Despite the fact that at present the central position is occupied by independent, independent of external factors, autonomous heating, there is also such a useful device in the form of a Buleryan stove. She is also called Breneran. If you do not go into details, then such furnaces consist of furnaces, to which several bent pipes are connected. Thanks to this design, the process of burning wood and other types of solid fuels becomes more efficient. The cost for such an industrial model starts at two hundred dollars. To a greater extent, it depends on the size and technical characteristics of the firebox. Despite the complexity of the design of the device in comparison, for example, with a conventional potbelly stove, most home craftsmen can easily make a Buleryan stove with their own hands.

The principle of operation of the furnace and its scheme

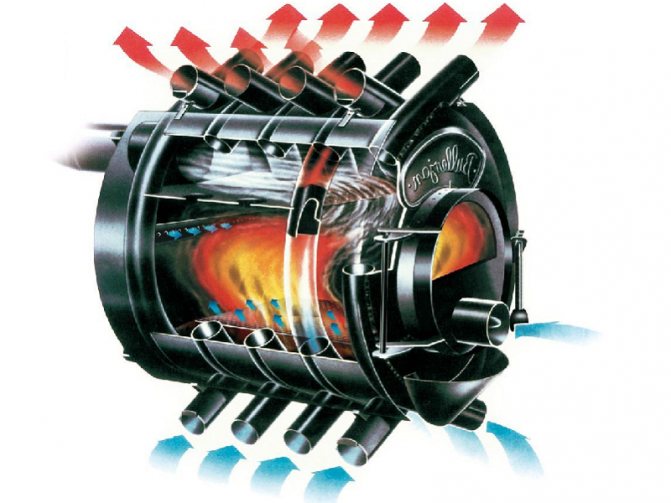

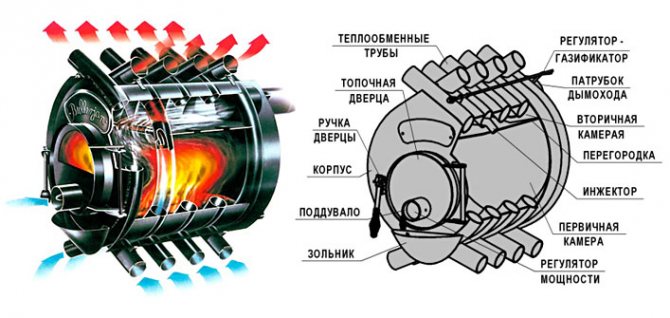

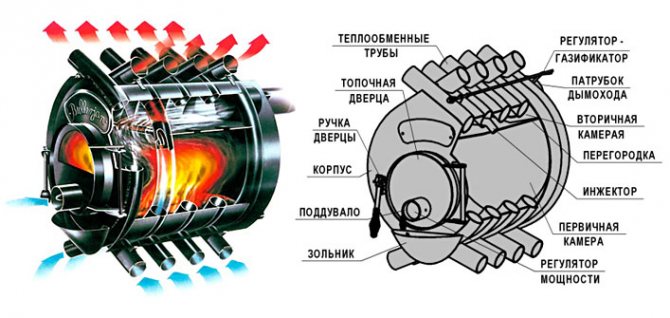

At its core, Buleryan is one of the most practical combinations of a wood-burning stove and a potbelly stove. The principle of operation is based on the physical phenomenon "forced convention".

A hole is provided at the bottom of the structure, into which cold air flow from the room enters. Moving along the pipes that interact directly with the firebox, it quickly heats up and goes outside.

Firewood combustion products are not immediately removed outside, entering another chamber, where they are re-combusted at very high temperatures. Afterburning the air-gas mixture allows you to increase the efficiency up to an immodest 80%.

The high temperature of the convection air at the outlet makes it possible to heat almost any room in terms of volume or a one-story spacious house. Thanks to surface pipes, access to the hot surface of the furnace is limited, which makes its use as safe as possible. Buleryan can be combined with a heating circuit on a liquid heat carrier.

Learn more about the technical characteristics of wood-burning stoves

Outcome

Even though at the present time the central position is occupied by independent, independent of external factors, autonomous heating, there is also a place for such a useful device in the form of a Buleryan oven. She is also called Breneran. If you do not go into details, then such furnaces consist of furnaces, to which several bent pipes are connected. Thanks to this design, the process of burning wood and other types of solid fuels becomes more efficient.

