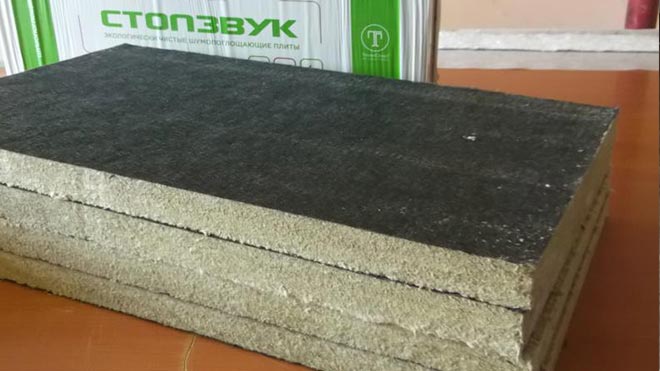

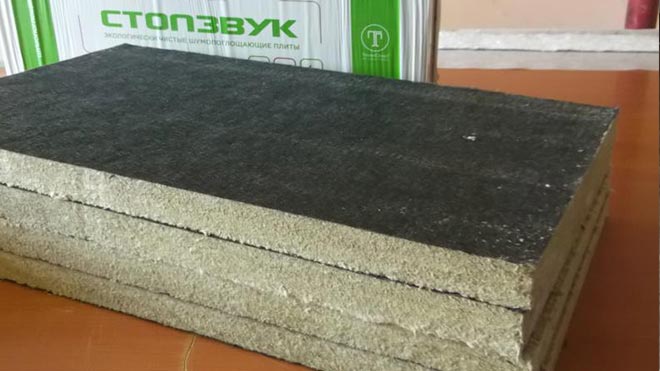

Acoustic mineral wool mats

Mineral wool mat is a material with increased sound insulation and thermal insulation. Cloths can be lined on one or two sides with fiberglass or metal mesh. Made from non-combustible, environmentally friendly materials.

Mineral wool is based on glass, sand, metallurgical slags, rocks.

Manufacturing is carried out in stages:

- All components in a certain proportion are poured into melting furnaces with a temperature of 1.5 thousand degrees. When melted, a liquid mass is formed.

- Then, by blowing with air, the fibers are formed. They can be horizontally, vertically or chaotically directed.

- The fibers are linked together by the addition of phenol-aldehyde resins.

- Further, the cutting and shaping of rolls, slabs or mineral wool is carried out.

Differences between stone and mineral

When we are told about mineral wool, we do not understand what it is. To make it easier for people to understand, in everyday life it is called, oddly enough, glass wool. That is, the basis is a material that is mined from mineral rocks, has excellent sound insulation, thermal insulation and consists of small fibers.

Views:

- Glass wool.

- Stone wool.

- Slagged.

After considering the types of minerals, the question of which is better disappears in itself, because the basis is the same, but the production technique is different. It is worth understanding.

They differ from each other mainly in the composition and content of raw materials.

In large industries of this type, such a rock as basalt is used. They are crushed into small parts, taken to production, heated to the melting point (1000 degrees). The resulting liquid mass is inflated, after cooling, small fibers are obtained. Further, for conversion into the final product, the liquid is combined with a solution with phenol formaldehyde. Ultimately, you should have slabs that resemble cotton wool, but more structured.

Fiber density

Mineral raw materials:

- Broken glass and quartz sand. No resinous substances are required to bond the material. Disadvantages - it crumbles during installation, can get into the lungs, there is a possibility that sharp parts will damage the skin, is problematic in operation.

- Waste from the metallurgical industry. They are made from clay and carbonate that reacts with potassium. Disadvantages - cannot be used for home use, as it is toxic and causes unnatural reactions in the body (allergies, general deterioration in health).

- Basalt heaters. They are made from environmentally friendly materials and are not harmful to health. Serves as the most popular for the insulation of roofing structures.

Also, for the manufacture of subspecies - glass wool and slag wool, quartz sand and remnants of broken glass in production are remelted, less often full glass.

Mineral wool rolls

Varieties of materials

According to GOST, mineral wool is divided into 3 types:

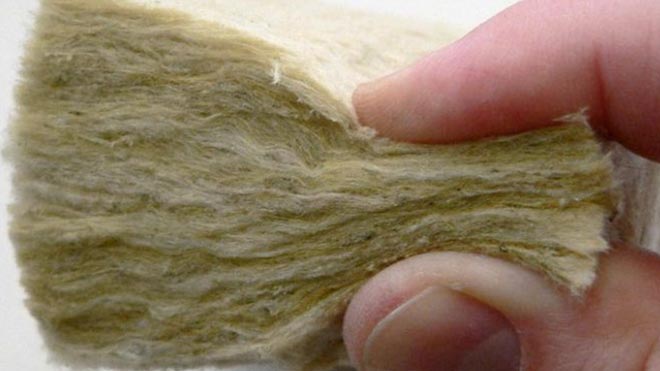

- Glass wool. This material, made of glass, is characterized by strength and resilience. The length of the fibers ranges from 15-50 mm, and the thickness is 5-15 microns. Work is carried out in respirators so that glass dust does not enter the lungs. Due to the fragility of the fibers, this type is not laid in residential premises. Available in rolls.

