for the collector, so they can be attached both to the right and to the left.

Special angle brackets for light sectional radiators

There are no floor-standing aluminum and bimetallic radiators. But there are racks that allow any of them to be installed on the floor. In this case, the rack is first fixed on the floor, and then the heating device is installed and fixed on it.

Floor mounting of aluminum radiators helps out if the walls cannot withstand even such a small weight (if they are made of plasterboard or aerated concrete, other similar materials).

Any sectional radiator can be fixed on such racks.

You will not be able to hang anything on the now fashionable glass wall

But then you need to pay attention to how the whole structure looks from the back side. In this case, it is more advisable to use convectors built into the floor for heating.

floor models of tubular radiators (at the same time can serve as a fence), cast-iron retro radiators.

Aluminum batteries

Aluminum batteries are cheaper and easier to install and maintain than their bimetallic counterparts. At the same time, they are not without certain disadvantages.

The main one is the increased sensitivity to the acidity of the coolant. In order to maintain the working condition of such batteries, it is necessary to regularly carry out anti-corrosion treatment. That is why it is not recommended to use them in the citywide network, because there is no guarantee that good quality water will go from the thermal power plant to your pipes. Aluminum radiators are the best choice for private houses and cottages when it is possible to individually design a heating system.

Let's sum up the advantages of aluminum batteries:

- lungs;

- look attractive;

- heat up quickly;

- withstand a lot of pressure

Of the minuses, as already mentioned, it is worth noting the sensitivity to the quality of the coolant and, in this regard, the possible need to use special additives. However, modern manufacturers are aware of this feature of aluminum and reinforce it from the inside with special protective coatings.

Alecord 350 belongs to the practical representatives of aluminum models. Unlike the bimetallic analogue, here the heat transfer of the section is 155 W with a weight of 0.87 kg and a capacity of 0.2 liters. Working / maximum pressure is 16/25 atmospheres. The interior finish is highly resistant to corrosion.

Compliance with installation standards

Even knowing how to install a cast iron battery, you should remember why you need to adhere to the norms approved by SNiP. Maybe someone will consider this optional, and they will be wrong, since any deviations from the parameters are not just a violation of security rules, but also a decrease in the efficiency of the system itself.

The general rules for installing radiators include:

- The position of the device relative to the vertical axis of the window. The middle of the battery should line up with it. The permissible deviation should not exceed 2 cm.

- The battery must have such a number of sections that, when assembled, it occupies 75% of the width of the window opening.

- The SNiP indicates how to fix the cast-iron battery to the wall. So the distance between it and the floor according to the standards is 60 mm, 50 mm under the windowsill, and 25 mm from the wall.

When the place is chosen and all the calculations are made, you can begin the installation of cast-iron heating radiators with your own hands. This will require the tools and necessary fasteners.

Requirements for the quality of the coolant

The water in the central heating system is of poor quality. It can be acidic or alkaline. It also contains a suspension of fine dirt particles, sand, etc.

Cast iron is chemically resistant and water quality does not affect it. But due to the large diameter of the channels, the volume of water in the radiator is large. The flow rate slows down in it and small particles of contamination settle in the lower part of the radiator. Over time, this leads to siltation, a decrease in throughput and a decrease in heating efficiency.

Silting up of heating pipes. The same dirt can settle on the walls of a cast iron radiator.

In a bimetallic radiator, the steel core undergoes light corrosion in the warm season, when there is no water in the heating system. If the inner part is made of copper, it becomes covered with a patina and the process of destruction stops.

Placement of heating devices

It is of great importance not only how to connect heating radiators to each other, but also their correct location in relation to building structures. Traditionally, heaters are installed along the walls of rooms and locally under windows to reduce the penetration of cold air currents in the most vulnerable place.

There are clear instructions for this in the SNiP for the installation of thermal equipment:

- The gap between the floor and the bottom of the battery must not be less than 120 mm. With a decrease in the distance from the device to the floor, the distribution of the heat flow will be uneven;

- The distance from the back surface to the wall on which the radiator is mounted must be from 30 to 50 mm, otherwise its heat transfer will be disturbed;

- The gap from the upper edge of the heater to the window sill is maintained within 100-120 mm (not less). Otherwise, the movement of thermal masses may be difficult, which will weaken the heating of the room.

