The outer part of the chimney can be built from refractory materials on a metal base. Sandwich chimneys are not inferior to brick counterparts in terms of resistance to environmental influences. Such a three-layer material can replace a deformed brick structure. It is important to properly build the transition from a brick pipe to a sandwich, so as not to disrupt the traction system.

The advantages and disadvantages of such a connection

Switching to stainless steel sandwich pipes provides the following advantages:

- easier and faster installation of a new chimney;

- you can do the installation yourself;

- less expensive;

- the design is lighter in weight, smaller in size;

- soot and other combustion products do not accumulate on smooth walls;

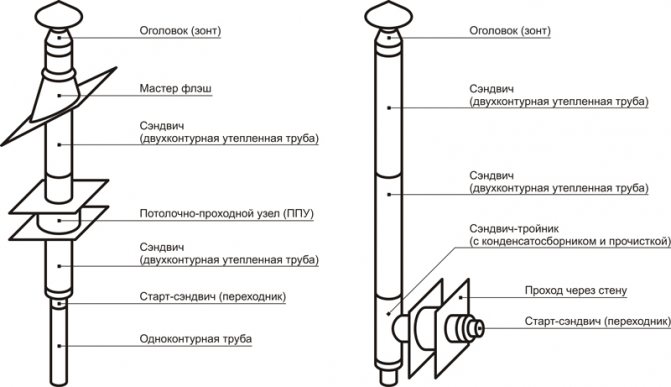

- the device can be brought out both through the roof and through the wall;

- the presence of an insulating layer, which to a certain extent reduces the amount of condensate;

- the possibility of installation through the rafter system.

The disadvantages of sandwich chimneys are the same as for all modular smoke extraction devices:

- over time, some loss of tightness at the joints;

- significant price of the kit and its installation;

- service life limitations (15-30 years).

Brief conclusion

A stove in a home has a number of important functions. The heating system must be cleaned of combustion products in time. A wide range of alternative elements of chimney systems is presented on the modern building materials market. Often the usual masonry is combined with lighter sandwich pipes. In this case, it is important to make the connection of the two elements tightly using one of the transition methods, observing building codes and regulations. Don't forget about safety. Flue streams must be free from the system.

Permanent address of the article

Do the work yourself or call the wizard

Assembly and installation of a sandwich chimney is feasible for almost every middle-aged man, taking into account the need to work on the roof. However, it must be borne in mind that a mistake in design, choice of a kit, installation of a structure can lead to unstable operation of the stove or fireplace, the appearance of carbon monoxide in the house. As a result, to eliminate the negative consequences, additional cash costs, loss of time and nerves will be required.

In order to save them, it may be better to invite professionals with experience in installing this type of chimney.

Estimated cost of work

The cost of installation work for installing a sandwich depends on:

- assembly channel length;

- the height of the house;

- type of roofing;

- roof configuration.

So the fee for the standard installation of a chimney for a private house with a roof ridge height of up to 6 m will be from 26 thousand rubles. As a rule, the price is specified by the master directly on the spot.

Often the installation price is set per running meter, on average from 1,700 rubles per running meter.

