Gas-fired boilers are devices with increased hazard properties. If such a device is misused, then it can cause such troubles as:

- spontaneous combustion, entailing a fire;

- people can be poisoned by carbon monoxide;

- gas poisoning may occur due to leakage;

- an explosion can also occur.

To prevent such dangerous situations that can entail human casualties, all processes that take place in heating boilers are put under the control of automation. Automation for gas boilers carries out vigilant control to ensure that all systems work accurately and smoothly.

All installations that provide heat to houses and premises and operate on natural gas are certified only if they have a high safety class, and this is achieved only due to the fact that automation is used for gas heating boilers.

What is automation for a gas boiler

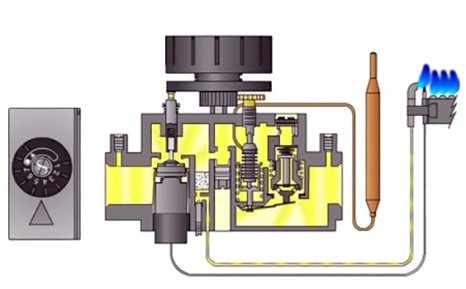

After the gas boiler starts up, control over its operation is assigned to a specialized device, which begins to operate within the framework of the program laid down in it. One of the main points of application of automation for gas boilers is to ensure the safe operation of the device. And also all models automatically regulate the maintenance of the necessary and predetermined heat temperature in the premises.

According to its functional capabilities, automation for gas boilers is divided as follows:

- devices that are volatile;

- devices in which control devices are volatile.

The first type uses models that require electrical energy, they have a fairly simple design and work on the principle of residual. A pulse signal is received from a sensor that controls the temperature, also called a thermal sensor, and a valve operating on an electromagnetic principle, following the instructions of such a signal, closes and opens, thereby either interrupting the gas supply, or, conversely, provoking it.

The second type includes volatile devices that operate on the basis of the properties of the physically used substance, the one that circulates within the circuit of the device itself.

When a substance heats up, it expands and creates pressure inside the unit itself, which increases. And also, under the influence of increased pressure, the boiler itself comes into action, which runs on gas. When the temperature drops, respectively, compression occurs and the chain works in the opposite direction.

Savings on heating without shutting down the equipment

Fuel consumption strongly depends on the characteristics of the building and the heated premises. If you see that gas consumption is too high and you don’t want to pay a lot during the heating season, follow our advice.

- Take care of the insulation of the outer walls of the house, attic, basement. It is here that the heat loss of the house is greatest - more than 50%. Without high-quality insulation, the temperature will constantly drop, and the boiler will consume more fuel.

- Install more energy efficient windows and doors. Or seal the old ones carefully.

- You can install special energy-reflecting aluminum foil screens. They need to be placed between the wall and the heating radiator. Thus, some of the heat will not just go into the wall, but will be directed into the room.

- Insulate the cold bridges.

- Do not cover the radiators with curtains, this also prevents the penetration of heat into the room.

- Better insulate the boiler and boiler, plus the pipes that extend from them.

- Clean the heat exchanger regularly. We recommend cleaning it at least once a year. Dust and dirt are constantly collected here, which is why the unit consumes more gas.

- If the gas column does not work, the burner must be inactive. She is capable of “blasting off” up to a cubic meter of gas per day.

By following these tips, you can save up to 20-30% on heating costs. In this case, the equipment will work constantly and will not wear out as quickly as with constant manual shutdown.

What is the principle of operation of automation

If we take into consideration the principle on which the safety system of the device works, then an unambiguous conclusion will be drawn from this - the main points of the entire structure of the structure are:

- safety valve;

- main valve.

They are responsible for stopping the gas supply to the working chamber. They also open up access to fuel. All automatic equipment for gas boilers is built on this principle.

The difference is observed only in the fact that there are functions that go as additional devices in the operation, which are equipped with automatic adjustment.

That is, the device itself works due to the fact that both valves interact.

Basically, all systems operate according to the following scheme:

- The regulator is set to the position required for the temperature to begin to heat the room.

- A signal is sent to the sensor that the system is working.

- The shutoff and simulator valves begin to regulate the amount of fuel flow. As a result, the intensity with which the boiler is heated is set.

In order to understand how all these internal processes occur, it is necessary to consider the very design of the automation device for gas boilers.