Bimetallic heating devices

To understand how to connect bimetallic radiators to each other, you need to know that almost all of them are suitable for any type of connection:

- They have four points of possible connection - two upper and two lower;

- Equipped with plugs and a Mayevsky tap, through which you can bleed the air collected in the heating system;

Diagonal connection is considered the most effective for bimetallic batteries, especially when it comes to a large number of sections in the device. Although very wide batteries, equipped with ten or more sections, are undesirable to use.

Advice! It is better to ponder the question of how to properly connect two heating radiators 7-8 sectional instead of one device of 14 or 16 sections. It will be much easier to install and easier to maintain.

Another question - how to connect sections of a bimetallic radiator may arise when rearranging sections of a heater in various situations:

The place where you plan to install the heater is also important.

- In the process of creating new heating networks;

- If it is necessary to replace a failed radiator with a new one - bimetallic;

- In case of underheating, you can build up the battery by connecting additional sections.

Aluminum batteries

Interesting! By and large, it should be noted that diagonal connection is an excellent option for any type of battery. Not sure how to connect aluminum radiators to each other. connect diagonally, you won't go wrong!

For closed-type heating networks in private houses, it is advisable to install aluminum batteries, since it is easier here to ensure proper water treatment before filling the system. And their cost is much lower than that of bimetallic devices.

Of course, over time, moving along the radiators, the coolant cools

Of course, you will have to try before you connect the sections of the aluminum radiator for regrouping.

Advice! Do not rush to remove the factory packaging (film) from the installed heating devices before finishing the finishing work in the room.This will protect the radiator coating from damage and contamination.

The work process itself does not take much time, you do not need any special skill or expensive equipment, you can purchase all the necessary tools at any hardware store. And do not forget, the connection will serve you for a long time and without hassle only if you used high-quality materials in your work and followed all the rules for installing the heating system.

We are talking about exactly what is indicated in this figure.

In the video presented in this article, you will find additional information on this topic.

Housing office activity when changing radiators

When tenants come to the decision that their heating system is outdated, they ask a fair question, who should change the radiators in the apartment.

In this matter, you need to rely on the following facts:

- The change was caused by a failure (depressurization or other reason) of the system, which means that all work must be carried out by employees of the communal service

. - Old radiators heat, although badly, but there is a desire to embellish the apartment with their more modern counterparts, then this "whim" will fall on the shoulders of the user.

In any case, the heating batteries in the apartment are being replaced through the housing office, even if all the costs are borne by the tenants. Any work without permits is considered illegal. Sometimes consumers ignore such a requirement, wanting to issue documentation already upon the work performed. This can only happen if the housing office employees consider the new heating system safe for the entire structure.

If the tenants have a question whether it is worth changing the heating batteries in the apartment, then the answer is an unequivocal "yes", if they have become unusable or just old. The replacement procedure is not so difficult, even taking into account the paperwork. It will also not be difficult to choose a brigade suitable for these works, but it is worth it to know that for the next 25-30 years the apartment will be heated by beautiful and modern radiators.

Replacement of batteries in winter is carried out in emergency cases when they do not warm up the room. This issue is coordinated with the organization serving the house. The work is performed by a specialized organization. Reasons for replacing batteries in winter can vary. A situation is possible when an accident has occurred, the replacement period cannot be postponed until the end of the heating season, then this work must be performed immediately. Replacing the heater, installing a screen or other dismantling and installation work can in these cases be carried out without hindrance. For example, heating devices that have worked for more than twenty years cannot fully perform the functions assigned to them for heating the premises, therefore they must be replaced.

Some requirements during the execution of work

The fact that the heating system is in working order in winter will allow you to immediately assess the quality and efficiency of the work performed. The replacement must be carried out in turn, when not all radiators are turned off in the apartment, but only one of them. After it was launched, the next one comes. Installation of one battery can be done within one hour, but for this (preliminary) measurements must be made, all tools and accessories prepared.

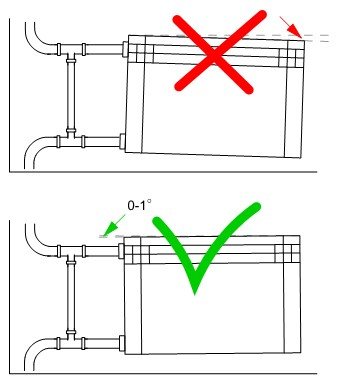

In order to avoid heat loss and personal health, not to pay extra money for heating the house, the batteries must be installed correctly. In addition, it must be remembered that the radiator is mounted in a horizontal manner, while it must be parallel to the wall. It is installed on three brackets, one of which is at the bottom and two at the top, which will bear the main load. In the case of a large number of battery sections (more than 12), one more bracket is fixed in the upper part in the wall (optional). It is necessary to observe the distance between the top of the battery and the bottom of the window sill, it must be at least 10 cm, otherwise the heat curtain in front of the window will be weak.

