Advantages of foil insulation

Foil insulation protects any surface with high quality, reflecting heat and preventing it from escaping. His main advantages are:

- increased ability of foil-clad material to reflect up to 95% of heat;

- excellent waterproofing - foil-clad material retains moisture;

- such material does not freeze in winter and does not dry out in summer;

- provides excellent noise insulation - foil contributes to additional absorption of incoming noise;

- is an environmentally friendly material, safe for use in decoration;

- durable subject to correct installation;

- an excellent solution against moisture accumulation on the ceiling.

Ceiling insulation with foil insulation, in particular - penofol, is gaining popularity every year for various reasons.

Interesting that this material is new ultra-thin polymer insulation, which is made by foaming.

In this case, it is polyethylene foam welded to reflective aluminum foil. Excellent foil insulation is suitable for the ceiling inside an apartment or a private house - and, contrary to popular belief, for this purpose, you can use not only penofol or folgoizolone, but also basalt wool or polystyrene with metallized foil.

"FOLGOIZOLON" - SOLUTION OF COMPLEX PROBLEMS IN REFLECTIVE INSULATION

In modern conditions, the issue of saving energy used for heating buildings is of great importance. This problem can be successfully solved by using duplicated thermal insulation materials, spending not too much money at once on the insulation of walls, roofs and foundations.

Such materials include "Folgoizolon-l" and "Folgoizolon-m" offered by LLC "Lenta".

Traditional heaters do not retain thermal infrared radiation inside the building, which takes up to 25-30% of the total heat loss. "Folgoizolon-l" and "Folgoizolon-m" installed with foil inside the room, reflects up to 95% of this radiation, which reduces heat loss of enclosing structures and building elements.

Polyethylene foam duplicated with a metallized film on a lavsan base is one of the most effective types of thermal insulation, in some cases, due to the effect of light reflection, it surpasses even polystyrene foam and polyurethane foam. Its use is preferable in combined structures together with other thermal insulation and building materials.

The aforementioned advantage of "Folgoizolon-l" - (metallized with a film on a lavsan base) is achieved by the fact that its base - "Izolon" is a unique material that has practically no analogues in the Russian building materials market. It has a closed-cell structure, that is, it is an oil-, gas-, steam-, moisture-resistant material, the temperature regime of application is from - 60 to +95 ° С, an excellent heat insulator - a thermal conductivity coefficient of 0.031 W / (m K), an excellent sound insulator - sound absorption up to 60% at 6000 Hz.

"Folgoizolon-m" - (laminated with metal foil) - application mode from - 80 to + 105 ° С, thermal conductivity coefficient 0.038 W / (m · K), sound absorption up to 50% at 6000 Hz. They are hygienic, environmentally friendly and harmless to use.

The lavsan metallized coating "Folgoizolona-L", according to the Mosstroy Research Institute, does not corrode, which makes it possible to safely use this material under a concrete-cement screed (resistant to aggressive media - alkali and acid, unlike aluminum foil), and amounts to " Isolon "or" gas-filled NPE "homogeneous layer.

"Folgoizolon-l" and "Folgoizolon-m" allow, with a small thickness and minimal heat loss (thermos principle) in summer, to significantly reduce overheating under the roof, and in winter not to let cold air inside and not to let out warm air.

Scopes of materials with Mylar-based metallization:

- Decoration of walls, floors, ceilings, roofs, attics, mansard and basements;

- Insulation in the "Heat-insulated floor" system;

- Reflective insulation behind heating radiators;

- Insulation of pipelines, tanks and fittings in water supply and heating systems;

- Insulation of air ducts in ventilation systems;

- Insulation of refrigeration units;

- Insulation of bodies of cars and trucks.

To achieve the effectiveness of insulation, it is imperative to provide an air gap of at least 2 cm between the reflective surface of the material and the next layer of the structure.

Insulation of the ceiling with isolon

Izolon is a brand under which polymer materials with a closed-cell structure are produced for insulation, sound and noise insulation. There are several product lines:

- adhesive tapes;

- isolon 100 - non-cross-linked polyethylene foam;

- isolon 300 - foamed chemically cross-linked polyethylene;

- isolon 500 - physically cross-linked polyolefin foam;

- reflective insulation - foamed polyethylene (metallized lavsan film).