It is better to dwell on this point in detail, because then the question of which boiler to choose for home gas heating will be more understandable. And it will also be possible to purchase the most efficient model with a high safety threshold.

Can the boiler be turned off?

Is it necessary to turn off the boiler is a question that users usually ask with the onset of the warm season. Gas equipment belongs to the objects of increased danger and must always be in good condition, both from the side of the internal elements of the unit and external auxiliary equipment, including utilities of gas, electricity and water supply.

The main working element of the device is the internal heating systems of the boiler, made of metal, which undergoes corrosive processes, both inside, under the influence of O2 in an aqueous medium, and on the outside due to the presence of soot. Therefore, all manufacturers recommend to carry out their preservation of the boiler during long shutdowns to reduce corrosion processes. The type of conservation will depend on the type of fuel burned, the quality of the tap water and the material of the boiler pipes. The conservation technology is clearly described in the operating instructions for the unit and must be performed flawlessly by the service personnel.

Boiler conservation is carried out in several ways: dry, wet and overpressure:

- The dry method is used when it is required to turn off the boiler for a long shutdown in the cold season at negative temperatures. It consists in the fact that the device is completely freed from water and, with open air vents, is dried with an external source, for example, with an air blower, boiler heating surfaces from water residues.

- The wet method is used when there is no danger of low temperatures. In this case, the unit is filled with water with alkaline reagents that create a uniform protective film on the metal surface.

- The overpressure method consists in maintaining pressure in the unit, disconnected from the gas, which prevents oxygen from entering it from the air, which is the main aggressive corrosive element. With this method, before the boiler is turned off, it must be filled with purified water from the filters.

Preservation of gas boilers is carried out by dry, wet and overpressure method

All of the above methods of preservation require the complete tightness of the fittings and fittings of the device.

Automation design

All internal equipment of automation for gas boilers, which is used when installing a heating system, can be divided into categories, there are only two of them:

- the first category is those devices that ensure the safe and correct operation of all boiler equipment;

- the second category is those devices that can significantly increase the comfort when using the boiler.

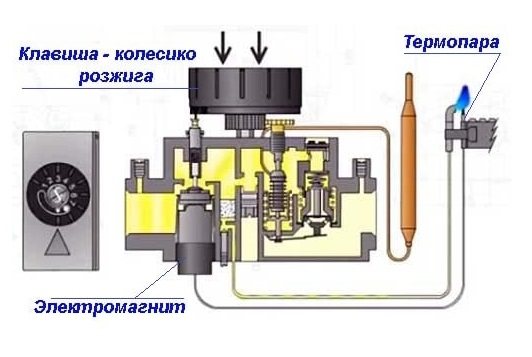

Safety automation for gas boilers consists of the following elements:

- the module that provides control over the flame. It consists of a thermocouple and a gas valve acting as an electromagnetic valve and shutting off the fuel supply;

- also there is a device that protects the system from overheating and maintains the required temperature regime, the thermostat takes on this task. He independently, if necessary, turns on or off the boiler, at those moments when the temperature approaches the specified peak levels;

- the sensor that controls traction. This device works on the basis of vibrations, depending on how the position of the bimetallic plate changes. It, in turn, is connected to a gas valve, which cuts off the gas supply to the burner;

- there is also a safety valve that can be responsible for dumping excess coolant (for example, air or water) in the circuit. Some manufacturers immediately provide an element to help shed excess.

The devices that are included in the security system are divided into the following types:

- mechanical;

- and powered by a power source.

They work either under the influence of a drive and the controller that controls them, or they are coordinated electronically.

Safety and comfort elements

The group of automatic devices for boilers includes many elements that can be divided into two large groups: mechanisms that ensure the safety of work, and devices that contribute to the comfortable operation of the boiler.

The following details are responsible for safe operation:

- thermostat;

- traction and flame control sensors;

- safety valve.

Flame detector consists of a thermocouple and an electromagnetic gas valve that shuts off or switches on the gas supply.

Flame temperature controller (thermostat) maintains the required temperature of the coolant, and also protects against overheating. This module turns on or off the boiler as soon as the coolant reaches a critical point (maximum or minimum).

Traction control module stops the gas supply to the burner as soon as the location of the bimetallic plate changes due to the increased temperature (it bends when heated, blocking the pipe through which the fuel is supplied).

We have considered in more detail temperature, draft, pressure and flame sensors in this article.

