The need for roof insulation

Hardly anyone will insulate the attic roof. The cold attic in private houses of old traditional construction serves as a storage place for items that have served their time.

A person who, with the help of an attic, is going to significantly increase the volume of a residential location, can build a difficult insulated roofing unit. That is, he creates additional living space under the roof of his house.

Its device will require a different technological content. The traditional roof unit has been thoroughly modernized, introduced into its structure new elements necessary for the construction and long-term functioning of the insulation layer.

The modern attic usually serves as the main sleeping area for family members. The room is equipped with all types of plumbing and sewerage systems:

- showers;

- toilets;

- natural and forced air ventilation;

- electricity.

All this requires a certain positive temperature for its normal functioning.

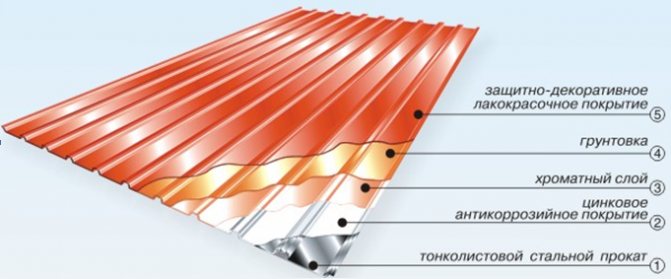

An insulated roof covered with corrugated board, metal tiles, painted reeds and other roofing materials can create a favorable operating mode.

Warming. Requirements for thermal insulation materials

So, if the roof is meant to be warm, then from the inside the insulation will be located under the layers of interior decoration (wood panels, drywall) and vapor barrier.

Laying can be done in two ways:

- filling the space between the rafters with material is cheaper, but the insulation will be incomplete, there will be "cold bridges";

- in addition to the first option, put a second continuous layer - a more expensive, but much more reliable and comfortable method for living.

It is desirable that the work on the arrangement of thermal insulation is carried out before laying the roofing, this avoids mistakes, but in reality this does not always happen. Weather conditions, lack of necessary materials - for these and many other reasons, the roof has to be insulated from the inside.

Preventing heat loss through the roof is a demanding task, which not any thermal insulation can cope with. The material must have the following properties:

- Low coefficient of heat conductivity. Insulation must effectively retain heat inside the house with a minimum layer thickness;

- Resistance to temperature extremes. Insulation structures must withstand up to 25 freeze and thaw cycles without reducing resistance to heat transfer;

- Relatively low density. There is no need to make the roof heavier, and therefore to increase the load on the load-bearing walls. Therefore, it is better not to use insulation with a density higher than 250 kg / m3;

- Safety in the event of a fire. The insulation should not ignite, support combustion or release toxic substances during combustion;

- Water vapor permeability. Provides air outlet through the ventilation layer of the roofing cake;

- Environmental friendliness;

- Biostability. Lack of a tendency to decay and the appearance of mold, as well as "unattractiveness" for rodents and insects;

- Durability. The service life of the insulation should correspond to the service life of the coating.

This list is general for any topcoat. For corrugated board, the presence of sound-absorbing properties of the insulation will also be relevant.

Based on these requirements, the use of basalt wool and ecowool will be optimal for the insulating layer of the roofing cake under the corrugated board.

If it is planned to insulate the roof with ecowool, then the help of qualified specialists may be needed for installation. Independently, without experience and specialized equipment, it is unlikely that it will be possible to blow the roof with ecowool quickly and efficiently.

With a limited building budget, it makes sense to pay attention to cheaper "wadded" heaters.

What heat-insulating materials are needed to insulate a roof from corrugated board

Private housing construction has received an exclusive direction for the manufacture of insulated mansard roofs. From the various methods of constructing a warm roof covering, the best option has been singled out, which has become the dominant element today.

