by dakar, 08/06/2015

When building a new house or at the stage of repairing an existing house, it becomes necessary to finish the facades of the building. This procedure is important not only for aesthetic reasons, but also for improving performance.

High-quality finishing allows you to significantly insulate the building and increase its resistance to external influences. Facade tiles have become very popular, the features of working with which we will consider in this article.

Finishing the facade of the self-supporting insulated wire of the house with turnkey tiles RUB 2300 per m² *

SIP facade decoration at home Full construction

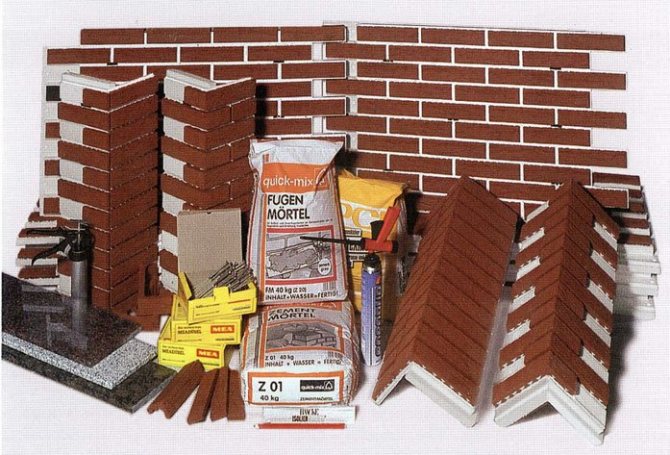

this is a complex of works and materials:

- wind and moisture protection;

- edged board 100 × 25 mm;

- lathing for tiles;

- antiseptic composition for wood;

- brick tiles;

- fasteners;

- corner elements;

- platbands;

- slopes;

- delivery and unloading.

Popular product brands

Many manufacturers produce ceramics for external facades. Among such an abundance there are options with both a classic design and a very unusual one. It is worth considering the options that are in great demand among the masters:

- Barwolf. The German company produces various types of ceramic finishes. Many collections are designed in antique or classic style.

- Cerpa Ceramica or RHS. In the field of ceramics decoration, Spanish and Italian firms have proven themselves very well. The quality of their products is at the proper height, the choice is good news.

- TERREAL. The French manufacturer offers customers conventional finishing tiles, as well as ventilated facades. The collections include terracotta, hand-molded tiles and clinker.

- Arcana Ceramica. There are options for both interior and exterior decoration. In the collections, the Spanish manufacturer uses a natural range of colors, which is obtained by mixing different types of clays.

- Falcon. Leader among Russian manufacturers. The material is made using Italian equipment.

- Ceramo Marazzi. Here, attention is paid to product design. Large selection of facade tiles.

Low porosity porcelain stoneware is an excellent material that is ideal for facade cladding. Low sensitivity to cold, water resistant, practical and eye-catching - it stands the test of time well. In addition, this finish is easier when compared to brick cladding.

Finishing the facade of a turnkey wooden house RUB 2500 per m²

External finishing of facades Full construction

it is a complex of works, services and materials:

- brick-like tiles for facade decoration;

- stone tiles for finishing the basement;

- corner elements;

- platbands;

- lathing for insulation, bar 50 × 50 mm;

- mineral insulation;

- wind and moisture protection membrane;

- lathing for tiles, edged board 100 × 25 mm;

- fasteners, screws, dowels, scaffolding;

- delivery and unloading.

Material mounting technology

The process may seem simple, but without equipment and experience, it is almost impossible to cope with it. If knowledge allows, then you can get down to business. Step by step creation process facade cladding will look like this:

- Preparing the walls. The old finish is removed, the surface is treated with a deep penetration primer. The frame will hide all minor irregularities.

- Wall markings.

- The brackets are fixed after treatment with liquid waterproofing, if any. If the roll version is used, then the brackets are installed first. For brackets, there are usually special slots in the material.