The safety valve is used to regulate, distribute and shut off the gas flow

In a heating system, a safety valve is an integral component of pipeline fittings, which is important in controlling the volume of the coolant used in the circuit.

The opening in the valve through which the gaseous fuel flows is called the seat. To turn off the device, cover it with a disc or piston.

Depending on the number of operating positions, gas valves can be one-, two- and three-stage, as well as simulating:

- Single-stage devices have only two operating positions: on / off.

- The two-stage device is equipped with one input and two outputs, while the valve opens when it is turned to an intermediate position, due to which the switching on occurs more smoothly.

- Boilers with two power levels are supplied with a three-stage device.

- Modulating valves are used to smoothly change the power rating of devices.

Automation used for convenience includes options that are usually performed by users of heating systems. These include auto-ignition of the burner, self-diagnostics, selection of the optimal operating mode, and others.

How the security system works

The device of a security system in an automatic machine for gas boilers is a necessary attribute, since all internal processes are under its control.

The following points are automatically adjusted:

- the gas pressure is regulated;

- if the values fall below the one set by the manufacturer or the user, the fuel access is blocked. This is ensured by the fact that the locking mechanism lowers the valve;

- if the operation of the module depends on energy sources, then pressure control is carried out by means of a relay that fluctuates depending on the pressure. They consist of a kind of membrane provided with a stem. And when the pressure stabilizes, the membranes take a position that helps to open the contacts that provide power for the heating installation. But if the pressure returns to normal, then the contacts close again, and the installation works;

- providing a flame in the burner. If there is no flame, then the thermocouple quickly cools down and the production of the required current stops. And the damper, operating on an electromagnetic principle, stops the supply of fuel to the burner itself;

- the presence of the necessary draft in the channel that ensures the removal of smoke. When the thrust decreases, the bimetallic plate takes on a different shape from heating. The rod that connected the sensor and the valve removes the system from the operating mode. The flow of fuel to the burner stops;

- the presence of a thermostat that monitors the temperature fluctuations of the coolant itself circulating in the circuit. Almost all safety systems that meet modern requirements are equipped with relays and sensors that guarantee the control of the presence of the coolant inside the circuit.

But you need to understand that automation for gas boilers needs preventive examinations by specialists, because even the best automation can fail for many reasons. But if the master periodically examines it, then the system should work flawlessly.

Do I need to turn off the gas heating boiler at all?

If this is not urgently needed, we do not recommend doing this. The potential gas savings are actually quite small. Or absent altogether. Yes, sometimes you can save a few cubes, but this negatively affects the operation of modern equipment. This is because it is during the startup and shutdown process that the system is most stressed. Accordingly, heating equipment wears out faster. If, nevertheless, a disconnection is necessary, then there must be long intervals between several switching on.

Starting after the coolant has completely cooled down has a particularly detrimental effect on the system. For example, if you turned off the boiler for the weekend and the heat carrier (water) has completely cooled down during this time. In this case, after ignition, condensation may form on the heat exchanger and burner.And over time, he can provoke equipment failure.

Many owners, in an effort to save money, do not turn off the floor or wall-mounted boiler, but only screw on the gas valve. Firstly, this is ineffective, and secondly, it also has a bad effect on the operation of the equipment. Gas burners can only work properly at a certain level of gas pressure. If the pressure drops, the burner can continue to operate, but the fire will come noticeably closer to it, shortening the service life.

Important!

We strongly advise against changing the factory settings of any gas equipment.

Output

Of course, only the user will decide what is more convenient for him, but boiler manufacturers advise first to invite an engineer so that he can estimate the volumes and calculate which installation is needed. After all, sometimes it makes no sense to install a huge expensive heating system, and sometimes it is an indispensable necessity.

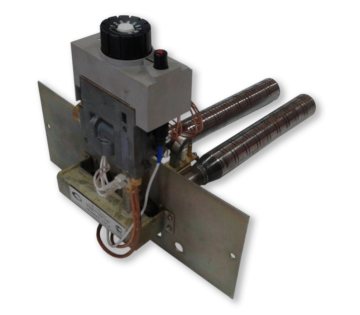

The newest models of gas boilers are characterized by high power and heating speed. However, the prices for them, to put it mildly, bite. You can try to use a more economical option and put new automation on the old boiler or fix the old one. The principle of operation and the device of automation of gas heating boilers of the old model will be explained in this article.

