Thermal insulation of a balcony with a brick parapet

Insulating material will help to effectively insulate the balcony of their bricks.

Most of the facades of new houses make up a single architectural composition. Violation of its integrity by piling up additional materials for insulation is unacceptable or is associated with multiple bureaucratic coordination delays. The best way to insulate cold-glazed balconies is to use insulating materials from the inside of the room.

A balcony or loggia often has a brick parapet. Installation of aluminum windows with this design takes place directly on the top row of bricks. Insulation of such a room will be effective due to the fact that an insulating material with low thermal conductivity can be laid against the parapet wall.

Warming a loggia without replacing cold glazing - Masters Club

Insulation of cold glazing is sometimes used, although usually this activity takes a lot of time and effort, but does not give the desired result, since in most cases it is carried out incorrectly. Before work, you should find out how to correctly insulate a balcony, making it a comfortable room.

What kind of glazing is considered cold?

Quite often, when purchasing an apartment, the owner is faced with the fact that she already has glazing. Often, the developer does not use expensive materials and installs cold glazing without insulating the balcony in any way. In this case, replacing cold glazing with warm glazing may be relevant., which will significantly improve the final result, as it will help eliminate heat loss that occurs precisely through the window frames.

However, you can tackle the improvement and cold glazing. Most often, aluminum frames act as it. Aluminum itself has a high thermal conductivity, so the room cools down quickly. Plastic double-glazed windows can also be cold. Most often this is a problem of single-chamber designs. This type of glazing can protect against precipitation, wind, dust, but it does not resist frost well. Therefore, the insulation of the cold glazing of the loggia or balcony plays a rather important role in creating a comfortable atmosphere in the house.

How to insulate a balcony with cold glazing?

Insulation of cold glazing may be useful, but it is very important to carry it out correctly; to insulate such a structure, you will need the following:

- Close and insulate any seams that you can find between the window frame and the wall.

- After that, you need to close up all the cracks in the walls, special attention should be paid to the corners of the structure.

- Insulate the floor, walls, ceiling.

Frame for laying insulation on the floor and walls, underfloor heating

Insulation can be external or internal. If permission may be required for the external, since changes will be made to the external appearance of the building, then you can carry out the internal without collecting papers, since such insulation of cold glazing occurs without changing the facade. You can also insulate the structure from the inside on your own, without attracting expensive specialists and without endangering your life when working at height.

How to insulate the seams between the frames?

Thermal insulation of the balcony without replacing cold glazing should begin with finishing all the seams of the structure, since most of the heat goes out precisely through them and through them cold air enters from the street.In addition, moisture can penetrate through the seams, which negatively affects the state of the structure as a whole. Because of it, fungus, mold, and other unpleasant phenomena can form. In order to get rid of the cracks, you will have to do the following:

- Clean the joints from old paint, plaster, debris and polyurethane foam. To do this, you can use a spatula with a width of 100 mm.

- Check for empty spaces or gaps. It is convenient to do this in sunny weather.

- The voids are filled with polyurethane foam, less often with cement mortar.

- After the foam dries, which will take about a day, its excess is cut off, and the joints themselves are sealed with a special waterproof tape.

- The seams can be covered with a layer of putty, plastic strips can be installed. When insulating the side walls, finishing is not required at this stage.

Insulation of glass

Most of the heat will go through the glass

In the case when plastic double-glazed windows are installed, the window will not require additional insulation. To isolate the leaky joint between the glass and the frame, a special polyurethane sealant is applied to the joints to prevent air penetration.

The greatest heat loss will occur through the glazing.

Insulation of window frames

If the sealant used to seal the joints of the windows is not enough and cold air enters the room, you cannot do without additional insulation of the window sashes. It is very easy to check whether the window joints cool down: the presence or absence of traction is determined in windy weather, for this it is enough just to run your palm along the seam.

Insulation is carried out by additional sealing of window seams with polyurethane sealant along the frame perimeter, both from the inside and from the outside.

Floor insulation

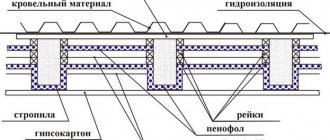

Penofol can be used as insulation

An important component in obtaining a warm room is floor insulation. For better thermal insulation, you can use the following materials:

- Penofol.

- Electrical floor insulation.

