Plastic pipes are widely used, they are used for water and gas supply, installation of sewerage, storm drains, etc. Pipes of various types can be found on the market, so the consumer may have quite understandable difficulties with the choice of a specific version of pipes for the task he is solving.

Some of the most popular today are polypropylene (PP) and polyvinyl chloride (PVC) pipes. Each of the options has its own merits, therefore, when choosing pipes, first of all, one should take into account the purpose for which they are purchased. The main difference between PP and PVC pipes consists in the materials used in their manufacture, which determined their properties and scope.

Polypropylene pipes: advantages and disadvantages

The main positive advantages of these products are:

- Ability to withstand pressure equal to 20 bar and above. Although in multi-storey buildings, it rarely exceeds 10 bar.

- Thermal insulation at a high level.

- Affordable price.

- Easy installation and transportation.

- Anti-corrosion resistance.

- Hygienic material. The current conductivity remains zero, no sediment is formed inside.

- Able to serve for fifty years.

But polypropylene pipe products also have certain disadvantages. This is important for those who are interested in how to choose polypropylene pipes. Let's list the main disadvantages.

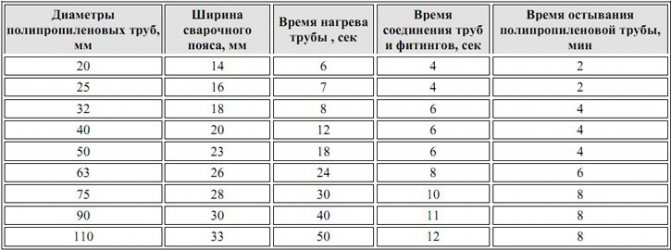

- The need to use a welding machine.

- Difficult to carry out repairs and maintenance.

- Failure to tolerate temperatures over 1000 degrees.

Video: advantages and disadvantages

Applications

Due to its properties, polypropylene has become one of the most demanded modern polymeric materials, and the area of use is expanding every year. Let's designate the demanded areas of application:

- Production of containers used for industrial and domestic purposes. Polypropylene containers and tanks are neutral and corrosion resistant. They are suitable for storage, transportation and technical processing of water and various aggressive liquids.

- Manufacturing of plastic pipes used in water supply and sewerage networks. Durable pipes are not subject to corrosion, which provides them with many years of service.

- Production of packaging materials.

These are just some of the areas of application of polypropylene - the scope of use is much wider. Its consumption in industrial areas is increasing every year.

About technical characteristics

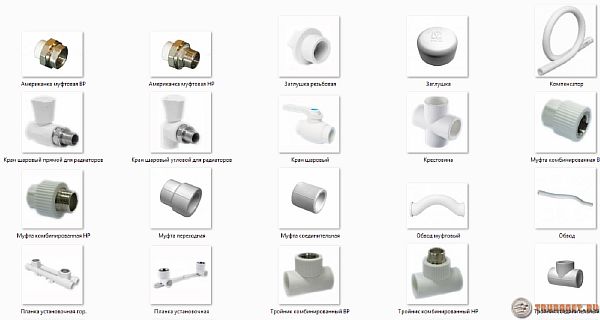

The advantage is that, thanks to special fittings, polypropylene is easy to connect to metal. And any plumbing fixtures that are already inside the room.

Angle fittings usually have a slight slope, 900 and 66, 45 and 33 degrees. If it is necessary to connect several polypropylene blanks together, then the soldering method is used.

Polypropylene pipes are available in different colors - black and green, white, gray. These products, except for color, hardly differ from each other.

Only the black ones have a protective layer so that the ultraviolet rays do not damage the structure. Which polypropylene pipes are best for plumbing is determined by the following characteristics.

A diameter of 16-100 millimeters is enough if the water supply is installed in an apartment building. Homopolymer pipelines are needed in order to conduct cold water. Block copolymer varieties do the same job perfectly.