The representative of the service organization (after the completion of all work) is obliged to turn on the risers of the heating system. You must check the tightness of the joints so that there are no leaks at the joints of pipelines, shut-off and control valves.

www.kakprosto.ru

Installing cast iron heating radiators with your own hands

- Required tools and materials

- Stages of installation work

Cast iron radiators are a fairly popular battery, with the help of which heating is carried out in multi-storey buildings. This is due to the fact that cast iron batteries have undeniable advantages over other types of heating. In addition, most of the installed batteries in homes have already expired and now need to be replaced. That is why information on the installation of cast iron radiators is very relevant. Installing heating systems is not an easy task, but it is quite feasible for business executives.

Radiator piping in a one-pipe system.

An important role is played by the site on which the installation of cast-iron radiators will be carried out.

The surface composition of the installation site will be reflected in the heating installation stages. Installation of devices can take place on a wooden wall. In this case, you will need one strip and one stand for each radiator for installation. Batteries can also be installed on a brick plastered wall. You will need a bracket, a window sill and a niche here.

Also, a lightweight wall can become a place for installation. Here you will need a solid support on which the heater will be installed. It should be noted that it is advisable to choose a place for installing a cast-iron battery with the condition of convenience, not beauty. To add beauty elements to heating appliances, you can resort to simpler methods of decorating and decorating batteries, for example, using rattan grates.

Why are we not satisfied with old batteries?

When replacing a heating system, you need to draft a new one, calculate the required number of radiators and valves. Next, you need to purchase equipment, including a pipeline. All this is associated with a large investment of money and time. Therefore, owners often ask themselves the question: is it necessary to change the heating at all, are such costs justified or not?

First, the service life of cast iron batteries is 30-40 years. They have long worked out their due date, and if they are not replaced, then one day they will simply flow at the seams. Secondly, old radiators do not fit into the overall interior of modern apartments and houses. And finally, the poor performance of the system. This is a reason to think about the constantly rising energy prices.

Preparatory work

In order to choose the right parts and calculate their number, you should know the type of wiring of the heating system - one- or two-pipe. In a single-pipe, the heated coolant rises along the riser, and the heating devices are connected to the descending line. In a two-pipe system, the heat carrier moves from the heater to the heating devices and vice versa. One line is designed to supply hot water, the second is to return the cooled coolant to the boiler. There are two ways to connect system elements - horizontal and vertical.

All the nuances of the connection should be clarified before starting work. Before installation, you need to drain the water from the system, dismantle the old heating devices, remove the fasteners on which they were held. The supply of hot coolant to the system must be stopped before the end of the work.

Assembling cast iron heating radiators

The first step is to group the sections. To do this, you need radiator keys. The device is fixed on a workbench; radiator keys must be inserted into the lower and upper holes so that they rest against the internal projections. Both nipples must be deployed at the same time to avoid skewing the sections, so the manipulation is performed with an assistant. The nipples should be greased with linseed oil, and gaskets should be put on them. The keys are rotated in the opposite direction to the thread.If it is left, then turn to the right, and if it is right, to the left. You need to screw in 1-2 threads.

Hydraulic tests of the finished structure are carried out on a special stand, where a pressure of 4-8 kgf / cm2 is created using a press. The performance of the device is checked by a pressure gauge. If its indicators begin to decline, it means that either defective sections are connected, or the work was performed poorly. In the first case, the elements are replaced, in the second, the nipples are tightened. If minor damage appears, it can be repaired with epoxy adhesive. If the connections are incorrect and the joints are leaking, the gaskets should be changed.

Painting the radiator after assembly

After the tests, the heater is painted and dried. Two thin coats of paint must be applied to obtain a durable and even finish. As a result, radiators must meet the following requirements:

- Heat-resistant coating of the device body. It must withstand temperatures of 80 degrees, without softening and not emitting harmful substances into the atmosphere.

- The painting should be of sufficient quality to protect the radiator from corrosion as much as possible.

- The selected composition should not change in color.

