The need for thermal insulation

Before a foreman who decides to optimize the heating circuit, two questions inevitably arise: why do this and how to insulate the heating pipes?

Thermal insulation of heating pipes on the street and at home is highly desirable for the following reasons:

- This measure helps to significantly reduce the loss of thermal energy during the transfer of the heat carrier (usually hot water) from the place of primary heating to radiators and other devices.

- Thermal insulation of heating pipes on the street allows you to prevent thawing with subsequent subsidence of the soil layer in the places where the heat supply line passes.

- Covering heating circuit elements with an insulating layer is an excellent means of preventing corrosion processes (if metal pipes are used to supply heat).

- Since, as statistics show, when the heat carrier (including water) is transported over long distances, up to 25% of thermal energy is lost (in some cases, more), timely high-quality thermal insulation of pipes allows you to reduce the cost of paying for heat.

Materials used

Today, thanks to the development of the chemical industry, leading not only to an improvement in the quality of the final product, but also to the creation of new materials with increased ergonomics, a huge number of materials are presented on the market that allow you to insulate heating pipes on the street and in the house.

In addition, a large selection allows each craftsman to choose a product that ideally suits him in all technological characteristics - from operating conditions to cost.

Insulation for heating pipes on the street or in the house must meet the following requirements:

- low thermal conductivity of the material - it is necessary to reduce heat loss to a minimum;

- incombustibility, fire resistance - allows not only to use the material on the hottest pipes, but also to provide additional fire safety of the building and adjacent areas;

- ease of use - it should be possible to install and change heating elements without applying much effort.

According to the method of application and the form of release, materials for insulation of the heating circuit are divided into the following categories:

- Sheet (piece) material.

- Insulation in a roll.

- Insulating casing elements.

- Filling heaters.

Below we will consider the most popular types of insulation materials.

Criteria for choosing heaters for heating pipes

Looking at a hardware store, and even more so in a hypermarket, you can get confused by the abundance of thermal insulation materials. Moreover, this diversity is manifested both in the assortment of goods and in its value. When choosing, first of all, you need to focus on the technical characteristics of the material. A good insulation must meet the following requirements:

- low thermal conductivity;

- low water absorption;

- resistance to high temperatures;

- durability;

- ease of installation.

The times when multilayer insulation of pipes was widely used have long sunk into oblivion, leaving behind pictures with disheveled heating mains that are well known to all of us. Today, the priority is simple-to-install, practical and neat thermal insulation solutions.

How not to insulate heating mains

The following materials are mainly used:

- mineral wool;

- stone wool;

- polystyrene (penoizol, expanded polystyrene);

- polyethylene (penofol, polyethylene foam);

- artificial rubber;

- thermal insulation paint;

By the method of installation, the following types of heaters for pipes are distinguished:

- Roll

- Shroud

- Sectional

- Sprayed

The choice of a specific type of thermal insulation depends on the financial capabilities of the developer, the method of laying pipes and their availability, the temperature of the coolant, and the availability of installation tools.

