Basic features and properties:

- Long service life. According to statements - up to 80 years. You understand that, given that the material is only a few years old, it has not yet been possible to test it in practice. But, as you know, mineral wool lives for a very long time.

- Low thermal conductivity. It is no more than 0.034 W / (m ° C) at a temperature of plus 10 degrees.

- Compressive elasticity. The compression ratio is no more than 10%.

- Increased moisture resistance. A minimum layer of waterproofing is required.

- Soundproofing. Noise penetration is reduced by 3-4 times.

- Water vapor permeability. The material allows for a breathable facade.

So, it's not hard to see that there are enough pluses. By the way, read about the cons at the end of the article. But, in fact, there are different types of this insulation, more precisely THREE. In addition to the most common insulation Technoblock Standard, there are two more:

- Optima;

- Prof.

Classic "Technoblock"

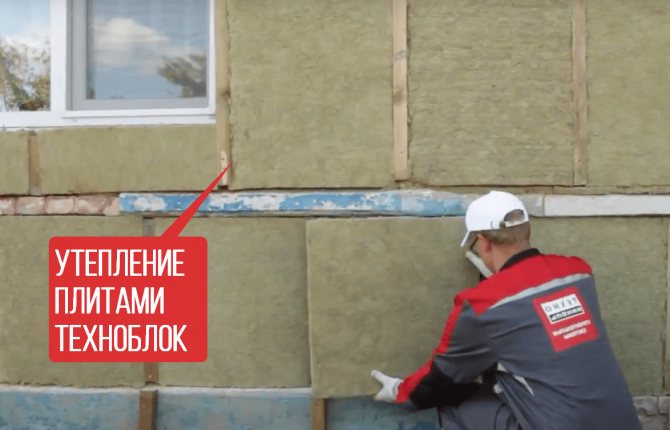

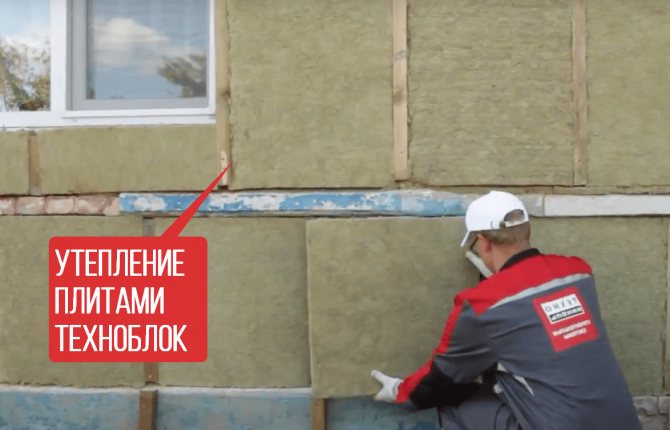

Insulation TechnoNikol Technoblok Standard has a density of 40 to 50 kg per cubic meter. This type of thermal insulation does not withstand high loads, and therefore it is used in frame structures. For example, in decorating a house for siding. The video below shows how the company's specialist insulates the wall under the crate.

The thickness of the slabs can be from 50 to 200 mm. For central Russia, the manufacturer recommends plates of 100 mm. Considering the cost, insulation of 50 mm is most often used, laying it in two layers.