Which way is better

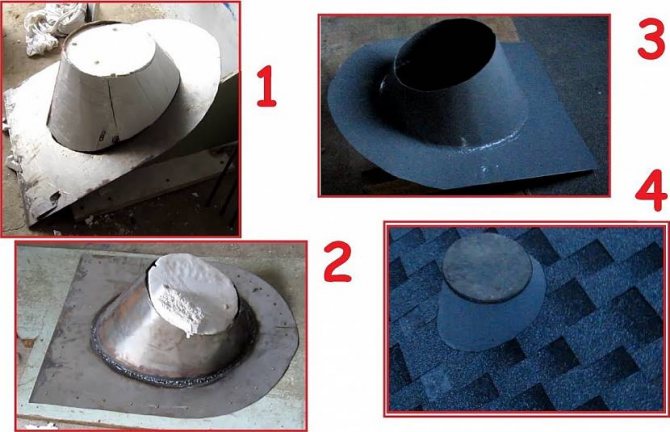

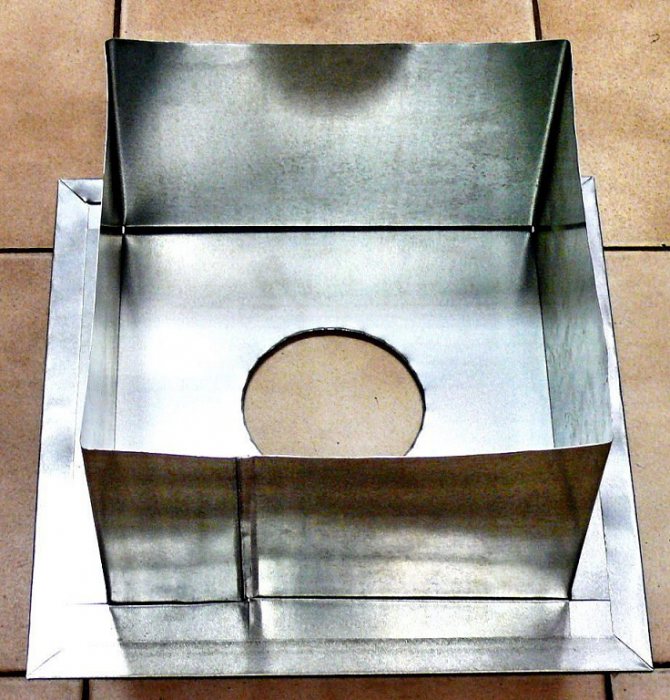

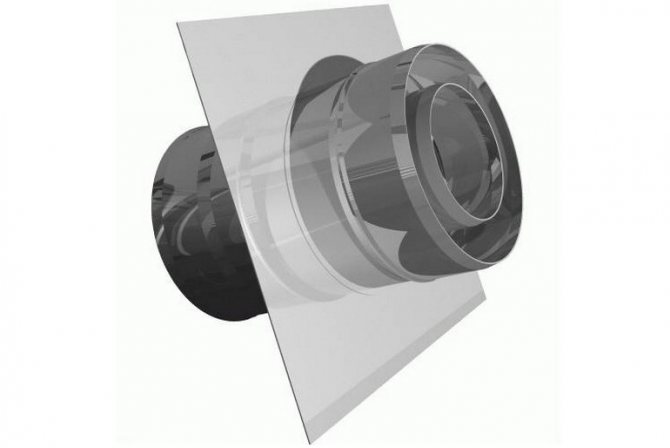

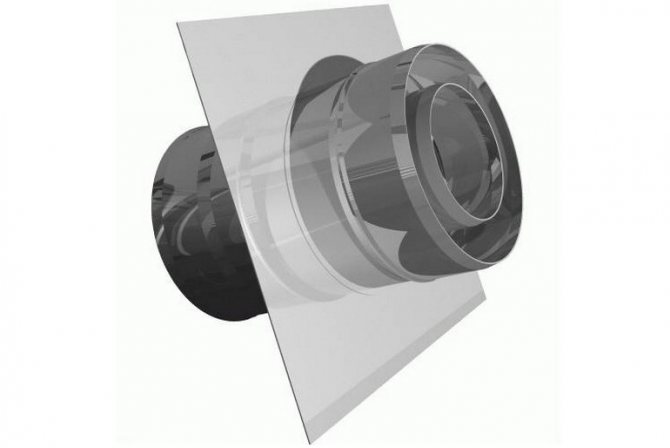

The most versatile adapter is made in the form of a metal mounting platform, with two nipples in the middle: one at the top, the other at the bottom. The site is laid on an old brick channel, sandwich pipes are inserted into the nozzles. When docking, as a rule, gaps are formed, for which sealant is used to seal. A simple adapter of this type can be ordered from a professional tinsmith. This photo shows the above adapter.

In the second method, an inner pipe of a double design is placed into the prepared hole, the gaps are closed with an oven solution.The outer pipe, resting on bricks, is coated with the same mortar at the joints.

In any case, the main requirement is to ensure the tightness of the structure. Therefore, only a special refractory sealant for chimneys is used as a hermetic composition.

Of course, the use of adapters reduces labor costs for installing the chimney and makes the connections more reliable and durable.

GOSTs and standards

The connection of the sandwich to the brick pipe must be carried out in accordance with the general rules and regulations established for the installation and operation of chimneys.