Conclusions and useful video on the topic

In the video presented, you will find a short instruction on how to install a gas boiler equipped with an automatic Eurosit system.

A modern gas boiler is a rather complex design, which provides many useful functions. Automation of most models greatly facilitates their operation, takes control of mechanisms and control over their operation.

This significantly increases the level of safety in the operation of the heating system, and also increases its efficiency by selecting the optimal mode.

Do you need to adjust the automation of your gas boiler? Do you want to tackle this problem yourself and want to clarify some points? Do not hesitate - ask your questions under this article, and our experts will try to help you.

Or have you successfully coped with the automation adjustment and want to share your experience with other users? Write your advice, add a photo showing the main points - your recommendations will be very useful to other owners of the same boiler.

What is gas automation for?

The old-style boilers were manufactured in accordance with the gas parameters and the characteristics of the heating system, which were in use several decades ago. These are, for example, the KChM and AOGV models. Moreover, their strength makes it possible to operate them for many years to come. But the trouble with automation, quite often it breaks down. In such a situation, there are three options:

- diagnose existing automation and replace the necessary parts;

- equip a reliable and high-quality unit with a modern automatic system;

- purchase a new boiler.

The difference, of course, is in the price of the issue, the efforts and time of the owner.

Consider the cheapest option - troubleshooting gas automation for an old boiler. However, to begin with, let's figure out why an automatic system in the coolant is generally provided.

Gas automation allows you to regulate and maintain the required temperature level of the coolant, and also serves to automatically stop the gas supply in an emergency situation. Installing automation on an old gas boiler will make sure that if the burner flame goes out, then after a short time the system will work to stop the gas supply without your participation.

The principle of operation of automation on old-style gas boilers

Frequent problems when heating a room with gas boilers are the attenuation of the flame in the burner and the gas contamination of the room. This happens for several reasons:

- insufficient chimney draft;

- too high or too low pressure in the pipeline through which the gas is supplied;

- extinction of the flame on the igniter;

- leaks in the impulse system.

In the event of these situations, the automation is triggered to stop the gas supply and does not allow the room to be gassed. Therefore, the installation of high-quality automation on an old gas boiler is an elementary safety rule when using it to heat a room and heat water.

All automation of any brand and any manufacturer has one principle of operation and basic elements. Only their designs will differ. Old automatics "Plamya", "Arbat", SABK, AGUK and others work according to the following principle. In the event that the coolant cools down below the temperature set by the user, the gas supply sensor is triggered. The burner starts heating the water. After reaching the temperature set by the user on the sensor, the gas sensor is automatically turned off.

On a note! When using modern automation, it is possible to save heat up to 30%. The old-style automation is non-volatile and does not need electricity. Its adjustment, connection and disconnection are made by a person. Commands are transmitted using electromagnetic pulses.

The video tells how the automatic equipment of gas boilers AOGV, KSTG works.

Safety-related automation

According to the rules set out in the regulatory documentation (SNiP 2.04.08-87, SNiP 42-01-2002, SP 41-104-2000), a security system must be provided in gas boilers. The task of this unit is to urgently shut off the fuel supply in the event of any breakdown.