- Stone wool. Has a cellular structure. It is made in the form of canvases. It is used as sound insulation on various surfaces.

- Slag wool. It is considered the cheapest type of mineral wool. It is rarely used in construction, because it can sinter when overheated.

general description

Mineral wool has two varieties, differing in the raw materials used during production: it can be slag or stone. Stone-based mineral wool is made from recycled rocks or mineral rocks of volcanic origin. This variety has more advanced functional properties, but its cost is also high.

In the manufacture of slag wool, waste from metallurgical enterprises (both ferrous and non-ferrous metallurgy) is used. Its characteristics and area of use differ little from stone wool.

Glass wool is a completely different matter - it is based on glass fibers, the thickness of which varies between 3-15 millimeters. Despite its widespread use in the past, today this material is not used so often and is considered morally obsolete. The reason for the gradual replacement of glass wool lies in the low level of operational safety.

Mineral wool brands

Depending on the density, the following brands of mineral wool are distinguished:

- P-75. It is used for laying in horizontal planes, in places where there is no heavy load. It is also used for insulating gas pipes.

- P-125. Possesses high sound insulation properties. Installation is carried out both on the surface of the walls and the ceiling. It is used for buildings made of bricks, aerated concrete and foam blocks.

- PZH-175 and PZH-200. Such grades are characterized by increased rigidity. Installation is carried out on walls made of metal or on reinforced concrete structures.

Mineral wool properties

The material, in addition to soundproofing properties, has other characteristics:

- Water vapor permeability. The property lies in the conductivity of the condensate so that it does not linger or accumulate inside. The best indicators are for stone wool. They amount to 0.35 mg / m2. x h x Pa.

- Density. Such indicators for stone wool range from 20-220 kg / m3. Depending on the density, the rigidity of the material changes. Wool with a density of 200 kg / m3 can withstand a load of up to 700 kg. The lower the density, the softer the cotton wool, therefore, it is easier to work with it on curly surfaces, in places with increased irregularities.

- Thermal conductivity. According to the norms, this value should correspond to the value of 0.45 W / mx K.

Mineral wool is a non-combustible material. When heated, no corrosive substances are emitted. Withstands temperatures up to 700 degrees without any consequences.

About mineral wool

Mineral wool today is the best heat and sound insulation material, which consists of flexible and long fibers of material of inorganic origin (dolomite, basalt, limestone, diabase, quartz, etc.), melted and stretched into a thread.

Mineral wool, depending on the raw materials used in its production, can be of several types: stone, slag, glass.

Noise protection circuit.

Stone wool is a high quality product. It can only be obtained when using rocks as raw materials. Glass wool is made of glass or limestone, soda and sand, and slag wool is made from waste of non-ferrous and ferrous metallurgy. The latter is much inferior in quality to stone and glass wool.

This building material is produced quite simply. Raw materials for mineral wool are melted by bringing to a temperature of about 1500 ° C, while it is important to know that the thickness and length of the fibers obtained will depend on the degree of melt viscosity, which will affect the thermal insulation and dynamic properties of the mineral wool itself. After that, the melt is placed in a special centrifuge, where, with the help of supplied air and centrifugal forces, it turns into thin long fibers.

Scheme of mineral wool Technonikol.

To impart certain properties to the mass, in particular high mechanical strength and hydrophobicity, special binders and water-repellent substances can be added during production. The result is a mass consisting of randomly intertwined fibers, which is subsequently formed either in the form of heat-insulating mats without filler or in the form of plates in which the fibers are adhered to each other with a binder. In the polymerization chamber at a temperature of 200 ° C, the fibers solidify, turning into a finished product. The obtained material of the required size and quality is packed in polyethylene shrink wrap.

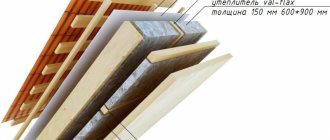

Depending on the type of raw material, mineral wool can have a different fiber structure: vertically layered, horizontally layered, spatial, corrugated - this affects its use in various structures.

Back to the table of contents

Installation of soundproofing of the ceiling and walls

Noise that penetrates from above spreads along the supporting structures. It is absorbed by soundproofing material, but often this is not enough. For full absorption, you need to use an additional coating, for example, in the form of drywall.

Insulation material requirement:

- ensuring dryness of mineral wool during transportation and storage;

- the thickness of the soundproofing layer must be at least 4 cm.

Installation technology is as follows:

- Ceiling base preparation is in progress. The old coating is removed. Irregularities are removed. Alignment is carried out and markings are applied.