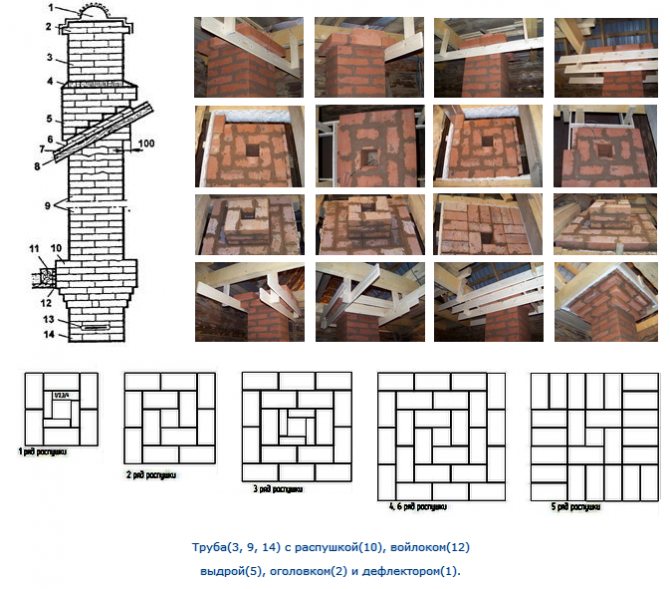

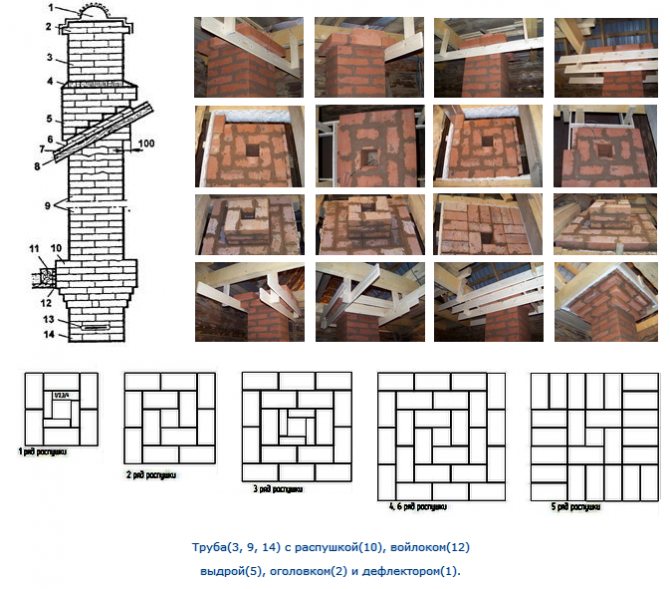

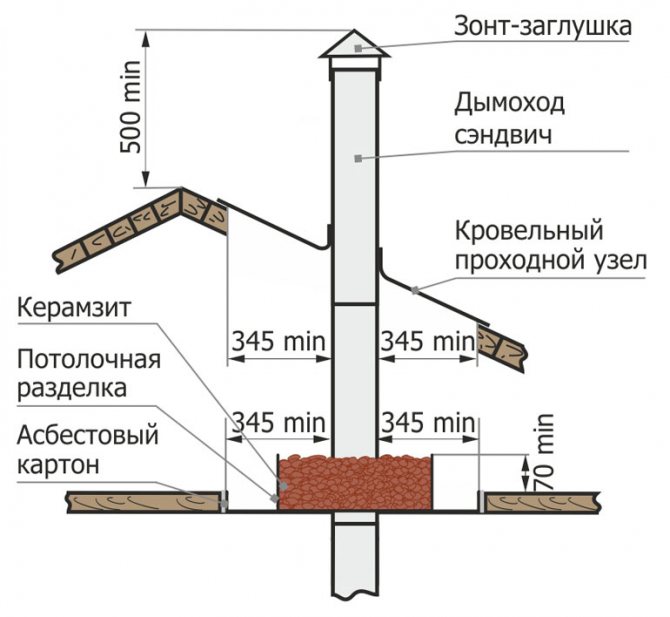

The total height of the brick and sandwich chimney from the fireplace or stove to the head must be at least 5 m, which provides the required draft.