- Attach the vertical posts to the brackets. The distance between them is determined by the weight and size of the facing sheet.

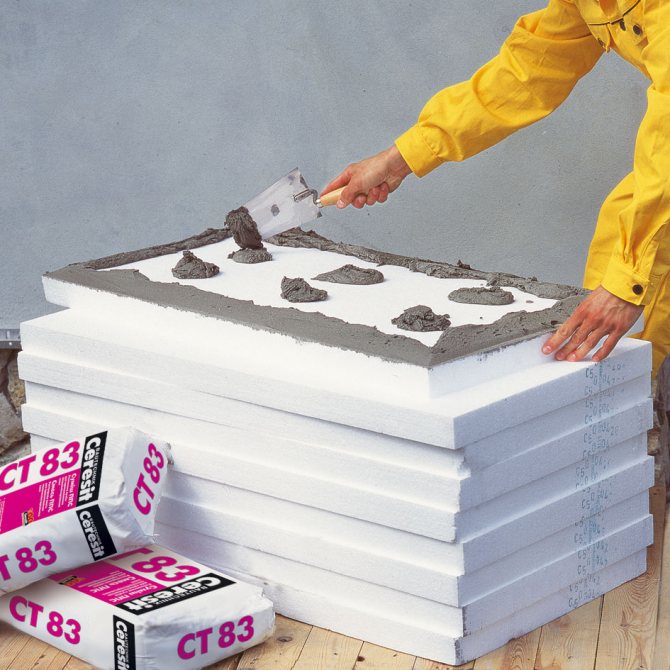

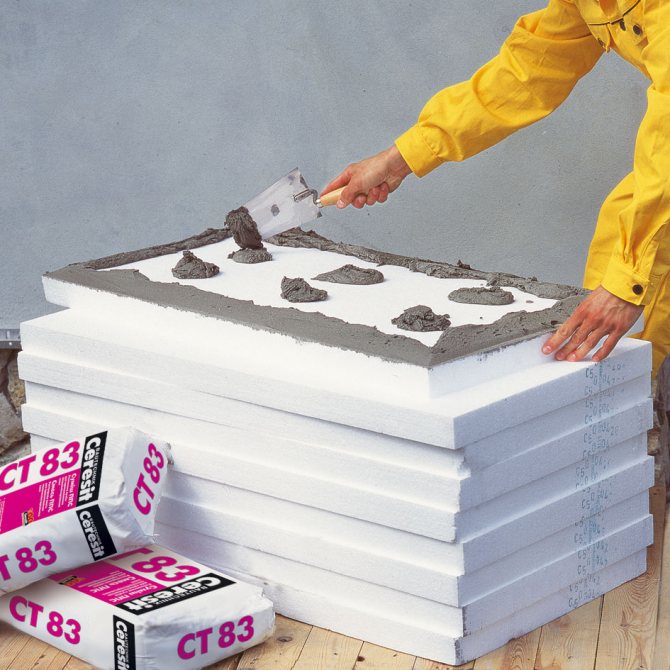

- Heat insulator plates are placed between vertical posts: the material must be sufficiently deeply deepened into the cell. The slab is fixed in the center and at the edges with glue, then fastened with disc dowels. The windproof membrane is attached over the heat insulator.

- Next, the transverse profile is fixed.

- The tiles are hung taking into account the fastening provided by the manufacturer. Usually these are holes for special screws, with which the material is attached to the constructed frame. But mounting on kleimers is allowed.

After the installation is completed, it remains to wipe the tiles with a suitable composition. Grouting is not required if a seamless installation method was used, for example, marbled porcelain stoneware.

House cladding made of turnkey aerated concrete 2600 ₽ per m²

Facing a house made of aerated concrete begins with the selection of the appropriate fasteners for attaching the battens to the foam block. A dowel for aerated concrete with a self-tapping screw securely fix the crate under the insulation. The wind-moisture-proof membrane protects the insulation from moisture. Next, a crate is installed under the tiles. Facing tiles are attached to the battens with self-tapping screws.

