General information about the material

It would be superfluous to describe the foam, since almost every one of us has come across this material. But in most cases, we saw it as a packing element that fills the space in a box and is designed to fix its contents and reduce damage in the event of a fall. Not everyone knew, but the use of foam is actually not limited to the packaging industry, as the material is extremely widely used for insulation. At the same time, the properties of the foam are such that it can also be used to insulate the outer walls.

Pros of Styrofoam

Foam has the following advantages:

- light weight;

- does not rot;

- not afraid of acids and alkalis;

- working with it is not only easy, but also simple. The foam is processed (cut) by a very simple device made of a stretched nichrome wire through which an electric current is passed. However, with a great reluctance to tinker with different wires there, and, moreover, under current, you can get by with a simple sharp knife with a thin blade (the author of this article does just that);

- not afraid of moisture (not always, but more on this below);

- available, because it is sold in almost any building goods store;

- and is also available for the price.

Material advantages

- Styrofoam is very durable. The material is not of interest to pests (mice do not eat it, but they can arrange it inside the nest), fungi and mold do not appear on it, and also does not change its structure for a long period of time. Its active service life, if properly installed, can be several tens of years;

- Low cost. It is not in vain that polyfoam is used in the packaging industry, since, with its technical characteristics, it is incredibly cheap, and its use does not greatly increase the cost of the finished product. The same rule applies to insulation. Therefore, if you want to insulate your home effectively, but at the same time on a budget, then foam will give you that opportunity;

- Complete environmental safety. This finishing method does not emit toxic substances into the air;

- The material has a low dynamic stiffness, which enables it to be a good sound insulator;

- Low weight. Also the quality of this material is known to all. The use of foam allows you not to reinforce the foundation, and also not to mount a solid frame structure. In addition, the low weight also has a positive effect on the complexity of the work;

- High resistance to moisture. Polyfoam does not reduce its insulating properties when it comes into contact with water. Therefore, it can be actively used not only in outdoor insulation, but also in "wet" rooms;

- Versatility. The material is perfect for indoor and outdoor use, and can also be used for both vertical and horizontal surfaces (floors, ceilings). At the same time, foam can also be used for roof insulation;

- Extremely low thermal conductivity. Since the overwhelming majority of its mass consists of air, enclosed in polymer granules, it conducts temperature extremely poorly. But for this, it is advisable to use sheets of 10 centimeters and thicker.

Important! In winter, it gets colder in the premises, not because cold air penetrates there from the outside, but because heat leaves the environment. After finishing the walls with foam, we will reduce their thermal conductivity and prevent heat from escaping into the surrounding space.

Polyfoam: why is insulation with this material not recommended?

Insulation has been done with expanded polystyrene for a long time, ignoring all the recommendations of SNiPs and construction masters.The thing is that polystyrene (aka ordinary expanded polystyrene) is the cheapest insulation that can only be found on sale. Its affordable price has made it extremely popular. However, experts do not recommend insulating a living space from the inside, and not only with foam. Why?

What is dew point?

Dew point. Knowing how it works is essential

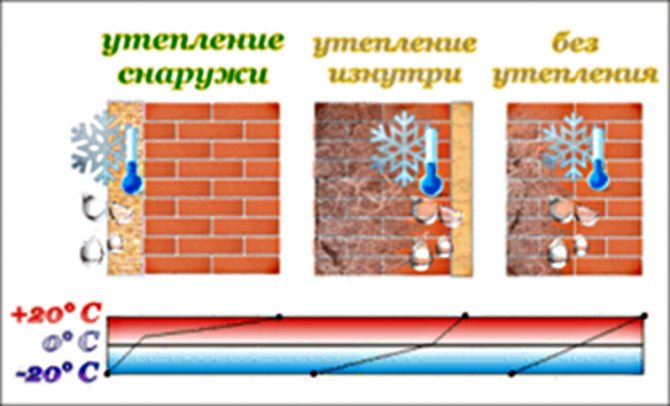

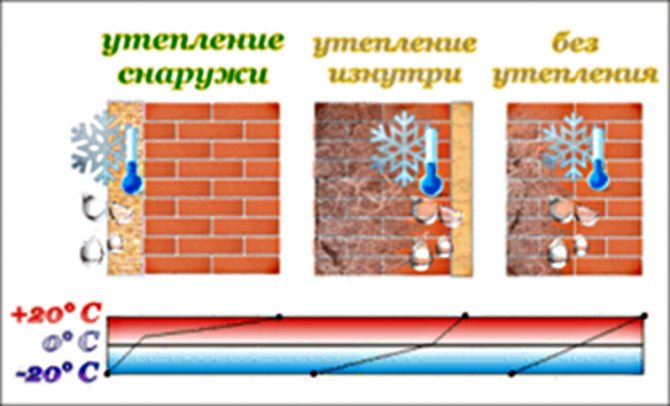

Internal insulation with foam or any other material has always been considered a last resort. From the inside, they insulate apartments in multi-storey buildings located in the city center or in buildings that are of historical value. In all other cases, experts and SNiPs recommend the installation of external thermal insulation.