Expanded polystyrene

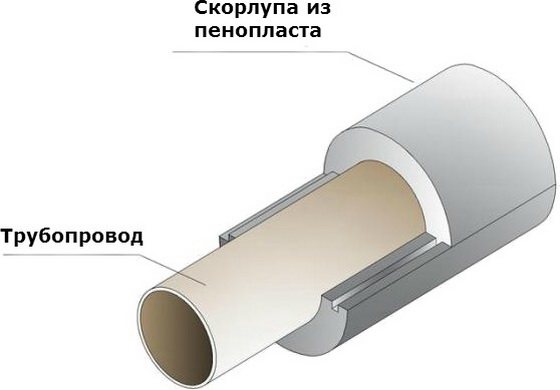

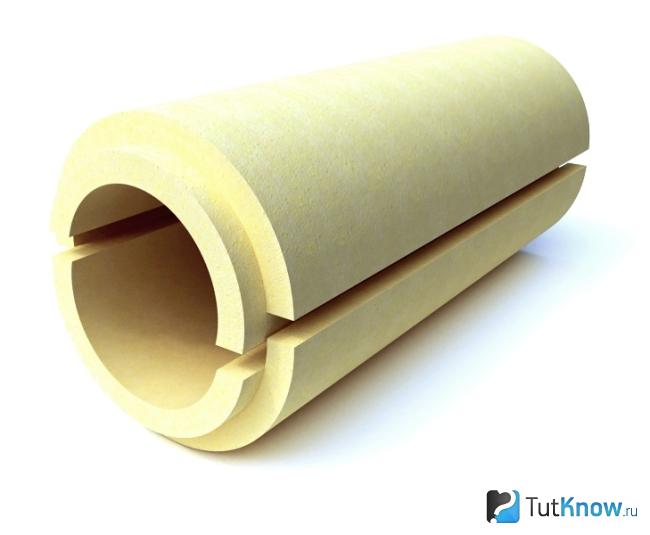

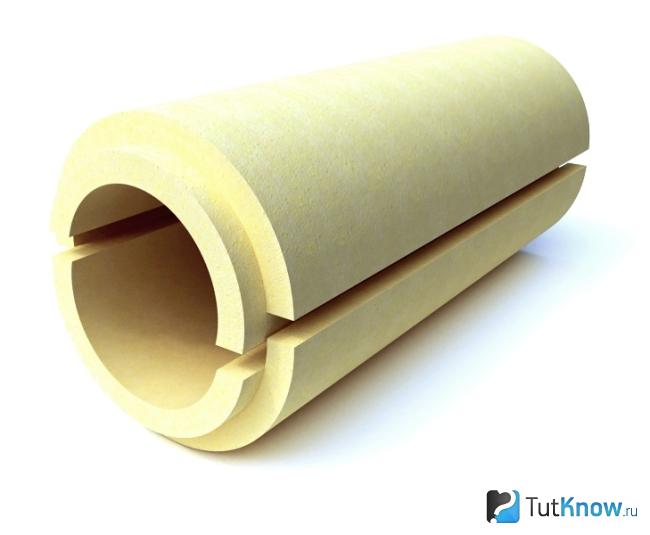

Also, a polymer material that has become a traditional one, called, because of its rigidity, "shell". The insulation consists of two hemispheres with recesses for the size of the insulated pipeline elements.

- low cost;

- small value of heat transfer;

- moisture resistance - polystyrene foam does not absorb liquid;

- ease;

- ease of installation;

- the ability to combine with metals and polymeric materials.

The main disadvantage is the inadmissibility of using on excessively hot pipes.

Advantages and disadvantages of foam insulation

Polyfoam (also known as PPS, polystyrene foam, expanded polystyrene, "polystyrene" in colloquial speech) is a popular insulation for pipes, designed for maximum protection against the effects of cold and moisture. Foam heaters are easy to install, provide a high class of thermal protection, and also protect pipes from physical impact (within reasonable limits). The foam is reliable and able to withstand even constant ground impact, which makes it possible to use it to protect the pipes laid in the soil, which most need it.

In addition, the foam can also be used as an acoustic insulator, so if you are annoyed by the sound of water in the pipes, this is the only way out. It is worth noting that the foam shell is reusable, so if you need to replace the pipe or even dismantle it, you can always remove the shell and use it somewhere else. Given the maximum ease of installation, this is very important.

It is also worth noting that shells are inexpensive, especially if the only alternative is to lay pipes deep on a concrete base. A running meter of foam protection will cost about 160 rubles for a pipe with a diameter of 110 mm (the standard for laying water supply / sewage throughout the house). For larger products, the price will increase exponentially - for example, a pipe with a thickness of 219 mm will cost 310 rubles, which is still more profitable than alternative options.

This insulation has no drawbacks (if high-quality foam is used, and not oversaturated with styrene), so we recommend using it.

In addition to foam, another insulation is actively used, which came straight from Soviet times. Mineral wool is the simplest known insulation. Half a century ago, he ruled the market. The main problem is the complexity of installation, since the insulation is supplied only by weight and requires that it be securely fixed to the pipes in some way. The classic solution is to wrap the pipe with a water-repellent fabric, on the inner surface of which cotton wool is glued. The method is complex, unreliable and disposable, which is why mineral wool (and its kind - glass wool) is almost ousted from the market these days.

A little more popular is inshell mineral wool - a recent decision, an attempt to bring this material back to the market in a new form. It is a shell made of solid material (usually polyurethane foam, but foam is also found) and actually combines the advantages of polyurethane foam and the low price of mineral wool.

However, this solution is not particularly popular due to its theoretically low reliability and weak protective characteristics relative to the same foam. Perhaps one day it will be able to compete with foam or even full-fledged polyurethane foam, but at the moment it is treated with distrust.

Penofol with a heat-reflecting aluminum foil layer

This insulation roll is an aluminum foil with a layer of polyethylene foam applied. The material is lightweight, reliable and easy to use.

