Not a single new building will last even a decade if it was built without the use of thermal insulation materials. Thanks to them, maximum heat savings are achieved, there are no drafts and "cold bridges" inside the walls, and the service life declared by manufacturers allows you to forget about major repairs of the building for decades.

Among heaters, mineral wool is considered one of the market leaders in terms of a number of parameters. It is divided into three groups:

- basalt;

- glass wool;

- slag.

The process of making one mineral wool from another is different, but the meaning of use remains the same - achieving maximum comfort with a minimum cost of money and effort. At the same time, it is desirable to fulfill a number of operational and GOST requirements.

The materials of the IZO- series stand out among the mineral wool. They appeared on the market relatively recently, but are already in consumer demand. Heaters made from natural raw materials with a minimum amount of artificial additives are supplied in slabs or rolls, and one of them, called Izobel, will be discussed in more detail.

Insulation features

The area of use of isobel is to reduce the thermal conductivity of buildings for various purposes. In the production of insulation, EcoSafe technology is used, which reduces the amount of moisture absorbed by the material. Izobel slabs are a type of basalt wool (material with the lowest thermal conductivity) and are manufactured without the use of blast furnace slags. Typically, the insulation has a standard size (1000 × 600 mm, 1000 × 1000 mm, etc.).

Isobel can be produced not only from heavy basaltic rocks, but also from lighter ones like limestone or quartzite.

The resulting slabs weigh less and do not keep heat so well, but their density is higher, which affects the durability. A similar izobel is used for cladding places in a house where thermal insulation does not play a special role, and fire resistance and noise absorption are much more important (non-residential attics, ceilings, pitched roofs).

Features of installation isobel

Due to its ease of use, insulation is used almost everywhere. Thermal insulation with its help will be justified in such places:

- partitions between floors;

- floor;

- sloped roofs;

- attic;

- walls.

The only place that is undesirable to insulate with isobel is the foundation, since the slabs can get wet from interaction with the soil and fail.

Like any other mineral wool, insulation requires two additional layers - hydro and vapor barrier. The first protects the plates from getting wet from the outside, the second - from the inside. When installing Isobel on a sloping roof, it is recommended to make an air gap, the purpose of which is to drain the accumulating condensate.

The key difference between isobel like mineral wool and foam is that it is not mounted directly to the wall with glue, but is placed inside the cells formed by a wooden crate. Plus such a need - additional strengthening of the building frame, minus - financial investments.

Isobel insulation production technology

During the production of basalt material, a special method of hydrophobizing treatment is used, due to which the material receives a low water absorption capacity.

The applied technologies make the heat insulator frost-resistant. Insulation ISOBEL does not change its technical characteristics throughout its entire service life. It is not subject to decay, mold and mildew, and rodent damage.In addition, technologies make a high-quality non-combustible product from the material, which has the appropriate fire safety certificates.

In construction IZOBEL insulation (product reviews can be found on our website) is used to provide sound and heat insulation of the room, to increase the fire resistance of the entire structure.

The heat insulator is used when working with roofs, ceilings, walls, floors, pipelines, ventilation systems, etc.

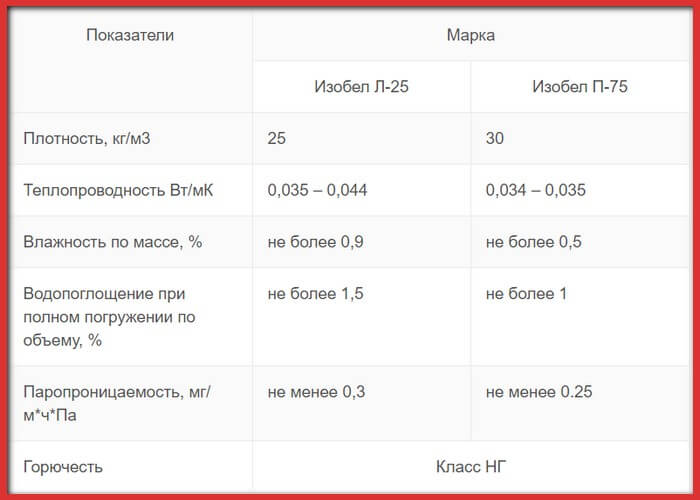

Material specifications

Izobel heaters have approximately the same physical characteristics. For example, a plate with a size of 1000 × 600 mm is considered below. Its characteristics will be:

- density - 25 kg / cu. m;

- thickness - from 40 to 250 mm;

- vapor permeability - from 0.3 mg / m * h * Pa;

- flammability class - IV (best);

- thermal conductivity coefficient - 0.03-0.04 W / m * K;

- absorption of liquid when fully immersed in water - up to 1.5%;

- moisture content by weight - up to 0.5%.

The key advantage is obvious - the low degree of water absorption makes it possible to use isobel even when external walls are insulated.

Insulation from mineral wool boards IZOBEL (IZOVOL)

Again, the vertical crate, but already with a step of mm, since such a step is necessary for siding and it is better to process the timber than not as easily soiled as working off, I think to use Senezh for the second part of the house. Full size Starter for siding.

In principle, Penoplex is also a good insulation, but it seems to me that it is more suitable for insulating floors and foundations. The Isobel slab is a natural insulation made from refined basalt fibers without the use of blast furnace slags.