- A profile is stuffed onto the ceiling.

- Sheets of mineral wool are cut. Their width is taken 1 cm more than the step between the filled profiles. This is done for a tight abutment of the sound insulator.

- With the help of self-tapping screws, drywall is screwed.

- To install soundproofing walls, the following steps are taken:

- Complete cleaning of the surface from the old coating is in progress.

- If the walls are brick or foam concrete, then they are plastered with subsequent treatment with a liquid waterproofing material. When dry, a film appears that prevents the formation of dampness.

- The frame is stuffed with profiles.

- A vapor barrier film is laid on the bottom. It is attached to the frame with adhesive tape.

- Sheets of mineral wool are cut and placed between the profiles.

- Plasterboard sheets are stuffed on top.

To isolate a room from sound penetration, mineral wool is a convenient material. It can be used to mount on any surface. It all depends on the density of the material.

The best option is stone wool, which has the best characteristics.

It should be remembered that in order to improve sound insulation, it is necessary to form a pie of several elements on the surface. It can be mineral wool and drywall.

Ceiling soundproofing methods

There are several ways to protect living quarters from external noise:

- The easiest way is to fix the soundproofing material directly to the base surface. Frameless soundproofing of the ceiling allows you to preserve the original height of the room, since there is no need to build a lathing or frame to fix the material. The sound insulator can be glued to the ceiling, fixed with dowels with caps. Also, frameless insulation is performed using liquid mixtures.

- To fix soft insulators on the shelf surface, you need to build a crate. Soundproofing of ceilings with ecowool and mineral wool is carried out using frame technology. A wooden lathing or metal frame will lower the height of the room. To hide the supporting structure, a suspended, suspended or suspended ceiling is installed.

Important! Some materials for soundproofing the ceiling can only be installed using frameless technology, while others are suitable for installation in different ways.

Soundproofing materials

Noise insulators such as mineral wool, ecowool, coke fiber, felt and some roll types are fixed on the base between the strips of the supporting frame. The membrane insulation can be glued directly to the ceiling surface. The same goes for self-adhesive soundproofing for the ceiling and foam foam. Consider the characteristics, pros and cons of the most common sound insulators.

Acoustic foam rubber

This is the most inexpensive noise isolator. Foam soundproofing is lightweight, so it can be easily glued to silicone or double-sided tape. The minimum slab thickness is 2.5 cm, and the maximum thickness is 10 cm. One side of the acoustic slabs is embossed. All slabs are classified according to the type of sound waves they dampen. The surface relief depends on this. Foam rubber can be used both independently and together with other materials.

The advantages of foam rubber include its elasticity and flexibility, simplicity and speed of installation, and an increased sound absorption coefficient.

The disadvantages of the material are as follows:

- foam rubber burns, smokes and melts in case of fire;

- the material collapses when heated and under the influence of ultraviolet radiation;

- deteriorates with mechanical stress.

Styrofoam and expanded polystyrene

Extruded polystyrene foam and polystyrene foam are made from foamed plastic. The materials protect the room well from noise and heat loss. In modern houses, sound insulation of the ceiling with Technonikol foam is used, because it is inexpensive, easy to install and has a high sound absorption coefficient. The panels are glued on liquid nails.

Important! The sound absorption coefficient of polystyrene foam plates is 0.4-1, depending on the frequency of sound waves.

- The material can be used in high humidity conditions. It is not spoiled by microorganisms.

- Ease of installation and processing, as well as durability and resistance to temperature extremes are additional advantages of foam.

- High sound absorption coefficient and low thermal conductivity.

- Reasonable price and light weight.

However, polystyrene and expanded polystyrene have significant disadvantages, due to which its use in housing is increasingly being abandoned. Foamed plastics burn well and emit harmful substances with smoke. They do not allow air to flow to the base. When heated, the foam will release toxic compounds. Low mechanical strength of the surface is also a disadvantage.

Areas of application of mineral wool

Mineral wool for sound insulation has the following advantages:

- low values of the ability to conduct heat - allows the material to be used as insulation;

- fire resistance - the structure is based on crushed stones that do not burn;

- strength - the finished sheet is high tensile strength;

- deformation protection;

- immunity to moisture;

- long service life.

Thanks to these advantages, the material is used for noise insulation and insulation:

- external, internal walls of buildings;

- fences, protective structures;

- industrial equipment;

- roofs.

Sound insulation with mineral wool is achieved by the presence of pores inside, which trap and neutralize sound waves.

There are many varieties of acoustic mineral wool designed for specific applications. For walls with a frame, universal acoustic panels URSA GEO, ISOVER OL-E are used.

For insulation and warming of surfaces with further application of plaster, rolls of Knauf, URSA, Isover mineral wool are used. Their texture allows you to level the walls by applying plaster over the material.

If additional ventilation is required, mineral wool sound insulation with additional gaps is used. Such models are produced in slabs, in rolls by Knauf, VentFasad, Izover.