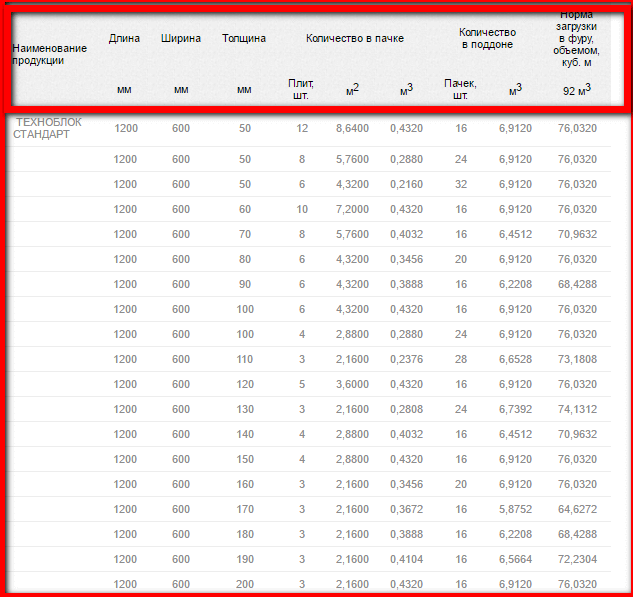

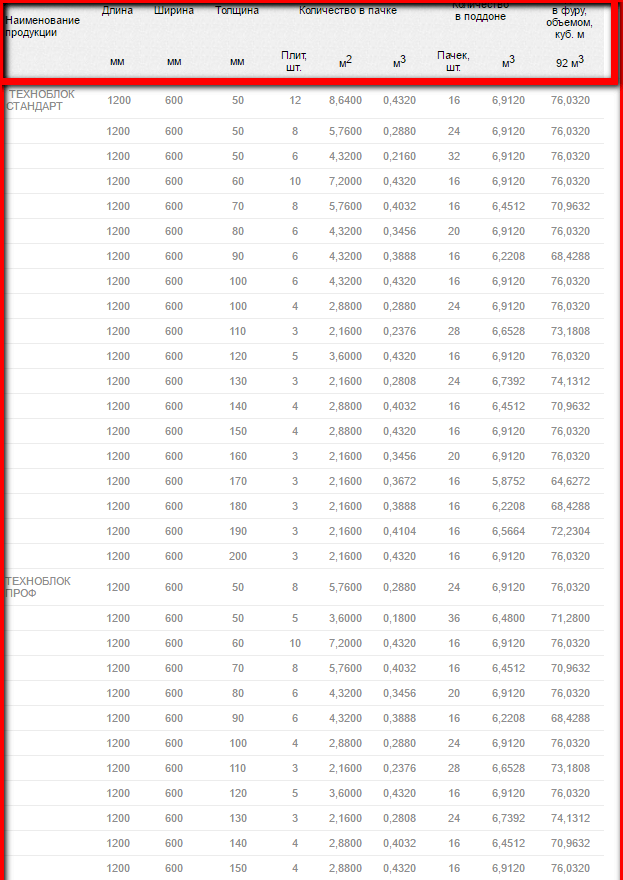

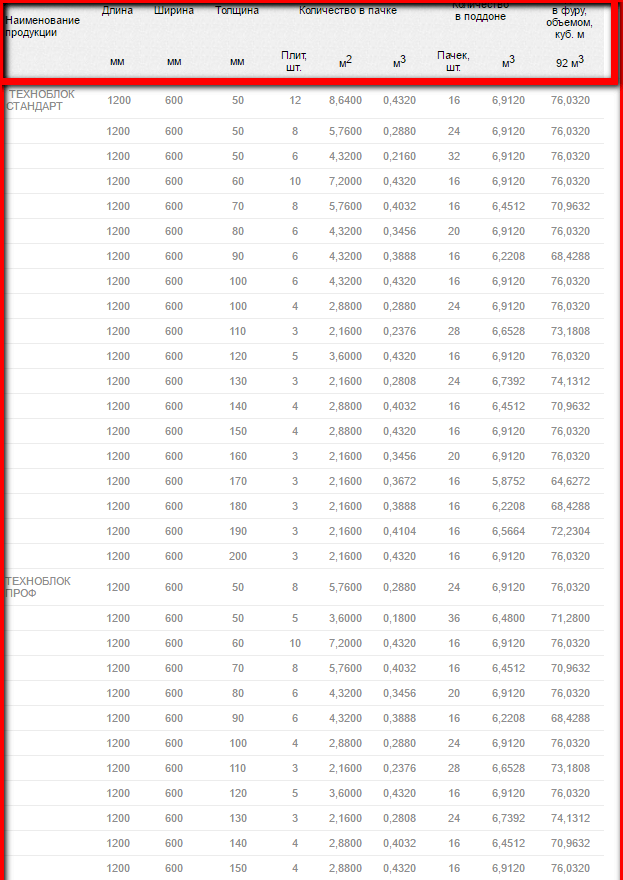

Below in the table you can see all existing types of packaging and material parameters.