The cost for such an industrial model starts at two hundred dollars. To a greater extent, it depends on the size and technical characteristics of the firebox. Undoubtedly, the manufacture of Buleryan's stove can hardly be called simple, because an ordinary potbelly stove will take much less time and effort. But the ease of use and high efficiency fully justify the energy expended!

Which pipe is suitable for the chimney

Before direct installation work, you should decide from which pipe the chimney will be made

It should be remembered that Buleryan is a long burning stove, therefore it is important for it to select the highest quality elements. Otherwise, in the process of using the structure, you can expect that there will be constant smoke in the house.

If the work is done by hand, then usually the choice is made independently.

The most popular chimney elements are:

Ceramic products that are ideal for this particular type of oven. In appearance, the chimney looks like a sandwich pipe. Ceramics are characterized by excellent resistance to high temperatures or temperature drops.Also, it is this material that reduces the likelihood of condensation on the walls of the structure.

It will be quite simple to install such a pipe with your own hands, but it is important not to damage it during this work. The chimney made of stainless steel is also well suited for buleryan. However, such a design, in any case, needs additional insulation.

During operation, very often the metal is deformed from high temperatures or under the influence of other factors. The installation of such a pipe is considered simple, since it is already initially sold complete with various fittings, tees and other necessary parts. The asbestos pipe is not considered suitable for the selected stove. It initially needs high-quality and full-fledged insulation, however, even such work cannot guarantee that condensation will not form on the inner walls. Its constant presence will negatively affect the service life of the entire stove as a whole. In addition, asbestos is distinguished by an unpleasant and pungent odor, which will be present in the room as well. Brick is considered a good choice for a chimney. It is time-tested and also considered a traditional material for the formation of stoves and fireplaces. However, it is important to remember that the structure made of it will not be mobile, therefore, it will not be possible to transfer it from one place to another in the room.

When choosing a material, it is important to take into account that the work will be done by hand, and you should also take into account the location of the furnace itself, the frequency of its use and other important points.

Design features and principle of operation

When developing the brandaran, Canadian experts used the long-known design of a long-burning convection boiler, called a hot-air furnace. Due to the increase in the furnace door, it became possible to load not only chopped logs, but also parts of rhizomes, as well as large blocks of wood.

The new form of the blower - in the form of a pipe cut into the loading hatch - made it possible to abandon the two-door scheme. To adjust the amount of air required for fuel combustion, a throttle was installed inside the blower - a rotary-type round damper. The throttle control lever brought out to the outside allows, if necessary, to reduce or increase the air flow, thereby controlling the power of the buleryan.

