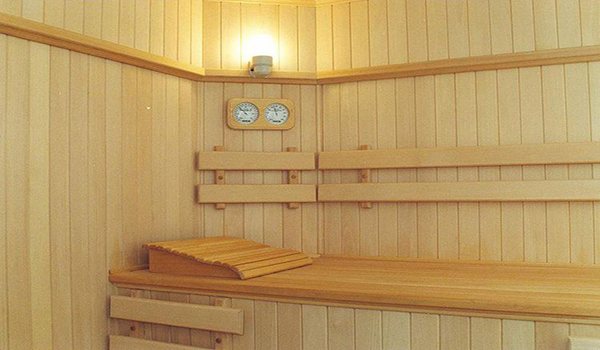

Bath visit good for your health, cleansing the body of toxins and just brings pleasure.

But just building a bathhouse made of bricks, foam or expanded clay concrete blocks will not be enough. Bath absolutely necessary insulate.

Various heaters are used for thermal insulation of the bath, but the most popular mineral wool and penoplex are considered.

Without insulation, the building warm-up time increases up to 3 times, and the cooling rate, on the contrary, will be quite high.

The advantages of internal insulation

Yes, yes, we will talk specifically about internal insulation, since this method has fundamental advantages over insulation of a bath outside. There are at least three such advantages that come to mind.

The first is the ability to reduce heat loss in an already built bathhouse, but during the construction of which, mistakes were made when insulating the foundation. This defect cannot be corrected by insulating the building from the outside, since the heat will escape through the floor, and it can only be isolated from the inside.

The second advantage is purely economic. Thermal insulation of a bath from the inside requires much less materials than full sheathing with thermal insulation and cladding of the entire building - the area of work is much smaller. In addition, insulating the bath from the inside, often the main work is carried out only in the steam room, which is even smaller in size.

Of course, other premises, such as the dressing room, the shower room also need to be insulated, but the degree of material consumption for them is several times less than for the steam room, therefore, all this takes an order of magnitude less money.

The third benefit only comes into play if the winters in your area are particularly harsh. In this case, the bath must be insulated both outside and inside, especially if the building is built of brick or aerated concrete. Even log baths, which are known for their thermal insulation properties without special treatment, in such winters will not do without additional internal thermal insulation.

Vertical lining

With this layout of the boards, the crate is installed horizontally. The bars are pretreated with impregnations against decay and pests. The locations of the guides are marked on the wall in increments of 40-60 cm. The dowel or self-tapping screw is deepened into the wall by at least 50 mm. If necessary, the hole is reamed.

Before fixing the lining, determine the most visible angle. The first profile is nailed. Alternately insert the board with a spike into the groove of the previous element, fix it with fasteners to the crate. Verticality is controlled by the building level.

The hardware is driven into the bottom shelf of the groove at an angle, the caps are recessed so that the crest of the next lining can freely enter the recess. The last board is trimmed to the size of the remaining piece and nailed down.

The choice of material for insulation

At the moment, a huge number of different heaters for walls are presented on the construction market. But not all of them are suitable for a bath. You need to choose thermal insulation based on two facts:

- The conditions in which the thermal insulation will fall;

- Characteristics of the insulation material itself.

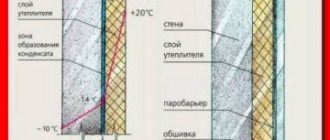

The first fact is the operating conditions. In the bath, they are more than aggressive, high humidity and temperature. Its big drops, especially in winter. From the street side, frost will "press" on the insulation, and on the other hand, heat. This combination will inevitably lead to condensation.

Related article: Eliminating the squeak of a plastic balcony door

In addition, the high temperature turns many popular insulation materials hazardous to human health. Also, do not forget that the bathhouse is a building with an increased risk of fire, so there is no need to insulate it with materials that burn well.

As for the characteristics of the material, they must correspond, again, to the operating conditions. To make it clearer, I will give an example of thermal insulation, which should not be used when insulating a bath. This material is ecowool. Yes, she is an excellent heat insulator, but her tendency to accumulate moisture spoils everything. When ecowool is wet, it loses its properties.

What materials cannot be used to insulate the bath?

In addition to ecowool, it should be a taboo for you to insulate the walls of the bath from the inside using foam, other materials based on it, such as penoplex, and also forget about using classic mineral wool as insulation. I explain why they are not suitable.

Polyfoam and all its derivatives at high temperatures begin to emit harmful substances that can lead to suffocation, in the conditions of the steam room this can not even be noticed. In addition, the foam burns well, which is not good.

As a binder in classical mineral wool, formaldehyde resins are used, their vapors are destructive to humans. Yes, all manufacturers declare that these fumes do not exceed the norm. But who cares if this is the norm of the poison. And besides, this norm stands out under normal conditions, and the bath does not differ in such.