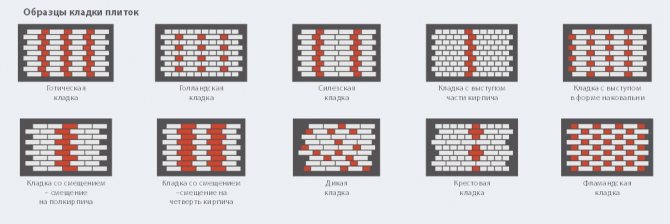

Styling features and materials

Laying the facing material is not much different from the internal one. The evenness of the surface is important here, so special attention is paid to the preparation of the walls. The glue is selected carefully, cement mortars are not suitable due to their low water resistance. The exterior adhesive must be of good frost resistance. The beginning of the installation is the only difference, here it starts from the corners.

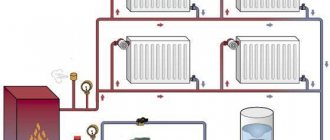

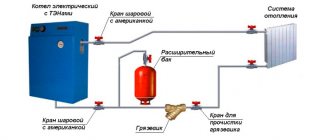

Ventilated facades can be called a more practical and efficient system, but its installation is associated with certain difficulties.

It is better to entrust the arrangement of a ventilated facade to specialists if there is no certain knowledge and skills in construction. To build such a facade, you will need the following:

- Ceramic tile. Usually, the material for a ventilated facade already has technical holes for future fixings;

- T and L-profiles, it is easier to use a ready-made system than trying to build a frame yourself;

- cleats, screws, brackets;

- liquid or roll waterproofing;

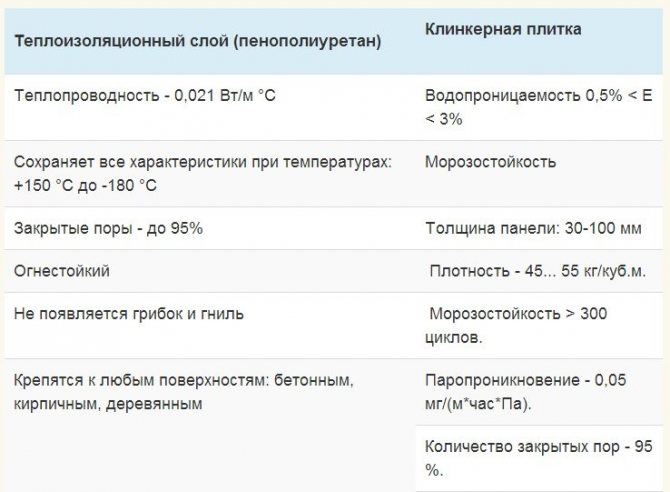

- heat-insulating material in the case of building insulation, polyurethane foam or mineral wool is suitable;

- drilling tools, drills - all these must correspond to the material of the load-bearing wall.

House cladding price

Facing a turnkey wooden house RUB 2500 per m²

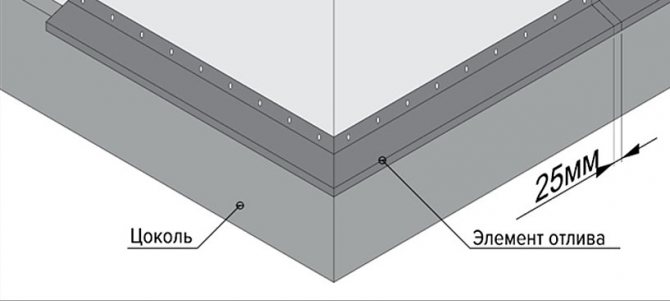

The cost of work, taking into account the materials: facade panels for brick, facade panels for stone, wooden lathing for insulation, mineral wool insulation, wind protection for the walls of the house, frame for tiles, self-tapping screws, window ebbs, basement ebbs, window frames, window slopes, corner elements ...