For basements, attics, roofs, material with a polymer film is used. This is required to prevent the appearance of cold bridges. For such purposes, for example, Rockwool stone wool, 3-10 cm thick, is suitable.

The raw materials for manufacturing are:

- basalt rock;

- glass;

- blast furnace slags;

- recycled cellulose.

Basalt

It is based on processed basalt rock split into fibers, it is mined by melting basalt to the state of lava. In the process, the lava jets are separated from each other, and then cooled by a fan. For pressing to the state of cotton wool, threads up to 15 mm long with a diameter of no more than 12 microns are used.

Basalt sound-absorbing wool has the best heat and sound insulation performance. The permissible exposure temperature without loss of properties is 600 degrees Celsius. This material is environmentally friendly. It poses no danger to humans.

In the process of working with him, you do not need to protect your hands, since he does not inject.

Glass

Glass wool is made from recycled glass and limestone with the addition of sand and soda. This combination provides high strength and resilience. It is resistant to high temperatures - up to 500 degrees Celsius. The glass variation is produced in the form of rolls.

Slag acoustic wool can be used as an insulator, but it should not be used in places with high humidity and in the immediate vicinity of water. It is produced from blast-furnace slags with characteristic residual acidity. Because of this, contact with water leads to the appearance of an aggressive environment.

Ecological mineral wool is made from recycled cellulose. It is both a heater and a sound insulator. For application to the surface, specialized equipment is required. It allows you to use it on complex shapes (pipes, walls with complex relief).

The same types of acoustic wool have different densities. There are three categories:

The light density category includes materials with indicators up to 90 kg / m3. Insulation of this type is installed in places of low load. For example, grade P-75 with an indicator of 75 kg / m3 is used in work with pipes, gas pipelines, etc.

Rigid material is wool with a density of over 90 kg / m3. It can be subjected to stress (the permissible weight varies depending on the model). Hard mineral wool is used to create an insulating layer on walls, ceilings, floors.

Technical

A special category of super-hard wool is technical. This type of material is used with production equipment, as it holds back heavy loads. For example, the PPZh-200 brand is used to increase the resistance of the structure to fire and high temperatures.

Sale of heat and sound insulation based on stone wool in the Rockwool online store

Your region:

Unfortunately, the online store only works in Moscow, St. Petersburg and their regions.

Unfortunately, the online store only works in Moscow, St. Petersburg and their regions.

Your shopping cart is empty.

Total in the basket

| Volume: | 0 m³ |

| Area: | 0 m² |

| Weight: | 0 kg |

Request a call back *

Enter your phone number and we will call you back within a few minutes:

* The service is available from Mon-Sun. from 9:00 to 21:00

Application accepted, wait for a call!

Average processing time during business hours is 3 hours.

* - required fields

Application accepted, wait for a call!

Upon purchase of 3 packs of Acoustic Ultrathin

Upon purchase of 3 packs of Acoustic Ultrathin

Rockwool Calculator

Start calculation

Promotion for Sauna Butts

Promotion for Sauna Butts

ROKFASAD

Popular goods

ACOUSTIC BATTS

Soundproofing Soundproofing of non-residential premises, Partitions in residential premises, Overlapping on logs

from 138.33 rubles. 1 m 2

FLOR BATTS

Sound insulation Slabs between floors with a wet screed, Ceilings between floors with a dry screed, Floors

from 143.75 rubles. 1 m 2

ROKFASAD

Insulation of walls under a plaster facade

from 333.33 rubles. 1 m 2

SCANDIC

Thermal insulation Balconies, Frame walls, Attic, Partitions, Overlapping floors, Floors, Cold basement floors, Pitched roofs, Siding walls

from 98.96 rubles.1 m 2

fire safety

Rockwool stone wool prevents the spread of fire, thus allowing more time to save people and property in the event of a fire.

The fibers of the material can withstand temperatures up to 1000 ° C, providing protection against fire and thus preventing their destruction. The material does not emit heat, smoke or burning droplets in the event of a room fire.

environmental friendliness

ROCKWOOL is the first thermal insulation to receive the EcoMaterial Green label. It confirms the safety of using the material in all types of buildings and for interior decoration of premises, including bedrooms and children's rooms. Thermal insulation plays a huge role in solving the issue of saving energy and conserving natural resources. Well-insulated houses require less energy for their heating and air conditioning, which means they reduce the human impact on the environment. For our part, we are constantly improving the technological process of stone wool to minimize the impact of enterprises on the environment. All factories of the company have a closed production cycle: cotton wool trims are returned back to production in order to make it as lean as possible. In addition, Rockwool insulation is one of the few industrial products with a positive energy balance. This means that the amount of energy that our products save is many times greater than the amount of energy that was used to produce them.