- The bar is wooden.

- Styrofoam or mineral wool.

- Polyurethane foam.

- Floor board.

Foil-clad penofol is laid on the surface of the concrete floor. This material has excellent insulating properties. It will prevent condensation from accumulating in the floor, providing oxygen access to prevent moisture and mildew. The next step is to install an electric underfloor heating.

Warm floor - one of the options for insulating a balcony

The thickness of the lag sets the size of the insulation layer. The larger its layer, the better the thermal insulation. When installing, it is necessary to take into account the height from the future floor to the parapet. In the standard version, it ranges from 95 to 105 cm. The safety of a person on the balcony is always in the foreground, so you need to choose the thickness of the log, taking into account the height of the floor construction cake.

Parallel to each other in one plane, wooden blocks are installed with a step of 30-40 cm. Mineral wool or foam is placed between them. All the cracks formed during the installation process can be sealed with polyurethane foam. In the winter season, a special polyurethane foam is used, which has the properties of hardening at low air temperatures.

On the laid logs, a floorboard is laid for painting and varnishing. You can use rough wood and then lay some finishing material on it.

Features of designs and installation of cold glazing

Since the main purpose of windows is considered to be protection from external precipitation, dust, moisture, wind and slight cold, respectively, they can be made of a single-sheet glass unit filled in a narrow aluminum or plastic profile.

With this technology, the weight of the window is not high due to one sheet of glass and an aluminum profile, which allows them to be installed in runners and used as sliding structures in a horizontal plane.

For areas with frosty conditions in winter, it is better to use the technology of hinged windows with plastic profiles or sliding frames with an offset. This method ensures easy opening of windows even in winter.

Reliable protection of the loggia from the environment is ensured by tightly closing the windows and docking technology. Therefore, all technologies of sliding structures refer to cold methods of protecting premises.

The use of an aluminum profile as a frame structure in cold glazing works provides:

- ease of design and the ability to manufacture different shapes and sizes;

- installation of a single-chamber or two-chamber double-glazed window in a window case;

- use an opening design with sliding doors;

- external aesthetic appearance and structural reliability.

Also read: Sliding windows to the balcony - the main advantages

These parameters are especially important for balconies with a small internal area and where it is problematic to open the window sashes inside the room.

To carry out work on the installation of frame structures of cold glazing, a number of preparatory measures should be performed:

- before the installation of window frames, all construction work must be completed to strengthen the balcony frame;

- the place for the installation of window frames must be even in size and not have deviations in the vertical and horizontal plane;

- the places of fastening of windows must be strong, reliable and provide a rigid connecting connection with the frame structure;

- construction measures must be taken to ensure protection from direct exposure to rain during installation work.

When deciding to independently perform cold glazing of balconies, you must:

- Prepare the frame structure for the installation of the window frame;

- To remove the dimensions of window spans to fulfill an order for the manufacture of a balcony window;

- Upon receipt of the window frame, check the conformity of the order with the specified dimensions and check separately the dimensions of the joining of individual or common frames with the perimeter of the window space;

- Fasten fastening plates to the common frame in the upper part and on the sides intended for aligning and fastening the frame to the building surfaces of the balcony in the axes;

- Fasten the frames or the common frame through anchor bolts to the surfaces of the building structures of the balcony on all sides, checking for deviations along the axes and tight joints in the corners or when bending the surfaces of the docking frames;

- Mount window frames in the installed frame with opening fittings and check the freedom of opening and closing of the frames and their tightness of the docking;

- The window sill is checked and adjusted to the installation location with the frame;

- At the end of the installation, the installation site of the window frames, the window sill with the building parts of the balcony must be sealed with mounting foam and all cracks.

Also read: Glazing a balcony with plastic windows: views, tips - how to glaze

The final stage of work on cold glazing of the loggia will be external and internal finishing with various building materials.

Insulation of walls and ceilings

For wall insulation, you can use the following components:

- Penofol.

- Wooden bars.

- High density foam.

- Polyurethane foam.

For strengthening the balcony, see the video:

Walls requiring insulation are sheathed with penofol. The lathing is usually made from a 50x50 mm bar. For convenience, the step between the bars can be made in accordance with the width of the filler. Styrofoam is placed between the bars and attached to the wall using plastic "fungi".The slots formed during installation are also sealed with polyurethane foam. As a cladding, you can use eurolining or imitation of a bar. Plastic panels are also suitable for wall cladding.