House cladding made of turnkey aerated concrete 2600 ₽ per m²

The cost of work, taking into account the materials: facade panels for brick, facade panels for stone, wooden lathing for insulation, mineral wool insulation, wind protection for the walls of the house, frame for tiles, self-tapping screws, dowels for aerated concrete, window ebbs, basement ebbs, window frames, slopes windows, corner pieces ...

Facing a turnkey frame house RUB 2500 per m²

The cost of work, taking into account the materials: facade panels for brick, facade panels for stone, wooden lathing for insulation, mineral wool insulation, wind protection for the walls of the house, frame for tiles, self-tapping screws, window ebbs, basement ebbs, window frames, window slopes, corner elements ...

Finishing the facade of the self-supporting insulated wire of the house on a turnkey basis 2300 ₽ per m²

The cost of work, taking into account the materials: facade panels for brick, facade panels for stone, wooden lathing for insulation, mineral wool insulation, wind protection for the walls of the house, frame for tiles, self-tapping screws, window ebbs, basement ebbs, window frames, window slopes, corner elements ...

Facing the basement of the house on a turnkey basis 2300 ₽ per m²

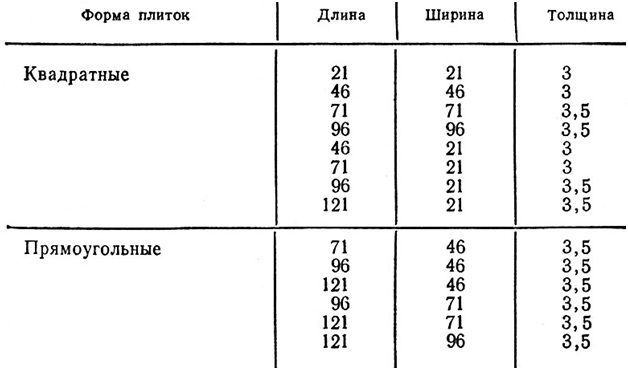

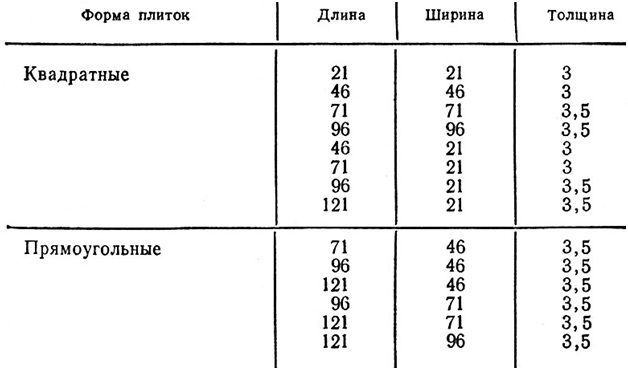

Dimensions of ceramic products

In principle, facade ceramics can be of almost any size, but in reality this is limited by the aesthetic factor.

It is worth considering separately the dimensions of each type of material for facade cladding:

- Terracotta. Produced in the form of small tiles, the sizes are usually medium: 302 × 148 × 12 mm and 240 × 71 × 11 mm. Lay on glue. But sometimes facade panels are made up to 4 centimeters thick and up to 180 in length.

- Boar. Typical dimensions for bricks: 285 × 85 × 9 mm, 250 × 100 × 8 mm, 120 × 60 × 8 mm. Everything is simple here - the material imitates a brick, therefore, its dimensions too.

- Porcelain stoneware. Here the sizes can vary widely. There is a very small tile of 30 × 30 and 45 × 45 centimeters, which is placed on the glue. And there are large panels for ventilated facades. The thickness rarely exceeds 14 millimeters, because porcelain stoneware is already four times stronger than granite, such a cladding does not need thickness.

Small tiles are usually chosen when decorating low-rise buildings. A large one is preferred when finishing industrial facilities and office buildings.

Tiling from natural materials

Most often, marble or granite is used for its manufacture. A building faced with such tiles confirms the high status of its owner.