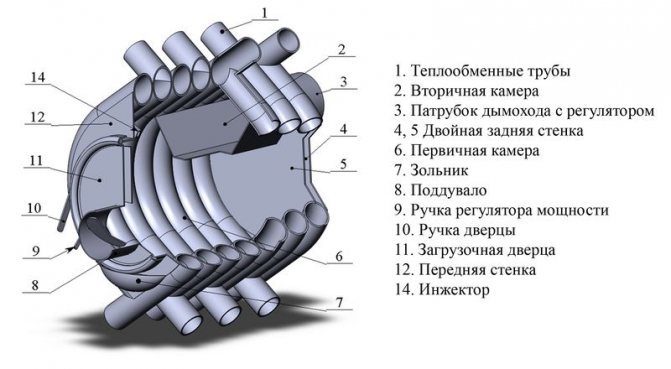

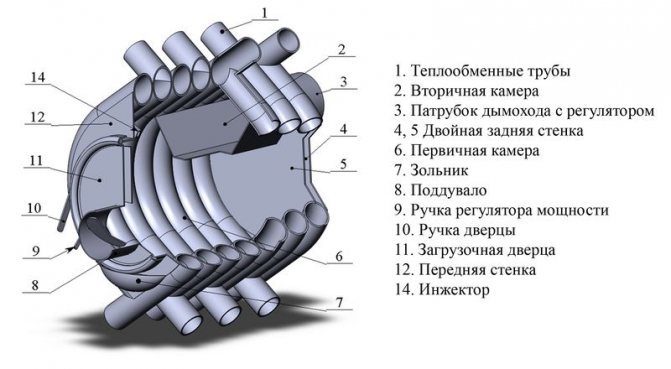

Buleryan design

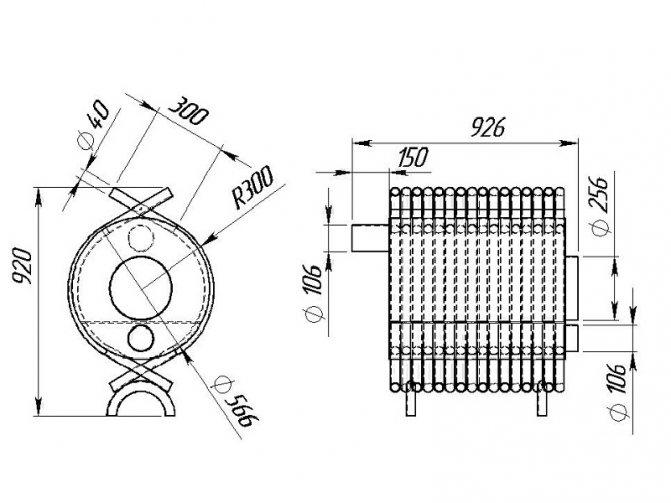

The furnace of the heating unit is a metal cylinder, from both sides of which tubular metal heat exchangers bent in the form of knees are cut through at equal intervals. Due to the fact that two-thirds of the diameter of the pipes are recessed into the body of the stove and are in the combustion zone, the air receives up to 70% of the heat that is released when burning wood.

The remaining kilocalories heat the body of the stove and are subsequently also spent on heating the room. Due to this distribution, the buleryan body usually heats up to only 60–65 ° С, while the air that comes out of the convection channels has a temperature of more than 100 ° С. It must be said that it is precisely the high heating rate that ensures the active suction of cold air masses in the lower part of the tubular heat exchangers and their ejection from the upper openings of the air heater.

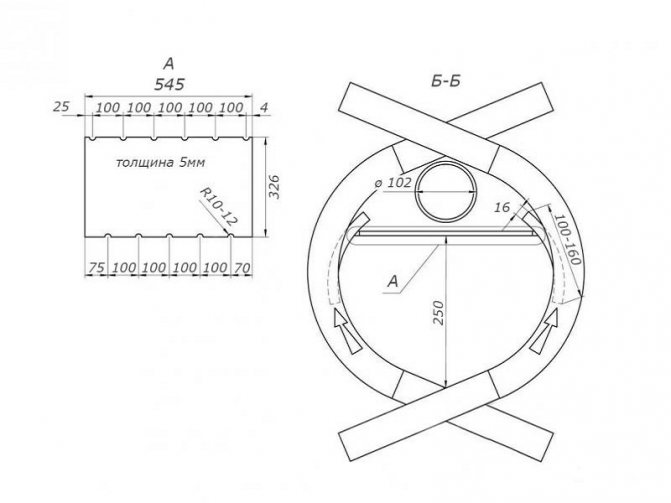

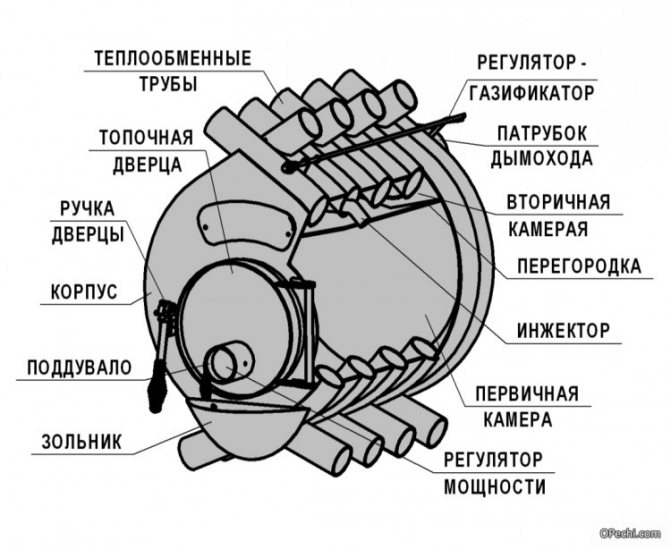

The combustion chamber inside the device is divided into three chambers. In the lower part of the furnace, at a height of up to ¼ of the body diameter, a metal under or a removable grate is installed. You can do without these elements, but with them it will be easier to light the furnace and remove ash. Under the arch of the furnace, at the same distance from the body as under, a perforated metal sheet is welded in, which does not reach the loading hatch for a quarter of the buleryan's length. The upper chamber is designed for the afterburning of volatile compounds that are released during the operation of the unit in the gas generator mode.

Rapid air heating is provided by convection heat exchangers that make up the furnace frame

The combustion products are discharged through an opening located in the afterburner, on the side of the rear wall of the unit. At the beginning of the smoke channel, a damper with a cut-out 90-degree sector is mounted. In addition, there is a gap of at least 10-15% of the chimney diameter around the gate (a metal plate that regulates the chimney draft).

