Types of floors

Views:

- Solid wood flooring. This is the warmest option. The best base for solid wood flooring is tamped soil or concrete foundations. The design includes a rough flooring, logs, finishing boards.

- Leaking flooring. A cheap option, since a small number of consumables are used to assemble it. There is a concrete floor under the structures with a slope to one side. A drain hole with a grate is installed at the lowest point. Water does not linger on the wood, flows down the concrete base, is removed from the bath through the drain.

The last type is concrete foundations with cladding. The most durable, strong structures, for the creation of which you need to spend a lot of money on consumables and tools. From above, the concrete base can be covered with ceramic tiles or porcelain stoneware.

The main qualities of expanded clay

Recently, various manufacturers have begun to produce new safe sandwich pipes for baths and saunas. With such a design, there is no longer any need to worry about how to secure the pipe in the bath (for more details: “Advantages of a pipe for a sandwich bath in the construction of a chimney”). The design of such pipes assumes a quick and convenient assembly of sections that are inserted into each other. Moreover, it is optimal to use such pipes with an iron stove.

A sandwich pipe is a multilayer structure, inside which there is a stainless steel frame, then a mineral or basalt wool insulation is laid, and a galvanized casing is put on top. Thanks to this structure, soot does not accumulate inside the chimney, the outer layer of the metal does not experience overheating, and the whole structure looks beautiful and laconic.

Expanded clay is a bulk material used in construction, which is produced on the basis of clay, by means of its high-temperature treatment in special kilns that rotate during the firing of raw materials.

Expert opinion

Konstantin Alexandrovich

Indicators of energy efficiency, namely the thermal insulation of the material, are determined by its special structure, consisting of many pores. This allows you to create the effect of a thermos. The material varies in size of fractions, which ranges from sand to crushed stone. For thermal insulation of the ceiling surface, expanded clay is most often used with granule dimensions from 10 to 20 millimeters.

The size of the granules is as follows:

- Expanded clay sand. The grain size of the substance is 0.1 - 10 millimeters. Such material is mainly used as a filler in the composition of mortars, as well as backfill for warming the ceiling zone of bath buildings. The recommended backfill layer thickness is up to 50 millimeters. The cost is about 150 rubles per bag.

- Expanded clay gravel. The dimensions of the granules of such material vary from 1 centimeter to 2 centimeters. It can be used for thermal insulation of any premises of the building. The approximate price is about 200 rubles per bag of material.

- Expanded clay crushed stone. The size of the fractions varies in size from 2 centimeters to 4 centimeters. In order for the backfill mixture to have a higher density index, it is often used in combination with gravel. Prices start at 200 rubles per bag of rubble.

Like any material used for insulation, expanded clay differs in the presence of a list of advantages:

- Resistance to negative temperatures. Expanded clay is able to withstand about 25 cycles of complete freezing and thawing without destroying the structure and losing its basic properties.

- Fireproof, does not burn and does not support the combustion process.

- Possesses biological neutrality.

- Differs in extreme ease of installation.

- The weight of the material is quite low (1 m3 weighs about 250 kilograms), which makes it possible not to create unnecessary loads on the main structures of the building.

- The thermal conductivity is between 0.12 and 0.15 W per m3.

- Affordable price.

Along with this, expanded clay also has a number of disadvantages, which include:

- the process of filling the material is accompanied by the release of a large amount of dust and small debris;

- expanded clay is distinguished by its ability to absorb moisture well.

Expanded clay refers to building materials of natural origin. This means that it does not pose any danger to human health and the environment. It is made on the basis of clay that has undergone processing at elevated temperatures, which at the same time foamed and hardened.

To ensure high-quality thermal insulation of the space located under the roof, it will be necessary to lay a layer of expanded clay, the thickness of which will vary from 20 to 30 centimeters. For this purpose, it will be necessary to equip a solid structure, which will result in additional financial investments.