Heat and sound insulation boards EURO-TIZOL

TIZOL SUPER-LIGHT

Non-combustible bulk (blown) cotton wool TIZOL SUPER-LIGHT

for insulating unloaded building structures: walls, partitions, floors on logs, attic floors, roofs, attics, etc.

EURO - LITE

Lightweight heat and sound insulation boards with a density of 25 to 50 kg / m³ for use in unloaded roof structures, frame walls and partitions.

Brands: EURO-LITE 25, EURO-LITE 30, EURO-LITE 35, EURO-LITE 40, EURO-LITE 50.

EURO-BLOCK, TIZOL-BLOCK 50

Special slabs for use in three-layer external walls made of bricks, lightweight concrete panels or blocks.

EURO-VENT, TIZOL-VENT

Heat and sound insulation boards with a density of 40 to 110 kg / m³ for use in hinged ventilated facade systems.

Brands: EURO-VENT N, TIZOL-VENT N 40, EURO-VENT, TIZOL-VENT 70, EURO-VENT V, TIZOL-VENT V 90.

EURO-RUF, TIZOL-RUF

Heat and sound insulation boards with a density of 81 to 210 kg / m³ for use in multi-layer roofing structures.

Stamps: TIZOL-RUF N 90, TIZOL-RUF N 100, TIZOL-RUF N 110, EURO-RUF N, TIZOL-RUF N 120, TIZOL-RUF 135, TIZOL-RUF 150, EURO-RUF, TIZOL-RUF V 160, TIZOL -ROOF B 170, EURO-ROOF B, EURO-ROOF B Super.

EURO-FASAD, TIZOL-FASAD

Heat and sound insulation boards for facade systems with a thin plaster layer. Brands: EURO-FACADE OPTIMA, EURO-FACADE, EURO-FACADE UNIVERSAL, TIZOL-FASAD 100, TIZOL-FASAD 110.

EURO-SANDWICH, TIZOL-SANDWICH

Heat and sound insulation boards for wall and roof sandwich panels.

Brands: EURO-SANDWICH S, EURO-Sandwich K, TIZOL-SANDWICH 80, TIZOL-SANDWICH 95, TIZOL-SANDWICH 125.

EURO-TIZOL boards - a key element of an energy efficient building

In 2008 at the enterprise complete modernization

mineral wool production: two modern import lines for the production of non-combustible heat and sound insulation boards EURO-TIZOL were put into operation

TU 23.99.19-010-08621635-2018 (instead of TU 5762-010-08621635-2006).

Latest production technology

allows the production of up to 60,000 tons of non-combustible

hydrophobized

slabs density

from 25 to 210 kg / m3

and thick

from 30 to 200 mm

... Plates are produced without covering material, or laminated with fiberglass or foil.

EURO-TIZOL boards have a universal purpose, which allows you to perform heat and sound insulation of all types of building structures: roofs, walls, internal structures, as well as insulation of industrial equipment.

At the end of 2011, a new EURO-LITE light board packer was launched. Now our products

, which is optimal for low-rise housing construction,

easy to transport and store

... Hermetically sealed packaging with pre-compression of the boards can significantly reduce the volume of packaging and, accordingly, save on transportation costs, as well as facilitate the storage of boards.

Slabs EURO-TIZOL

have been tested in various climatic conditions from Sochi to Yamal and are used at such socially significant objects as: educational institutions, residential buildings, museum complexes and architectural monuments, retail, office and entertainment centers, international airport terminals, metro stations, power plants and many others ...

Benefits

High quality thermal insulation

The fundamental indicator of any heat-insulating material is the coefficient of thermal conductivity: the lower it is, the better thermal protection the material provides. The low coefficient of thermal conductivity of the materials of JSC "TIZOL" is achieved due to chaotically intertwined basalt fibers and the presence of the smallest open pores with immobile air between them. The use of TIZOL products significantly saves the costs of heating and maintenance of buildings, and also provides an increase in the service life of technological equipment.

Fire safety

All products

JSC "TIZOL" is certified and

belongs to the group of non-combustible materials NG

and fire hazard class KM0. This is due to the fact that we use rocks of the basalt group for the production of heat-insulating and fire-retardant materials. Basalt fiber is capable of withstanding temperatures over 1000 ºС without melting, therefore materials based on it are a reliable barrier against fire and prevent the spread of flame along structures.

Effective sound insulation and sound absorption

Application of materials produced by JSC "TIZOL" allows you to isolate building structures from airborne and impact noise

and ensure optimal acoustic comfort in rooms. The efficiency of sound absorption by our materials is due to the presence in them of a large number of small open through pores with a large specific surface area. Due to the light fiber structure and sufficient density, heat and sound insulating

materials of JSC "TIZOL"have increased sound-absorbing properties

: not only insulate the structure, but also do not collapse themselves from sound vibrations.

Environmental Safety

Products of JSC "TIZOL" are made from natural raw materials: the basis is the rocks of the basalt group. Our products do not contain toxic substances and are safe for the environment and human health.