In the photo below, a specialist is laying Technoblok slabs on the front wall.

After installation, the thermal insulation must be covered with a vapor-waterproofing film.

Of course, the material can be used not only for insulating external walls, but also, for example, in structures:

- Interior partitions;

- When insulating the attic;

- Balcony floor.

Insulation Technoblok and Technolblok standard: characteristics

Technonikol is one of the largest manufacturers and suppliers of high-quality thermal insulation materials. Their modern insulation systems reduce heating costs and are sound-absorbing. Insulation material under the brand name Technoblok Standard is a mineral wool slabs made of basalt fiber, used to insulate external walls for decorative finishing or layered masonry.

Composition and features of Technoblok products

For the production of thermal insulation products, the company uses minerals of the basalt group. The increase in the environmental friendliness of products is facilitated by a decrease in the amount of binding organic substances in the composition of the plates. Insulation Tehnoblok, due to the chaotic interweaving of fibers, absorbs the acoustic signal by 80-90%. It is popular in the creation of a soundproof barrier for framed walls and partitions.

The mineral base makes the material non-flammable and resistant to chemicals. Microorganisms, mold and rodents do not damage the insulation layer. The products are designed for a wide range of temperature fluctuations from -60º to + 200º C. They do not change the working properties and do not have harmful emissions, the melting of the fibers begins at 1000º C.

Moisture resistance is a prerequisite for high-quality insulation of external walls, therefore, during the production process, special additives are included in the slabs that contribute to hydrophobization.

Fiber boards are characterized by high elasticity, they shrink without problems before being packed in plastic wrap, and when opened, they quickly return to their original shape. The material is easily cut with scissors, easy to install.

Basic characteristics of basalt slabs

- thermal conductivity coefficient - 0.033-0.036 W / m * K;

- vapor permeability - 0.3;

- water absorption - 1.5 %%

- organic matter - 2.5%;

- flammability degree - NG.

Products are produced with standard parameters: 1000/1200 × 500/600 mm, thickness - 50-170 mm.

Line of insulating materials Technoblok

Basalt slabs are available in three types:

- Standard - density 40-50 kg / m3, insulation under load is compressed by 10% of the volume. The material is neutral to metal and concrete structures.

- Optima is a material with a high density of 60 kg / m3. It is characterized by the stability of the shape of the slabs during long-term operation. By applying force, it can be compressed by 8%, after loading the mineral insulation restores its parameters.

- Prof is the most durable and resilient insulation of the Technoblok brand. It has the lowest thermal conductivity among the products of this brand of 0.033 W / m * K, its compressibility is at the level of 5%.

Professional insulation

For the most severe operating conditions, Technoblok Prof.

The density of the insulation is 60–70 kg per cubic meter. And the compression ratio is only 5%. And yet, this material is a semi-rigid mineral wool slab. This must be taken into account when choosing this type of insulation.

Technoblok Prof is a semi-rigid mineral wool slab

Prof can be from 50 to 150 mm thick. All types of slabs are shown in the table.

So, we saw that the main differences between the three types of this material are in density, that is, rigidity.