Insulation Izovol L has high physical and mechanical characteristics at a low cost.

Belongs to the class of economy class coatings. It is used for insulation, as well as sound and fire insulation of pitched roofs, the space between the attic floor beams, internal partitions, floors of all types, air ducts and pipelines. It is produced in the form of slabs with dimensions: length mm, width mm, thickness from 50 to mm in increments of 10 mm.

Insulation advantages

Minvata would not have become so popular among consumers if it did not have a number of advantages. With regard to insulation of the Izobel brand, the qualities listed below are considered as such.

- Excellent thermal conductivity - coefficient from 0.03 to 0.04 - one of the smallest among heaters. If you add to this the thinness and elasticity of basalt fibers, you get an almost ideal material that allows you to significantly save on heating the room.

- Fire resistance - isobel belongs to the IV group of fire safety materials. In the presence of a nearby fire site, its physicochemical properties will remain unchanged; also the plates will become an obstacle in the path of the spreading fire.

- Long service life - insulation made of basalt stone lasts for at least 50 years, subject to storage conditions. An excess of liquid will not in any way affect the material - the fibrous structure will easily let steam through and evaporate condensate.

- Weak water absorption - basalt is non-hygroscopic; only 1.5% of its volume can be filled with moisture. If water-repellent additives are used in the production, the value is reduced to 1%.

- Good vapor permeability - achieved by the fibrous structure of the material and promotes the use of isobel in baths, saunas or industrial premises.

- Sound insulation - depending on the thickness of the slab, they completely or partially neutralize extraneous noise.

- Resistant to corrosion, fungi, rodents, unattractive to birds.

- Affordable price - isobel is on average 15% cheaper than mineral wool analogues; for a slab with an area of 1 sq. m and a thickness of 50 mm, the consumer will give from 100 to 300 rubles.

- Environmental safety - achieved by a minimum amount of chemical components used to increase water repellency, and even then not always.

The above is only a part of the positive aspects of the izobel insulation. Other benefits are easier to perceive in operation rather than describe.

Isobel is a completely natural insulation that belongs to the budget category. Thermal insulation can be achieved using lightweight slabs, protected from water and made on the basis of basalt rock. The insulation does not support combustion, but begins to melt only if the temperature exceeds the threshold of 1100 degrees. This method of thermal insulation helps to minimize heat loss, that is, to save a significant amount on heating. If we consider technical indicators, we can see that Izobel insulation is many times superior to materials that are considered traditional. Materials are characterized by:

- Excellent performance in terms of thermal insulation;

- Resistant to deformation, that is, they are able to always maintain the original geometric parameters;

- The minimum level of moisture absorption, which allows you to maintain the thermal insulation properties at the maximum level;

- Excellent ability to protect against extraneous noise;

- Ultimate strength level;

- Long operational period;

- The absence of any difficulties during the installation process;

- Resistant to extreme low temperatures;

- Insulation is able to protect other materials from rust;

- Material processing can be carried out by cutting and sawing;

In the event that the insulation is installed on an inclined surface (for example, in the attic), then it must be installed in the gaps between the bars, which are located vertically. The spacing of the bars should be the same as the size of the slabs. On top of the slabs, it is mandatory to place a material that protects from the wind. The inner side of the insulation must be protected by a vapor barrier, which prevents it from humidifying from the air coming from the room. With the help of such a barrier, it is possible to avoid the appearance of condensation on the walls. From the inside, the attic must be sheathed with boards, drywall sheets or similar materials.

If Isobel is used to insulate interfloor floors, then it is installed on boards that are hemmed from below to the beams. On wooden logs, boards for the floor are placed, as well as the flooring itself. In the event that the floor is based on concrete, then the floor is equipped with logs. Isobel insulation is laid between the lags.

More related articles

Basalt insulation Isoroc

As you know, one of the best insulation materials is considered to be the one made on the basis of basalt fiber. It is to such insulation that the products of the domestic company Izorok belong.

| Insulation Isover (Isover) If you have a need to purchase reliable thermal insulation, then you should pay attention to Isover products that meet all high standards. |

| Heater Knauf Insulation (Knauf Insulation) If you expect from a heater for your home not only high technical performance, but also maximum environmental safety, you should take a look at Knauf products. |

Disadvantages of thermal insulation material

Alas, even Isobel is not devoid of disadvantages, although there are not so many of them. These include:

- the possibility of loss of thermal insulation properties at the joints of the slabs or in the area of contact with the crate (the joint is not sealed with a sealant or foam, like polystyrene);

- an additional waterproofing layer is required, since with a direct hit of water, the plate will swell and cease to be useful;

- a crate of certain sizes is required (according to the dimensions of the izobel insulation slabs);

- the process is complicated by the use of a mask, gloves and clothing that covers the skin; otherwise, small particles that come off the stove will get on the skin, causing allergies or scabies.

Despite the slight disadvantages of isobel, the material is still recommended for use in almost any room. It is accessible, it is easy for them to sheathe a section of the house, and the next replacement of insulation, subject to the installation technology, will not have to be done earlier than 50 years later. When buying material, the consumer will save a good amount, and during operation he will be convinced of the right choice.