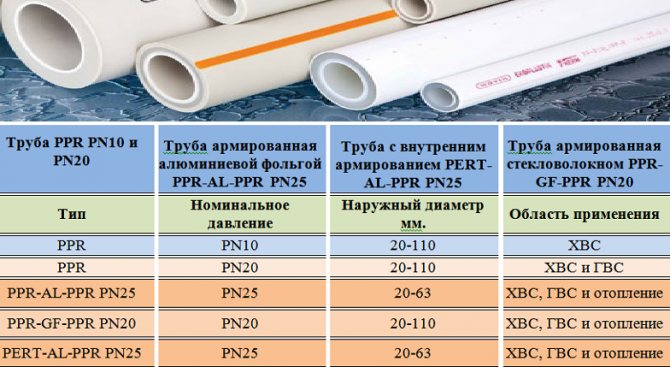

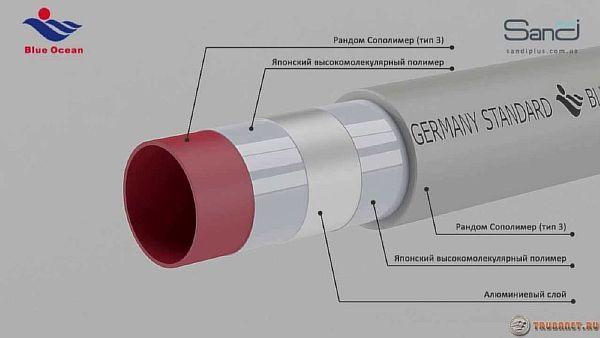

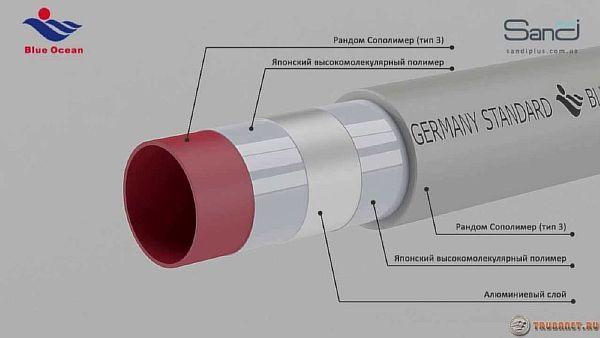

If there is an abbreviation on the marking PPR - this means that the structure contains aluminum foil reinforcement.This is necessary to reduce thermal expansion.

PPRC means that its coefficient is reduced by 5 times. This characteristic is an undoubted advantage when choosing pipes for hot water supply.

Reinforced-plastic pipes are designated PEX-AL-PEX. PN-10 or PN-20 best suited for cold water supplies.

If there is a marking PN-25 - it means that there is an additional layer of reinforcement, which is an indisputable advantage.

Therefore, they are used both in heating and for hot water supply. Polypropylene or reinforced plastic pipes? Everyone makes his own choice depending on the goals.

With lashes up to 4 meters, polypropylene pipes are usually produced, which are installed in the domestic water supply system. Diameter measurements are based on the outside of the pipeline.

Video: How to choose

PPRC pipes

These are pipes made of high temperature polypropylene. They are produced with a cross-section diameter of 20 ÷ 160 mm. Reinforced with fiberglass or aluminum. Their main difference is their low thermal expansion rates, low pressure loss. The production technology fully complies with GOST and the requirements of foreign standards. What are pprc polypropylene pipes? Specifications, properties and advantages of the plastic product:

- low thermal conductivity;

- high level of sound insulation;

- resistance to corrosion processes;

- resistance to aggressive substances;

- high strength;

- resistance to bending more than once;

- environmentally friendly material;

- ease of installation;

- affordable price;

- long service life.

Russian-made pipe products

The combination of quality and low price are the main advantages, for which they love the products produced by Russian manufacturers. PRO AQUA is one of the companies that has become popular not only among ordinary buyers, but also among real professionals.

Such structures continue to work quietly even at temperatures up to +95 degrees and more. There is a long service life, the ability to resist corrosion, aggressive chemicals.

PRO AQUA are suitable for those who need to maintain system performance at pressures up to 79 atmospheres.

Reinforcement with aluminum in the middle of the wall is a distinctive feature of the RVK brand. But their size is unstable, which is the main drawback.

Heisskraft manufactures products that help meet consumer demand. They are available in gray, but this shouldn't be surprising. During the manufacturing process, carbon black is added to the composition. It becomes a stabilizer for the structure.

The average level of quality is a distinctive feature of the assortment of the manufacturer Politek, which can undoubtedly be considered a disadvantage.

Video: choosing pipes for water supply

About Chinese products

The Chinese manufacturer cannot yet boast of the ability to maintain quality indicators at a high level. But even in this country there are manufacturers who deserve the attention of every buyer.

For example, Blue Ocean is a subsidiary of a British concern. It is engaged in the production of not only high-quality pipe products, but also fittings.

Polypropylene from China does not cause problems during soldering, which can be attributed to the advantages. The main thing is to use a nozzle with an inner rounding when processing the top layer. The disadvantage is the inconsistency of the indicators of the outer diameters.

Dyzain is known for its wide range of products. They do not require additional cleaning and preparation. Thanks to this, dismantling and installation work becomes much easier to carry out.

For hot and cold water supply, pipes with additional reinforcement are produced. Expansion in the linear plane due to heat is no longer a problem.

The main advantages of polypropylene pipes:

- practically do not corrode;

- excellent resistance to mechanical and bioactive influences;

- practically do not create noise and vibration;

- fittings are installed easily and into any part of the given material;

- almost absolute safety for human life and health;

- heat resistance and low heat loss when transferring hot water;

- durability of operation, which is several times longer than the service life of steel alloy pipes;

- ease.

Pipes from Turkey. Qualitative characteristics

TEBO manufactures 20-160 mm polypropylene base products. Such products are able to withstand the effects of almost any corrosive environment.

There is a special series with aluminum and fiberglass reinforcement, they are mounted in heating systems.

Pilsa designs are also widely used in practice. Largely due to the combination of such excellent qualities as wear resistance and strength, elasticity.

Video: polyethylene pipe rolls

The main thing is to purchase a line of pipes that is suitable specifically for a particular pipeline. Then the operation will not be associated with problems in the future.