Increased requirements are imposed on the buller chimney

A horizontal section of the chimney departs from the outlet opening, designed to reduce the temperature of the combustion products, and then an elbow is installed, which directs the pipe vertically. Here, at the "real" units manufactured by Bulerjan, a device for pyrolysis combustion of gases, called an economizer, is installed.

The chimney must be high enough to obtain high-quality draft and insulated so as not to allow the combustion products to cool down too much. If this requirement is not met, as well as when using fuels with a high moisture content, the temperature in the afterburner will be reduced, as a result of which the content of tar and other unsafe carbon compounds in the flue gases increases.

Buleryan furnace device

The device of the furnace determines the principle of operation of the Buleryan heater, which is assembled from the following elements:

Buleryan furnace device

- Arc-bent pipes that make up the body. Moreover, inside the body, at the very branch pipe for the removal of combustion products, there is a U-shaped sump that separates the primary combustion chamber from the secondary.

- Two-layer wall that works as an additional convector. In addition, a branch pipe of the chimney is also built into the wall.

- The front wall, into which the door is cut for loading fuel into the combustion chamber, the blower pipe with a throttle valve and the ash pan (container for collecting ash).

Moreover, it does not matter at all whether the Buleryan stove is assembled by hand or manufactured at the factory - the effect of using such a heating device will surpass all expectations. That is why the most economical homeowners strive to make such a stove exclusively with their own hands.

And further in the text we will acquaint you with the process of assembling the stove, and with the stage of installing the heater in the room.

That is why the most economical homeowners strive to make such a stove exclusively with their own hands. And further in the text, we will acquaint you with the process of assembling the stove, and with the stage of installing the heater in the room.

https://youtube.com/watch?v=-HFG5zFEgqM

Design features

Design features

Furnaces of this type are often manufactured in the form of a monolithic structure, which consists of a certain number of interconnected metal tubes. When fuel is burned, convection air flows are formed in the tubes, which lead to rapid heating of the room.

In parallel, cold air is drawn in by the lower ends of the tubes, warmed up in the combustion chamber and sent back to the room. Even the smallest versions of the Buleryan can pump five cubic meters of air for a minute. Obviously, such efficiency is quite enough for a regular garage.

Heating stove Buleryan

Structure

Diagram of Buleryan's device for heating a house

As can be seen from the figure, Buleryan is a structure of several bent pipes (usually more than six) (1), welded in such a way that a combustion chamber (2) and (6) is formed inside. To divide the combustion chamber into two zones, a special partition is welded into the structure. Firewood is first burned in the primary chamber (6), and then burned out in the secondary chamber (2), while ensuring maximum efficiency. Air constantly circulates through the pipes from bottom to top, ensuring optimal heat exchange in the room.Firewood and briquettes are mainly used as fuel for the stove. For laying firewood and extracting ash, there is a door (11) on the front wall of the stove, which, thanks to the seals and the special design of the lock (10), is able to close hermetically. A blower (8) is welded to the door to regulate the air supply to the primary chamber. To supply air to the secondary chamber, there are injectors on the pipes (14). Ash is collected in an ash pan (7). To regulate the combustion process, there are draft regulators (9) on the door and on the exhaust pipe located on the rear wall.

For normal operation of buleryan and less accumulation of soot in the chimney, it must be insulated.

How to properly drown Buleryan

The firebox of this model is practically no different from the firebox of an ordinary stove. In order to melt the stove properly, dry wood is required. It is necessary to lay as much fuel as is required to heat the chimney and form coal. If the furnace is cleaned before kindling, then you should not completely remove old coals and ash. It is necessary to leave such an amount of fuel residues that it covers the metal, thus protecting it from burning out.

After laying firewood, you need to fully open the chimney damper, and the blower, focusing on the dryness of the firewood, windy weather, or based on the required speed. When the first batch of firewood burns out, you can make the main laying of large and dry firewood. After that, the heated chimney will provide ignition and further burning of the wood in the desired mode.

The most economical mode of operation of the furnace when the blower and damper are closed. The combustion process will start to include the effect of afterburning of pyrolysis gases. If the air access is reduced by closing the blower, then the resulting gases due to lack of oxygen will additionally burn in the upper chamber, separated by a partition. Hot air is sucked in through the injectors. With its help, gases will give more energy when the wood smolders slowly.