Insulation of a dwelling from the inside with foam or other heat-insulating material shifts the dew point from the thickness of the supporting structure to the border with the insulation. This is fraught with the fact that the wall in an insulated room in the cool season will be constantly wet due to regular moisture loss.

The dew point is nothing more than condensation. When warm air from inside the room collides with cold air, in our case with a wall, water droplets appear. With external insulation, the dew point goes beyond the bearing wall to the surface of the insulation. This is the best option. The walls of a house or apartment cease to undergo regular freeze / thaw cycles, remain dry, and warm up from inside the room.

The dew point on an uninsulated wall is in its thickness. This option, as well as insulation from the inside, significantly shortens the life of the walls. They regularly get wet and freeze in winter. Water (dew point), located in the thickness of a brick or concrete, tears them apart from the inside.

Drops of condensation on the window are the same dew point when warm air from the room collides with cold slopes

Is it possible to somehow avoid the formation of condensation and the subsequent formation of mold on the topcoat? It turns out that it is possible if you use extruded foam for insulation from the inside - insulation with almost zero vapor permeability.

As practice shows, the dew point "works" predictably if the vapor permeability of the walls changes from zero (indoors) to high outside. If this rule is violated, it is difficult to predict the formation of condensate (dew).

Important... When insulating surfaces with foam from inside the room, there are many subtleties that must be observed in order to get the desired result.

Disadvantages of Styrofoam

- The material is flammable, and this is one of its most important disadvantages. Unlike mineral wool, this polymer insulation does not tolerate high temperatures. At the same time, it is very difficult to extinguish the foam, but when it burns, it emits black and very acrid smoke, which we all remember well from childhood;

- Low strength and high fragility. The material cannot be strongly bent as it will break. As a result, only straight surfaces can be insulated with foam. Low strength, on the other hand, translates into susceptibility to deformation even with minor external influences. So on top, the foam needs a reliable finish;

- The foam does not allow air to pass through. In this regard, the walls cease to "breathe", which violates the microclimate in the room. So, it can provoke high humidity;

- The material is afraid of many chemical compounds (turpentine, acetone, solvent, alcohol, gasoline, many resins, kerosene and others). All of these chemicals can erode the foam structure very quickly.

Important! In general, all the disadvantages of foam can be leveled by its competent use. It should be remembered that an equally large list of disadvantages in general can be found in very many heaters.

Styrofoam fire hazard

At a temperature of 180 degrees, the release of harmful substances begins and it already begins to stink and release styrene. Manufacturers and sellers say that there is 97% of the air and they say there is nothing special and there is nothing to burn, it is self-extinguishing.

Yes, that's right. But the devil is in the details.

Foam plastics do not burn without an open flame and do not sustain combustion. But this rule works up to a certain temperature, after which everything burns, even low-flammable ones (if the glass burst when extinguishing the fire from the heat, then the fire is 4 degrees and it is no longer extinguished, but they do not allow it to spread - for it is already useless to extinguish it). And since it perfectly insulates foam, the temperature in it and nearby very quickly builds up for such a fire. Do sellers talk about this? No, they are silent about it.

With proper wall cladding with foam, cutoffs are made against fire within the floor slabs, at windows and doors. This is done so that the fire does not spread under the plaster and can be evacuated safely. And the plaster itself protects against air inflow and open flame. But if done correctly!

A few breaths of air in a burning building with polystyrene are enough and you will be poisoned and lose consciousness. Because the smoke is very harmful! Yes, smoke from wood is also harmful, but more of it will stand out from the log, but it is not so dangerous and you will feel it faster. Sellers are silent about this.

How not to insulate the attic

Wood will not emit harmful substances before ignition, and foam begins to emit from 80 degrees, and the smell is practically not emitted. So it is dangerous without a fire. This is what the sellers are silent about. And this temperature can easily occur on a sunny summer day under a metal roof, especially if it is not ventilated in the attic or in the attic pie.

So there should be no foam inside the room. And foam is absolutely not suitable for roof insulation!

All stages of wall insulation by gluing foam

- Preparatory work on the walls. First of all, it is necessary to thoroughly clean the walls from dirt and other unnecessary elements. In this case, the surface is primed in order to improve adhesion with the adhesive composition;

- Starting profiles are attached to the wall, which are installed on special dowels with a step of about 30 centimeters;

- Applying glue to walls and foam boards. Prepare a special glue for mounting this type of insulation. The adhesive must not contain chemicals that can destroy the foam structure. At the same time, apply the composition to the walls and at least half of the area of the foam plates themselves, distributing it in an even layer. That is why it is important to align the walls at the preparatory stage, since otherwise the composition will have to be applied along the lighthouses;

- Bonding material. The foam boards are installed on the starting profiles and fixed horizontally. In this case, it is necessary to try to remove excess glue and not leave large gaps, which are then sealed with sealant or polyurethane foam. Fasten the foam sheets in a checkerboard pattern.