Thermal insulation methods

Technologies for insulating floors in the bath:

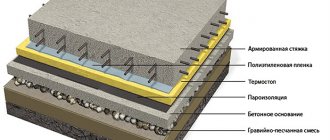

- A simple floor option. It consists of compressed soil, a mixture of sand and gravel, a concrete substrate, a vapor barrier, expanded polystyrene, a polyethylene film, and a reinforcing frame. To insulate it, you need to prepare the base, align it from bumps, cracks. On top of all layers, a screed is poured from a special insulating mixture.

- With a screed over the floor. For thermal insulation of the structure, a durable sheet of foam, pressed mineral wool is suitable. The base is made of a concrete slab, which is fixed to walls or strip foundations.

- By lags. It is better to use polystyrene, pressed material wool as insulation.

Varieties

Under the general name "expanded clay", you can find several varieties of bulk insulation, which have very different characteristics. Outwardly, they are almost the same - brownish granules of oval and round shape, very light and porous. However, the main thing will depend on the size and density of the granules - the efficiency of the insulation. Therefore, you need to select the appropriate type in advance, choosing from three options:

- Sand is small particles up to five millimeters in size. They are perfect for filling irregularities, thanks to the fine fraction.

- Gravel - the optimal particle size from five millimeters to four centimeters allows the particles to fill all the necessary volumes well and keep heat efficiently.

- Crushed stone is the third type of this loose heat insulator. The particles have an irregular shape and dimensions from two to five and even more centimeters. It is obtained by crushing large pieces and is slightly inferior in its properties to other varieties. However, it is excellent for filling large volumes.

There are no perfect variations. Usually, a complex solution is used from filling two, and sometimes all three types of fractions. This ensures the most efficient work of the material. For example, when insulating the floor with expanded clay on the ground in a bath, you can pour the base from the largest fraction, and then create a layer of a smaller backfill.

Types of heaters

Many owners doubt whether it is necessary to insulate the floors in the bath. Without high-quality thermal insulation of the concrete base, ice will form on its surface in winter, and it will be impossible to get rid of the cold inside the room.

Perlite is a material that is similar in structure to sand. For use as a heater, perlite is mixed with cement, water, and thoroughly mixed.The finished composition is applied in an even layer to the base, left for 7 days until it hardens completely.

Perlite advantages:

- light weight;

- low thermal conductivity;

- preservation of the natural microclimate;

- lack of harmful substances;

- fire resistance;

- sound insulation, durability.

Do not use perlite in ventilated areas. Any gust of wind will lead to its chaotic distribution throughout the room.

Expanded clay is made from clay. The feedstock is fired at a temperature of 1400 ° C. During heat treatment, individual granules are formed, which are used as thermal insulation material.

Strengths of expanded clay:

- high rates of thermal insulation, noise insulation;

- absence of harmful substances during strong heating;

- low price;

- low specific gravity;

- resistance to high loads.

The main disadvantage is the absorption of a large amount of water. Therefore, you need to do additional waterproofing.

Rectangular plates are made of polystyrene, with which it is convenient to insulate vertical, horizontal surfaces.

Benefits of Styrofoam:

- high thermal conductivity and density;

- easy assembly of individual slabs;

- low price.

Of the significant disadvantages, fragility can be distinguished. ...

You can also use:

- Jute felt. This is a material of organic origin, which has high strength, retains heat well. Fungus, mold does not form on it.

- Basalt slabs. Suitable for insulation of concrete floors. Before laying basalt, you need to make high-quality waterproofing.

- Penoplex. It is made in the form of durable plates of various sizes. Outwardly, it resembles foam. Does not deteriorate under the influence of moisture.

The heat trap can be made from glass or plastic bottles.

Pros - Cons

The advantages of such insulators are enough for this material, which has been used for a long time, to still remain popular:

- High environmental friendliness - the raw material used for the production of expanded clay is ordinary clay. The technology of its processing is not particularly complicated and the output is the same rounded granules with a porous structure.