- the density of the material is 25-100 kg / cubic meter;

- does not allow water and steam to pass through;

- has low thermal conductivity;

- foil material reflects 97% of infrared radiation.

Thermal insulation with isolon as an independent insulation gives insignificant results due to its small thickness.

In this case, in addition to the auxiliary protection of heat loss, the expanded polyethylene will perform the function vapor barrier... Glass wool, laid on the ceiling, is prone to absorbing moisture from the air, which makes insulation with isolon not so much desirable as necessary.

- mineral wool is laid between the ceiling joists;

- the isolon is fastened tightly along the lags;

- the crown lattice is stuffed;

- the final stage is the laying of the finish.

It is permissible to lay an isolon as a sound insulator directly under the finish. To do this, the material is fixed joint to joint on the working surface using a construction stapler, and the joints are sealed with tape.

Even in the presence of moisture on the insulator, it will successfully evaporate without being absorbed into the finishing materials.

Correct insulation of the ceiling in a private house. Ceiling insulation

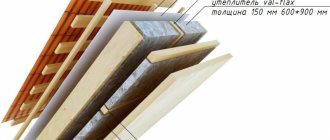

Consider the process of insulating the attic ceiling with mineral wool. The technology differs based on specific designs and selected schemes.

Outside

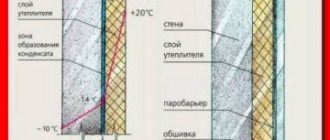

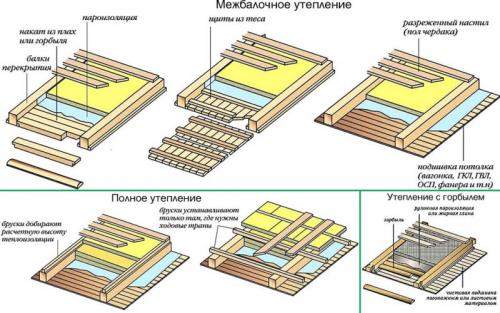

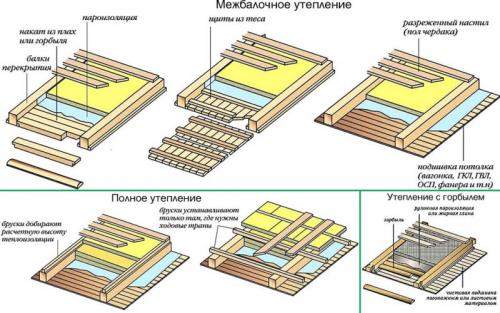

The easiest and fastest way of thermal insulation is interbeam. If the ceiling is made of massive boards, the vapor barrier must be wrapped around the beams or wrapped around the beams. If the ceiling is made of thin lining or planks, the foil vapor barrier film is attached below the beams, along the ceiling.

Methods for insulating a wooden ceiling from an attic

A complete insulation scheme requires significantly more labor, materials and time, but it is also much more effective. A double layer of slabs is added to the interbeam layer of rolls or mats. Layers need to be overlapped.

How to insulate a cold ceiling from the inside

choosing a way to insulate the ceiling from the inside, you need to understand that any of them will reduce the height of the room. The minimum height loss will be in the case of a stretch ceiling or plasterboard suspended ceiling. In this case, thermal insulation plates can be laid between the guides of the metal profiles.

Fastening basalt wool on disc dowels

If a suspended ceiling is not planned, then the insulation plates can be fixed in various ways:

- Still, make guides from wooden slats or metal profiles.

- Fix the panels with special disc dowels. One 1200 * 600 mm mat requires at least 4-5 dowels

- Glue to the overlap with mastic.

A reinforced mesh is glued to the lower part of the insulation, and a leveling primer and layers of paint are already applied to it.

No attic

When insulating buildings without an attic, in addition to solving the problem of preserving heat itself, it is necessary to ensure the removal of excess moisture, both contained in the air in the form of vapors and condensing on cold surfaces.

Folgoizolon - foil insulation for the ceiling

Folgoizolone is a fairly new insulation on the market that provides high-quality heat, moisture and noise insulation. The basis of the material is polypropylene or foamed polyethylene. Based on this, two types of products are distinguished, denoted by PPE and IPE.