What materials are suitable for insulation?

Among the recommended heaters, one can single out:

- Peat blocks;

- Sawdust;

- Fiberboard;

- Foam glass;

- Acrylic based mineral wool.

Peat blocks. This is regular peat mixed with natural fillers such as sawdust or straw. From these materials, they make "porridge" by dissolving it in water, using molds and a press, and produce blocks. They do not rot, do not burn, perfectly absorb, and also give moisture back. They have good heat and sound insulation.

Sawdust is a common production waste when sawing wood. Despite its small size, it is still wood, and it has good thermal insulation. The wall in the bath is insulated with slips, filling them into niches, which are previously covered with a vapor barrier and waterproofing.

Fiberboard - wood fiber boards, are nothing more than pressed wood chips. They have rather mediocre thermal insulation, but they are also inexpensive.

Related article: How to make a sliding table with your own hands

Foam glass. As the name implies, foam glass is foam glass with excellent thermal insulation characteristics. Does not emit harmful substances, does not burn, is indifferent to moisture. In my opinion, foam glass is the best option for warming a bath, but there is a drawback, like any other good product, the price for it "bites". But if the issue of saving is not an edge for you, then choose foam glass, you will not regret it.

Acrylic based mineral wool. These are the same slabs of mineral wool, with practically the same characteristics, but not emitting harmful substances. This is because the binder is not formaldehyde, but acrylic resin, which is absolutely inert to any chemical compounds and temperature extremes.

Insulation under the lining in the baths, built of different materials

How does the material of the walls affect the choice of thermal insulation? Let's sequentially consider the options of what a bathhouse can be built from, and compare the material and technology of insulation.

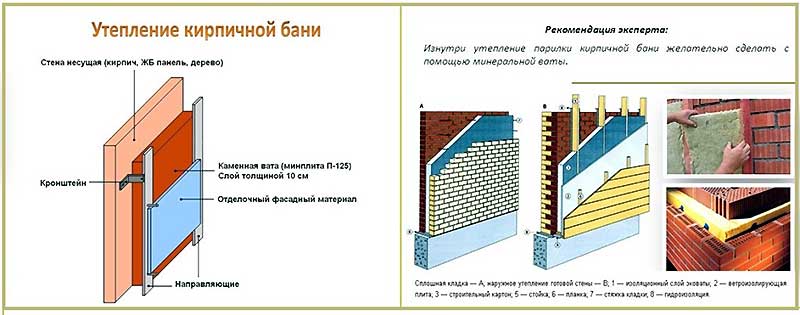

Brick

Brick baths - cold and non-flammable. The first circumstance prevents them from becoming traditional, because a cold bath (almost made of stone) needs to be heated for a long time, which is not particularly welcome in our high-speed age.

But the fact that it will not burn is a big plus, considering that the baths burn most often.

So, it is in order to reduce the disadvantages that thermal insulation should be used - it is most effective in this kind of buildings.

IMPORTANT! Thermal insulation of a brick structure can be not only internal or external, but also located between two layers of brickwork.

The latter circumstance increases the possibility of choosing a heater. Backfill expanded clay or ecowool Is a great solution. Ecowool, for example, is used in double-bar structures, and it has worked perfectly for decades.

You can also fearlessly fill the gap. polyurethane foam - it is expensive, it requires hiring a team with equipment, but it is reliable and safe, because polyurethane is flammable, and nothing threatens it in the gap between the brick layers, including ultraviolet light, which destroys it.

In other cases, the traditional mineral wool - most often, because, for all its shortcomings, it does not support combustion, and a high-quality one does not yet release volatile organic matter that is harmful to health.

More information about the technology of brick wall insulation can be found in this article.

Blocks

Of course, a brick is also a block, but in practice we often call products made of slag concrete, foam concrete, aerated concrete... Of course, they are larger and more like blocks, but they still have more internal similarities than with bricks.

The fact is that high-quality brick does not crack, holds fasteners well, does not pick up moisture. In essence, it is burnt clay, almost a stone. And concrete blocks either contain light (in terms of density) impurities in the form of slag, or foamed in one way or another, that is, they contain air bubbles.

You can learn more about the similarities and differences between various foam concrete and cinder concretes from here.

Both have a strong effect on a number of qualities. Substantially reduced thermal conductivity blocks, they themselves perfectly keep heat even without insulation. But most of them are afraid of water, all of them do not hold the fasteners well (hammering a nail into such a wall is problematic, but what can we say about fastening door frames, for example?). Breaking blocks is pretty easy.