- Sufficient efficiency when creating a pillow with a thickness of fifteen centimeters. A smaller thickness will not save heat too well and there is simply no point in making the layer thinner.

- The effective life of the material will be measured in decades, if the rules of its operation are not violated.

- Low thermal conductivity means heat saving efficiency. Due to its porosity, expanded clay is able to retain heat quite well.

- This material is not classified as combustible. He is not afraid of any high temperatures, and since it is made of clay, it does not burn.

- The porosity of the particles not only allows them to retain heat, but also ensures a low backfill weight.

- Various pests and rodents are completely indifferent to this material. It will also not be a comfortable base for mold or mildew.

- Versatility - bulk material can be used not only as an insulator, but also as a leveling layer for pouring concrete floors.

In addition to the advantages, this type of backfill will have several disadvantages. First of all, it is worth noting that a layer of expanded clay is needed thick enough for good heat conservation. It is this drawback that becomes an obstacle to its wider application. The second disadvantage will be moisture absorption. The material gets wet quite actively, but on the contrary, it dries very badly. Therefore, it is always necessary to waterproof it on the bottom and top side.

Principles of work

After getting acquainted with the heaters, you can proceed to self-thermal insulation. To do this, you need to prepare tools, consumables, draw up a project, perform work.

Materials and tools

Consumables, tools:

sharp knife;

- sheets of roofing material;

- ruler, tape measure, building level;

- sand, cement, water, a container for mixing the solution;

- electric drill, whisk nozzle;

- insulation;

- waterproofing.

The amount of consumables depends on the area of the room. On the thermal insulation material, the manufacturer writes how many square meters the package is enough.

Preparation and design

In order to properly insulate bath rooms, you need to prepare the base. To do this, you need to take into account some of the nuances:

- It is necessary to carry out insulation at the main stages of building construction. If this was not done, you will have to dismantle the flooring, fill in a new screed.

- The base should be flat, without bumps, cracks, chips. To level it, you need to fill in a fresh screed over the beacons.

- The materials with which the walls will be sheathed, it is not recommended to cover the floor in the steam room with antiseptics. They can release harmful substances when heated too much.

The insulation process varies depending on the type of room.

Thermal insulation of a wooden floor

Execution of works:

- When the concrete base is ready, it is necessary to create a frame for fixing the thermal insulation. To do this, fill a rough base of bars on top of the lag. Intermediate slats are laid out between the beams.

- The next step is laying the waterproofer.

- Insulation can be mounted on top of the waterproofer.

- From above, the heat insulator is closed with another layer of waterproofing.

The last stage of construction is the laying of finishing boards.