Benefits:

- maximum durability (up to 50 years and longer);

- beautiful appearance;

- environmental friendliness.

Disadvantages:

- high price;

- huge weight, which requires a very high-quality foundation.

Wet installation of clinker tiles

About fastening systems

Installation of facade panels involves various types of solutions to the task at hand. The most practical option for installing tiles is to mount them on a supporting profile that can be adjusted. If facade panels of different sizes are used for finishing, an adjustable support profile is the best cladding option. On the outside of the ventilated facade systems, a special aluminum substructure is provided, on which the facade panels are mounted. It should be noted: such substructures, where the cladding is attached, are distinguished by the nature of the seam. It can be closed or open.

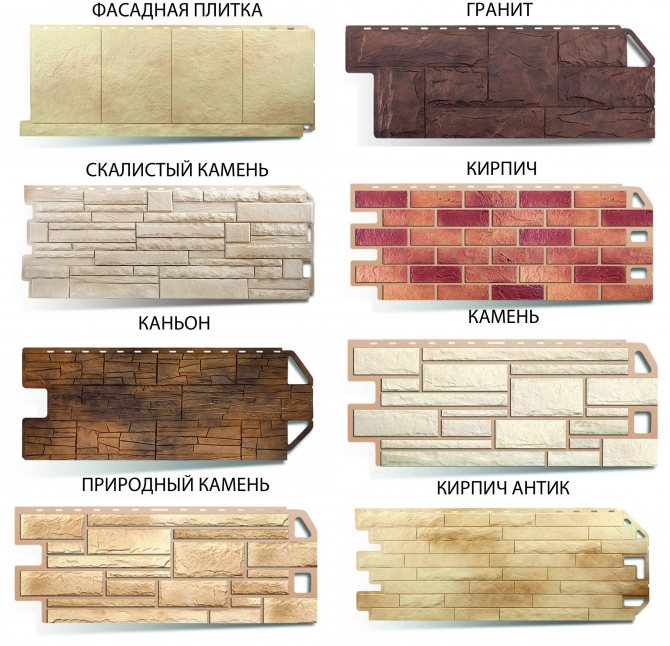

Facing tiles are capable of imitating any surface. If the assortment of a special hardware store or shopping center does not have the required color and size of front panels, manufacturers will quickly make these products to order. When choosing facade panels, it is necessary to take into account the style of the building, how they will look against the background of the general architectural ensemble. Eco-style cladding of residential and non-residential buildings is considered trendy these days. Such facade panels have all colors and shades of green spaces, wood, stone, earth.

Retro black and white cladding is mainly used for classic buildings. Facing tiles in bright colors - for trade and entertainment facilities. It is also very convenient in that any pattern can be applied to its surface. In cities, unique, custom-made ceramic cladding is increasingly common.

And for the production of large images for mosaics, facing tiles turned out to be quite a suitable material. Execution of ornaments in a mosaic style with its use is a fashionable element of the decor of the exterior of buildings. The facing ceramic surface can be combined with natural finishing stone and porcelain stoneware. Nowadays, you can often find options when the lower part of multi-storey buildings is finished at the level of human growth with granite or porcelain stoneware in dark tones, and above there is a ceramic tile of light color.

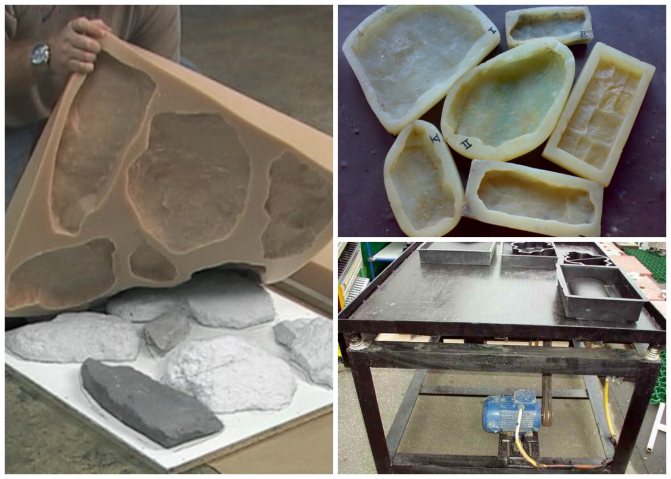

Features of making tiles

Natural stone plinth slabs are made from sandpit, tuff, limestone, granite and marble. The outer side of the raw material can have a rough or polished surface.