But we are talking about thermal insulation. Do the blocks need it? Yes, in the bathhouse and living quarters, it is needed, especially if the climate is harsh. But in addition to thermal insulation, it is worth taking good care of waterproofing wall material. To do this, it is covered with all kinds of films and membranes.

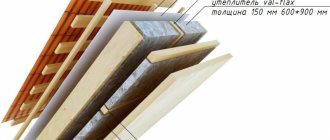

Thermal insulation technology "Pie"

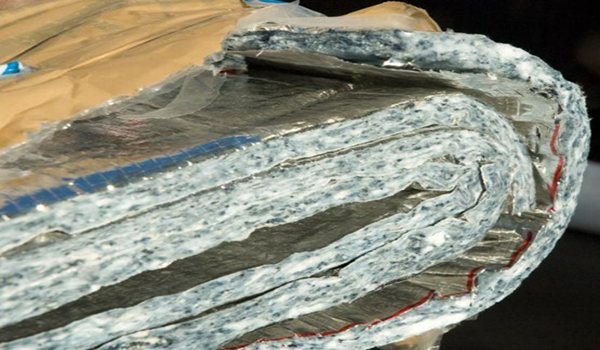

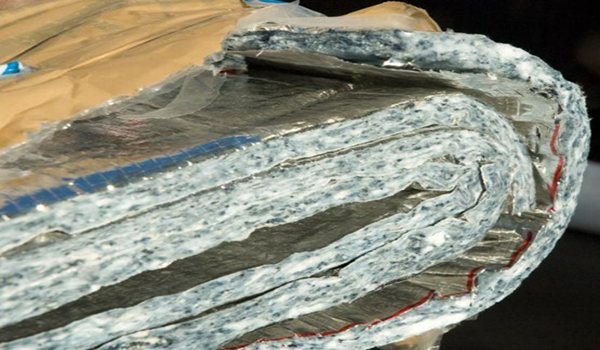

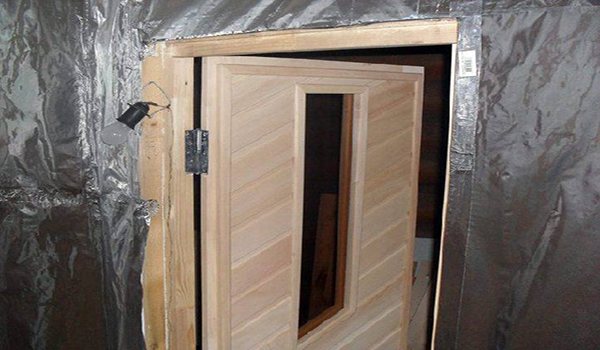

This technology has this name because of the several layers that make up the wall after the completion of the insulation work. The first layer is the load-bearing wall, the second is insulation, the third is the vapor barrier, and the fourth is the wall cladding, which is usually a wooden lining in the bath. To make it clear how to operate using this technology, I will give an example of how a bath can be insulated with mineral wool on acrylic resin.

The technology provides for starting insulation from the ceiling and ending with the floor. The "Pie" begins with mounting wooden blocks on the surface. They will serve as the basis for mounting mineral wool slabs, which, by the way, will be fastened to the spur, without the use of any additional fasteners.

In order for the insulation plates to reliably fall into place, the distance between the wooden bars of the frame must be 1 cm less than the width of the insulation, only in this case you can be sure that the insulation will not fall out. After the frame is ready, you can start stuffing it with thermal insulation. Make sure that during installation, the edges of the mats are not crushed, as this may negatively affect its properties.

Important: When installing insulation, all its component parts must fit snugly together.This is also necessary because if a gap remains between the plates, moisture will accumulate in this place, and a so-called cold bridge will form, through which heat will leave.

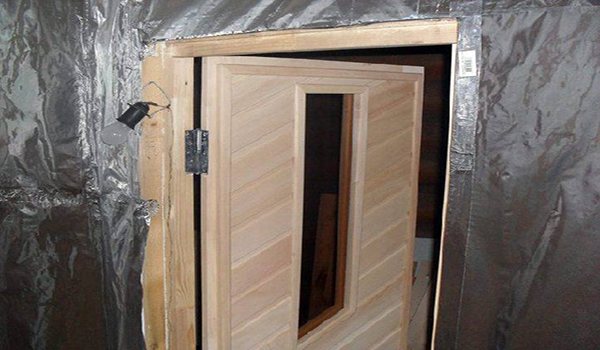

After installing the insulation, it must be covered with a vapor barrier. It can be a traditional roofing material or more modern foil vapor barriers. The side that is covered with foil must “face the interior of the room to reflect the heat back. All seams and joints of the vapor barrier must be sealed with aluminum tape.

Related article: Glue wallpaper in winter. Is it possible or better in summer?