How to insulate a balcony with cold glazing

When buying an apartment, a glazed balcony or loggia is included in the standard set of options. Almost all construction organizations hand over objects with ready-made glazing, which can be cold and warm.

Warm glazing involves the installation of massive plastic or wooden double-glazed windows. An expensive option. The scope is limited by the load-bearing capacity of the balcony slab.

Cold glazing is a common option from single-chamber plastic or aluminum double-glazed windows. They weigh little, do not overload the balcony. Protect from rain, snow, wind, dust. They will not save you from severe frosts. Therefore, insulation of the balcony with cold glazing is required. It includes:

- Renovation and insulation of seams between window frames and the wall.

- Floor insulation.

- Wall insulation.

- Insulation of the ceiling slab.

Distinguish between external and internal insulation. Outside is done by industrial climbers, therefore expensive. This method is not popular with consumers. Internal insulation is done by hand.

Insulation of seams between window frames and the wall

Seams are a weak point in window construction. They can allow moisture and wind to pass through. The glasses are constantly fogging up. Fungus and mold appear at the junction. To obtain sealed joints, you need to perform a number of actions:

- Clean the joints around the perimeter from paint, plaster, sealant, old polyurethane foam. You will need a spatula with a width of 100 - 150 mm.

- Inspect the seams carefully for gaps and voids.

- Fill the voids in the joints with polyurethane foam. Curing time 24 hours.

- Glue the joints with protective tape to prevent them from getting wet.

- Close up the seams. The method depends on further work. You can putty, paint or install plastic strips. If you plan to insulate the side walls, then no additional finishing steps are required.

Important! The polyurethane foam is available in two versions: for summer and winter use. This must be taken into account.

Wall insulation

An important stage, without which a warm and cozy loggia will not work. The order and type of work depends on the type of balcony.

A difficult option that requires lengthy preparation before insulation. Such balconies were in old panel houses. Consists of several stages:

- Replacing a metal fence with a stone wall. The railing is cut first. You will need a grinder, goggles and a safety rope. Then the walls are laid out of ceramic bricks or tongue-and-groove moisture-resistant slabs. The minimum height to the edge of the glazing is 1000 mm.

- Installation of the frame and insulation. The frame is made of wood and metal. It is needed for laying mineral wool and foam foam.

Important! These works are carried out together with the installation of cold glazing. It is better to entrust this part of the loggia arrangement to professionals.

For small balcony walls, two rows of guide profiles are sufficient. First, the horizontal guides are mounted at the top and bottom of the wall. Insulation is laid between them. To give the structure more rigidity, you can install a transverse profile with a step of 500 - 600 mm. Then the insulation will fit securely into the cells. The external finish is made of plastic or wooden lining. You can sheathe chipboard or OSB, and then plaster, paint, lay out ceramic tiles.

READ MORE: How to insulate a balcony with penofol

Thermal insulation with extruded foam is carried out using frameless technology. It is glued to the wall with tile glue and additionally secured with plastic dowels in the form of fungi. Then the surface is plastered, painted, revetted with ceramic tiles. This option is not suitable for clapboard decoration.In this case, you need to mount the frame as described above.

Important! Using mineral wool as insulation, remember that it absorbs moisture well. Therefore, a vapor barrier is laid between the wall and the insulation. It removes moisture from the outside and does not let it inside.

Balcony with brick or concrete walls

Most multi-storey buildings have balconies and loggias with brick or concrete walls. They are insulated in several stages:

- Installation of the frame. A wooden beam 25 × 50 mm is required. First of all, the guides are attached. These are beams laid horizontally, at the top and bottom of the wall. Between them, transverse jumpers are laid with a pitch of 500 - 600 mm. The bars are fastened together with self-tapping screws 30 - 35 mm, to the floor the dowel is fastened with nails 70 - 80 mm.

- Insulation laying. Mineral wool is inserted "in the spacer" between the bars. Layer thickness 50 mm. When insulating with foam, it is not necessary to mount the frame. It can be glued to the wall with cement-based glue. This method is suitable for further plastering and painting. True, in the case of clapboard, you cannot do without a wooden frame. Its mounting method is described above.

- Finishing finish. Insulated walls can be plastered, painted, tiled, sheathed with clapboard or siding.