The colder air from the bottom under the stove is picked up by the draft created by the already heated flow in the convectors and rises up. This process forces air masses to circulate in the room, due to which heating occurs rather quickly. But at the same time, the surface of the furnace itself remains low, which reduces the fire hazard and the possibility of getting burned.

Recommendations for use

- The chimney pipe for your stove should be assembled in the opposite direction to the movement of the exhaust gases, which practically reduces to zero the likelihood of leakage through it during the operation of wood resins. In this case, the latter will return to the chimney and burn out in it.

- Observe the fire safety requirements when arranging the installation site of the stove and the surrounding space.

- Be sure to provide for the possibility of simplified installation / dismantling of the chimney for regular cleaning from tar and soot deposited on the walls.

- The "Buleryan" stove must be configured according to your preferences.

- Remember to periodically inspect the top of the chimney to remove any resin build-up that appears.

- Empirically, the optimal furnace mode is selected, which is characterized by the maximum burning time and the minimum degree of flue gas pipe clogging. To operate the unit in the specified mode, the channel should be cleaned at least twice a season.

- Before placing the wood in the firebox, it is advisable to pre-dry it over the stove.

- In addition to logs, in order to save money, it is recommended to add briquettes made of sawdust and wood chips to the firebox.

disadvantages

From the foregoing, we can conclude that such a heating unit has no drawbacks. But do not rush to think so. There are important nuances to consider:

- Any fossil fuel, when burned, releases reaction water. It is analogous to metabolic water, which is formed in living organisms.Due to the low temperature in the furnace, there is more reaction water in the exhaust than other analogs of slow combustion furnaces.

- It is necessary to mention the mineral components of wood. There is ash in the wood initially, although the manufacturer points out the fact that there is no ash in the combustion of wood. So, the ash comes out through the chimney.

- And the last point is the presence of hydrocarbon radicals. What is it? These are very active chemical residues that do not completely decompose. As a result, the efficiency decreases to 7%. Exhaust accounts for the same share. For the household use of Buleryans, this indicator is catastrophic.

So, it's up to you to decide whether to do buleryan or not. We could not take into account all the nuances that every DIY master may encounter. We hope this article will guide you on the right track and help you make an informed decision. If you have already made a buleryan oven, then leave comments on this article. Your experience is invaluable, because practice is always stronger than theory.

Maybe,

The main positive design parameters

https://youtube.com/watch?v=zKA7kgImfnY

This wood-burning stove has many advantages:

- the installation of equipment is considered simple and quick, so you can even implement all stages with your own hands, which significantly reduces the cost of this process;

- the heat transfer rate is very high, therefore Buleryan is an effective and reliable equipment;

- during the operation of the structure, oxygen is not burned in the premises;

- the chimney is created from sections of the pipe that must be suitable for this issue, and the connections between them must be tight and strong;

- this stove can be used not only in a country house or in a bathhouse, but even in a private house, replacing full-fledged heating with various systems connected to central communication highways.

The disadvantages include the need for the constant presence of a person who must maintain combustion with fuel

Also, although the furnace is created quite simply, it is important to know what elements it consists of, while it is important to choose them correctly and correctly so that they perfectly cope with the tasks set, and also serve for a very long time, in accordance with the tasks set. Particularly much attention must be paid to the chimney, since if it is selected and installed incorrectly, it can be expected that gases from combustion will penetrate into the living quarters.

Step-by-step technology for making buleryan

- Before moving on to the product itself, it is necessary to prepare all the materials, if any, you can start. It is better to take 2 metal sheets, one of them can be useful for the convenience of welding. The number of pipes directly depends from the area of the heated room. We put the pipes oppositely one on top of the other, while welding them in turn, there should be a space in the middle. In order to make it convenient to weld, we put wooden supports.

- At the second stage, we make a stand (frame). This requires a serious approach, since it is she who will keep the weight of the entire structure on you... Do not change the first and second steps in places, as you may end up with a mismatch and all the work will go down the drain. The size of the supports will be selected precisely and it will be possible to visually see where it is better to make the connection with the main part. You can choose any material for the stand, the main condition is that it is not subject to ignition. Materials such as tiles, brick, stone or a simple sheet of metal are allowed. In order for the selection of air to be carried out more thoroughly, the base needs to be slightly raised, by about 300 mm. If this distance is not enough for convenient operation, increase it to waist level.

- It's time to fit and cut the metal sheet. The sheet must be cut into pieces such that they completely and tightly cover the space between the pipes. It should turn out strictly solid body, otherwise the efficiency will drop sharply, and the heating efficiency will decrease, the stove will not heat the room.