Further, after all the seams of the vapor barrier have become airtight, you can begin to make the crate, on top of the vapor barrier, on the protruding bars of the frame. When installing, keep in mind that the distance between the vapor barrier and the future cladding should be at least 5 cm. This is necessary so that the condensate can drain freely, otherwise it will fall on the lining, which will quickly rot because of this.

Horizontal lining

The lathing is mounted vertically from the corners, observing a step of 40-60 cm. To fix the insulation, horizontal bridges are additionally nailed through 1.2 m or an additional frame is arranged so that the plates do not slide down. Before fixing the lining, lay a vapor barrier, heat insulator and waterproofing.

The installation of the lamellas starts from the top element, since the last bottom bar is usually trimmed. At the level of the ceiling, a whole lining looks better visually, and a board that is non-standard in width near the floor will be covered with a plinth.

When fastening the lining horizontally, the spike is directed upward. Gently tapping with a rubber-tipped mallet or hammer on the trimming of a wooden profile, set each subsequent board in place and fix it from below with fasteners. The first and last element, as well as short pieces less than 10 cm long, are nailed or fastened with self-tapping screws.

If the wall is sheathed from the bottom up, the board is fixed to the crate from the bottom side, and a self-tapping screw is screwed into the spike at the top with a head flush with the surface.

Features of steam room insulation

The main feature of steam room insulation is the concentration of insulation in this room compared to others. Since the steam room is the main room of the bath, it is necessary to create conditions so that as much heat as possible remains in the room, and at the same time ensure good ventilation.

In order to warm the steam room conscientiously, as already mentioned, you need to use high-quality thermal insulation, and observe the technology of its installation at all stages, from surface preparation and installation of the frame, to the last stage, wall cladding with wooden clapboard. Once again, I would like to emphasize the importance of a good sealing of the vapor barrier joints and a dense installation of insulation.

Sometimes it is permissible to use several layers of insulation, but even in this case, do not forget that you need to leave an air space between the vapor barrier and the finishing wall cladding.

Choose the right oven

The most popular sauna stoves are still traditional woodburning stoves. But today this is not the only possible option. Many owners choose electric ovens because of their ease of use and the ability to regulate temperature and humidity. Another modern solution is gas stoves: kindling does not require special skills, and the result does not depend on the quality of the firewood. But for safety reasons, only specialists should install such an oven.

Unlike a bath, the stones in a sauna lie outside, not inside the stove. The climate that is created in the steam room depends on the number of stones in the stove: the fewer stones, the faster the stove warms up and the drier the sauna. But whichever oven you choose, the main requirements for it are safety and reliability.This is especially true for electric furnaces: too powerful devices will require special additional electrical equipment, and low-quality ones can be potentially fire hazardous.

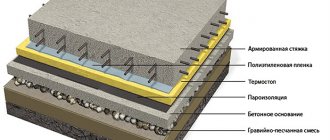

Insulation of the ceiling, floor and roof

Thermal insulation of all surfaces in the bath, technologically, has few differences. They consist of only a few nuances, and the basic rules are relevant both for walls and for a floor with a roof.

For example, as already mentioned, bath insulation starts from the top, that is, from the roof and ends with the floor, there are several reasons for this. Firstly, it’s more convenient, you see, it’s easier to go down systematically than to rush from the wall to the roof, and then to the floor.

Secondly, all surfaces must have uniform thermal insulation. That is, the heat-insulating materials should fit snugly to the same elements, but on a different surface, and the vapor barrier should also overlap onto the next surface.

For example, the thermal insulation of the roof and ceiling must be adjacent to each other, the vapor barrier on the ceiling overlaps the walls in order to further connect it to the vapor barrier on the wall using aluminum tape.

In turn, the thermal insulation and the vapor barrier of the walls are connected to the floor in the same way. Observing this technology, it turns out to achieve uniformity of thermal insulation and complete sealing of the room so that steam does not leave the room. The latter is especially true for the steam room.

How to insulate a bath from the inside

Thinking about the best way to insulate the bath from the inside, you should remember about the high level of moisture content in the internal space. Therefore, vapor barrier must be ensured. This will preserve the integrity and basic useful properties of the insulation material. The walls of the room will collapse less under the influence of moisture and high temperatures.

What is the best way to insulate the walls of the bath? The most convenient vapor barrier for a bath is considered to be aluminum foil. This material protects the heat insulator from destruction and helps to conserve heat in the interior of the bath. The seams between the sheets after the application of the foil must be sealed with a special metallized tape.

On a note! In different parts of the bath, there is a different level of moisture and temperature. Therefore, the decision as to the best way to insulate the bathhouse inside depends, first of all, on the specific room.

Various insulation materials are used, the technology of their laying is also different.