Below is a comparative table of characteristics

| Feature type | |||

| TECHNOBLOCK STANDARD | TECHNOBLOCK OPTIMA | TECHNOBLOCK PROF | |

| Density, kg / m3 | 45 ± 5 | 50-60 | 60-70 |

| Compression% is not large | 10 | 8 | 5 |

| Thermal conductivity at 10 ° С, W / (m. ° C) not more | 0.034 | 0.034 | 0.033 |

| Thermal conductivity at 25 ° С, W / (m. ° C) not more | 0.036 | 0.036 | 0.035 |

| Thermal conductivity under operating conditions A, W / (m. ° C) not more | 0.043 | 0.041 | 0.04 |

| Steam permeability, mg / (m.h.Pa) not less | 0.3 | 0.3 | 0.3 |

| Moisture at mass% not more | 0.5 | 0.5 | 0.5 |

| Water absorption at a volume% not more | 1.5 | 1.5 | 1.5 |

| Organic matter content% not more | 2.5 | 2.5 | 2.5 |

| Flammability | NG | NG | NG |

Does this insulation have any disadvantages? Alas, where without them. Let's highlight the main two:

- Relatively high cost;

- The need for a waterproofing layer, albeit a small one.

Insulation Tehnoblok standard

Comfortable housing is associated with warmth in winter and coolness in summer heat. Correctly constructed and well-insulated external walls of the dwelling contribute to this. Technoblok Standard products from TechnoNIKOL are excellently suited for additional insulation of various building structures in terms of their technical characteristics.

The article provides a description of the plates and the permitted uses.

Purpose of products

Technoblok Standard - mineral wool made using rocks belonging to the basalt group.

Mineral wool

Cotton wool is formed in the form of separate slabs, convenient for installation work.

What are they used for?

Mineral wool slabs, according to the manufacturer's recommendations, are used as:

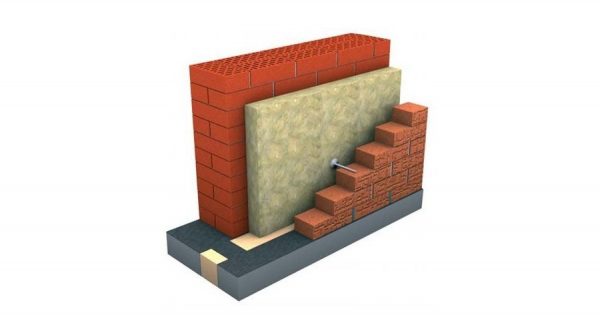

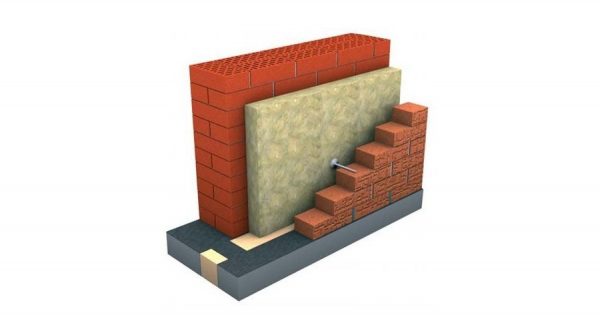

- Thermal insulation of brick masonry, foam, slag and expanded clay concrete blocks. The sheets are placed between the outer wall and the facing masonry.

- Soundproofing walls from the same materials.

- Heat and sound insulation of frame walls made of various materials, with further finishing.

- The first layer of insulation in the walls, equipped with the technology of the curtain facade.

Insulation on the crate

- Soundproofing partitions.

Insulation of laminated walls

Attention! Technoblok Standard is not intended for thermal insulation of facades with a wet method under plaster. For these types of work, the manufacturer produces other types of plates.

General requirements for insulating materials

The choice of insulation is influenced by its technical and consumer properties. "Good" thermal insulation must meet the following requirements:

- Have a low coefficient of thermal conductivity, which contributes to the retention of heat in winter and prevents excessive heating of the walls in summer.

- Environmental safety for people living in the house. The material should not emit toxic substances during heating and other unfavorable influences, and also not be a source of dust.

- Fire safety, be non-flammable and not meltable when exposed to open fire.

- Ease of installation.

- Maintaining the basic physical and mechanical characteristics during long-term use. These include maintaining their physical dimensions under different operating conditions, the plates should not "crumble" over time.

- Resistance to decay, infection by fungi and bacteria, low adaptability to the life of rodents.