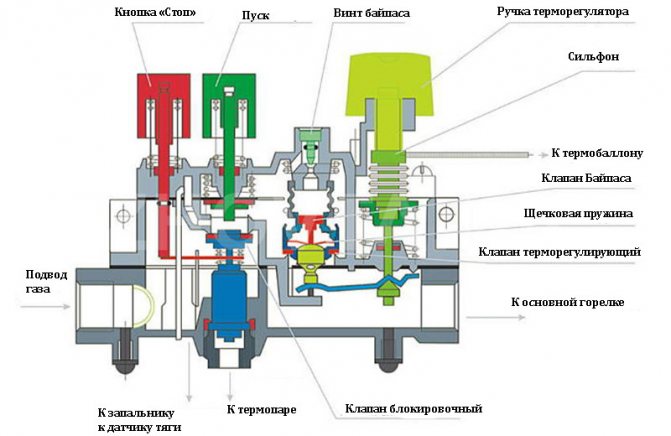

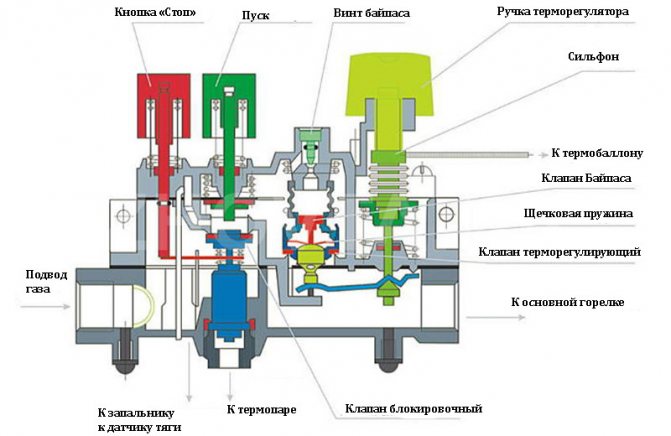

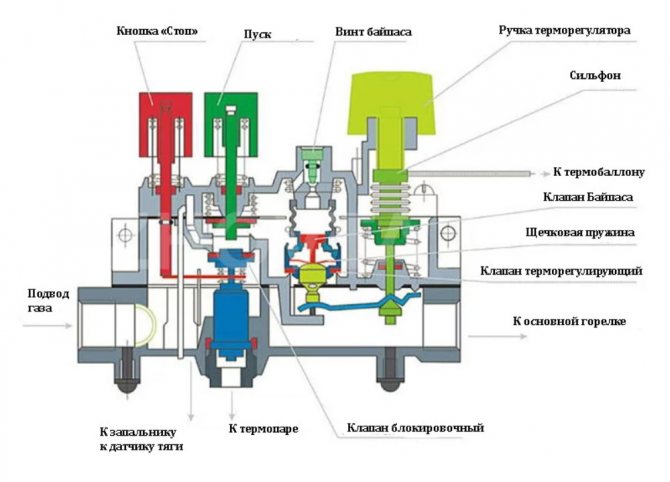

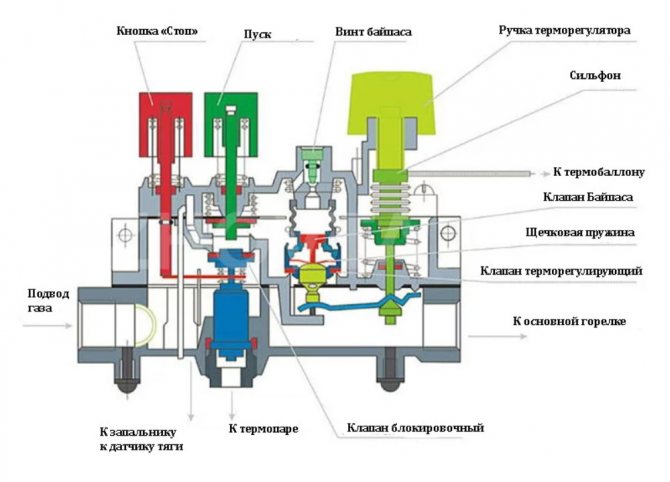

The diagram below shows an automation system that allows you to adjust the functions of the gas device, with a detailed image of all the constituent elements

The principle of safe operation of the gas boiler automation system is based on the control over the readings of the devices.

The control unit monitors the following factors:

- Gas pressure... When it drops to a critical level, the supply of a combustible substance is immediately stopped. The process takes place in automatic mode using a valve mechanism preset to a certain value.

- Gas supply... Responsibility for this property in volatile devices is borne by the maximum or minimum relay. The mechanism of operation consists in bending the membrane with a rod with an increase in the number of atmospheres, which leads to the opening of the contacts of the heater.

- No flame in the burner... When the fire goes out, the thermocouple cools down, which stops the generation of current, and the gas supply stops due to the closure of the gas valve by the electromagnetic damper.

- The presence of traction... With a decrease in this factor, the bimetallic plate heats up, which causes a change in its shape. The modified element presses on the valve, which closes, stopping the flow of combustible gas.

- Heat carrier temperature... With the help of a thermostat, it is possible to maintain this factor at a given value, which prevents overheating of the boiler.

The above possible malfunctions can cause the main burner to dim, as a result of which there is a possibility of gas penetration into the room, leading to fatal consequences.

This figure shows a schematic structure of the functioning of the control automation, designed to prevent overheating of the system or other disturbances in its operation.

To avoid this, all boiler models must be equipped with automatic devices. This is especially true for outdated samples, where such devices have not yet been provided by manufacturers.