Important! When insulating external walls in this way, a reinforcing composition is usually applied on top in two layers, between which a reinforcing mesh is laid. After that, the finishing is carried out with a special facade plaster that can withstand the effects of the external environment.

Pros and cons of thermal insulation of the bath floor with polystyrene foam

The huge advantage of the material is its versatility. Styrofoam is ideal for insulating most of the wooden floors in the break room and even in the steam room. Without being distracted by the search for other options, you can make concrete floors under the tiles in the bath using foam in the same sink or in the shower.

The second serious advantage is resistance to pathogenic microflora and mild heating.Microbes and mold on polystyrene foam do not multiply, and soft heating of the floor insulation to 60-70 ° C does not affect its strength in any way.

There are, of course, drawbacks. Firstly, foam sheets are a favorite wintering place for rats and mice, but if food is not stored in the bath, then you don't have to worry too much. Secondly, the foam allows warm water vapor to pass through, therefore, if you lay the material in the wooden floor of the bath, you will need at least a vapor barrier along the lower edge and waterproofing of the upper surface. Otherwise, in cold weather, the accumulating and condensing steam will break the lower layers into small granules.

For your information! Many garage owners, trying to insulate the gate with foam, save on vapor barrier on the outer surface of the insulation, as a result, after a couple of years, the sill and the floor are strewn with foam dust.

Insulation of a frame house with this material

- The frame surface must be pre-prepared and free from irregularities. Protruding nails and other elements also need to be removed, as well as cracks;

- Plates are laid in the gaps between the frame posts with a certain gap, which is then filled with a sealing compound in order to exclude "cold bridges". This allows the slabs not to change their position during thermal expansion. In this case, the plates are fastened either to plastic dowels or to an adhesive composition;

- Although the foam does not absorb water, moisture can still penetrate under the material and cause the wall to collapse. Therefore, the surface must be covered with glassine, various membrane coatings or plastic wrap. Try to achieve complete tightness by overlapping the coating sheets;

- In this case, the inner surface of the wall is covered with a vapor barrier coating;

- Finishing is carried out according to the existing project.

Below you can watch a detailed video on how to do the exterior wall decoration with foam plates with your own hands.

Is styrofoam harmful as a heater for health? Forgive me, dear visitors, here I have to repeat myself. In a more acute form, I am forced to once again draw your attention to common misconceptions that significantly reduce the attractiveness of foam in the market of building materials and insulation. In the articles of this block (about foam, etc.), questions about the safety, manufacturability and consumer qualities of foam are widely and in detail covered, and if you already know everything about expanded polystyrene and are not afraid of it, you can not read further, but go directly to pages of our catalog =), get detailed advice from our specialists by phone or e-mail, and express your opinion, order and purchase the quality material you need much cheaper than from our competitors, as well as become our partner or representative in your region.

Unfortunately, so far, a persistent dislike for foam as a building material (+ insulation) is based on three main misconceptions (or lies, often supported by very authoritative sources) ...

The most persistent myth is the fire hazard of expanded polystyrene.

In Russia, fighters for security and truth grab their heads and ask themselves: “What is wrong with our polystyrene? Why does the number of fire accidents continue to grow in Russia, when such accidents are at a minimum in Europe and the United States? " The answer is much simpler than it sounds. Firstly, in the Russian construction market, a huge percentage is made up of falsifications - goods that do not comply with GOSTs and Building Norms and Regulations (SNiP). With the modern scale of information on the Internet, even a non-professional can independently determine the quality of expanded polystyrene. High-quality foam, produced in compliance with all technological standards, certified and labeled, will not ruin people's lives.The second, no less important prerequisite for the safety of future buildings is literacy in construction and finishing work. Remember how in the Russian proverb: "You are crazy about not tapping with an ax or picking bast shoes." No matter how easy the foam may seem to use, but ... it turns out that there are also a number of mandatory norms, technology and standards of use, which many construction companies and sellers are silent about. Multiple accidents, which are repeatedly scrolled in the media, also occur due to a violation of GOSTs and norms of production and construction by a construction company or manufacturer.

The most gross and dangerous mistakes are violation of the following mandatory rules and conditions: 1) From the inside and outside, expanded polystyrene must be protected by a reinforcing mesh and a layer of plaster of at least 30 millimeters. This is necessary to protect polystyrene foam from ultraviolet radiation from the outside, and to increase fire safety - inside. 2) Wiring and boxes must be protected from direct contact with the foam using metal or plastic corrugated hoses. 3) Heating systems, fireplaces, stoves, radiators require competent installation.