All these properties are met by the basalt slabs produced and sold by TechnoNIKOL Corporation under the name Technoblock Standard.

Product properties

Technoblok Standard slabs are made by sintering basalt rock, which determines the useful properties of the products and their practicality. Plates have:

- Water repellent properties - do not absorb moisture.

- Resistance to open fire - the material is not flammable.

- High density, which contributes to resistance to caking and facilitates installation work. The material retains its structure under mechanical stress.

- High strength compared to roll materials.

- Long service life.

- Excellent heat and sound insulation properties.

- Not susceptible to damage by rodents and pests.

- Resistance to decay.

The disadvantages of products include the high cost, as well as the need for mandatory external finishing and protection from direct exposure to sunlight and precipitation.

Slab characteristics

Plates Technoblok Standard are manufactured and tested in accordance with State standards.

The main parameters of the products:

- Thermal conductivity from 0.037 to 0.040 W / m.

- Compression ratio (compressibility) no more than 10%.

- Water vapor permeability is not less than 0.3 mg / hr.

- Moisture absorption by volume - no more than 1.5%.

- Moisture content by weight of the leaf is not more than 0.5%.

- Flammability - not supported.

- The density of the material is from 40 to 50 kg / m 3.

Such indicators are sufficient for the thermal insulation of residential premises in accordance with the requirements of the governing documents in most of the climatic zones of Russia.

The Technoblock has a modification produced under the name Technoblock Prof. The main region for the supply of these products is the Far East of the country. The insulation has improved performance compared to the standard version and is more suitable for harsh climatic conditions. The thermal conductivity of the professional material is 0.036-0.039 W / m. The compressibility is only 8%, and the density of Technoblock Prof is in the range of 60-70 kg / m 3.

The length and width of the slabs for standard and professional products are 1200x600 mm.

The thickness of Technoblok Standard sheets varies from 50 to 200 mm, and for the Prof line from 50 to 150 mm. The step of products in thickness is 10 mm.

Delivery and storage

Technoblok Standard is supplied in bags wrapped in a shrink polyethylene film.

Correct storage in a closed warehouse

The manufacturer obliges sellers to store products on pallets separately by product type. During storage, the packages must not be under the precipitation.

The number of plates in a package depends on the geometric dimensions of the sheet. For example, with a thickness of 50 mm, the package will contain 8 sheets, and the insulation area will be 5.76 m 2, or 0.288 m 3.

If plates with a thickness of 100 mm are purchased, there will be 6 of them in the package, the total area will be 4.32 m 2, and the volume is 0.432 m 3.

Attention! Before buying, check the number of products supplied in the package from the seller - there may be differences in the complete set.

Based on the above characteristics, the choice in favor of thermal insulation Technoblok Standard is made in cases where types of insulation are planned according to the manufacturer's recommendations. The supplier guarantees a 50-year service life of thermal insulation without loss of basic consumer qualities, which makes the products in demand on the market.

What buyers say

This section has collected several reviews from those who have already used the material in their home or insulated them to order. You may find their opinions helpful.

Density of 45 kg per cubic meter differs from 35 Rockwool LIGHT BATTS. The cost of both is kept in a similar range Alexey

I enjoyed working with the material. Used in frame, and weaving and fifty. Keep in mind that it compresses slightly worse than the Optima, its density is 35. And one more thing: if the spaces between the racks are less than 580 millimeters, you may have to cut them. Yuri

A standard Technoblock should have a density of 40–50 kg per cube, and most often 40–42, with a minimum of walking. I personally have not seen quality passports with greater density. Well, at least I'm talking about the Yurginsky plant, I don't know about the others. Plus, keep in mind that they add slag, unlike Rockwool, so that as a result, the slabs look darker and the melt pellets are visible inside. And this is not only an external joke, but also improves thermal conductivity. So, with similar prices, I would still take Rockwool. Sergey

So, we have highlighted the main characteristics, reviews and description of TechnoNIKOL Technoblock Standard and its "brothers". Now you have all the information you need to make a decision about the type of insulation.