Insulation for the budget conscious. You can prepare your house for winter at no extra cost.

What improvised means can be used to turn a summer house into a winter house if the wallet does not allow you to purchase special modern heaters?

Hay, straw, reed, moss, sawdust or shavings are time-tested natural insulation materials.

Earth, turf and peat are natural insulation materials,

In many Russian villages, until the middle of the 20th century, huts were still insulated with the help of earthen, sandy or peat mounds.

They were arranged with the help of a wattle fence or a plank, creating a box around the house, into which the earth was poured or peat or turf was laid in layers.

Since ancient times, sod has also been used for roof insulation: it was laid in several layers on a multilayer birch bark substrate.

In villages, soil was often filled over the ceilings for warmth, and the houses themselves were buried. The warmth of the earth can raise the air temperature in the house by 1-2 degrees Celsius.

How it's done.

There are several options: the house can be deepened into a natural or artificial hill, you can create a multi-layer wall with cavities for filling earth or dried peat, you can erect the wall itself from bags of earth or overlay an existing one with bags of soil.

The main condition for the device of such insulation: all building structures that can rot on contact with the ground must be insulated from it with a moisture-proof layer (plastic wrap, bitumen roll material, or even birch bark plates).

Let's say you decide to insulate a small house 3 × 4 m in size and 3 m in height with bags of soil. With a bag width of 40 cm, only one wall will need about 4.8 m 3 of soil weighing 13 tons.

Good insulation slabs can be made from empty juice or milk bags.

How it's done. The bags must be washed, dried, sealed or sealed hermetically, stacked in plates and sealed in plastic wrap.

To cover one wall of 12 m 2, at least 770 liter bags are needed.

Many are attracted by the idea use corrugated cardboard from boxes for insulation.

How it's done. Dry boxes can be disassembled, folded into multi-layer boards, wrapped in plastic wrap and sealed. When installed in walls, all seams between such improvised slabs must be carefully taped or covered with plastic wrap.

To cover a wall with an area of 12 m2 with one layer of corrugated cardboard, you will need at least 12 cardboard boxes measuring 30 × 40 × 50 cm.To provide standard thermal insulation, one layer is not enough, you need a panel with a thickness of 360 mm, that is, at least 480 boxes.

Hay, straw, reed, moss, sawdust or shavings are another category of time-tested natural insulation. Moss was used to insulate (and continue to this day) inter-crown seams in wooden log cabins.

Roofs of houses were made of reed and straw, and their thickness could reach 1.5–2 m (near the ridge). Hay in the villages was covered with hay on the floor and ceiling in winter, and thick wicker mats made of straw were hung on the windows outside. The first post-war panel houses were insulated with shavings.

How it's done. Chopped straw, reed, shavings and sawdust can be used as backfill in wall panel structures. Organic material can be mixed with clay, cement, gypsum or lime.

To prevent ignition, sawdust and shavings are mixed with clay, cement, gypsum, lime (10 parts of sawdust for 1 part of the binder and 1 part of lime). Boric acid can be added to the mixture as an antiseptic.

Wall backfill made of organic materials is compacted layer by layer to eliminate the presence of voids in the insulated wall. Outside the house, the panel should be covered with a windscreen, and from the inside with a vapor barrier.

To insulate a wall with an area of 12 m 2 with a 20 cm thick panel, we need more than 2 m 3 of sawdust, 20 buckets of clay and 20 buckets of lime.

As a rule, the use of scrap materials as insulation requires either colossal labor costs, or extensive utility rooms for storing and processing materials, and most often both together.

When insulating your country house, it is very important not to harm the health of your family and friends.

A bit of physics

Before delving into the technological aspects of using the product, let's look at its physical and technical characteristics. And they are not very encouraging. So, the density of solidified clay is 1600-2400 kg / m3 (slightly less than that of concrete), and the thermal conductivity is 0.7-0.9 W / m ° C.

It turns out that clay as a wall insulation is, to put it mildly, useless, so why is it still used today?

The fact is that this material is an excellent binder, the strength of which is in no way affected by sucrose found in organic fillers (for concrete it is destructive), and this, in turn, opens up the widest scope for maneuver.

Waterproofing works

Ceiling waterproofing

The clay mixture is laid wet on the flooring. Therefore, you need to somehow protect the base from dampness. Usually a simple film is used for this. It is laid over the floor and attached to it with staples or in some other way. The same film will protect the insulation from fumes from the room, for example, if clay is used in a bath.