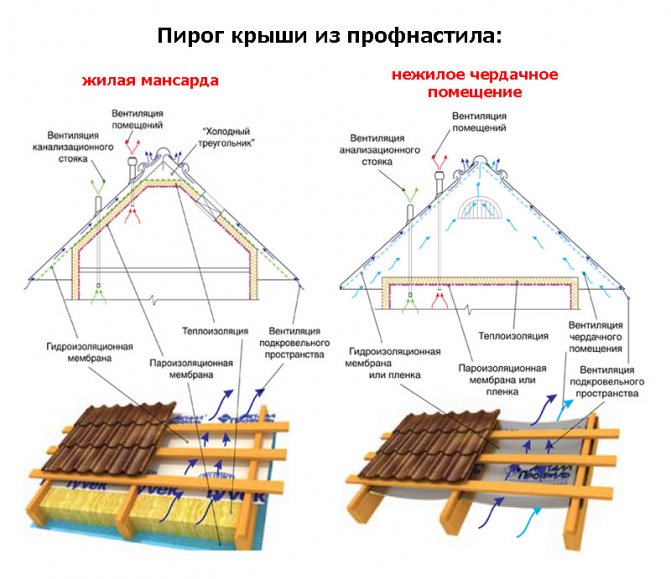

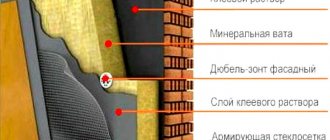

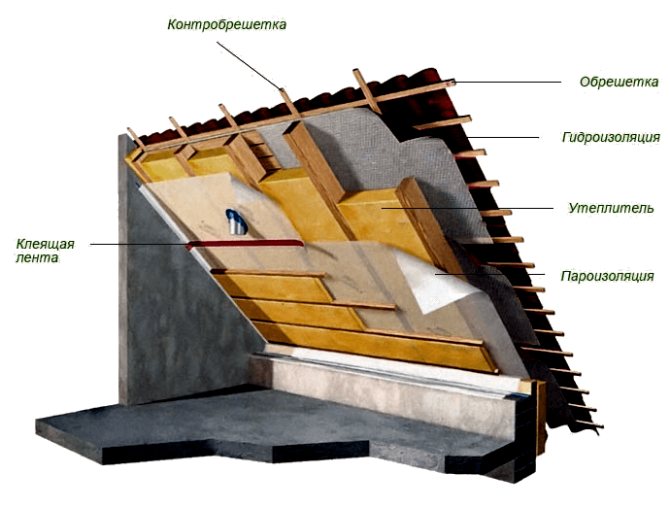

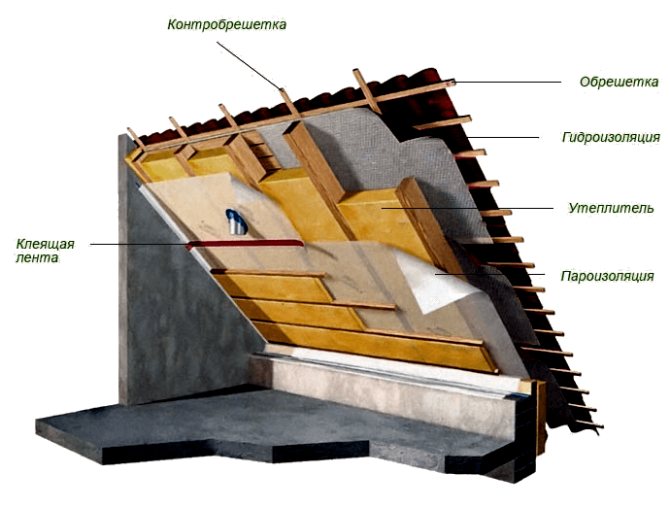

Integrated into the warm layer:

- lining or dry plaster;

- a thin layer of vapor barrier is placed on the inner finishing material;

- the inter-rafter space is filled with insulation;

- then they are totally covered with a hydro-barrier (roofing material, a special synthetic film);

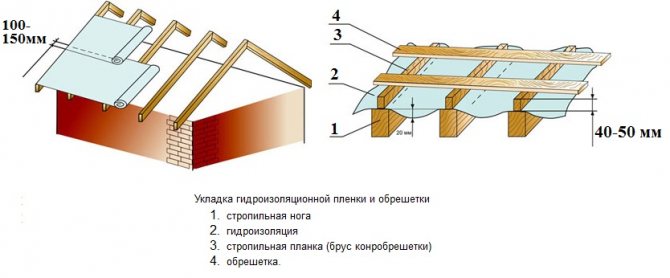

- they are sewn on top with a crate with a step of 1-4 cm. To organize the ventilation space, a counter-lattice is installed with a step of 40-50 centimeters.