The tile is attached using a cement-sand or glue mortar.

Possible sizes of manufactured tiles

Clinker tiles withstand moisture well

Plinth clinker tiles are made of special types of clay to match the size and color of the brick. Has a glossy lacquered surface that resists moisture well. In addition, this material is highly resistant to acids, therefore it is used in most cases for finishing industrial buildings.

As for the durability of raw materials, it surpasses all currently available types of facing materials in this indicator.

Tiles made on the basis of a polymer-sand composition have the appearance of a natural stone. Fastening of such elements to the facade is carried out using glue. Tiles can be attached to the wooden surface of the base with self-tapping screws.

Each of the constituent elements are fastened to each other due to a special latch that levels the surface and eliminates the difference in gaps.

Polymer sand tiles are characterized by increased frost resistance. Despite this, they can be easily cut in the desired place or bent at an angle.

The tile for finishing the basement made of hyper-pressed bulk mixes has good moisture resistance, high strength, low weight with an affordable price policy.

Before deciding which tile to choose for warming the basement of a house, you should study the characteristics of each of its types and consult with a specialist.

Types of facade cladding

Finishing the facade of a building with tiles can be done in two ways of facing, the technology of which is widespread and applied everywhere. The choice of the preferred method is not determined by eye or complexity, only on the basis of the dimensions of the tile itself and its type. In addition, the material from which the walls of the building were originally made play an important role. Their quality determines the need for additional insulation for a comfortable indoor microclimate in winter. Therefore, facing the facade of the house with tiles is not only a necessary, but also an extremely demanded type of work in our climatic latitudes.

Facade cladding by gluing tiles

For cladding the facade in this way, a technology is used that does not differ much from laying wall or floor tiles indoors. The only difference in this regard is the choice of the type of glue. For finishing the facade, a frost-resistant adhesive composition is required that will withstand the aggressive effects of the environment.

Facade decoration by gluing is a very capricious process and requires certain climatic conditions. The air temperature should be between 5 and 25 degrees. Otherwise, the adhesive cement mortar may lose its characteristics and the laying of tiles on the facade will be performed poorly.

Here is a brief instruction on the technology of gluing tiles to the facade. It consists in the following simple sequence of actions:

- First, calculate the surface area of the walls that you intend to tile, excluding the squaring of the openings of windows and doors. After purchasing the required amount of facing material of the selected type, you can start working. Do not forget to also take into account the surface of all corners in the openings, since the corners must be clad without fail.

- Please note that tile manufacturers indicate the recommended number of bars per unit area, taking into account the thickness of the seam, therefore, installation on the facade must be carried out based on this circumstance.

- Before laying the material, the surface of the walls must be leveled and, if necessary, primed. If the plaster layer is too thick, reinforcement mesh should be used to level the wall.

- Further, on the lower level, it is necessary to beat off a horizontal line and apply the adhesive composition with a notched trowel, forming a ribbed profile.

- The tiles must be laid starting from the corner. It is necessary to strictly maintain the thickness of the seam using special plastic pegs, which must be purchased prudently.

- An important tip: for a better cladding of the facade, it is better to apply glue not only to the wall, but also to each individual tile, including. The main thing is not to overdo it and make sure that the adhesive does not fall into the seams.

- Often, when laying tiles, you have to cut them. This operation is performed with a special stone disc. Cutting lines are marked on the tile, and then the excess parts are cut off with a grinder.