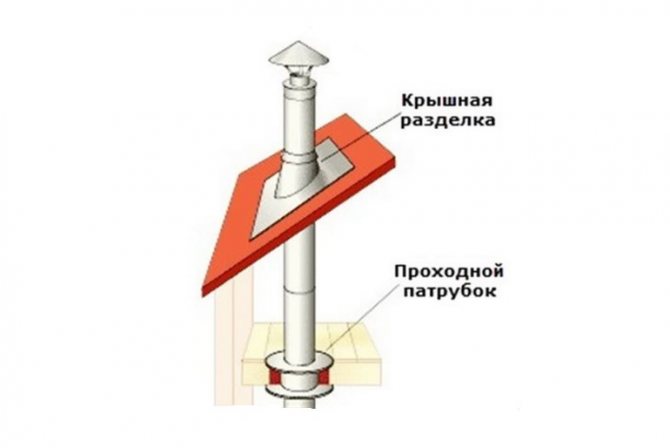

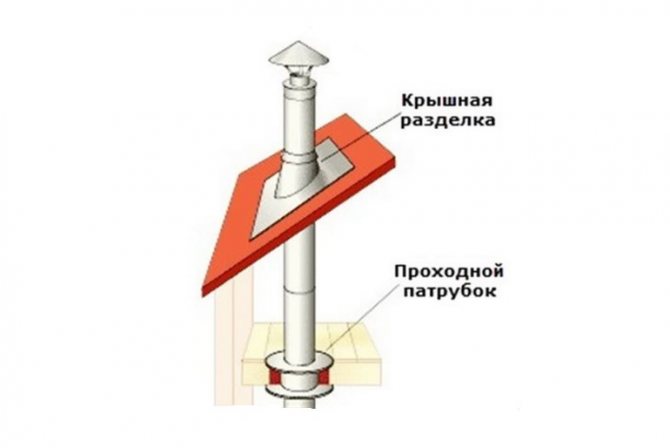

The assembly joints of the segments of the double device, the transition itself, are mounted so that they do not coincide with the ceiling and rafter floors.

The inner pipe must be made of stainless steel that meets the requirements of GOST.

The head of the sandwich is placed 50 cm above the roof ridge and at a distance of 150 cm from it.

You need to know that wood is capable of igniting at constant heating at 170 ° C. In this regard, compliance with fire safety standards is of particular importance. In the passages through the ceiling and roof, cutting is carried out - laying of a thermal insulation layer. The distance from the inner pipe to the edge of the ceiling in the passage must be at least 38 cm.

What is the chimney head

The design of the standard chimney outlet, which has a rectangular shape, is rather imperfect. It does not prevent dust and precipitation from entering the chimney, and with a high wind load, a reverse draft of flue gases is formed in the chimneycaused by the increased pressure of the moving air. These factors can significantly reduce the life of the chimney.

Pipe head

To avoid this, a head is attached to the top of the chimney outlet. There are a large number of variations in the forms and materials of manufacture of this product, but its inherent feature is the presence a protective cap that rises above the pipe outlet and protects it from moisture and dirt.

IMPORTANT!

Most headband models have droppers that accelerate the drainage of moisture. But some products are not equipped with them, so when buying a head in the store, you need to additionally find out about the presence of a drip.

Deflector, chimney, weather vane, umbrella, cap - it is synonymous with head, but there are minor differences between some of these names. So, a deflector is a product with a built-in diffuser, which is responsible for the correct distribution of air flows passing through the pipe. It prevents the formation of reverse thrust under wind load and enhances the forward thrust.

An umbrella is a product whose main function is to protect the inner space of the chimney from moisture and debris.... Unlike a deflector, it is not always equipped with a diffuser.

A weather vane is a head with an installed weather vane that determines the direction of the wind.

Some types of heads equipped with spark arresters to prevent sparks flying out of the pipe from entering the roofing. The easiest way to install a spark arrester is to install a metal mesh between the base of the cap and its roof, which at the same time will provide additional protection for the cap from debris.

DIY step-by-step connection technique

Video: installing the adapter and the passage of the ceiling:

Let's consider how to place the correct vertical sandwich pipe on an old brick channel.

- They dismantle an unusable part of a brick chimney.

- Prepare an adapter for installation: unbend the bends, cut off the outer rim at the bottom.

- Insert the mounting platform with the lower branch pipe into the channel of the old chimney on the oven mortar, fasten it at the corners with dowels to the bricks.

- Then the first segment is installed in the upper branch pipe and then the entire pipe in the assembly.

Required tools and materials

- For dismantling, you will need a puncher, a chisel, and a heavy hammer.

- To cut a hole in the masonry - a circular saw.