Roof insulation

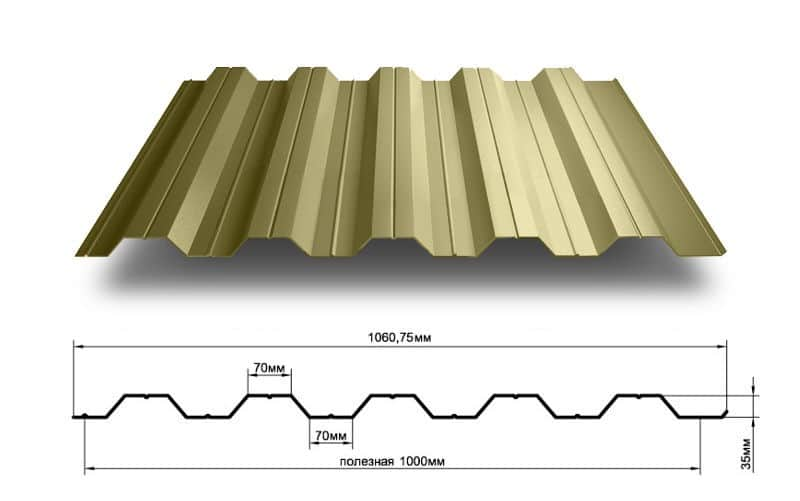

Profiled sheeting is attached to the crate. With a step of 35 centimeters, there is a guarantee that the wind will not "lift" the profiled sheets.

Important

- Use environmentally friendly heat-insulating materials.

- With a low coefficient of thermal conductivity.

- No unpleasant odors

What to cook before starting work

Insulation laying works

Classics of the genre - marking the profiled sheet with twine and chalk

Electric shears - for high productivity

An option that does not require insulation: the profiled sheet serves as a wall

In the case when the building does not require insulation, profiled sheet acts as a wallprotecting the interior from wind and precipitation. In this case, the profiled sheet is attached to the frame wall girders with self-drilling bolts with a sealing gasket. Fastening corrugated board to the wall it is made through one wave into the lower deflection, the joints of the profiled sheets are fastened with rivets with a step of 300 mm.

Basic requirements for materials when installing a warm roof from corrugated board

When insulating the roof, materials with the following characteristics should be used that have acceptable performance:

- thermal conductivity;

- by hygroscopicity;

- for vapor permeability;

- by elasticity;

- compressive strength;

- by elasticity.

A warm roof device needs high-quality materials. It refers to

- vapor barrier

- hydrobarrier

- insulation

- corrugated board.

A warm roof includes auxiliary materials: for steam removal, waterproofing devices.

Today, in construction trade enterprises, the developer will be offered a wide range of goods, both domestic and imported. Usually these are polyethylene films with the required performance characteristics. Inexpensive but functional.

Steam-hydro-windproof materials

Many people still use roofing material as a hydrobarrier. Cardboard impregnated with bitumen cannot be a suitable location for harmful bacteria, fungal colonies that can turn wooden units and elements of the roofing system into dust.

As for the insulation, they use all kinds of materials of organic and chemical origin:

- mineral wool

- stone wool

- bulk materials to be packed

- penoplex

- Styrofoam

- others

Heat insulating materials

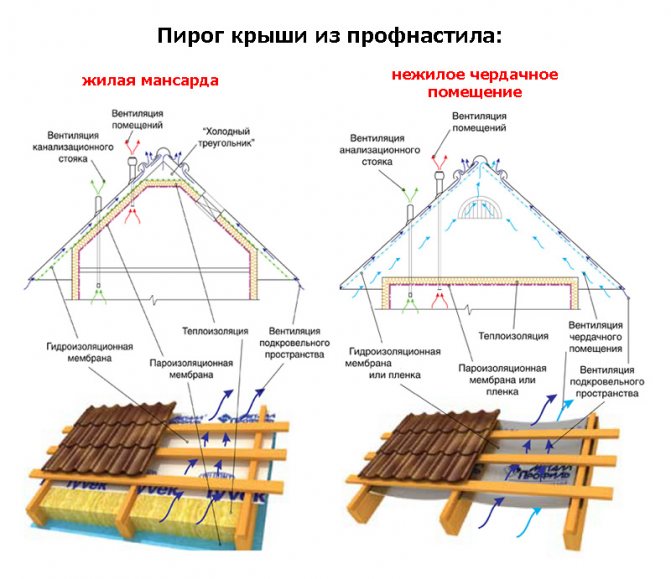

The procedure for laying a pie for a roof made of corrugated board

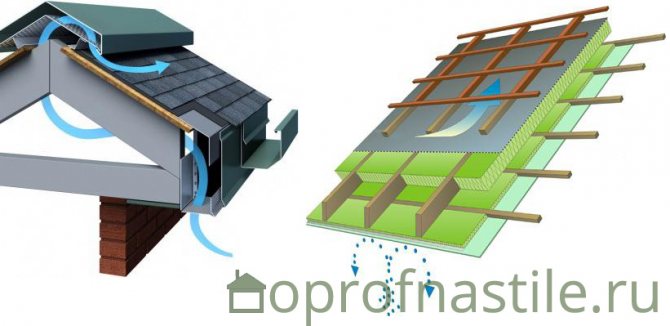

It was found that the average heat loss through the roof is about 20%. Therefore, they install a roof made of corrugated board with insulation.The creation of a roofing cake, which includes layers for insulation of heat and water, as well as a ventilation gap, helps to prevent not only the risk of heat loss, but also the processes of decay and the formation of moisture. In addition, the roofing cake protects the building from the summer heat, the sounds of precipitation and gusts of wind.

The number of layers of insulation is proportional to the purpose of the roof space, i.e. will it be residential or not. If there is an attic in the project, the thickness of the thermal insulation layer should be increased and work should be carried out to isolate moisture. This is due to the fact that when wet, the insulation loses twice its characteristics. As a result, the entire roofing cake freezes, characterized by the formation of ice and damage to the finish. Mold will form directly under the roof, causing rotting of the tree.

Proper maintenance of the insulation is necessary if the installation of the roof material was made with errors. It is also necessary if high evaporation occurs in living rooms.

Decking with insulation on pitched roofs

Private housing is rarely flat roofs. Most of the objects are with pitched types. And here it is necessary to strictly observe the measure.

A pitched roof with an optimal slope of 20% will be effective.

From below, fixed on the counter-lattice of the corrugated board, there is waterproofing, in the falling direction - insulation, then vapor barrier and internal finishing lining.

The entire layer is necessary not only for retaining heat in the attic. It dampens street noise.

If it were not for this layer, then it would be impossible to sit in the attic during a summer shower.

The choice of thermal insulation is a crucial moment

Let's consider in more detail the technical characteristics of some heat-insulating materials, we will try to find out their advantages and disadvantages.

Basalt wool

When selecting insulation for corrugated roofing, mineral basalt wool is preferred, based on fire safety. The advantages are the absolute harmlessness of the material and excellent heat-insulating properties - mineral wool fibers with a thickness of 2-10 microns form air-filled cells that do not allow cold to pass through.

The thermal conductivity of the material is measured at 0.041 - 0.043 W / mK. Due to its low weight, the installation of the insulation is not difficult. In addition to reliable heat retention, basalt fiber wool is an effective sound insulator.

basalt wool has so many advantages that it is rightfully considered one of the best modern insulation materials:

Installation of basalt wool as a heater requires the arrangement of good steam and waterproofing, since the material is hygroscopic and, being saturated with moisture, loses its heat-insulating characteristics.

Among the advantages of mineral wool are high strength and resistance to a wide range of temperatures (up to 700 ° C). The insulation is durable, does not shrink and can last over 50 years. Differs in high cost.

Glass wool

The basis for the manufacture of this fiber insulation, which has a thermal conductivity of 0.030 - 0.052 W / m · K, is glass production waste. The large thickness of the fibers (3-15 microns) compared to mineral wool provides increased elasticity.

Due to hygroscopicity, glass wool shrinks over time, as the fibers become more brittle and transform into a crystalline structure. The material is resistant to temperatures up to 450 ° C.

Working with a heat insulator requires special care, compliance with safety rules and the mandatory use of special protective equipment for the whole body, eyes, breathing - the smallest particles of glass can get into the eyes, lungs, and skin, causing significant discomfort.

Glass wool retains heat well, being at the same time a more affordable material for insulation than mineral wool based on basalt fibers. The service life is limited to 10-15 years.

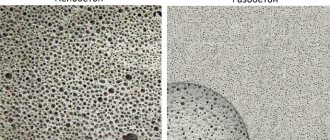

Polyurethane foam

Good insulating properties of polyurethane foam (PUF) are provided due to the special structure in the form of cells filled with a gaseous substance. The thermal conductivity of the material in solid form is 0.019 - 0.035 W / m · K.

PUF weakly absorbs moisture, is not subject to destruction by vapors of caustic chemical compounds, acids, resistant to alcohols, oils, gasoline. By applying sprayed polyurethane foam to the metal, you can not only minimize heat loss, but also protect the surface from rusting.