Experts recommend using alkyd enamels as a coating, because after drying, they are harmless and do not poison the air during operation. Option - acrylic compounds. They do not crack, do not change color and are resistant to heat. Both types of formulations have their own advantages: alkyd enamels are cheaper, acrylic-based paints are more durable. You can also use water-dispersion paints, which bear the manufacturer's mark that they can be used for painting heating devices.

How to correctly determine the location of the radiator

Heating devices are usually located under windows at a height of at least 6 cm from the floor and 5-10 cm from the bottom of the window sill. The distance to the wall should be at least 3-5 cm. The pipes of the system are placed under a slight slope, which is made in the direction of movement of the coolant. If there is no slope or distortions appear when installing a cast-iron radiator, air will accumulate in the batteries, which will have to be removed manually. An “airy” radiator will not be able to warm up normally and give off heat. The center of the device should coincide with the center of the window opening plus or minus 2 cm.

Materials for the production of modern radiators

In exchange for cast-iron radiators, you can install the following models:

- Made of aluminum.

- Of steel.

- Made of copper.

- Bimetallic.

The radiator, which is made of aluminum, usually has a small mass, but at the same time stylish design, good thermal conductivity and heat dissipation. The disadvantage is that it is necessary to constantly maintain the pH of the water that is in the system, as well as sensitivity to pressure drops. They are absolutely incompatible with copper pipes. Radiators made of steel also have good heat transfer and low weight, and they also have a fairly acceptable cost. But they cannot be left without liquid in the system and they are subject to corrosion, which is a significant drawback. Over time, the coating can peel off, and they also do not withstand water hammer well.

But bimetallic radiators are the most popular. They have increased heat transfer, they are resistant to pressure drops and can last for many years. It does not corrode, has an attractive appearance and is quick and easy to install. But such pipes are expensive and at first you will hear some crackling in the system due to steel and aluminum.

It should be remembered that before changing it is best to consult with a specialist so that the choice is perfect.

AlinaAuthor of the article

Did you like the article?

Share with your friends:

Comments (75)

- Nikolay February 05 2020 in 10: 16

I live in Petersburg. Cast iron batteries have been standing for 60 years. There are no problems at all, they do not flow, they heat well. The only thing is that there are no valves, or old ones, so I will put a new cast iron one, but with valves. Practice over theory.

Reply

- Alexander February 01 2020 in 22: 36

What is cooler honey or carrot, bear and hare argue ...

Reply

- SERGE January 31 2020 22 in: 06

WALKING THIS RAT TRADES BIMETALLIC

Reply

- Sergey January 31 2020 21 in: 05

I installed new, beautiful, modern, bimetallic heating radiators the year before last! Moron, idiot, stupid, he gave himself extra work, and threw the money away! They don't heat a damn thing! I put the iron pot again in the fall, now it's warm in the house!

Reply

- M.D. Custine January 28 2020 23 in: 37

In short, the goat wrote.

Reply

- Sibiryak January 29 2020 20 in: 33

I will not talk about animals ... ... I agree, NEW FASHION batteries are beautiful, light in weight .... They easily heat up and cool down ... .... True, they rot, the water, her mother, in Russia is not the same as theirs .... Our chugunina, even if it is not beautiful, but it is possible to place shoes for drying there ... It does not rot, it rusts, so after all it is necessary to drain the water for the summer period ... or change the water in the system

Reply

- edik January 30 2020 18 in: 07

It looks like an advertisement. In addition, installing batteries that give off more heat than according to the project means stealing heat from others.

Reply

Vasya January 30 2020 18 in: 34

Advertising what? I see only in one picture a blurry inscription from Rifarov radiators.

Reply

- Far East February 02 2020 in 1: 06

I support both. It is not destiny for us to live in a prosperous kingdom.

Reply

- Alexander January 28 2020 14 in: 33

Fraudsters can be in the store when they offer you something that they sell less, and the product needs to be sold. The author wrote you the pros and cons for you to choose, read the reviews of those who changed or who understands it! Everyone has a different concept well warming ... Good luck to everyone in your choice!

Reply

- SVETOZAR January 27 2020 21 in: 09

cast iron is the best way to heat a private house. And whatever one may say, but the larger the liter of heated water, the longer it cools down. I have a private house and my own boiler room. Do not convince me to put a bimetal! Cast iron is power! A bimetal grave!

Reply

- Alexander January 31 2020 20 in: 57

so if the displacement is more and it is necessary to heat longer !!!!