Whatever material a home craftsman chooses, pondering how to insulate heating pipes in the ground, he should remember that not only the type of insulation is important, but also the quality of the work performed; otherwise, the cost of the material will be in vain.

Uninitiated people may doubt the advisability of insulating the pipe running from the boiler room to the house along the street. In fact, why do we need hot line insulation?

Application of foil insulation for pipes

According to experts, the simplest way to insulate pipelines in the basement is the use of mineral wool, which is covered with a layer of foil, while the thickness of the wool reaches 50 millimeters, and the reflective layer is 10-30 microns.

Before proceeding with the insulation of pipes in the attic or in the basement, you need to study the operating conditions of the materials. For example, foil with foamed polyethylene is fragile and subject to deformation under external influences. Strength indicators can be increased if you prefer thermal insulation with foil for pipes and foam.

In turn, basalt insulation has many characteristics in common with mineral wool, but it is heavier because it has a higher density.

It is convenient to install self-adhesive insulation. If the foil is damaged, use aluminum tape. Lavsan film with foil and polyethylene foam do not reflect infrared radiation, therefore such material must have a significant thickness of the foil layer.

Why do you need to insulate street communications?

It would seem that this is an unnecessary occupation. Well, let's say the location of heating pipes in the open air, from the house to the boiler room, cannot be done otherwise. But they are always hot, so why also protect them from the cold?

In fact, outdoor pipe insulation is essential. The heat supplied through the highway is “lost” on the way in the cold. That is, the pipe, even in frost, will not freeze if a hot liquid flows in it. But the efficiency of the return will decrease, and accordingly the energy consumption will increase and, as a result, the prices spent on heating.

This is especially true for the DHW system. When insulating a pipe outdoors, the goal is primarily to maintain the temperature. The same measures will not be superfluous for the main pipelines in the autonomous heating of the house.