Insulation of concrete floors

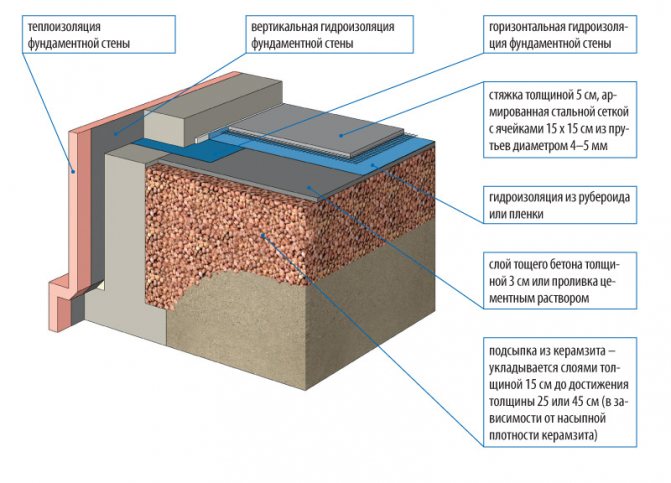

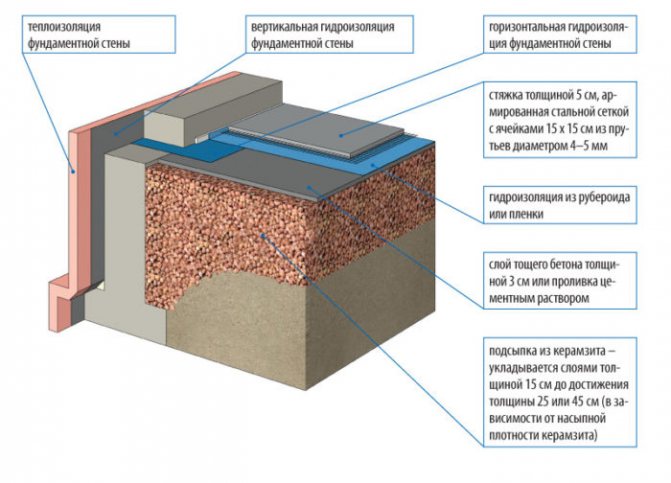

Execution of works:

- Preparation of the base.

- Leveling the concrete slab.

- Laying waterproofing.

- Distribution of slabs or bulk heat insulators.

- Reinforcing mesh laying. It can be knitted from individual metal rods.

Installation of the "warm floor" system

If you only want to step on a warm floor, you can install a special forced heating system for floor coverings. It is necessary to choose what it will be - electric, water, infrared. Next, you need to purchase consumables, start construction work. Main steps:

- Prepare the base, level the subfloor.

- Install a layer of thermal insulation.

- Fasten the reinforcing mesh over the heat insulator.

- Fix the system to the grids.

- Connect the structure to a public power supply or water supply system. Check functionality.

- Pour the subfloor.

- Wait for the concrete to dry.

It remains to complete the finishing.

Do-it-yourself thermal insulation of the ceiling of the bath with expanded clay

In order to make the surface of the ceiling warmer, it will not be enough just to fill in the required layer of material. This process is characterized by a number of features that must be considered in order to obtain the desired result.

Stage 1. Ensuring protection of the bearing surface from moisture.

For these purposes, it is recommended to use the following types of building materials of various types:

- roofing felt - produced in the form of rolls;

- membrane or film;

- mastic - applied by coating the surface.

The following work algorithm is considered the best option for arranging waterproofing:

- Roofing material is laid on top of the hot bitumen. The joints are also sealed with bituminous mastic.

If it is planned to install a screed over the layer of thermal insulation, a special damper tape is laid around the entire perimeter of the insulated room. This type of material is able to compensate for the linear tension of the concrete interlayer. This tape must completely overlap the edges of the waterproofing coating.

Stage 2. Carrying out the backfilling process

In order for the backfill surface to adequately fulfill its thermal insulation functions, a mixture of expanded clay with granules of various sizes mixed with each other is used. During work, a large amount of dust will hover in the air. Therefore, it is strongly recommended to provide high-quality ventilation in the insulated room.

Stage 3. Backfilling of the main structural elements of the bath room (pipes for exhausting smoke and boxes for ventilation)

In order to be able to seal the insulation layer, structures protruding above the plane of the attic floor are surrounded by special wooden boxes. These cavities are filled according to the same principle according to which the ceiling was insulated.

If in the future it is planned to equip the screed, then the following preparatory work is carried out:

- the expanded clay layer is spilled with "milk" based on cement;

- beacons are displayed;

- a reinforced mesh of reinforcement is laid, having a cell edge from 5 to 10 centimeters;

- a solution is poured from a mixture of sand and cement.

If you decide to build a bathhouse, then do not forget about the high-quality insulation of the stove, chimney, walls and ceiling. Otherwise, you may have serious problems with the fire of the building ceiling. Therefore, we will try to dwell in more detail on the pressing problem today - do-it-yourself pipe insulation in a bath.