It is not recommended to use various impregnations and chemicals. Moreover, varnish or paint. Especially in a bathhouse or in a room with a stove. When heated, chemicals begin to emit harmful vapors, and varnish and paint can melt, "cry" and also evaporate toxic substances.

Clay with sawdust as insulation

One of the most popular options is clay with sawdust for ceiling insulation. Wood shavings, especially in their loose state, retain heat well, and they can be collected in any carpentry shop for a nominal fee.

There is only one drawback: over time, the loose mass sags, while losing some of its thermal insulation properties.

But if it is mixed with gypsum or liquid clay, the "fluffy" structure will remain for a long time, which means that the use of such technology is not devoid of sense.

Straw wall insulation technology

Insulation of a multilayer wall with straw consists in the alternate installation of thermal insulation layers made of clay, as well as straw sawdust. In order to ensure the long-term operation of the insulation, you first need to prepare the walls.

Preparatory work before fastening the straw

Before starting the insulation process, it is imperative to prepare the surface of the outer wall. At this stage, we must conduct a thorough inspection for cracks, irregularities or deep seams. The surface is carefully cleaned from traces of old coating, finishing materials and dirt. Large indentations are manually sealed with filler mortar.

For filling, you can use conventional gypsum mixtures, which are inexpensive and do not shrink much. In stores you can find ready-made putties that do not have to be diluted with water and kneaded. But they are more expensive than dry ones and have a much shorter shelf life. Puttying is carried out either in 2 layers, or they use a masking net for this, on which the solution fits perfectly.

If there are protruding parts or dry plaster residues on the surface, they can be knocked down with a hammer and chisel.After that, the wall should dry well, otherwise moisture will destroy the insulated insulation.

If there are areas of accumulation of moss and mold, then after removal, they must be additionally treated with bioprotective drugs. Otherwise, residues of substances can grow through the insulation.

Now you can proceed to priming the surface, which will provide good adhesion properties. The primer is applied either with a roller or with a paint spray. To calculate the volume of the required substance, you can use the instructions indicated by the manufacturer.

Before you start applying the primer paint, be sure to protect all areas that should not be painted: doorways, windows, steps, blind area and plinth. For this, ordinary plastic wrap is quite suitable.

For thermal insulation, we need the following tools: a regular pencil, a ruler, a hammer, a plumb line, a jigsaw, a level, a screwdriver, containers for putty and paint, paint brushes and rollers, sandpaper of varying grain size, a fine sieve, a collapsible ladder, dry rags, a chisel, spatulas, usually.

It is necessary to prepare the following from materials and consumable components: sand, cement, briquetted straw, dry clay, siding panels for finishing, ground paint, putty, screws or nails, bioprotective and antiseptic solutions.

Straw Wall Mounting Instructions

The step-by-step algorithm will be expressed in the following actions:

- First, a vapor barrier is arranged on the walls. A plastic film is taken as a basis, which will protect our insulation from getting wet and condensation accumulation. Pieces of the film are cut in accordance with the size of each cell from the installed crate.

- The working mixture is kneaded from clay and straw in a ratio of 2: 3. To do this, it is convenient to use a metal trough, a boil or a large basin. Water must be added until the consistency resembles sour cream.

- The finished mass is laid out on boards already covered with a vapor barrier material. The layer is made 2-3 cm, after which it should dry completely.

- If we find cracks after complete drying, then they need to be repaired with the remnants of liquid clay.

- When the clay insulation finally hardens, it becomes covered with dry sawdust, straw, shavings. A layer of 5 cm is enough.

- If dry compressed straw is stacked, then this should not be done in a chaotic manner. Experienced installers calculate in a special way the optimal angle at which the fibers are located, which will reduce heat loss to a minimum.

- It is advisable to build a wooden flooring on top of the insulation. A board made of any well-dried wood is suitable for him. It is stuffed onto the mounted lathing so as to completely cover the frame.

Recipe

If you are interested in clay with sawdust as a heater, the proportions are simple. For three buckets of clay, two buckets of wooden shavings are taken, all this is mixed and the space between the logs is filled with the resulting mass.

With such insulation, you can easily not only walk, but also dance, but you cannot call it too effective. Of course, the proportion of wood material can always be increased, but then the insulation will lose its strength, which means that some kind of floor will have to be invented on top of it.