- After a couple of days, the adhesive on which the tiles were laid is completely dry. Only then can you begin to fill the seams between the material with a special mixture using jointing and a construction gun.

- Please note that the bonding method for facade finishing should never be used for large porcelain stoneware tiles. If a piece of trim accidentally peels off and falls off the wall, it may well injure bystanders.

Facing on the frame: installation features

Many men, and even professionals even more so, are well versed in the peculiarities of ventilated facades and understand how they are mounted.

- Suspended ventilated facades can be built using porcelain stoneware tiles, although it is quite acceptable to use clinker panels for these purposes. 2. The ventilated façade allows the building to be additionally insulated with the help of rigid thermal insulation boards, fixed under the decorative covering of the façade.

- This method is very popular, since it allows you to insulate the structure of the building and create a more favorable microclimate inside the building. This method of finishing is easy to do with your own hands, which only contributes to its widespread distribution. With the proper skill, it can be done without the involvement of professional craftsmen.

Facing with concrete tiles

This finishing material is made from ordinary cement and sand with the use of special additives and dyes. Like the sidewalk, it is made by vibrocompression.

Benefits:

- a light weight;

- a wide variety of colors;

- ease of installation;

- low cost.

Disadvantages:

- poor frost resistance, as a result of which it can crack;

- loses its appearance over time.

Wet method

At the very beginning, it is necessary to level and prepare the surface as much as possible. If your walls are concrete, then make notches. The base and the tile itself are pre-moistened with water. After that, glue is applied, which is leveled with a special notched trowel.

It is necessary to apply it only to the surface on which you can attach the tile before it dries. For alignment, you can use a tensioned thread or preliminary markings, as with the dry method.

The last operation is to grout the joints with a special mixture to prevent water from getting between them. It is recommended to perform it at least one week after installation and in clear sunny weather.

If you want to additionally insulate the house, then you will have to use the dry cladding method with crate. The wet method is suitable if it is not necessary.

Consider the most popular types of materials used for facade decoration:

OSB boards

A three-layer board made of pressed wood chips, bonded with epoxy resins, unlike chipboard boards, has high moisture resistance and increased strength. OSB boards are used as a rough cladding in the construction of houses using frame technology. Sandwich panels are made of them, which make it possible to dispense with the construction of a frame, since the strength of OSB boards allows them to themselves perform the role of a supporting frame in one-two-story houses.They are not suitable for internal work, because epoxy binder can give off fumes that are harmful to health.

It should be noted the excellent heat and noise insulation qualities of OSB boards. They are easily dyed, varnished, glued, machined with ordinary woodworking tools. Their service life is several decades.

Ceramic tiles for facades

Ceramic tiles are considered to be one of the most durable and durable materials used to decorate the facade of various houses. Such cladding has a large number of advantages, due to its low weight, ceramic tiles do not create powerful pressure on the foundation and do not harm the structures of the house, improves the thermal insulation parameters of the object.

In addition, of all the options for the finishing layer of the curtain facade, ceramic tiles of the "hog" type are distinguished by the best parameters in terms of price-quality ratio, they improve the appearance of the house and withstand even powerful atmospheric influences.

Ceramic facade tiles are currently presented on the market in the widest range, any owner will be able to choose a facing material with different colors and textures, which allow even the most daring design decisions to be realized.

Tiles for the facade, imitating the surfaces of other materials - brick (hog), wood, stone and others are very popular among owners of country houses.

Ceramic panels are produced today using modern technologies, due to which they are distinguished by excellent technical characteristics.

Today, such products are very popular among the population, they are considered quite fashionable, and in the near future, the appearance on the market of other materials with similar advantages that could replace ceramics is not expected.

Speaking about the cost of ceramic products, it should be borne in mind that the low cost applies only to standard, common panels. If the owner of the house is ready to allocate a large amount for the facing of the facade, additional finances can be used to purchase and install elite tiles with better quality and external data.