Due to the fact that the chimney and the stove quickly heat up, a fire may occur. Moreover, according to tradition, wood is the material for the bath. Even in the old days, it was customary to insulate walls, a ceiling, a stove, a chimney with an asbestos layer, clay and other available materials that are quite poorly conductive of thermal energy and resistant to high temperatures.

So how to lay the pipe from the stove today? Insulation of the chimney structure is necessary both for the purpose of fire safety and protection against condensation, so that cooling takes place more slowly and the flue system lasts longer.

A red brick is not always needed for lining a pipe, although it is endowed with excellent thermal insulation properties. The reason is that such a design is not combined for every bath in design.

It is a unique material with polyethylene foam sandwiched between a pair of foil sheets. With the help of thermal insulation, you can qualitatively insulate the chimney, moreover, independently.

The thickness of the thermal insulation varies from 2 to 10 mm, and the thicker the material, the greater its resistance to high temperatures.

The top layer of foil serves as a reliable protection of the pipe from significant overheating. With the help of a wire or tape of a metal master, heat insulation is attached, which is then wrapped around the chimney.

Modern material includes two layers: heat insulator and foil. The second one plays a reflective function and can store up to 90% of thermal energy in a building. Folgoizol is a harmless material compared to other analogs, since compacted food foil acts as a foil. The material is resistant to ultraviolet radiation and high temperatures in the range of -65 to 175 degrees Celsius, a good insulator.

Whoever does not yet know how to insulate the chimney pipe in a sauna, we recommend covering the ceiling of the steam room, walls and chimney with foil insulation. As a result, you will get a room that looks like a thermos. The heat will remain in the sauna, and the bath will quickly pick up the temperature, and then slowly cool down. Sometimes a mesh is installed on the pipe for stones in the bath, which is very convenient and practical.

We suggest that you familiarize yourself with the Stove for a bath from a pipe: how to make a homemade bath stove for working off with your own hands

For those who wish to equip a safe chimney in the bath, we suggest using a sandwich pipe.This design includes several sections that can be easily placed into each other, i.e. looks like a layered cake.

Here are the main components of a sandwich pipe:

- stainless steel layer (inside);

- insulation in the form of basalt / mineral wool (in the middle);

- zinc coated steel (outside).

This creative design represents the insulation of the chimney integrated into the overall system and is designed to solve two problems at the same time:

- protection against accumulation of soot inside;

- maintaining an optimal temperature outside.

At elevated temperatures, refractory red brick retains its operational properties, therefore it is in demand when building a chimney in a bath with a stone stove. In this case, you are guaranteed the protection of the pipe from fire and long-term preservation of heat.

The service life of the structure depends on how well the brick pipe is folded. Do not skimp on materials during the construction of the chimney, because then the repair will be much more expensive for you.

Let's take a closer look at how to isolate a pipe in a bath from the ceiling:

- Use asbestos to line the pipe outlet on the ceiling and through the roof.

- Using galvanized material, insulate the walls from the inside of the pipe. Standard iron sheets are completely unsuitable for this purpose due to their tendency to corrosion.

- Run a box around the pipe where it passes through the ceiling.

- Pour expanded clay into the box to preserve heat and protect wooden floors from fire.

You professionally wrapped the pipe, but this was not the end of the work on the arrangement of the chimney. The next step is measures to insulate the stove, ceiling and walls of the bath.

Modern metal stoves are mounted on a foundation, while sheathed with sheets of the same material on the back and side of the wall. If you independently beat the stove with only metal, then its appearance will not be very aesthetic. It is better to make the external brickwork with red brick, which insulates the stove from fire and keeps the heat in the bath.

Due to the fact that asbestos emits toxic substances at elevated temperatures, it is not recommended to use it in a steam room. Natural felt is considered harmless, which, moreover, is a good insulator. For the price, this material is more expensive than asbestos sheets, and when smoldering it emits a specific smell (felt does not ignite), which can be immediately felt.