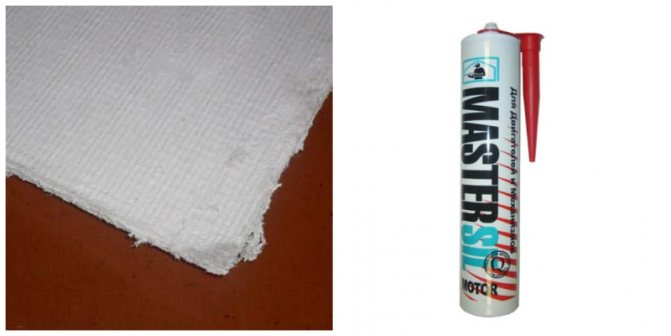

- For installation and fasteners - oven mortar, trowel, sealant, screwdriver, self-tapping screws.

Work progress

Often, the part of the old brick canal in the house is in good condition. Therefore, the output in the attic and roof is dismantled.

In this case, dismantling begins, before reaching the ceiling of 20 cm, prepare a flat surface for the adapter.

The gaps between the nozzle and the brick are sealed with a heat-resistant sealant.

In the places of passage through the attic and the roof, a fireproof platform is made.

The assembly joints of the sandwich, if provided by the manufacturer's instructions, are additionally secured with clamps.

On the roof, the pipe is fixed with a special roofing element, sealed with a silicone nozzle, and the external design of the chimney is made.

Installation features

If the brickwork has to be disassembled close to the brick oven, then the first link of the transitional chimney is better to make a thick-walled single steel pipe made of stainless steel. This area, especially in sauna ovens, is characterized by high temperatures during peak loads. The pipe with insulation will overheat and burn out quickly.

To protect the chimney from wind and rain, improve traction and smoke exhaust, a deflector is put on top of the pipe, securing it with galvanized self-tapping screws.

We carry out the transition using a metal platform with a pipe

In order to switch from a rectangular brick chimney to a round metal chimney, you will need a flat steel platform with a branch pipe, the diameter of which corresponds to the diameter of the steel pipe.

The outer dimensions (perimeter) of the brick chimney are 500 x 370 mm.

I purchased a 500 x 500 mm stainless steel platform with a 200 mm diameter pipe in the center. (that is, with a cross-section equal to that of the stainless steel pipe).

Now the platform with the branch pipe must be fixed somehow.

We will fix the platform with dowels and screws.

Application of sealant for stoves and fireplaces |

| The transition from a brick chimney to a metal one should be not only reliable, but also airtight, that is, there should be no gaps and cracks between the bricks and the stainless steel platform. To achieve the required tightness, we will use a special fireplace sealant. I used TYTAN fire resistant silicate sealant for stoves and fireplaces. It is intended for long-term repairs, filling joints, cracks, cracks in fireplaces, stoves, furnaces, chimneys and is characterized by: - good adhesion (adhesion of surfaces of dissimilar solids and / or liquids) to many building materials: metal, brick, concrete; - high temperature resistance - up to 1250 ° C and good resistance to frost and moisture; - does not crumble or crack after hardening, does not contain asbestos. In general, TYTAN fire-resistant silicate sealant is what we need in our case. |

Installation of a steel platform with a pipe |

| Now let's in order about the installation of a steel chimney ... What we have to do in order to move from a brick chimney to a metal one: We cut out the site in such a way that it would correspond to the dimensions of the brick chimney: 500 x 370 mm. (or did not exceed them). We estimate the attachment points of the platform to the brick chimney. Be careful: the attachment points should not line up with the masonry joint or fall into the edge of the brick. Now is the time to remind that in order to strengthen and give strength to the masonry, I laid out the last two rows of the brick chimney on a complex cement-clay-sand mortar. After the attachment points of the steel platform with the pipe are determined, we drill holes in it for self-tapping screws, and drill holes for dowels in the bricks. We insert the dowels into the prepared holes. We install a metal platform on a brick base, on which we first apply a fire-resistant sealant. We evenly pull the platform with self-tapping screws along its entire perimeter. Although the pad is well tightened with self-tapping screws (I spent a lot of them), I decided to wait for the sealant to dry. And only after that you can proceed directly to the installation of the chimney from stainless steel pipes. |

We suggest that you familiarize yourself with How to fix the chimney pipe on the roof with guy wires

This method allows you to arrange the chimney without a special adapter.