Environmental safety of products is confirmed by expert opinions and laboratory test reports.

Moisture resistance, vapor permeability

The products of TIZOL JSC have excellent water-repellent properties and practically do not absorb moisture. Special hydrophobic additives reduce the water absorption coefficient of materials up to 1%

... Our products do not lose their original thermophysical properties even in a humid environment, which allows them to be used in all operating and climatic conditions without restrictions. Thanks to

high vapor permeability

products of JSC "TIZOL", excess moisture in the premises can freely pass through the materials and evaporate from their surface, without accumulating in the thickness of the insulation and without reducing its heat-shielding properties.

Durability

The products of TIZOL JSC retain their heat and sound insulation properties throughout their entire service life. Resistant to aggressive environments and high temperatures, does not deteriorate under strong vibration loads, does not rot and mold.

Our products are made from basalt and have unique stone strength and durability. As the world experience in the use of mineral wool thermal insulation shows, the service life of the insulation, when properly used, is at least 50 years.

Mineral wool for soundproofing walls

Today, the most demanded material used for soundproofing walls is mineral wool.Made from natural basalt, stone wool not only absorbs noise and provides acoustic comfort. Due to its excellent thermal insulation characteristics, soundproof mineral wool maintains an optimal temperature regime in the interior.

ACOUSTIC BATTS® - from noise and fire! Do voices, music from neighbors or sounds from the street interfere? Use ACOUSTIC BATTS® in any partitions in an apartment, office building or hotel.

Mineral heat and sound insulation based on fiberglass. Produced according to eco-technology GEO.

Mineral heat and sound insulation based on fiberglass. Produced according to eco-technology GEO.

ACOUSTIC BATTS® - from noise and fire! Do voices, music from neighbors or sounds from the street interfere? Use ACOUSTIC BATTS® in any partitions in an apartment, office building or hotel.

The material with the best thermal insulation characteristics in its class with increased elasticity and increased moisture resistance.

Thermal insulation URSA Terra Noise protection is specially designed for sound insulation in the structures of frame sheathing partitions and claddings.

Thermal insulation URSA Terra Noise protection is specially designed for sound insulation in the structures of frame sheathing partitions and claddings.

ACOUSTIC BATTS® - from noise and fire! Do voices, music from neighbors or sounds from the street interfere? Use ACOUSTIC BATTS® in any partitions in an apartment, office building or hotel.

ACOUSTIC BATTS® - from noise and fire! Do voices, music from neighbors or sounds from the street interfere? Use ACOUSTIC BATTS® in any partitions in an apartment, office building or hotel.

Thermal insulation board for general construction purposes for use in various building structures.

Thermal insulation board for general construction purposes for use in various building structures.

FLOR BATTS I slabs are intended for installation of acoustic floating floors, as well as for thermal insulation of floors along the ground. They have dynamic characteristics that meet the requirements for noise protection and belong to the class of high-performance sound-insulating cushioning materials.

Want to have fun without disturbing your downstairs neighbors? ROCKWOOL FLOR BATTS® - floor sound insulation. It is used in acoustic floating floors for dry or wet screed.

ROCKWOOL Acoustic ULTRAFINE - the thinnest stone wool acoustic solution - only 27 mm thick. Plates are used as additional sound insulation of walls and ceilings from airborne noise. The material is absolutely environmentally friendly, can be used for children's rooms and medical institutions. Ultra-thin non-combustible stone wool slabs provide not only protection against extraneous noise, but also fire safety.

Want to have fun without disturbing your downstairs neighbors? ROCKWOOL FLOR BATTS® - floor sound insulation. It is used in acoustic floating floors for dry or wet screed.

Want to have fun without disturbing your downstairs neighbors? ROCKWOOL FLOR BATTS® - floor sound insulation. It is used in acoustic floating floors for dry or wet screed.

Materials for soundproofing walls, ceilings

Stone wool

Stone wool is a sound-insulating material made from molten rocks of the basalt group.

Specially developed sound-absorbing boards (for example, TECHNOACUSTIK, ACOUSTIC BATTS), the acoustic properties of which may differ from those of heat-insulating materials by several times.

Acoustic mineral wool slabs are composed of the finest fibers intertwined with each other in different directions and forming numerous tiny air cavities that communicate with each other.

The degree of pore openness of the slabs, along with the density of the material and the diameter of its fiber, directly affects its sound-absorbing properties.Correctly selected ratio between the fiber thickness and its amount in the board (density) allows the production of a material with the required acoustic characteristics.

Density of cotton wool for sound insulation

The density of the acoustic material is selected in accordance with studies that have shown that the optimal density for fibrous sound-absorbing material is 45 kg / m3. For materials with a lower density, the value of the sound absorption coefficients in the region of low and medium frequencies is noticeably lower, and a significant increase in density leads to a decrease in the elastic properties of the material, which negatively affects the sound insulation characteristics of the structure.