If you intend to install the stove on a wooden floor, then first it is better to spread the felt material in a couple of layers, then lay out the brick in three rows. For walls and floors, it is advised to lay sheets of metal as an insulator, the height of which varies from 50 to 70 cm.

Having followed all our recommendations correctly, you will extend the term of operation of the entire smoke exhaust structure and protect it from fire. And you will no longer have any questions about how to wind chimney pipes.

One of the most important stages in the construction of a bath is the installation of a chimney. And its insulation is a mandatory process during construction, which has two goals: fire safety and corrosion protection.

If you do not make thermal insulation, then under the influence of temperature differences, condensation will form, gradually flowing inward and contributing to the destruction of the structure itself.

The insulated smoke exhaust ducts warm up faster, which makes the stove in the bathhouse work much more efficiently.

Depending on what the chimney of the bath is made of, various materials are used for its thermal insulation.

There are several types of already insulated chimneys for a sauna stove, the most common of which are stainless steel sandwich pipes. A good option is ceramic sections, which are already installed in expanded clay modules.

During the operation of a sauna stove, its chimney gets hot, and the inevitable proximity to combustible materials can lead to a fire.

If the chimney is made of bricks, it heats up less, and if the chimney is made of metal, then much more.

Metal pipes are heated above 600 ° C, and their proximity to the wooden sheathing of the steam room is very dangerous, especially if the bath is close to residential buildings.

Recommendations

Also, attention should be paid to floors that are fixed on pile foundations. Stages of work:

- Tie the pile heads with special screw beams.

- Lay a layer of waterproofing on a wooden base made of beams.

- Stuff rough beams on the undersides of the beams.

- Lay sheets of thermal insulation, cover them with a waterproofing film.

- Put in a finishing coat.

It is important not to confuse the installation method of the waterproofing film. The instructions are on the packaging.

Concrete floors in bath rooms need to be insulated. If this is not done, they will be very cold despite the warming up of the premises. For thermal insulation, you need to choose one of several types of materials. It is important to take into account the peculiarities of insulation when carrying out work on your own.

Advantages and disadvantages of expanded clay insulation

When comparing expanded clay with other insulation materials, the following advantages of this insulation can be distinguished:

- Not biodegradable during use. Over time, most of the heat insulators used for thermal insulation of bath rooms undergo decomposition, which provokes the release of substances harmful to human health from their composition into the air. Expanded clay, in spite of the service life, does not emit harmful chemicals and does not deteriorate its thermal insulation characteristics.

- The insulation does not attract rodents, which allows it to be used for almost unlimited time.

- Thermal insulation of the ceiling in the bath with expanded clay guarantees high fire-resistant properties of the floor, high sound insulation characteristics and increased resistance to water vapor.

- The insulation has high frost resistance. This building material is able to withstand up to 25 full freeze cycles followed by thawing without loss of thermal insulation properties.

In addition, expanded clay is characterized by low heat transfer rates, which vary in the range from 0.07 to 0.16 W / m, which makes it possible to use it as an effective insulation for a bath room.

The main advantages of such material are:

- high thermal conductivity;

- light weight;

- long operational period, reaching fifty years. According to this indicator, expanded clay exceeds many insulation materials;

- increased resistance to aggressive chemical environment;

- ecological cleanliness;

- acceptable cost, determined by the cost of manufacturing;

- the material is not biodegradable during operation, does not emit harmful chemicals, does not reduce thermal qualities;

- expanded clay does not attract rodents;

- the ceiling insulated with expanded clay guarantees a high fire-resistant quality of the floor;

- The insulation material is distinguished by a high level of frost resistance, is able to withstand at least twenty-five freeze-thaw cycles, without reducing its thermal insulation qualities.

A pronounced drawback is the difficulty in achieving complete sound insulation. To solve this problem, you have to fill in expanded clay with a layer of up to half a meter.

In addition, expanded clay needs additional means to help retain moisture, in the form of steam and waterproofing. And if the premises are very damp, it is not possible to insulate them with the help of expanded clay.