Reply

- Alexander January 26 2020 22 in: 35

Cast iron radiators are durable, BUT LOWER IN HEAT RELEASE AT TIMES, Heard at times. BIMETAL IS THE BEST OF EVERYTHING IF YOU WANT TO WARM THE ROOM, AND NOT WATER IN CAST IRON !!!!

Reply

- Iskander the Laughing January 27 2020 19 in: 54

What did you want to say, Alexander? Let's get closer to the topic, and be more selective.

Reply

- Vasya January 30 2020 18 in: 37

Factor of? Can you argue with numbers? Well, for example, the cast iron section has a heat transfer of 400, and the bimetal section is several times higher, say, 2000, i.e. exactly five times higher. So?

Reply

- Uncle Kolya January 26 2020 18 in: 55

Of course, everything you want should be taken into account - the design of the cast iron is certainly larger and more varied than the modern ones of the same design (white ones), the color of the cast iron can be varied and durable, but here the price will be decent. The method of transferring heat energy in a cast iron is mainly infrared - which is very good for living rooms, and in (white) most of the heat is transferred by convection - which is very bad for human health, especially for small children (they are mainly on the floor, or rather at an altitude of up to 1 m, there is an active movement of air, adults of course feel this less than children). The quality of the coolant, the temperature difference, whether or not there is a coolant - the cast iron is indifferent, except that it loses in weight and, of course, in price.

Reply

- Peter January 26 2020 17 in: 13

Cast iron has stood since 1965 and it's still worth seeing how your aluminum will stand! The article was rolled out by sellers of aluminum batteries

Reply

- Michael January 26 2020 21 in: 48

It is immediately evident that the article was written by the seller of "batteries".

Reply

- SANYA January 26 2020 16 in: 48

FULL IN POST. DELIVERY OF THE 1ST SECTION OF THE CAST IRON SECTION 180 W OF BIMETAL 156-178 W THE HEATING SYSTEM MUST ALWAYS BE CORROSION IN THE PIPES AND NOT ONLY IN THE BATTERIES.

Reply

- Constantine January 27 2020 22 in 22

Not ORI!

Reply

- Sergey January 24 2020 15 in: 44

It is forbidden to install a valve in the bypass (jumper) in apartment buildings.

Reply

- Igor January 23 2020 11 in: 54

Scammers are ordinary article authors, I hope with this approach you will never have customers

Reply

- Semyon Ilyich January 23 2020 0 in 40

... just an ordinary freak wanted to show himself - it didn't work out! Not everyone in the village is fools !!!

Reply

- Pyatunin Joseph Grigorievich January 22 2020 08 in: 25

Dear friends, it is clear that the article is ordered. - Cast iron, as the author of one of the comments said, clearly surpasses all other metals in its consumer qualities, except, perhaps, beauty. Well, don't drink water from your face, as the proverb says. You can add only one thing - if the floor is at an angle of 45 degrees, approximately, to the battery, put a small and weak fan and turn it on, then the heat transfer of the battery will significantly increase.

Reply

- Sergey January 21 2020 21 in: 25

Sanhnik's experience 15 years, engineer experience 20 years. Steamer section cast iron 32 mm, aluminum 25, volume of water in one section cast iron 3 liters, aluminum 0.5 liter. So learn the materiel, read the primer, and do not confuse a pussy with a booty ,,,, For a private house for your boiler yes, for Central heating no. After a year, aluminum becomes clogged with dirt and must be removed and washed, and cast iron itself is cleaned

Reply

- DS60 January 26 2020 16 in: 17

Sergei, is your plumbing and engineering experience from the priests or from the priests? TWENTY-FIRST YEAR IN A ROW (since April 1998) in my apartment building (in a region with a climatic norm of January according to SNiP at minus 38 degrees) aluminum "Italian girls" function remarkably well, which have never been removed or washed, because they did not clog dirt contrary to your assurances. And not a single leak! Yes, I know that aluminum has chemical reactions, I know that an aggressive environment leads to corrosion. But the advantages of devices, not only external ones, are still great, and especially the convection effect. Previously, cast-iron radiators periodically leaked in places where plugs were installed. And in February 1998, a water hammer in the system simply knocked out a piece of the section and a little black boiling water gushed around the apartment, urgently demanding overhaul :))

Reply

Senya January 26 2020 21 in: 47

You're just a provocateur of the custom DS60.