Due to the interwoven fibers and density of 45 kg / m3, mineral wool slabs have high resistance to mechanical stress and low compressibility, because of this, during operation, the slabs do not deform or compact, and the thickness of the material does not change. In addition, over time, the soundproofing characteristics of the structures in which they are installed do not deteriorate.

For the production of slabs, water-repellent stone wool is used. Due to this, the material practically does not absorb moisture, having negligible water absorption. Moisture that gets on the surface of the slab does not penetrate into the mass of the material and is not absorbed. Due to this, the material remains dry and maintains high insulating properties for a long period of use.

Effective sound insulation with mineral wool

Stone wool is widely used for soundproofing floors, suspended ceilings, internal partitions and attics, since it has a high sound absorption coefficient. It comes in several forms:

- stitched mats;

- soft and hard plates.

Soundproof mineral wool excellently withstands high-temperature heating, does not emit harmful substances into the environment, does not contribute to the development of rodents, moldy fungi and microorganisms. In addition, it is easy to cut with simple tools, extremely easy to install and lay. That is why sound insulation with mineral wool is actively used in construction, agriculture, refrigeration and aircraft production.

The best manufacturers of mineral wool

Mineral wool producers cannot be added to the list by identifying the best or the worst. Each of their material has its own disadvantages, advantages, there is a difference in characteristics.

The following brands are trusted:

Rockwool

The goods are produced and sold in Russia, although the roots of the enterprise are in Denmark. The price markup is minimal, the product is of decent quality. The builders confirm that the products are worthy of respect. There are increased indicators of fire safety (up to 1000оС), noise absorption. Environmental friendliness is confirmed by the international certificate EcoMaterial Green. Buy only from reliable suppliers - there are a lot of fakes on the market.

| Material name | Type of material | Purpose | Thermal conductivity coefficient (W / mK) |

| Rockmin | plate | heat and sound insulation of ventilated coverings and attics, roofs, walls, timber joists, suspended ceilings, light frame walls and partitions, as well as floors on logs. | 0.039 |

| Domrock | mat | heat and sound insulation of ventilated coverings and attics, roofs, walls, timber joists, suspended ceilings, light frame walls and partitions, as well as floors on logs. | 0.045 |

| Superrock | plate | heat and sound insulation of ventilated coverings and attics, roofs, walls, timber joists, suspended ceilings, light frame walls and partitions, as well as floors on logs. | 0.035 |

| Panelrock | plate | heat and sound insulation of walls of external buildings | 0.036 |

| Wentirock max | plate | thermal insulation of ventilated facades | 0.036 |

| Monrock max | plate | insulation of all types of flat roofs | 0.039 |

| Dachrock prof | plate | insulation of all types of flat roofs | 0.045 |

| Fasrock max | plate | heat and sound insulation of external walls with a facade insulation system using the "light wet" method | 0.037 |

| Fasrock L | plate | heat and sound insulation of external walls with a facade insulation system using the "light wet" method | 0.042 |

| Fasrock | plate | heat and sound insulation of external walls with a facade insulation system using the "light wet" method | 0.039 |

| Stroprock | plate | heat and sound insulation of floors on the ground and floors under a concrete screed | 0.041 |

| Alfarock | mat | insulation of pipes and pipelines | 0.037 |

| Rockmata | mat | insulation of pipes and pipelines | 0.036 |

| Wired Mat and Alu Wired Mat | mat | insulation of pipes and pipelines | 0.042 |

Paroc

Cotton wool perfectly keeps the size, does not begin to crumble even after 10 years of operation. The products are decent, but the price is high. The manufacturer focuses on high performance of thermal insulation. Noise isolation is also excellent.

| Material name | Type of material | Purpose | Thermal conductivity coefficient (W / mK) |

| PAROC InVent 80 N3 / N1 | plate | noise insulation for ventilation ducts | 0.034 |

| PAROC High Temperature Slab (НТ-900) | plate | designed for high operating temperatures (withstands temperatures of 900 0 С) | 0.055 |

| Paroc Extra 50 mm / 100 mm | mats | universal thermal insulation material that is used to insulate frame structures of all parts of the building | 0.035 |

| Paroc UNS 37 | slabs | universal thermal insulation board made of non-combustible mineral fibers, which are used for thermal insulation, sound insulation and fire protection. | 0.037 |

| Paroc Extra Finnish Standard | slabs | used for heat, sound insulation and fire protection of walls, roofs and floors in all types of buildings. | 0.042 |

| Paroc ROS 30, 40, 50, 60 | plate | rigid slab for single-layer flat roof structures | 0.037 |

| Paroc Linio 10, 15, 18, 20, 80 | plate | for the creation of thin-layer plastering systems in low-rise buildings. | 0.036 |