Insulation of the ceiling slab

Suitable for balconies on the top floor. Also where the next balcony is not insulated. In other cases, it is enough to sheathe with clapboard, plaster or paint. Insulation is done in the same way as walls.

Interesting:

- To reduce wind permeability, the balcony cladding from the outside with a profiled sheet will help;

- it is better to cut polystyrene with a tool with a fine tooth, the cut is smooth, without chips;

- before insulating a loggia or balcony, it is necessary to inspect the balcony from above, if it is not glazed and not insulated, then it is not recommended to carry out work at home.

READ MORE: Insulation of the ceiling of the balcony and loggia

Clearly following the advice, even with cold glazing, you can achieve a comfortable temperature on the loggia. The temperature inside the apartment partially depends on how to insulate the balcony. For maximum protection from the cold, change the single - cold to double - warm glazing.

Thermal insulation of panoramic balconies

Panoramic balconies have an excellent appearance, have a number of advantages over partially glazed balconies in terms of aesthetics. But the insulation of such a balcony with cold glazing will result in large financial costs. Insulation of the floor, ceiling and walls, except for the facade, can be done in the same way as in the case of parapet balconies, but a glazed wall will require a different method of insulation.

How to insulate panoramic balconies, see this video:

The frame of the cold glazing window system consists of an aluminum profile, which has excellent thermal conductivity.

The supply of heat to such a room at a negative air temperature outside will lead to the formation of ice on the glass, and heating will be insignificant due to serious heat losses.

As mentioned above, unauthorized changes to the facade of a residential apartment building can cause a conflict with local authorities and with the rest of the residents of the building.

Advantages and disadvantages

So, in order to understand why aluminum windows used for glazing loggias and balconies are still popular, you need to understand what positive and negative qualities they consist of.

Advantages

Let's start with the merits, so as not to spoil the impression:

- It is from aluminum profiles that sliding structures are being built today. In fact, this is a big plus for small loggias and balconies. There are no opening sashes, they are mixed along the window opening along special guide profiles using plastic rollers.

- This is not the largest specific gravity when compared with metal-plastic models. This criterion is very important when it comes to old balcony structures in old houses. In this way, the problem of reducing the loads on the balcony slab can be solved. For many apartments, this is the only possible way to carry out glazing.

- Currently, manufacturers of aluminum profiles offer a huge assortment in terms of color design. After all, aluminum lends itself well to painting. So there are no problems with a choice in this regard at all.

Advice! Anyone who is limited in the budget that is allocated for the purchase of windows for glazing loggias and balconies should know that cold glazing of balconies is the cheapest option.

disadvantages

In principle, cold glazing has many advantages. But do not forget about the disadvantages:

- The biggest disadvantage of aluminum windows is that they really cannot contain cold temperatures from the street. The thing is that aluminum is a metal with high thermal conductivity. So the aluminum profile is a huge cold bridge. Although experts assure that even this profile slightly restrains the penetration of cold at 10C.

- The disadvantages include low sound insulation. First, it has to do with aluminum again. Secondly, in such window structures, not a double-glazed unit is usually installed, but one glass with a thickness of 4 mm. If a sliding model is installed on a loggia or balcony, then it is not one hundred percent sealed either.

- We add that icing is common in the cold season. So you will have difficulty opening sliding systems.

Note that these disadvantages are common in all metal structures. And if you are ready to put up with them, then choose the budget option - cold glazing for balconies and loggias.

Installation of an additional glazing contour

When installing an additional glazing contour, the usable space will not decrease much

Installation of the second row of double-glazed windows will not damage the overall appearance of the building. The resulting air chamber will provide heat retention on the balcony or loggia. The disadvantage of this method of insulation will be the inconvenience of washing the glasses inside the chamber. The usable space of the room will be reduced by the indent and the thickness of the inner wall, which can be a significant disadvantage in a limited area.

Replacing a profile

To insulate the frame of the structure, you can replace the existing aluminum profile with the same analog, but with a special insert made of polyamide. This method is quite expensive, since you will have to completely replace the entire frame of the glazing wall.

Thermal insulation of the balcony, which was originally thought out by the designer as a cold room, is a rather costly and time-consuming task. It is advisable to obtain competent advice from specialists in the field of construction before making a decision on insulation.