Any manufacturer requires buyers to strictly adhere to the rules set forth in the instructions for use. Pilsa, for example, does not allow its pipelines to be bricked up in the wall, which is an undoubted drawback.

It is better to install a controlled boiler on the system in order to achieve the best results. It will allow you to maintain a temperature inside that does not exceed 95 degrees.

Novaplast manufactures an assortment characterized by a fairly low cost, a small selection of external fasteners. But the quality remains high.

VALTEC also boasts reliability and durability. This applies not only to pipes, but also to fittings. PP-R 100 is a polypropylene brand that has become the main one for production processes.

Firat adheres to all standards when it puts its products on the market. Therefore, its products are able to withstand even severe rust. True, there is also a drawback in the form of a high coefficient of thermal expansion.

The manufacturer Kalde covers its pipes with a continuous shell of aluminum. Therefore, the quality of products is somewhat reduced when compared with Ecoplastic, for example.

Polypropylene of Czech origin

WAWIN Ecoplastic is a Czech company that has become practically the leader in this area of production. Quality products are not the only indicator of a manufacturer's superiority. The products are fully compliant with world-class standards. Where can Czech products be used?

- Underfloor heating and cold water supply.

- Cold water supply with high pressure, hot water supply.

- For distributions that go to hot water supply, central heating.

- With central and underground heating.

- In order to transport hot water from cold, air distribution systems.

In specialized stores, buyers can easily find:

- Fittings, all-plastic with combined varieties.

- Fiber is a series of polypropylene products.

- Stabi is a multi-layer pipe brand.

- Pp-r is a brand of all-plastic pipe products.

Fibera are plastic pipes that are reinforced with fiberglass. Linear expansion due to heat is minimal. With a low weight, the strength is quite high. The surface does not require additional treatment before welding begins.

Video

FV-Plast is another company that manufactures polypropylene products. They can be used not only for water supply with heating, but also for underfloor heating systems.

The manufacturer produces tubes with a rigid structure, which are protected from temperature changes by an aluminum insert. They can be installed in systems with any level of complexity.

Physicochemical basis of polypropylene

Polypropylene is directly obtained from propylene gas by polymerization. This process takes place in the presence of metallocene catalysts. Initially, polypropylene is a white substance.

The beginning of active production of this polymer is associated with the use of catalyst installations of Ziegler and Natta, when in 1957 it became possible to obtain isotactic polypropylene. It is obtained at a temperature of 80 ° C under a pressure of 10 atm.

There are several types of polypropylene used in the production of final products:

- Isotactic.

- Atactic.

- Syndiotactic.

Isotactic propylene has become the most demanded in production.

This was due to the peculiarities of this species, where the side CH3 groups, which are located unusually in relation to the main chain, received a special position. This structure of polypropylene has determined a number of its main qualities: high crystallinity and strength, hardness, ability to maintain shape at high temperatures.

Some finished products have successfully used a combination of several different types of polypropylene. For example, when atactic polypropylene is added to the composition, it is possible to endow the manufactured part with flexibility and softness.

The main physical and chemical properties of polypropylene can be presented in the form of a table:

| P / p No. | Property of polypropylene | Indicator value |

| 1 | Density, g / cm3 | 0,90-0,92 |

| 2 | Tensile strength, kg / cm2 | 260-400 |

| 3 | Elongation at break at break,% | 200-700 |

| 4 | Melting point, ° С | About 170 |

| 5 | Material brittleness onset temperature, ° С | -10…-20 |

| 6 | Dielectric constant, at 106 Hz | 2,2 |

| 7 | Specific electrical resistance, Ohm | 1016 |

| 8 | Volumetric expansion coefficient when heated | 0.00033 at 20 ° C |

| 9 | Frost resistance, ° С | -20…-25 |

| 10 | Specific heat, cal / (g × deg) | 0,4…0,5 |

Thus, if we analyze the tabular indicators, polypropylene manifests itself as a stable neutral material. It does not significantly change its properties at positive temperatures. At the same time, it remains neutral in relation to electric current, excessive air humidity and high temperatures.

A special feature of propylene is its neutrality towards many chemicals. So, this material is resistant to the effects of acidic and alkaline solutions, alcohols, as well as many inorganic compounds, including salt solutions. An exception may be interaction with some solvents. So, polypropylene, when placed in benzene, ether is capable of swelling and subsequent dissolution. It is noteworthy that in the case of timely removal of the swelling source, for example, benzene, polypropylene completely restores its structure while maintaining its original properties.

The most destructive effect on polypropylene is concentrated acids - sulfuric and nitric, chlorosulfonic.

Among the disadvantages of polypropylene, several characteristic features can be noted at once:

- low frost resistance. The fragility arising under the influence of negative temperatures, however, is eliminated by introducing ethylene units into the material. In practice, materials such as ethylene-propylene rubber and butyl rubber are also actively used;

- sensitivity to external light effects, as well as to interaction with oxygen. This drawback manifests itself in the form of the ongoing process of decomposition, external clouding of the material, loss of gloss and even the appearance of small cracks.In order to prevent active aging of the material, manufacturers are forced to somewhat smooth out this effect by introducing special polymer additives-stabilizers into the composition.