Isover

Only glass wool and stone wool are produced. The manufacturer has a well-deserved good reputation in Russia and abroad. We have all the necessary quality certificates. One of the new products is dust-free glass wool with minimal thorniness. The price / quality ratio is optimal here, although the quality of the products is unlikely to be compared with more expensive brands.

| Material name | Type of material | Purpose | Thermal conductivity coefficient (W / mK) |

| ISOVER Classic | roll | thermal insulation of structures, where the thermal insulation material should not bear the load | 0,033-0,037 |

| ISOVER Frame-P32 | plate | thermal insulation of frame structures | 0,032- 0,037 |

| ISOVER Frame-M37 | mat | thermal insulation of frame structures | 0,037- 0,043 |

| ISOVER Frame-M40-AL | mat | thermal insulation of frame structures | 0,040- 0,046 |

| ISOVER Sound Protection | plate | thermal insulation of frame structures | 0,038- 0,044 |

| ISOVER Floating Floor | plate | sound insulation of partitions, false ceilings, walls inside the premises | 0,033-0,046 |

| ISOVER Frame-P34 | plate | sound insulation against impact noise when installing a "floating floor" | 0,034-0,040 |

| ISOVER Pitched Roof | plate | insulation of multilayer walls of buildings from small-piece materials | 0,037-0,043 |

| ISOVER OL-TOP, OL-P, OL-Pe | hard plate | pitched roof insulation | 0,037-0,042 |

| ISOVER Vent Facade | plate | flat roof insulation | 0,032-0,040 |

| ISOVER OL-E | hard plate | wall insulation with ventilated gap | 0,034- 0,039 |

| ISOVER Plaster Facade | hard plate | wall insulation with plastering | 0,038- 0,043 |

Knauf

It manufactures many products for the construction market. Thermal insulation is one of the best, it is used in all areas. Insulation can be specialized, that is, it serves a specific purpose: insulation of heat, noise, steam. Other indicators can be underestimated, thereby lowering the price of the product.

| Material name | Type of material | Purpose | Thermal conductivity coefficient (W / mK) λ10, λ25, λА1, λБ2 |

| Thermo Plate 037 | plate | insulation for the whole house | 0,037, 0,040, 0,041, 0,043 |

| HEATROOF 037A | plate | roof insulation | 0,037, — , 0,041, 0,043 |

| HEATWALL 032 А | plate | insulation "under siding", prefabricated wall sandwich panels, insulation of hinged ventilated facades | 0.032, — , 0.039, 0.042 |

| HEAT roll 040 | roll | thermal insulation of floors in attic rooms, attic and interfloor floors, floors on logs | 0,040, 0,044, 0,044, 0,047 |

URSA

Offers a new generation of mineral wool. It is carried out using a special technology. The product is environmentally friendly. Acrylic binder, completely safe for health.There are many other types of wadding available that do not differ in price and quality from other manufacturers in the top.

| Material name | Type of material | Purpose | Thermal conductivity coefficient (W / mK) |

| URSA GEO М-11 | roll | universal material (floor, roof, wall insulation) | 0.04 |

| URSA GEO Universal plates | slabs in roll | universal material (floor, roof, wall insulation) | 0.036 |

| URSA GEO Pitched roof | slabs in roll | insulation of pitched roofs | 0.035 |

| URSA GEO Sound protection | slabs in roll | insulation of frame partitions and walls when cladding from the inside | 0.039 |

| URSA GEO Light | roll | insulation of floors, ceilings, acoustic ceilings | 0.044 |

| URSA GEO M-11F | roll | insulation of walls when facing from the inside, insulation of floors, ceilings, baths | 0.04 |

| URSA GLASSWOOL FACADE | mat | ventilation systems with ventilated air gap | 0,032-0,043 |

| URSA GLASSWOOI P-15 | plate | insulation of pitched roofs | 0.042 |

| URSA M-25 | mat | insulation of complex structures | 0.038 |

Often a detailed analysis of competitors, material properties, characteristics, dimensions of insulation, mineral wool or some other, allows you to determine which option is optimal. It will not be possible to determine with mineral wool. Many manufacturers supply a really high-quality product, approximately equal in price and characteristics.

Soundproofing Rockwool

is the official dealer of Rockwool acoustic mineral wool boards since 1996

Retail price: 867 rubles / pack

Retail price: 882 rubles / pack

Price: 4287 rubles / cubic meter

Retail price: 888 rubles / pack

Price: 8964 rubles / cubic meter

Dealing with noise is an important problem in modern society. Its solution is especially important in large cities and megalopolises. An increase in noise in comparison with the norms by 1-2 dBA reduces labor productivity by at least 1%.

You can buy the entire line of specialized soundproofing materials made of Rockwool mineral basalt wool. The price for them is reasonable and corresponds to the conditions of the dealer of the first category, since we have been successfully selling these excellent materials for over 20 years. High soundproofing qualities are confirmed by the leading certification centers of the State Construction Committee of the Russian Federation.