- In the fourth stage, we will add designs rigidity and stability, and also we will divide Buleryan into 2 zones, one of which will be responsible for the combustion of fuel, and the second for the afterburning of gases. To do this, we weld the rear end to the oven and the spacer. For even greater convenience in use, you can now make a fuel stand according to a convenient scheme for you.

- Further it is necessary weld the wall with a ready-made door. It is quite difficult to make a wall with a door yourself; you need to buy a ready-made one and cut it to the desired size, and then weld it.

- After the last end is welded, be sure to check everything for tightness. Each seam must be strong and in no case let air pass through, since the pressure during the fire will rise pretty high... To check the seams, you can use an ordinary lamp, run it over all the places where the welding was going on.

- At the last stages, we have a finished case and a stand, they need to be welded into one piece. It is necessary to install all the details in the place where the buleryan will always stand, carry out the installation with maximum accuracy. Be prepared for the fact that after heating, the metal expands slightly.

- It remains to add the gates and the chimney. Choose a fireproof material for the chimney. The height of the chimney must be 600 mm higher than the top of the roof. If metal is selected, ensure that it is the thickness was at least 0.75 mm.

Buleryan is ready. If thermal insulation is carried out next to the furnace, the material must be non-combustible.

For heating a garage or a small summer cottage, a long-burning sawdust oven is suitable. Manufacturing details are presented in this article:

Getting Started

So, the theoretical part is over, so you can already start manufacturing the heating device.

Take 8 equal pieces of metal pipe and bend them in the middle with a pipe bender, making an angle of about 80 degrees. To create a medium-sized furnace, pipes with a length of 1-1.5 m will be enough.

The prepared pipes are welded together into a single structure.

This structure will also serve as a frame. Therefore, metal sheets are welded to the pipes, which will become the furnace body. The metal plate will become a tray for the firebox and firewood will burn on it. To make it easier to care for the stove, you can weld a pallet of two plates at an angle.

Buleryan furnace tubes

The next stage is the preparation of the front and rear walls of the buleryan. First you need to make a pattern from thick cardboard, based on the resulting parameters of the stove. According to this template, walls are cut from a metal sheet. In the front part, you need to make a hole for the door. Its diameter is usually equal to the diameter of the oven divided by two. It is better to shift the center of the window slightly below the buleryan axis. Around the perimeter of the window from the outside, a ring should be welded from a narrow metal strip.

Pipes in the buleryan oven

The back wall is done in the same way, only the hole in it will correspond to the diameter of the branch pipe and be located in the upper part.

We turn to the manufacture of doors for the oven. It is made from the same metal cut to fit the diameter of the front hole. To improve the tightness, it is advisable to weld a narrow metal strip onto this workpiece along the entire perimeter. Also, it is imperative to make a hole in the door and weld a blower with a valve to it.

The stage of creating a Buleryan oven with your own hands

To ensure safety of use, a semicircle made of metal sheet must be welded to the inner surface of the door, which serves as a heat-reflecting screen.

The hinges are welded to the outer wall and you can already fix the door.

A chimney from a T-shaped pipe with a diameter of 110 mm is mounted to the hole on the rear wall. A cutout must be made in the pipe for connecting a branch with a valve.

Buleryan stoves serial versions

You can also DIY this valve. A metal circle must be cut out along the inner diameter of the bend, and a hole must be drilled in the bend itself so that the valve axis is inserted horizontally. All these parts are assembled and welded. A piece of a rod is fixed outside, which will serve as a handle. You can put a wooden block on it for convenience.

Now we make legs from pieces of pipes and the oven can be tested.

Ready-made Buleryan oven made by yourself

In making buleryan with your own hands, as well as in another responsible business, you just need to adhere to the technology and the created product will certainly delight you with excellent work.

Buleryan oven review

Preparation for manufacturing

Buleryan stove can be made by yourself. Although this is far from the easiest task, this option is much cheaper than purchasing in stores. Prices for such a product are extremely high, so it is better to negotiate with a familiar welder and do everything yourself.

Advice! The novice welder is better off not trying himself in this business. The seams in the furnace are constantly exposed to high temperatures, therefore, a mistake in operation can lead to the destruction of the structure after several furnaces.

The following materials are needed for manufacturing:

- Metal scissors;

- Bulgarian;

- Welding machine;

- Pipe bending tool.

As materials, pipes, a metal sheet and a corner will be needed. The sheet thickness must exceed 0.75 millimeters. The body will be formed from pipes and sheet, depending on the previously selected design.