In general, among all the important advantages of this type of facade finish are:

- light weight;

- reliability;

- waterproofness;

- long service life;

- resistance to fire and high temperatures;

- resistance to negative effects of negative temperatures;

- preservation of external attractiveness throughout the entire life of the material.

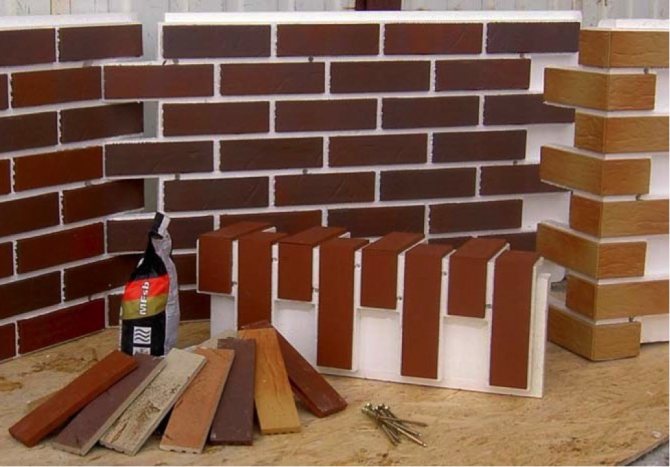

Installation of tiles on walls without insulation

1. No special surface preparation is required. Not necessary, as long as the mold is removed and treated with an antiseptic.

2. The first row of tiles is leveled and fixed to the wall through embedded elements using dowel-nails 6 × 40 mm on a brick or concrete surface or with a self-tapping screw for wood. The installation of the next row is carried out similarly to finishing with siding - the lower part goes into the lock under the previous row, and the upper part is attached to the wall with dowel-nails. This installation option is discussed in more detail on the next page - "Methods of fastening facade tiles".

The procedure for lining the basement

Before proceeding with installation, you should prepare the surface around the perimeter of the entire building: smooth the surface with a spatula; remove old finishing materials; to strengthen the reinforced mesh, which will ensure the reliability of the fixing of the tile to the plinth. The whole process of tiling the basement with tiles, see this video:

The base / plinth tiles have different shapes. This determines where and which tiles for facing the basement should be placed.

Work order:

- Having prepared the cement-sand mortar, you should add a little PVA glue to it.This will give it strength and provide a reliable connection between the facing surface and the material to be bonded.

- When using glue-cement, the thickness of its application should not exceed 5 mm. At the same time, it is recommended to apply it both on the surface of the basement and on the back of the tile.

- When facing, it is necessary to use special spacers for the device of an even seam horizontally and vertically.

For an even seam, special spacers are used

Clinker cladding

This material came to us from Holland. Natural stone is not mined there, so they had to make an artificial one from clay using high-temperature furnaces.

Benefits:

- the service life of the material can reach 40 years;

- high resistance to abrasion of the tile surface;

- frost resistance;

- does not absorb water;

- a large number of textures and colors;

- resistance to aggressive chemicals, which makes it suitable for use in large industrial areas.

There are practically no drawbacks, except that the strength of the clinker tile is slightly inferior to the stone one.

Types of facade tiles

It should be noted that the most popular and reliable materials for the manufacture of tiles for facade decoration are porcelain stoneware and clinker. Of course, you can decorate the walls outside the house with natural stone, to be more precise, with tiles from this material, but the cost of such cladding will be prohibitively high and not everyone can afford it.

Plus, cheaper counterparts have very slight differences in properties, but much cheaper. That's why they got such popularity.

Still, facing the facade with ceramic tiles is an even cheaper process, but such slabs do not have the same reliability and durability as porcelain stoneware slabs. At the heart of the standard materials are minerals, kaolin and clay, but due to some features of the production of porcelain stoneware itself, the strength of such tiles increases significantly.

Due to the fact that the tiles are pressed under very high pressure, even the smallest pores in the clay disappear. Also, porcelain stoneware is fired, and this leads to the fact that such tiles have only minor differences in characteristics from natural granite.