Insulation for polystyrene foam pipes features of manufacture and use

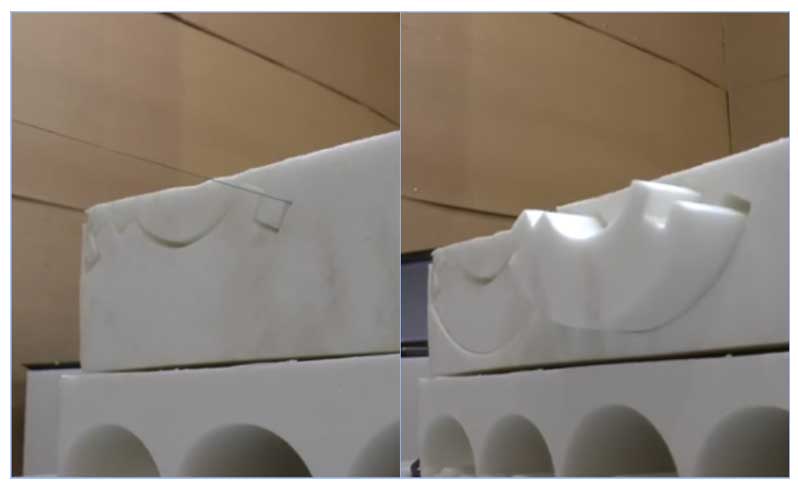

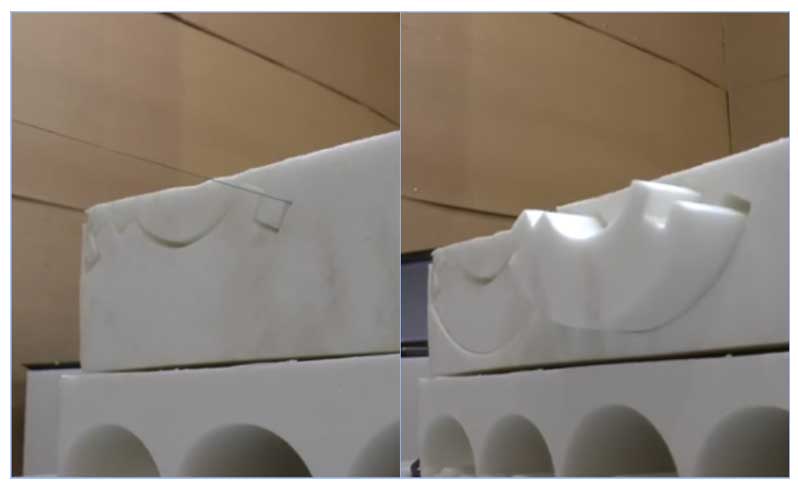

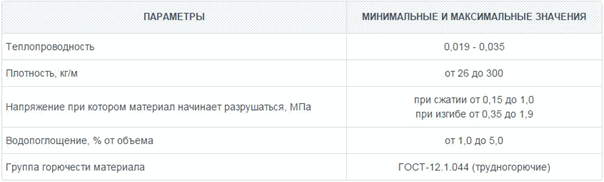

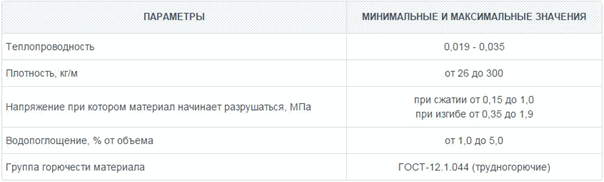

Foam shell is made on special machines by cutting a segment from foam plates using a heated string. The industrial insulation shell has the following operational parameters:

- Insulation is produced in the form of a prefabricated cylinder of various lengths and thicknesses, a standard casing for pipes has two or four segments, for wells their number can be up to 8.

- Standard materials for the manufacture of the shell are PSB-S foams of various densities; for open pipelines, a material with a stronger structure is used.

- The temperature of the pipes on which the shell is installed should not exceed 80 C., with special additional gaskets, it is possible to operate the insulation at temperatures up to 110 C.

- The standard size of the shell has a length of 1 meter, the minimum diameter of the inner circle is 17 mm., The maximum size of the inscribed circle is 1220 mm. wall thickness may vary.

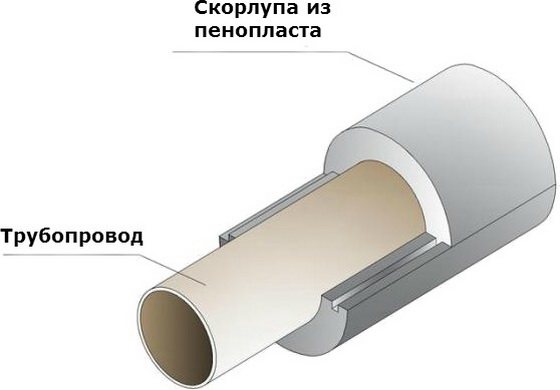

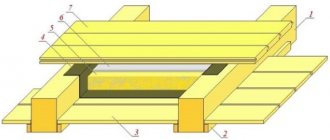

Fig. 6 How the insulating shell is obtained

- All halves of the shell have protrusions, which ensure the connection of the thorn into the groove; glue or tape is additionally used to fix them. The assembled shell can always be disassembled without damage or deformation.

- For outdoor work, a polystyrene shell is used, covered with a material that protects its surface from exposure to ultraviolet radiation.

- Machine tools with programmed control make it possible to produce sheaths of the required thickness and diameter on request; in some modifications, a groove for laying the heating cable is provided.

Technological requirements for insulating material

The modern market is rich in various offers, so there will be no problems with the choice. In order to reliably insulate the highway on the street, it is better to give preference to specialized materials that meet the following characteristics:

- low thermal conductivity;

- resistance to aggressive environment;

- wide range of operating temperatures;

- long service life;

- simple installation.

Several materials meet these criteria, and each option is subject to consideration.

Features of insulation with mineral wool

Material that does not need extra words. An old, reliable product for pipe insulation, indoors and outdoors. With its use, not only the insulation of the pipe from the cold is provided, but also protection from external factors. The material does not burn, is immune to acids, and is inert to alkalis and other chemical compounds. The cost of mineral wool, which is one of the lowest in the segment, also has a positive effect.

Like most porous insulation materials, mineral wool is hygroscopic and absorbs moisture well. This is a disadvantage. Water absorbed into the material will contact the pipe, causing a corrosion reaction. Therefore, using it as a heater for highways on the street, it is necessary to additionally provide waterproofing. But with an eye on which pipes are selected for heating the house. Plastic or polypropylene does not require such modifications. If the line is laid from metal pipes, then outside the insulation is wrapped with roofing material or foil films. Which will certainly affect the increase in the cost of work.

Technical characteristics and quality of expanded polystyrene

Simplicity and quality distinguish this type of outdoor heating pipe insulation. These are two polystyrene half-cylinders fixed with a special tape. At the joints, special grooves are provided to ensure a tight fit.