PU foam is a flame retardant material. Depending on the manufacturing technology, the density varies in the range of 30 - 80 kg / m³, for each task you can choose a material with an optimal ratio of characteristics and cost.

PU foam is lightweight, adheres perfectly to any surface, does not require additional fasteners. One-piece thermal insulation without joints and seams tightly fits the structure, however, it is necessary to perform protection from ultraviolet radiation. The service life guaranteed by manufacturers is 20-30 years.

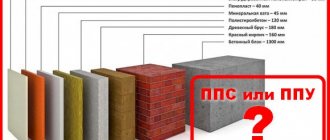

Expanded polystyrene

It is not afraid of water, perfectly retains heat due to its low thermal conductivity (0.037 - 0.043 W / mK), and has high strength. It is not a suitable medium for the development of dampness and fungi, does not rot.

According to the degree of combustion support, polystyrene foam plates are self-extinguishing. The cellular structure makes the lightweight material suitable for noise and sound insulation.

The cost of insulation with extruded polystyrene foam is less significant compared to the choice in favor of basalt wool. Correct installation ensures the preservation of working thermophysical and mechanical properties for 40 years.

Roofing device. Roofing cake

Reference! It has been calculated by builders and heating engineers that 20 percent of the heat from the house goes through the roof.

It turns out that people use valuable fuel, especially natural gas, to heat the air basin. Helping industry create a greenhouse effect. The heat is escaped through the objects that have attics. They are not insulated, they are used ineffectively.

People began to think and today it is clear that an active offensive is underway on the irrational waste of home heat. With success. A significant amount of thermal energy can be conserved in attic houses. It is due to the roofing cake made of various materials. To confirm these words, consider what it consists of:

- A roofing cake is formed from several dissimilar materials with different technological characteristics.

- The most important layer is corrugated board, which creates conditions for the formation of the best performance characteristics of the roofing cake. It does not allow it to get wet during rain, snow, melt water and so on.

- To help him is a hydro-barrier - a kind of gasket between a warm cake and metal profile sheets.

- Further, the insulation is located in the roofing system. Its task is not to let thermal energy into the atmosphere and not to allow cold air to penetrate into the attic.

- The last layers, vapor barrier, regulate the removal of vapors from the attic room. Even lower is the finishing material, which creates a creative interior in the attic.

We are convinced that each element of the roofing cake performs its own profile function. And the more rationally the layers are selected, the better the roofing cake will work.