The third point is the observance of safety measures by the residents of the house. A significant number of fires occur due to the careless handling of fire by the owner of the house. High-quality construction foam is a self-extinguishing material, it does not support combustion. Even in an open flame of a gas burner, the foam only melts and barely burns without smoke and soot and immediately extinguishes, one has only to remove the source of the open flame aside. However, even without foam, there is something in the house to burn: for example, linoleum, plastic, furniture, fabrics - they burn much more readily and hotter.

Note that foam of any other (non-construction) brands, packaging for example, burns quite well and at the same time stinks terribly, using material unsuitable for this in construction is not stupidity, but a crime.

The standard grade of expanded polystyrene PSB-S, with proper installation, guarantees 30 minutes of free evacuation after the occurrence of a fire source. Remember the main thing: our safety - to a greater extent depends on ourselves.

The second persistent myth is the release of harmful substances into the atmosphere by foam plastic during its operation: This is complete nonsense and nonsense - in this regard, foam plastic is the safest, (non-toxic and non-carcinogenic) stable material of all existing ones. And if a certain scientist - a chemist with foam at his mouth proves to you from the TV screen that a house built using construction foam polystyrene is a gas chamber, he is a liar by definition and misleading us, most likely fulfills someone's order ... A chemist cannot but know , what .. I'll tell you now.

Yes, the derivative of expanded polystyrene - polymer - its monomer styrene - is certainly moderately toxic and carcinogenic poison.

Yes, this smelly, volatile and water-soluble liquid is produced in the world in the amount of 12 million tons per year, it is used in the production of many polymers, plastics and rubbers, products from which surround us in our daily life from all sides.

- and this very styrene in its free form is simply not able to exist.

Without stabilization with antioxidants, styrene polymerizes without residue already at room temperature - and you need to heat the polymer (foam, rubber) to a temperature of 320 degrees so that its vapors appear in the air - while styrene molecules barely have time to appear in the atmosphere are instantly oxidized, bound by atmospheric oxygen tightly, turns into polystyrene, an absolutely harmless substance.

Styrene is contained in natural gas and this does not prevent us from burning this fuel in our kitchens in an open way! Styrene is found in many plants, albeit in negligible quantities, but we eat them ...

The third lie is that polystyrene is supposedly an airtight barrier and is capable of absorbing moisture, while being subject to biodegradation (decay), destruction from climatic factors ... with all the ensuing consequences - mold and dampness in the room. Absolutely - the foam itself allows air to pass through, but does not let water through and does not absorb almost at all ... mold on the walls lined with foam is a consequence of a violation of the application technology and errors in calculations! Polyfoam, unfortunately, does not rot, it is a relatively eternal material ... It can only be destroyed by ultraviolet light ... Manufacturers of building materials and builders who use them: hands must be straight, conscience must be clean, and head on shoulders is bright, that's all ...

Demand quality certificates from the manufacturer, make sure of the quality of the materials you buy!

Other myths ... there are many ... the funniest one is the statement that mice and rats eat polystyrene, prefer it to any other food, not only fill their bellies with pleasure, but even digest it ... need comments?

If you know of any other frightening myth about Styrofoam - write to us and together we will understand its value.

Misha, the rat's brother

Vendors say the foam is not gnawed by mice. There are heaps of photos that they do not eat and do not notice.

I declare responsibly - this is not so! At our construction site, they insulated a room-shed made of polystyrene foam 100 mm from PSB-S-25 from the inside and removed it in the summer. So in this foam, the mice made moves, be healthy!

Indeed, they do not eat polystyrene, but they live in it just fine - it is warm and dry there, it chews easily. So you definitely need to think about how to protect foam from rodents.

Errors when working with foam

Styrofoam should not be left on a wall that is not plastered. It can burn out and darken. And when it burns out, it can lose its properties. If this is already happening, then it is necessary to putty it.

Fastening the foam to the walls, it must be well sealed so that mice cannot penetrate into it. If mice get to the foam, they will completely destroy it. As strange as it sounds, mice can eat Styrofoam. To avoid this, you need to nail a drywall profile from below and insert the bottom sheet of foam plastic inside it. Thus, a reliable level of protection from below will be created. From above, you can also use such protection.

It is better not to use psb-s-35 foam in living quarters. It can only be used in a screed on the floor, where it is covered from all sides by a layer of mortar or concrete.

How well the walls are protected from the cold will determine how heat is retained in the house. The more heat your home retains, the lower your heating costs will be. If your house has autonomous heating, then it is worth insulating the house, as this will significantly reduce your costs. And if you think about the cold winter, it becomes clear that by insulating your house you will significantly reduce your heating costs for your house.