The cost of polystyrene foam insulation is not much higher than mineral wool. It is preferable to use it for insulating water pipes in the basement and attics. It is convenient to insulate them and risers. Simple design and easy installation, allow you to fix it even in hard-to-reach places, bypassing complex exits of pipe lines.

On a note. In all, the positive material has a small drawback - the impossibility of processing folds, which makes you think about its use.

Reliable protection of communications with penoizol

Insulation of heating pipes with penoizol is considered one of the most reliable. In terms of quality, this material can be compared with polystyrene. The only difference is in the application. The pipe is insulated in the open air by spraying a liquid product, which, after solidification, acquires a shape characterized by high density. For individual heating, this is one of the best options. It is possible to treat the most inaccessible places with penoizol.

No additional work is required after processing. The material is absolutely inert to any impact: it does not absorb moisture, air does not pass through it, chemicals do not cause any harm to the structure. For decoration purposes, you can wrap it on top with roofing felt.

Liquid insulators for the protection of street communications

These are relatively new materials that can be used to reliably insulate heating pipelines. In this line, there are two types of insulators:

- Sprayable. Spray applied and requires special equipment;

- Painting. For application, use a regular brush or roller.

The advantage of both types of liquid insulators for heating pipes is the ability to apply to any, even the most inaccessible places.

Foamed polyethylene: when is the best time to use this material?

Such pipe insulation is sold on the market in rolls. This is a foil-coated film of various thicknesses. It is cut in parts and wrapped around the lines. The advantages of expanded polystyrene include the following qualities:

- moisture resistance;

- durability;

- easy installation;

- hygroscopicity.

Masters have different opinions about this material. Given the low thickness, at least 3 layers must be applied to create a cold air barrier. If polypropylene pipes are selected for heating, then at least 5 layers. The work is simple, but time consuming. In addition, many have doubts about the reliability. Insulation in 3 layers will protect the highway in regions with a mild climate. To prevent pipes from freezing in severe frosts, it is necessary to wrap them in at least 7–8 layers, and this is already a high material consumption and laboriousness.

Foamed rubber: market novelty on guard of heat

According to its characteristics, such thermal insulation of heating pipes located on the street surpasses all the materials presented above. But it should be noted that the cost of the material also ranks high. Therefore, the range of application does not apply to the private sector.

By class, thermal insulation belongs to roll materials, and of the positive qualities, the following can be distinguished:

- resistance to low temperatures (up to –40 ° С);

- immunity to ultraviolet light;

- fire safety.

Varieties of heat-insulating materials and methods of their use for insulating pipes on the street

The range of heat-insulating materials, despite the high requirements for their characteristics, is very wide today, therefore, the budget becomes the guiding criterion when choosing how to insulate the pipes of the heating system on the street.

Foamed polyethylene

Polyethylene foam (PPE) is reasonably considered one of the most effective heat insulators, since its thermal conductivity is only 0.035 W / m2 deg. C is two times lower than that of mineral wool (0.07 W / m2 deg. C). Such polyethylene is offered to the consumer in rolls, sheets and in the form of sleeve-covers of various sizes.

The elastic bubble structure of PPE in its roll version facilitates the implementation of insulation on valves and pipelines of a complex configuration, since it allows you to cut the material into strips of the required width and wrap problem nodes with it. Polyethylene is vapor-water-tight, therefore it is not only heat, but also a waterproofing coating.

The specific density of PPE, depending on the structure, is 32 - 35 kg / m3, so the heat-insulating shell from it does not create significant loads on the pipeline and supports.

Despite the fact that polyethylene can be set on fire, its flammability is low (class G-2), and when ignited in the absence of additional sources of fire, the PPU quickly goes out, while the substances released by it during combustion are of little toxicity.

For the device of thermal insulation of straight sections of the pipeline, it is more convenient to use PPE sleeves (with or without a side notch), since winding pipes with coiled material with the necessary technological overlap requires additional reinforcement of the insulating layer with knitting wire or clamps and does not look aesthetically pleasing.

With many advantages, the price of PPE is not high, which explains its high popularity among owners of private houses.

Penofol

This insulation is a type of PPE and differs from it by the presence of a foil layer on one side, which is a reflector of heat waves, which increases the heat-insulating as well as hydrophobic properties of the shell.

Thermal insulation made of foamed foam - foil-clad PPE is also produced in the form of rolls, sheets and cylindrical shells.

Important!