Perform installation in the following sequence:

- cut a pad out of the metal plate. Its size should match the configuration of the brick part. Try not to protrude the plate over its edges;

- outline the points of attachment of the platform to the brick opening. Make sure that the fasteners are not located at the edges of the brick or at the seams;

- in the pre-marked places of the metal plate, drill holes for the self-tapping screws. Make holes in the brickwork, but already for the dowels;

- insert dowels into the holes made;

- apply silicone refractory sealant to the surface of the masonry;

- install a metal pad on the sealant layer;

- using self-tapping screws, pull it evenly against the brick surface;

- after allowing the sealant to dry, proceed with the installation of a part of the chimney system from the sandwich pipe.

The adapter plate must be securely fixed to the brick base

By installing a homemade adapter with a pipe, you will speed up the installation of the chimney due to the fact that the pipes fit together perfectly through the holes with an expanded and narrowed end.

How to make the transition without an industrial adapter

How to make a transition if there is no adapter?

- After dismantling the collapsed part, a hole slightly larger than the diameter of the inner channel of the sandwich is cut out in the brick channel.

- The inner pipe is inserted into this recess, the gaps are sealed with oven mortar.

- In this case, the outer pipe will rest on the masonry. The slots at the point of attachment are simply coated with the same oven solution.

- Collect subsequent segments by inserting them into each other.

- In the passage through the hole in the ceiling, a cutting is performed, and only then a channel is passed through it. The sandwich is brought out to the roof, fixing it with an assembly platform or simply with scraps of a metal profile.

- The pipe fitting method can be used.

- After dismantling, a superstructure with a gradual narrowing is laid out on a suitable remaining part of the brick trunk with a rectangular masonry. She will act as an adapter.

- A so-called mono-thermo transition is inserted into the resulting hole.

- The outer part of the sandwich is trimmed and the protruding inner end is inserted into the superstructure. All this is sealed with a solution.

Related articles

Wooden floors in a brick house - types, how to install, instructions, advice from bricklayers

Facing windows with bricks - options, stages of implementation, instructions, advice from bricklayers

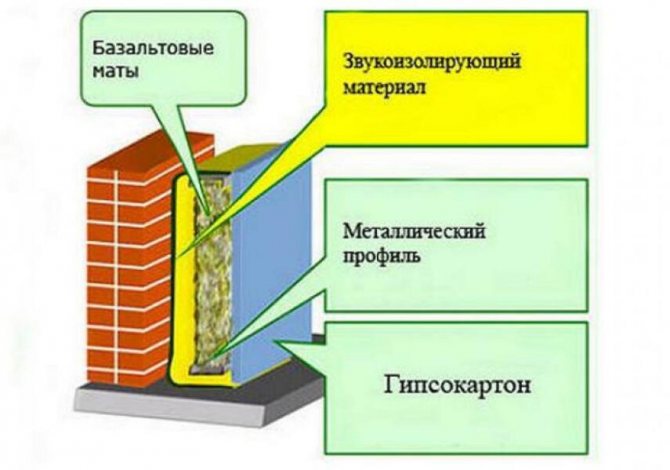

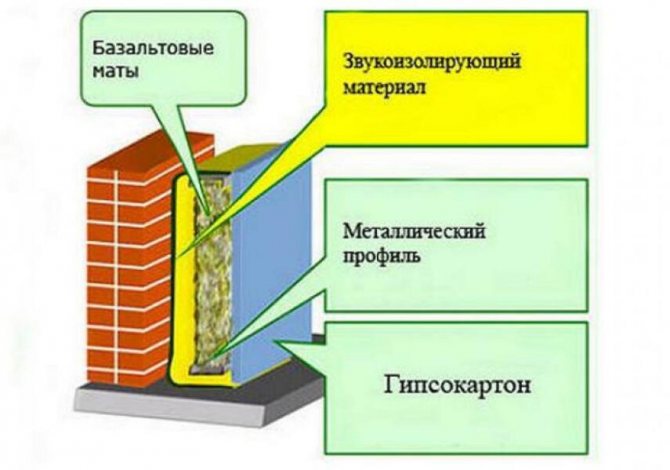

Soundproofing a brick wall - what can be done, instructions, advice from bricklayers

Wiring diagram in a brick house - how to make a wiring, instructions, advice from bricklayers

How to deduce zero with a brick on a foundation - methods, instructions, advice from bricklayers

Brick plinth on a strip foundation - masonry technology, instructions, advice from bricklayers

Switching from brick to sandwich - installation, pros and cons, instructions, advice from bricklayers