- lightness of material, which makes it possible to trim any basis, provided that there is no need for preliminary measures to strengthen it;

- small thickness - does not reduce the size of the room, while maintaining its useful area;

- elasticity - unlike some heaters (such as polystyrene foam boards), this foil material allows you not to waste time on careful preliminary alignment;

- multifunctionality, or a combination of "3 in 1", contributes to a significant reduction in the cost of purchased materials (mastics, films, fasteners, etc.) and a reduction in construction or repair time;

- ease of cutting - foil-insolon can be easily cut with a sharp knife, which eliminates the need for a specialized tool;

- lack of moisture absorption - one of the most important factors ensuring the extension of the operational life not only of the foil insulation itself, but also of the structural elements covered by it;

- environmental Safety - does not emit harmful substances even at temperatures above 100 ° C. Among other things, insects or rodents will never start in this material.

So, is it possible to insulate the ceiling with foil insulation? Considering the material above, we can safely give a positive answer.

Foil insulation - purpose and properties

The main property of folgoizol is reflected in the name - heat preservation. Unlike most analogs, insulation with aluminum foil consists of two components: in addition to a metal strip, it contains a mineral base. It is represented by three main types of polymers:

- Polyethylene foam is the cheapest version of foil insulation and the thinnest of its types. Its thickness is 2–10 mm. Most often, foil-clad polyethylene foam is used as a substrate for a laminate.

- Fiberglass is the most commonly used in construction. In addition to the ability of the metal to reflect heat inside, this type of thermal insulation perfectly prevents the penetration of cold from the outside. This is achieved due to the low density of the fiberglass sheet, which has an air gap between the thin threads. This foil insulator is used to insulate floors, walls and ceilings of buildings.

- Stone wool is intended for use in extreme temperature conditions: thermal packaging of pipes, saunas, steam rooms in baths.

The vast majority of all these materials are covered with aluminum foil on one side. The only exception is polyethylene foam: some seals are metallized on both sides.

Insulation of the ceiling with foil insulation

Foil sheets should be spread over the ceiling surface so that the foil "looks" into the room. After that, the insulation must be pressed with a clamp rail. The foil layer serves to reflect heat radiation, which can be used as an additional advantage if foil insolon is used together with foam or foam. In this case, the foil-clad material will act as a vapor barrier.

Useful video

Let's look at the video what types of foil insulation are:

Thus, it is best to use foil insulation for internal insulation of the ceiling.The unique characteristics of this product, elasticity and lightness ensure its demand in the market.

Polyethylene foil insulation has gained such widespread popularity that the name of the famous brand - "Penofol" - has become a household name. But often homeowners and would-be craftsmen use the material thoughtlessly, violating the thermal and humidity regime of the operation of a country house. Sellers are also cunning, greatly overestimating the real performance of this heat insulator. Let's clarify the situation: we will tell you where Penofol insulation is effectively applied and describe the technology in detail according to the manufacturer's instructions.

What is "Penofol" and its analogues

Thin polymer insulation is made from the following materials:

- The main insulating layer is 3 ... 10 mm thick foamed polyethylene with closed air pores. The thermal conductivity coefficient λ of this interlayer lies within the range of 0.037—0.051 W / (m • ° С), depending on the operating conditions.

- The outer reflective layer is 14 micron thick aluminum foil, securely glued to the polymer base.

- The third layer on the back of the polyethylene can be glue for ease of installation, or the same aluminum.

Reference. All specifications are taken from the manufacturer's official website. Thermal insulation performance of other brands may vary. For example, the thickness of a similar material reaches 150 mm.

The peculiarity of the material is impermeability to moisture, the declared indicator is simply scanty - 0.001 mg / m • h • Pa. The insulation is quite light - the density is in the range of 16 ... 35 kg / m³, it is sold in rolls. Due to these parameters, the material serves well as an internal vapor barrier.

Penofol is available in 3 versions:

- two-layer type A;

- three-layer - the base is covered with aluminum on both sides (type B);

- the same, with an adhesive layer - Type C.

The foil side acts as a reflector of the radiant (infrared) component, the polyethylene foam resists direct heat transfer. For wall cladding outside, the perforated version of "Penofol" is offered, shown in the photo. Many small holes are intended for the escape of water vapor from the thickness of building structures.