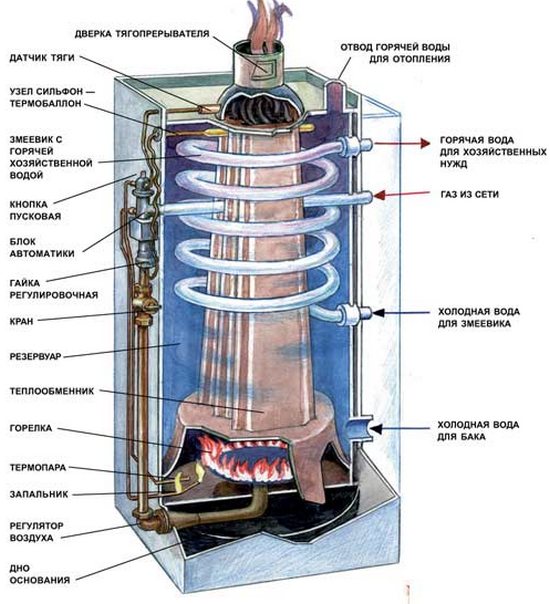

Basic elements of automation

The main elements of automation for a gas boiler are:

- thermostat;

- shut-off valve;

- thrust sensor;

- flame sensor;

- igniter tube;

- igniter;

- burners.

Let's try to explain in an accessible way how the automation for a gas boiler works, disassembling it into basic elements and telling about their functions.

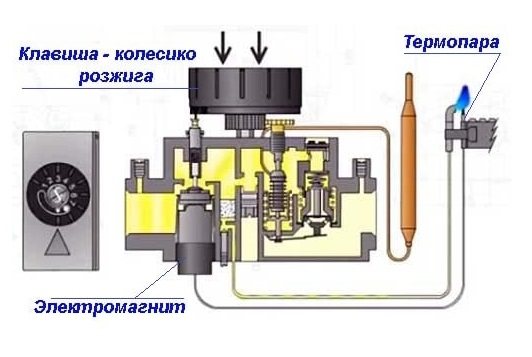

The gas passes through the gas cleaning filter. Then it goes to the solenoid valve that regulates the fuel supply to the burner. Temperature and draft sensors are located next to the valve, which monitor the indicators and signal that they are outside the permissible limits. Also, the set of automatics for gas boilers includes a thermostat with a bellows and a stem, designed to set the desired temperature. A special button is used to adjust the indicators. When the water heats up to the temperature set by the user, the thermostat is triggered, the gas supply to the burner stops, while the igniter continues to work. When the water cools down by 10-15 degrees, the gas supply is resumed. The burner ignites from the pilot. Automation is started manually.

Flame and draft detectors

Flame and draft detectors work according to this principle. The draft sensor reacts to the deterioration of the smoke draft and transmits an impulse to the control system. It is located in a smoke hood. Equipped with an alloy plate of two metals: iron and nickel. When draft deteriorates, flue gases accumulate and heat up the plate. It is deformed, the contacts open at the same time, the flow of fuel into the combustion chamber stops. When the temperature decreases, the plate returns to its normal state.

The temperature sensor works the same way. When the water in the boiler heats up above the set temperature, the lever mechanism is triggered and the temperature regulator valve closes. The gas flow stops and the burners go out.

When the water cools down, the sensor bellows is compressed, the lever mechanism is triggered, the temperature regulator valve opens, gas begins to flow, and the burners light up.

During the heating season, the gas is sometimes turned off. It is a fact.

For different reasons. There would be nothing wrong with that, no longer than a couple of hours the gas supply is usually turned on. If not for one small detail - most household gas boilers do not start on their own after a temporary gas cutoff.

If you are away at this time, and the heating system of your house does not have an automatic reserve, then the heating system, and at the same time the water supply system, comes to an end. The house is cooling down, the boiler and pipelines freeze and burst, the freezing water destroys expensive plumbing and plumbing fixtures embedded in the walls.

Why doesn't the boiler restart after a gas cutoff?

The fact is that the boiler automation does not control the presence of gas. It monitors the presence of a flame in the boiler combustion chamber. If there is no flame, then after three ignition attempts, the boiler goes into emergency mode. Standard boiler automation cannot determine why there is no flame, and in order to protect against dangerous situations, for example, starting ignition electrodes in a gas-polluted room, the boiler goes into emergency mode, to exit from which a manual restart by a person is required, after checking the boiler room.