The use of foamed polyethylene and penofol is limited to the upper limit of the application temperature of 85 degrees. This value is sufficient for the use of materials on the pipelines of an autonomous heating system, but the higher temperature of the central heating mains degrades the characteristics of the PUF and makes it unsuitable for use in these conditions.

Mineral wool and products based on it

To insulate the outer heating pipes with ordinary or foil-clad mineral wool, wrapping the main line with a strip of this material with fixation with a knitting wire is the oldest method of thermal insulation. But the popularity of this technology, due to the rather high efficiency of its application and affordability of costs, is still high - the choice of mineral wool as an insulating material for large volumes of work is quite justified.

Mineral wool is produced in three varieties:

- glass wool;

- stone;

- slag.

The first two varieties meet most of the requirements for thermal insulation - they have low thermal conductivity, are neutral with respect to the insulated surface, are quite elastic, chemically resistant and fireproof. As for the slag variety of this material, the process of its manufacture determines the presence of residual acidity in such cotton wool, which negatively affects steel pipelines - in this regard, pipes have to be coated with a special paint, which negates the advantage of slag in the price.

However, all three varieties of mineral wool are water-permeable and hygroscopic to varying degrees, therefore, insulation made of these materials must be protected with galvanized iron casings, which will simultaneously protect against mechanical damage.

Polyurethane foam insulation

Polyurethane foam (PPU) is produced in texture as elastic (foam rubber), rigid and sprayable. Rigid and sprayed polyurethane foam is used as thermal insulation - an effective and functional insulating material with more than 30 brands.

All PPU brands are united by the following advantages:

- breathability;

- resistance to chemicals (higher than that of expanded polystyrene foam);

- low moisture absorption (good hydrophobicity).

Rigid polyurethane is produced in the form of a prefabricated shell-shell or cylinders with a mounting slot, having certain dimensions, with a foil-coated outer surface. The products are placed on the pipe and fixed with clamps, heat-resistant sealant or their own self-adhesive inner surface.

Pipes are also produced, on which thermal insulation is already made of polyurethane foam with a protective sheath - the so-called pre-insulated, which are joined together by welding followed by insulation of only welded joints.

The sprayed polyurethane foam is applied to the previously prepared surface of the pipeline with a special spray device in layers and, as it solidifies, the thickness of the insulating layer is increased to the calculated value. To perform thermal insulation using this technology, special expensive equipment and protective clothing are required, therefore, it is not used in domestic conditions.

Foamed rubber

The raw material for this high-quality material is synthetic rubber, the production cost of which is much lower than the cost of natural material, but the quality characteristics are just as high.

Foamed rubber properties:

- high elasticity with a large margin of tensile strength;

- low specific density of the material - 40 - 80 kg / m3;

- high thermal insulation characteristics;

- no shrinkage during operation;

- low flammability;

- zero vapor and water resistance;

- chemical inertness.

Rubber thermal insulation is produced in the form of roll material, sheets of a certain format and tubes-sleeves for standard pipe sizes. When using foamed rubber as insulation for heating pipes outdoors, it is necessary to use protective covers made of galvanized roofing iron, which will protect the material from dust pollution and mechanical damage, including vandalism.

The price range of rubber insulation, depending on the thickness and manufacturer, is wide enough and allows you to choose a material with an objective value for the price / quality ratio.

Places where communications need to be isolated

Each business has its own nuances. Insulation of the heating pipe and all related works are adjusted by the weather conditions in the region, and by the design factors of the systems. Insulation is necessary if the highways run underground, in open spaces, in attics and basements, and of course in open areas.

Polymer pipes are less susceptible to cold. But nevertheless, in severe frosts, heat transfer is disrupted in them. And, regardless of which of the heating options for a private house is laid, pipe insulation allows you to reduce heat losses, as well as protect them from abrasion and physical damage.

Despite the rigidity, metal heating pipes are also not omnipotent. They are exposed to external factors. In addition to the fact that they give off heat more intensively, the metal is also susceptible to corrosion. Insulation for the heating pipe and hot water supply is able to stop these shortcomings.

There can be no doubt that the insulation of heating pipes is necessary. Long years of operation have shown weak points, so engineers of many companies are struggling to develop perfect materials that help reduce heat losses.

Heat losses in the pipeline are one of the most pressing problems for both autonomous and central heating systems. In the event that utilities are involved in this problem in the regions, then in private houses thermal insulation for heating pipes is the concern of homeowners. And due to the fact that the amount of work is quite small, it is quite easy to do it yourself.