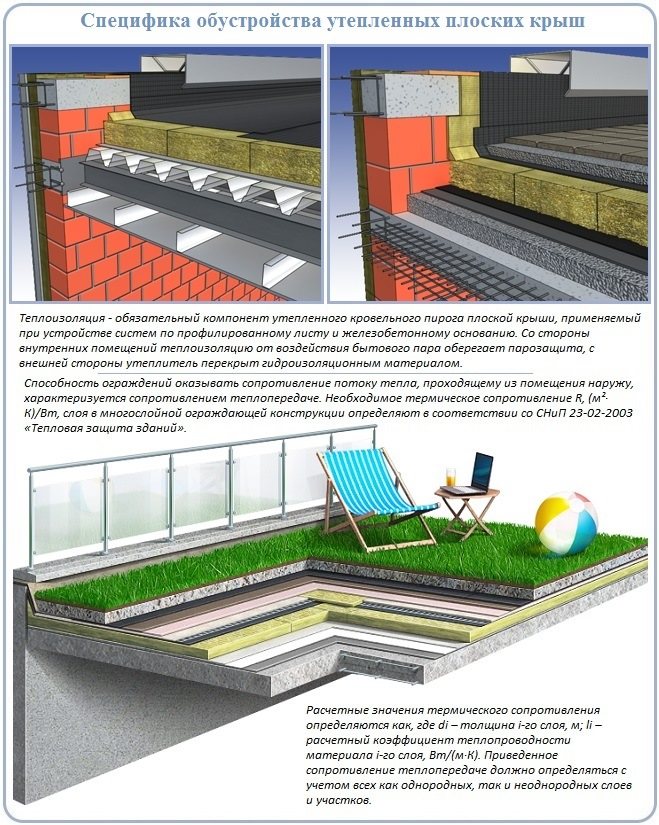

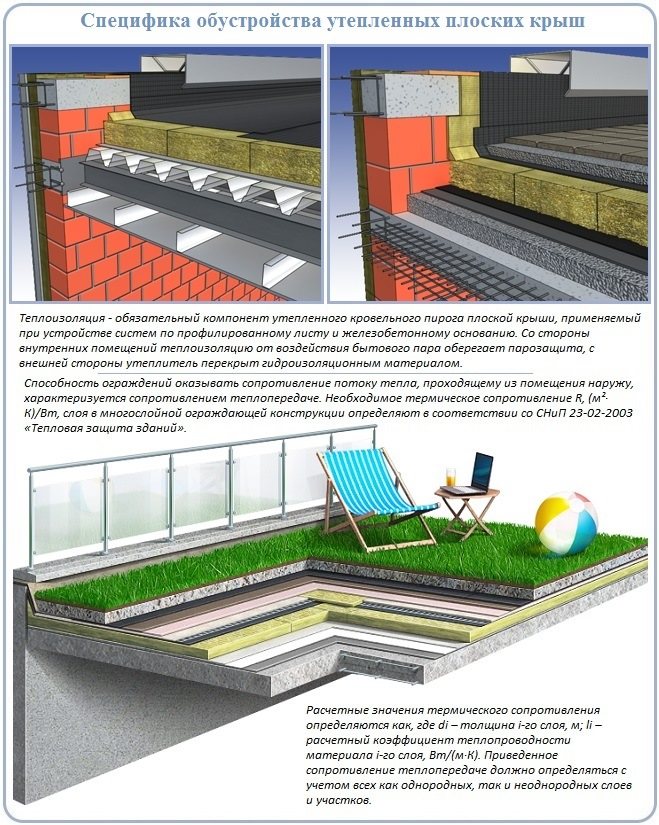

The device of a warm roof from corrugated board on flat roofs

The technology of installing a warm roof on flat roofs has not gone far. It existed before, but with the advent of innovative materials, it did not become worse, but better.

Profiled sheeting is used in large volumes in the construction of flat roofs for offices, private houses, buildings of small and medium-sized enterprises, warehouses.

Flat roofs are:

- traditional;

- inversion.

Their structure includes bases that are subjected to power loads. It can be

- reinforced concrete floor slabs

- corrugated board

- or another basis.

If there is a reinforced concrete floor, then first a small thickness cement screed is made, a heater is put on top, then a waterproofing layer. The topcoat is roofing felt poured with heated bitumen mastic.

This is the traditional method with a limited number of layers. If there is no lump insulation, then a layer of expanded clay is used.

In recent years, they began to be used as a material, a vapor layer.

They began to integrate into a warm pie

- glass cloth

- geotextile

- other materials.

Moreover, bulk insulation began to be used as a material that forms the slopes of the roof.

In the middle, make the layer thicker, reducing it towards the cornices.

Inversion structures are arranged on ready-made roofs. Gardens are laid out on them, terraces are arranged.

Warm flat roof cake

Polyurethane foam

This option will be the most costly, but at the same time it can become a universal solution for any buildings and premises. Its most important advantage will be a very thin layer of the applied mass, which reliably retains heat and does not let cold air into the house. However, sprayed polyurethane foam creates a completely vapor-tight surface and the room will need quality ventilation.

The advantages of this method of insulation can be attributed to the fact that when cleaning from dirt, no other surface preparation is required. The foam, in the form of which the insulation will be sprayed, adheres perfectly to any planes. After spraying, it hardens and forms a solid mass that retains heat perfectly.

Options for insulating a flat roof outside and inside

The versatility of the insulation of such roofs is obvious. But they have one drawback. There is no rafter system. That is, the sinuses between the rafters. There are many options for insulating both outside and below. Choose the best insulation and hang it, for example, to a concrete floor using plastic dowels. After that, the insulation is covered with a special cement mortar, painted or whitewashed.

Task number one: It is good to arrange the junction of the water removal, steam outlet. Work on the waterproofing device

Insulation of a flat roof

How to make insulation with polyurethane foam

This is a high-tech technology for insulating any structures of private houses. To create a consistency, equipment has been created and is being sold with the help of which both vertical and horizontal structures can be insulated.

The blowing or pouring method is used. It is more productive to use the spraying method, which occurs:

- filling all gaps of any size;

- expanding in volume, creates a solid, durable coating.

Polyurethane foam is obtained by mixing a polyol and a polysationate in a liquid state. Mixing takes place without oxygen access during spraying. The consistency is applied to the structural elements with a pistol. Cooling down, the material increases in volume several times.

Important! Polyurethane foam is a versatile insulation. Used for insulation of walls, ceilings, floors, roofs