Ordinary home insulation

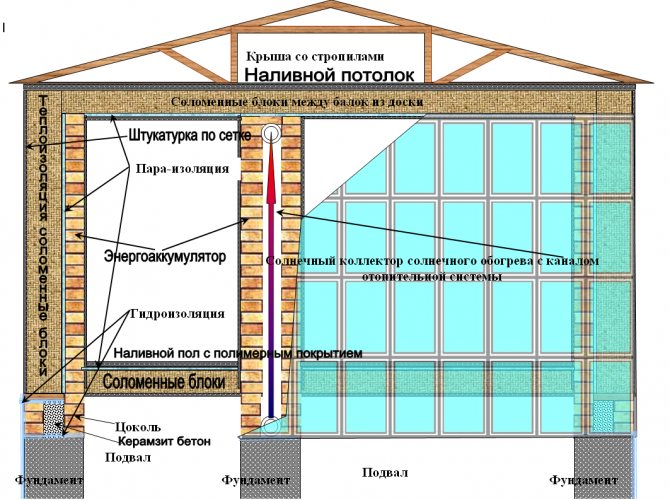

Diagram of a thatched house.

Internal and external insulation of the house can be carried out with warm plaster, magnesium oxide and expanded clay sand, perlite sand and so on. Each of these methods has its own disadvantages and advantages, for example, internal warm plaster of 3 cm and external 3 cm will replace 30 cm of brick wall thickness, but external waterproofing is needed.

It is necessary and correct to select insulation materials, they cannot be the same for brick walls and wooden ones.The materials must have the correct parameters for thermal expansion, para-permeability, resistance to temperature changes and durability. In addition, you cannot do without hydro and vapor barrier, since without this, all work on house insulation will be ineffective.

Also, we must not forget about the insulation of the floor and roof, since through them the heat leaves the house. And only careful installation of the roof and floors without cold bridges, using high-quality and not very cheap heat-insulating and waterproofing materials, will help make the house cozy and warm. Warmth and comfort can be much cheaper if the house is insulated with straw.

Saman as insulation

Another interesting use for clay is adobe. Previously, it served as the main structural material for the construction of walls, but today it is used only as insulation.

Here the filler is no longer sawdust, but straw. Once again, an environmentally friendly product with excellent thermal insulation properties, and again the purchase of which will not ruin your budget.

To acquire adobe, you only need to have a wooden shape and a desire to work. Kneading (and kneading clay with straw with feet) is usually done right next to the clay quarry, there the forms are filled with the resulting mass, and the blocks are dried there.

The whole process is quite time consuming, but if this item does not bother you, you can get a material with a thermal conductivity of 0.1 W / m ° C, and this is already a pretty good indicator.

Advantages and disadvantages of wall insulation with straw

Let's highlight the following strengths from the use of straw as insulation:

- Despite its apparent fragility, straw is more durable and stronger than wood due to its increased silica content.

- As a porous material, it has high sound insulation characteristics.

- It has a low thermal conductivity and a high coefficient of heat transfer resistance.

- Resistant to biodegradation.

- Economical due to its low cost.

- The undoubted plus of the rammed blocks lies in the practicality of their use: in case of significant damage, a fragment of the block is simply cut out and replaced with a new piece.

- With a moisture content of not more than 20%, it is not subject to decay processes.

- The material has the ability to "breathe", which means that it can not only absorb moisture and harmful substances, but also return them back.

- Unlike a number of other heat-insulating materials, straw does not lower, but, on the contrary, increases a person's energy by 10%.

- The material that has worked out its operational resource is easily disposed of by burning or using it as fertilizer for the garden.

- Straw blocks can be easily and quickly cut with a chainsaw.

- Straw easily maintains favorable indoor climatic conditions.

- Insulated buildings significantly reduce energy consumption, which, as practice shows, does not exceed 38-40 kWh per square meter per year.

- The low weight of this material greatly facilitates installation work.

Consider the possible negative qualities from the use of this insulation. It is believed that straw itself is a highly flammable and combustible material. However, this does not apply to bales that are covered with plaster according to building standards. They are able to withstand up to 2 hours in open confrontation with fire.

The criterion of the durability of this insulation also depends on a number of subjective factors. For example, was the straw removed from the field correctly, where and how it was stored, how well it was packed and processed. Failure to comply with any of the requirements will lead to a deterioration in thermal insulation properties.

Rodents can start in the straw because it creates favorable climatic conditions. But this only happens if it was not sufficiently compressed and not treated with plaster or slaked lime.

Note! When working with such insulation as straw, a large amount of waste is necessarily generated. They must be cleaned up in a timely manner, do not smoke nearby, and also have a portable fire extinguisher on hand.