How can I tell if my boiler starts up after a gas cut-off on its own, or a manual restart is required?

It's simple. If your boiler is a floor-standing boiler with an external forced draft burner, it will restart, since the forced draft burners are equipped with gas pressure control devices. The rest of the boilers are not. And yours, unfortunately, too, if you have any wall-mounted boiler or floor-standing atmospheric boiler, working on the natural draft of the chimney.

What to do?

The good news is that the situation is not hopeless. You just need to modify the boiler gas supply scheme by installing a gas pressure switch on the gas pipe.

It's safe?

Yes, it is completely safe.The gas pressure switch is produced by the famous German manufacturer Kromschroder and has all the necessary certificates and permits. For heating equipment of premium class, this device is installed as standard or is included in the recommended configuration.

How it works?

The gas pressure switch is set to the minimum pressure specified in the instructions for your boiler, at which the boiler remains operational. When the pressure in the gas pipeline falls below the critical minimum, or when the gas is completely cut off, the relay will cut off the power to the boiler burner. The boiler will remain in standby mode, it will not go into an accident, the boiler pump will work, circulating in the network to protect the pipelines from freezing. After turning on the gas, the boiler will switch to operating mode and start on its own.

Is the installation of a gas pressure switch an unauthorized tampering with the boiler?

No, the relay is installed in the standard boiler connector, in the open circuit of the room thermostat 220 v, or, if such a thermostat is not installed, instead. Installing a minimum gas pressure switch is an absolutely legal measure to ensure additional safety and ensure the viability of the heating system, which does not in any way affect the warranty of your heating equipment. Contact us and you will be able to leave home with complete peace of mind, even for a long time!

The cost of the gas relay is 8500 rubles, the cost of installation is 2500 rubles. Call and order the installation +7 (383) 209-05-40

The most common malfunctions of automation and methods of their elimination

Before setting up the automation on the boiler, it is necessary to diagnose it. As a rule, serious malfunctions occur that require specialist intervention. The adjustment can also be entrusted to the gas master. Or you can make it yourself by reading the instruction manual.

Attention! The safety sensors must be checked before each seasonal operation.

Most often, the filter becomes clogged, problems arise with the valves, sensors burn out due to voltage surges, and a gas leak is detected. The correct cleaning of the filter must be done by a master. You can try to replace electronic elements yourself, having carefully studied the operating instructions for your boiler.

In order to replace the temperature sensor, it is necessary to turn off the gas boiler and cool the water to a temperature of 40 degrees. Shut off the flow of coolant, remove the control knob by unscrewing the screw. Next, dismantle the PTV adjustment screw. Remove sensor bellows with support washer. Unscrew the union nut of the sensor bulb. Install the thermal bulb of the serviceable sensor into the boiler jacket and screw it tight. Install the sensor bellows into the pipe socket, install the support washer on the bellows, install the PTB adjustment screw and adjust the temperature.

If there are problems with ignition of the igniter, then one of its possible causes is a malfunction of the draft sensor. In this case, it must be dismantled, diagnosed, verified contacts, cleaned, if necessary replaced with a new one.

Also, common reasons why the igniter does not ignite can be:

- malfunction of the gas valve;

- clogging of the hole in the igniter nozzle (it is possible to clean it with a wire);

- strong air draft;

- low gas inlet pressure.

When the gas supply is turned off, it is necessary to check the chimney (it may be clogged), the electromagnet, the gas pressure at the inlet to the gas boiler.

Attention! It is necessary to invite a specialist to diagnose and repair the automation of a gas boiler. Inappropriate actions can exacerbate the problem and have undesirable consequences.

For automation systems AGUK, AGU-T-M, AGU-P, the most common problem is the burnout of the bimetallic plate, which is used as a sensitive element.

In "Arbat" and "Orion" you can replace only the thermocouple and the thrust sensor, as well as the solenoid valve (rarely). The automation unit is practically beyond repair. In "Arbat" the system shutdown button often breaks.

My home is for dummies. How to turn off the heating for the summer.

Yes, yes, this is exactly what you thought ... A wonderful series of computer (and later and not only ...) books, Simple and understandable, which was very useful to many.