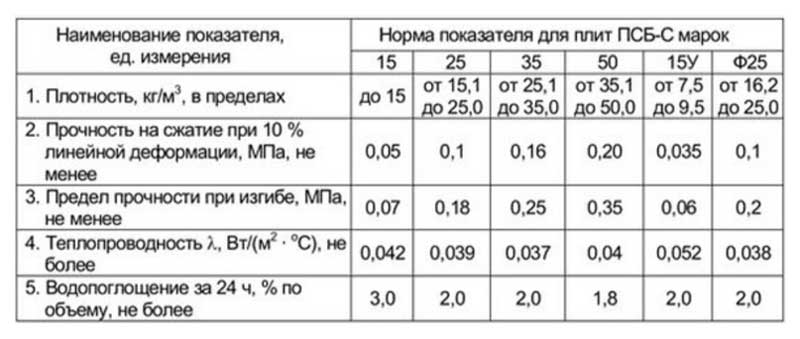

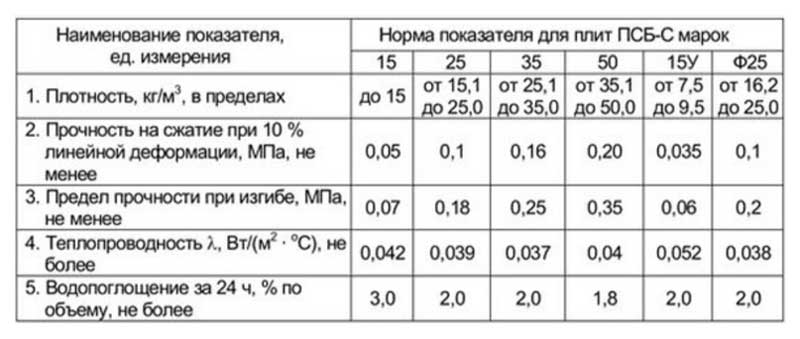

Expanded polystyrene and its types

Fig. 2 Foam sheet - structure

The shell for pipe insulation and insulation is made of polystyrene foam, which is expanded polystyrene foam with an air content of more than 90%. Cylindrical segments of insulation pipes are cut from foam sheets of various thicknesses and grades.

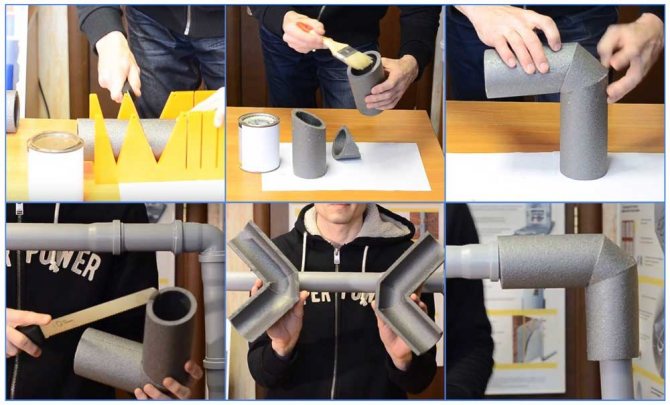

Depending on the manufacturing technology, there are three types of foamed plastics (PPS): non-pressed (PSB), pressed (PS) and extruded (EPS).

PSB is produced by foaming a polystyrene foam suspension at high temperatures, it has an industrial marking, which includes, in addition to the letter designation, a digital indication of its density and the C symbol - self-extinguishing. It is a common cheap material widely used in construction for insulating the outer surfaces of buildings and interiors for various purposes.

PS is made after mixing and pressing polystyrene and porophore, after which the pressed blanks are foamed in a steam environment. Well-known brands - PS-1 and PS-4 have a higher density and better physical characteristics than conventional PSB.

EPPS - extruded polystyrene foam is produced by adding catalyst gases to polystyrene, leading to its foaming, after which the material is squeezed out of a special installation (extruder). In the construction industry, extruded polystyrene foam under the Penoplex trademark is widely used, which has the highest strength indicators of all types of foam.

Fig. 3 Technical characteristics of PSB expanded polystyrene

How to choose a heat insulator?

A wide range of insulation makes it possible to choose a specific type of thermal insulator that is most suitable for a specific situation and wallet.

Requirements for heat-insulating materials:

- a low coefficient in specific thermal conductivity, is the main condition for the suitability of the material to perform the main task (thermal insulation);

- sufficiently high thermal stability - the material must be able to maintain its characteristics and structure at high temperatures, (105 ° C - in use, up to 700 ° C - in production) without any reaction with surrounding substances, not be a catalyst for chemical reactions and not emit harmful substances.