Reply

- Sergey January 21 2020 21 in: 03

better than cast iron in terms of heat transfer, no, it's some dilettante who wrote or pushes bullshit for grandmother

Reply

- Dmitry January 21 2020 18 in: 44

It is necessary to kill the author of the article, because a fool is not so terrible as a fool with initiative!

Reply

- Roman January 21 2020 10 in: 18

The article was written by an obviously dropout consultant who has never practiced. I have more than 25 years of experience in working with radiators. Better in terms of heat transfer and durability than cast iron is not present. The minus is the appearance and the big pressure test, no more than 6 Bar. They cannot be installed in high-rise buildings. Otherwise, it's the best. P. S. I live in a Stalinist house and replaced my cast iron only after 60 years of service.

Reply

- Vasya January 30 2020 18 in: 44

However, in all high-rise buildings (and in ordinary cities, high-rise buildings mean 9-12-storey buildings), built somewhere before the 1985s, there are precisely cast-iron batteries.

Reply

- Gennady January 20 2020 22 in: 33

This was not written by amateurs. A ton of ferrous metal costs 13,000 rubles. minimum. Consider how much a cast-iron battery weighs, which will last another 100 years and tell who benefits from it?

Reply

- Vladimir January 20 2020 22 in: 08

The idea of a dropout.

Reply

- Olgerd January 20 2020 19 in: 18

Cast iron radiators are not bad at all, only they must be connected diagonally.

Reply

- Worker January 20 2020 19 in: 21

22 years ago, I installed Italian aluminum radiators - and my apartment has a temperature 2-3 degrees higher than that of my neighbors in an apartment building.

Reply

Vladimir January 20 2020 22 in: 16

Cunning ass only hurts the cause. Example: all apartments have the same taps, one "smart guy" decided to outwit and put on the tap twice as much, there will be more water. Others are not stupid either, they also installed huge taps.As a result, the pressure dropped, there is not enough water for everyone.)))

Reply

- Oleg January 19 2020 19 in: 34

Paid For Advertising Mediocrity author Complete Mediocrity. On Caster HER.

Reply

- Natalia January 18 2020 15 in: 07

The bullshit is written .. Cast iron radiators keep heat well .. and these cool down right away ..

Reply

- Vasya January 30 2020 18 in: 46

So it is good for some that they cool down quickly. For example, we have a minus, but as soon as the sun appears from behind the clouds, an instant sun, heat and stuffiness comes in the apartment. And so the thermal head will instantly react and the battery will maintain the set temperature.

Reply

- Andrey January 31 2020 15 in: 57

Natalia, such quality of the battery as "keep warm" is rather a disadvantage, and the advantage is "to give off heat", because, in my opinion, you should not be interested in an overheated boiler and a thermos instead of a battery, but in a quick release of heat into the room. If, nevertheless, you are interested in keeping the batteries warm, put pillows over them. Only this will not make the room warmer. By the way, painting cast-iron batteries, which from time to time needs to be done for aesthetic purposes, is a kind of manufacturing a thermos. The service life is no longer for you, but on the topic is also a question, since there is experience in operating cast-iron batteries - large and understandably - on the other hand, much less - in operating aluminum ones, they just appeared relatively recently. Both are clogged. In my MKD there are aluminum ones, for 9 years already. I have never regretted and remain their supporter. I took off one - to glue the wallpaper, washed it at the same time. There was dirt, I will not hide it. But I'm sure there will be no less in cast iron. I would like to ask: “Maybe someone was filming the“ chugunin ”so that the wallpaper was glued? I did not see. I saw how they were filming and washing - so this is a whole SHOW. The article can be customized, which is called for advertising, well, after all, Mercedes are also advertised. Although, of course, the crane on the "bypass" cut my eyes too.

Reply

- ELVIRA January 18 2020 13 in: 47

MOTHER STANDS CAST-IRON-IN THE APARTMENT (IN SPEAKING ON THE FIRST FLOOR AND NO SUN IN ALL) WHEN THE HEATING SEASON IS DRY AND WARM. THINK TO CHANGE.