Your new home has honestly looked after you all winter. Saved from bad weather, protected from precipitation, wind, cold ... But then the sun warmed up, long ago the trail was gone from winter snowdrifts. May. It's time to turn off the heating in the house. But as? There is so much of everything in the boiler room that you can open, close, switch, turn off ... Right there, almost like an airplane pilot

There are some important nuances of the operation of a single-circuit boiler for a "short", as a rule, a hot water supply circuit, but I will talk about this in my next article.

Principle of operation

The principle of operation of the gas boiler draft sensor is to timely supply a signal to the valve, which shuts off the gas supply to the burner. The device is triggered if there is a violation of the current of the combustible products in the correct and natural direction (from the boiler equipment through the chimney to the street). Otherwise, smoke from carbon monoxide, carbon dioxide, water vapor, soot will penetrate into the house where the boiler is located, and can harm human health.

Understanding how the sensor works is not difficult. Everything is based on the standard laws of physics. It is a bimetallic relay that works to turn on / off the boiler. There is a metal strip inside the thermostat that reacts to temperature changes

The next thing the user needs to know is that the fixture adjusts to the temperature according to the fuel being used. If it is natural gas, then the temperature is 75-950 ° C. If liquefied gas is used, then 75-1500 ° C.

If the sensor senses that the traction in the gas equipment is very poor, then there will be an increase in its heating of the smoke gases and the subsequent blocking shutdown (immediately, after a few minutes after switching on).

In gas boilers with an open combustion chamber (atmospheric units), a safety thermostat controls the presence of draft and flue gas temperature, with a closed combustion chamber (turbocharged units) - the pressure of the air blown out by the turbine.

Is it possible to disable

When installing the sensor and using gas equipment, it is often possible to observe periodic shutdowns in operation. In this case, you may want to turn off the traction device completely. However, there is no need to rush.

Draft sensor for gas boiler AOGV and AKGV

There are several reasons for this:

- Firstly, disabling the sensor may indicate poor traction performance. Weak intensity of movement of smoke gases leads to overturning of draft in boiler equipment. In this case, harmful vapors will enter the house in large quantities.

- Secondly, the problem may lie in the reverse thrust. An air lock is formed. Exhaust smoke gases move up to a certain mark in the chimney, and then fall back. This is due to poor heating of the pipe, poor thermal insulation.

Of course, it is theoretically possible to disconnect the sensor, but this entails a great danger. If an emergency situation arises, then there will be no protection. Therefore, it is not recommended to operate a gas unit without such a controller.

Reasons for triggering

The reason for the activation of the automatic control system may be various malfunctions in the installation of the smoke exhaust structure, malfunctions of the sensor parameters themselves.

Flue gas safety thermostat 70 ° C

Let's consider the most common:

- Strong wind. A gust of wind can blow out the gas burner. To prevent this from happening, they purchase a stabilizer for the unit and install it in place of the outlet pipe.

- Chimney system clogged. In this case, cleaning is required.

- Weak traction parameters. The gas boiler draft sensor reacts when heated to 950-1500 ° C. Due to the complexity of smoke extraction, overheating occurs inside the smoke extraction system and the gas valve is turned off.

- Incorrect installation of gas equipment.

- Incorrect calculation of the dimensions of the chimney. The chimney height is measured depending on the distance between the chimney and the roof ridge. The recommended location is exactly in the center of the roof. In this case, the head will rise more than half a meter above the ridge.

Boiler flame modulation

Today there are different types of flame modulation in the burner: hydraulic, electronic, ionization.

Flame modulation - this is an automatic change in the power of the burner of a gas boiler, depending on the heat consumption.The burner power automatically adjusts to the power required for heating or water heating, smoothly in the range from 40 to 100% for most wall-mounted gas boilers 10 - 24 kW.

The exception is condensing boilers, their modulation is at the level of 30 - 100%, and in new models it is already from 18 to 100%

Hydraulic modulation - this is the regulation of the burner power according to the principle of direct relationship between the given proportions of flow and gas to maintain a constant outlet water temperature.

Electronic modulation - implies an indirect relationship through a water temperature sensor due to coordination, - an increase or decrease in the gas flow rate when the water flow changes.

Ionization flame control - this is the principle of recording the current in the circuit that arises when ions appear between the ionization electrode and the burner section. The flow of ions occurs during the oxidative reaction (combustion) between methane or propane and oxygen in the air. The flow of ions in the flame closes the electrical circuit and a signal is sent to the control unit that ignition was successful and the burner continues to burn.