- chemical resistance - the ability of a material not to react with organic substances;

- sufficient hydrophobicity - water-repellent characteristics that prevent the heat-insulating layer from getting wet, due to the fact that when the pores are filled with water, the material becomes an excellent heat conductor and at the same time contributes to the formation of corrosion on the pipeline;

- vapor permeability - the ability of a heater to dry quickly if it gets wet;

- air permeability - a characteristic that prevents the heat insulator from filling up by air movement with dust particles, which increases the thermal conductivity of the insulating material (all solid heat insulating materials meet this requirement, for soft ones additional protection is needed);

- durability - the material must retain its characteristics and meet all requirements throughout the shelf life, which is indicated in the instructions for its use.

Advantages and disadvantages of pipe insulation with expanded polystyrene

Expanded polystyrene is the most popular heat insulator for sanitary installations.

Its advantages include the following qualities:

- Good thermal conductivity, which reduces heat loss in systems by 2-4 times.

- High density, which allows it to withstand high mechanical loads throughout the entire service life.

- The ability to reuse the product. This property allows you to disassemble the system and install the insulation in the old place.

- The material has a long service life.

- Expanded polystyrene absorbs a minimum amount of water and can be used without waterproofing. It completely eliminates the ingress of moisture on the surface of the pipeline, protecting it from corrosion.

- The insulation is well resistant to salt solutions and aggressive substances, which are abundant in groundwater.

- It is not afraid of bacteria, mold and mildew, it is not eaten by animals and insects.

- The shell retains its qualities at any temperature extremes.

- Expanded polystyrene refers to self-extinguishing products. It burns for only 2 seconds, which is a good indicator for rooms. For reliability, the insulation can be additionally treated with fire retardants so that it does not react to open fire.

- The shell reduces assembly time. The procedure can be performed even by a person without plumbing experience.

- Even the longest cylindrical pieces are very lightweight and can therefore be stacked without helpers. Low weight allows transporting large quantities of elements in a passenger car.

- When working with expanded polystyrene, there is no reason to fear that it can harm the human body.

- The casing is available in various sizes and shapes, which allows you to select samples for each specific case. It looks very aesthetically pleasing and does not require decoration.

- Insulation refers to universal insulators, it can be used both outside and inside the room.

- After installation, there are no cold bridges left on the pipes.

- Expanded polystyrene absorbs noise well, so the sound from the movement of the coolant will not be heard.

- The diameters and thickness of the product are set, the dimensions are maintained with great accuracy, which increases the thermal insulation and the speed of installation.

Even such a modern insulation has drawbacks. These include such unpleasant properties:

- The shell must not be painted and varnished with products containing gasoline, solvents and other liquids that can destroy it.

- The material is quickly destroyed by ultraviolet radiation, therefore, in open places it must be protected from sunlight.

- The insulation is fragile.

- Under the influence of an open fire, polystyrene foam emits poisonous smoke.

Instructions on how to insulate pipes yourself

- it is necessary to calculate and purchase thermal insulating materials;

- wrap the pipes with foil tape or foil. Foil in this case plays the role of a heat reflector;

- installation of insulation around the pipe. The rigid sectional casing and soft insulation just need to be put on the pipe. With regard to other soft materials, they must be cut into blanks equal to the width of the pipe diameter. Then wrap it around the pipe and fix it with clamps, tape or wire. With rigid insulation, the situation is more complicated. From it, it is necessary to create a kind of box around the pipe (or use pipe shells of the required diameter);

- inspect the pipe for the presence of "cold bridges" and eliminate them;

- fix thermal insulation on the pipe with metallized or plumbing tape;

- if necessary, cover the thermal insulation with a protective material (film), and seal the joints with adhesive tape.

The money spent on the purchase and insulation of pipes quickly pays off thanks to savings on payments for heating the home.

Insulation installation

The shells in the form of which insulation for expanded polystyrene pipes is sold can be paired, trinar or four-part structures. In other words, one complete insulation ring, put on the pipe, is assembled from two, three or four shells. At the ends of the shells there are grooves and protrusions - the so-called locks, which serve to fasten them together.

Collect the shells not directly, but with an overlap, or stepwise. This is necessary so that you can reliably connect many shells together without glue, tape or the like. However, for reliability, it may still be worth using scotch tape.