Reply

- Alexander January 18 2020 13 in: 15

For yourself, your beloved only cast iron radiators, which are practically eternal. With regards to: 1. A small number of radiators are located on the required area. Because of this, the room is not heated properly. - increase the radiators with additional sections, which will not take much more space under the window sill. (As a rule) 2. Lack of a thermostat. - put it on an eternal cast-iron radiator, or a simple ball valve. 3. Poor space heating. - to heat 1 m3 of a room to the required temperature, N calories of heat are needed, which gives S the heat transfer area of the adopted eternal cast-iron radiator. 4. The model of the heating system has long been outdated and has become unusable. - If this is a model of the system, then it is necessary to change the model and not the eternal cast-iron radiators. 5. The presence of corrosion on the radiator, various damages in the form of cracks and leaks of the system. - Corrosion of aluminum manifests itself many times faster. For the best bimetallic radiators (aluminum + steel), the service life is up to 15 years. Pure aluminum 5-10 years max. Cast iron-eternal. Cracks appear on them only after being hit with a heavy metal hammer or when defrosting at negative temperatures. Cast iron radiator leaks bluff. If the new one does not flow (along the gaskets between the sections), then it will not flow later, and even more so (the joints coke to death). If leaking, have a dealer replace or stretch the turnbuckle, or go over and replace the gaskets. But this is in theory, since they do not flow.

Reply

- Vasya January 30 2020 18 in: 52

The ball valve is not a control valve. A ball valve is a shut-off valve.... Well, yes, to me, in order to build up a couple of sections on my cast-iron battery, what should I do? To dump a lot of money so that the locksmith would drain the water, remove the battery with the help of a grinder and such and such a mother, at the same time ruining the entire wall and pipe of the riser, then they heated this battery to red for an hour with a primus to unscrew the plugs, etc. in reverse order, only this time without refunding my money. Meaning? It is easier to immediately install new radiators with a thermal head.

Reply

- Nikolay January 17 2020 15 in: 54

I have such modern ones, I just want to change them due to the fact that neighbors both above and below can be heard very much (the sound of the voices of sometimes screaming neighbors comes straight out of them). They broadcast like a TV. I think the cast iron is viscous and not everything will be transmitted through it. ...

Reply

- The speed of sound in air 1200 m / s, in cast iron 5000 m / s 23 Jan 2019 at 9:44

Sound speed in air 1200 m / s, in cast iron 5000 m / s

Reply

- max January 17 2020 14 in 23

aluminum heats up faster and cools down quickly and cast iron, on the contrary, heats up and cools down longer and the heat output is the same, so what's the point of changing registers, unnecessary overpayment of money and a waste of time?

Reply

- Y January 17 2020 13 in: 51

simple crap ad

Reply

- Petya January 17 2020 4:10

The topic about heating is interesting, it puzzles everyone. I have had cast iron since the end of the 80s, I wanted to replace it at the turn of the 2000s, a leak appeared in one joint. A locksmith came, replaced the squeegee and said, don't try to change it to a modern one. In general, my system is already 30 years old and except for one joint, thank the builders! While pah-pah-pah, there are no problems with heating, but with the rest of the pipes, everything had to be changed. Think about it, whether it is the merit of the installers that they did not sell the pipes to the left. Either the water of which we heat, or the pipes themselves with batteries. And the topic was interesting, because, right before writing, as many as 2 emergency gang cars arrived at the next entrance, and the frost was below -20

Reply

- Register January 16 2020 at 13:26

A bit of theory ... When the MKD is designed, calculations are also made on the consumption and consumption of heat, all according to the consumption standards for the amount of heated area - hence the type and number of batteries and sections in the battery. Modern radiators are manufactured with higher heat transfer parameters, i.e. accordingly, and the consumption of his majesty's heat Now a question! Have not the home-made craftsmen ever thought that the time is not far away when the so-called "metering officers" from the management company will come and issue additional bills for the excessive consumption of heat consumed in excess of the design standard? Indeed, the UK does not officially give the go-ahead for the installation of new radiators. We are waiting, sir ...!

Reply

- KIR January 20 2020 23 in: 39

WHAT TO WAIT. IN NORMAL HOUSING HOUSES, LIKE US, THERE IS A GIGAALORIE COUNTER, WE PAY FOR HEAT ON THE COUNTER, AND IN NEW BUILDINGS, GIGAALORIES COUNTERS ALREADY WORK, WHEN IN EACH ROOM.

Reply

Constantine January 27 2020 22 in: 27

Don't YOU SHOULD.

Reply

- Ivan January 15 2020 9 in: 52

This was written by Mitrofanushka.

Reply

- Alexander0458 January 15 2020 4: 58

What a "eccentric" all this wrote. An absolute layman with a claim to a "specialist".

Reply

- Dimon January 14 2020 8 in: 53

He wrote an obvious layman and ignoramus