The outer wall cladding is made with a special perforated insulation

Features of the use and installation of foil insulation

The most important point for using all the best qualities of the material is the direction of laying - with foil inside the room. The maximum efficiency of an aluminum thermal reflector is achieved if there is an air gap of 20–30 mm between it (foil) and the decorative facing of the walls or ceiling. To do this, it is enough to mount the frame from the rails directly on the foil insulation. It is better to lay the sheets of insulation end-to-end, and not overlap. The seams are connected and sealed with foil tape.

Conflicting reviews about the benefits of a foil underlay for laminate flooring are caused by the lack of a recommended air layer between the metal and the bottom of the flooring. However, experience shows that the thermal effect is also present in this case, especially on unheated floors or when assembling a laminate on a balcony. As a compromise, it is possible to lay a fine paint net on foil.

It is worth choosing a heater with aluminum foil depending on the repair area. For walls and ceilings, fiberglass foil insulation is used, and in rooms with high humidity and open fire, it is safer to lay stone wool. Any type of insulator against cold, noise and moisture is easy to install on your own, however, if you have no experience, it is better to turn to professionals.

Real characteristics of thermal insulation

At the beginning of the publication, we mentioned the overestimation of the operational parameters of the material by unscrupulous sellers. Common myths about the properties of an insulator look like this:

- The innovative insulation "Penofol" has the best thermal insulation characteristics. The thermal resistance R of a sheet with a thickness of 4 mm reaches 1.2 m² • ° C / W, which is comparable to the laying of red brick 0.67 meters or 46 mm of expanded polystyrene.

- The "Penofol" layer serves as an excellent sound insulation.

- The insulation can be freely poured with a cement-sand screed, expanding the foil upwards.

Backside adhesive (type C)

Reference. The manufacturer claims: for the most efficient operation, the heat insulator must be placed inside a closed air gap. When mounted close to other materials, the aluminum coating will not perform its function of reflecting radiant heat. Infrared waves can travel through open space, but not through concrete.

The heat transfer resistance of one insulation layer is easy to calculate using the classic formula from the course in building thermal physics:

- R is the value of the thermal resistance of the material, m² • ° С / W;

- δ - insulation thickness, m;

- λ - coefficient of specific thermal conductivity, W / (m • ° С).

Substituting the manufacturer's data in the formula (we take the best option), we get R = 0.004 mm / 0.037 W / (m • ° С) ≈ 0.11 m² • ° С / W. Knowing the thermal conductivity of the foam (λ = 0.043), it is easy to determine the corresponding layer thickness: 0.11 x 0.043 = 0.0047 m = 4.7 mm. Roughly speaking, 5 mm of expanded polystyrene and 4 mm of expanded polyethylene will keep the same amount of heat, there is no talk of any 46 mm.

Scope of application

With the help of Penofol, you can significantly increase the energy efficiency of any home - a private house or apartment. Where the material is applied:

- thermal insulation of the roof of the attic or cold attic;

- cladding of ceilings and walls from the inside - as an addition to the "pie" of the main insulation;

- under a fine floor covering, laid on logs;

- strengthening of the outer heat-insulating layer;

- internal insulation of balconies and loggias;

- covering heating pipes and ventilation ducts.

Addition. "Penofol" type C (adhesive surface), many drivers insulate the car body - interior floors, doors and roof. The cut blanks are glued to the metal over the bitumen vibration isolation.

It is undesirable to use the material as an independent insulation for external fences - you will not achieve the desired effect, just protect the building from being blown by the wind. The exception is products of great thickness from 20 to 150 mm of the Tepofol brand, suitable for complete insulation of a house.

Insulation technology

Knowledge of the correct use of the material will come in handy in any case - you are going to isolate the house with your own hands or hire a team of performers. It is important to comply with 2 conditions:

- An air gap is made between the foil side of the insulation and the adjacent surface. Then "Penofol" will reflect about 95% of infrared heat radiation.

- The porous polyethylene base should not be squeezed by external static load. Short-term dynamic impact is permissible. Example: laying the material under the laminate as a heat and sound insulation underlay.

Note. It is important to observe the requirement for the arrangement of an air gap when insulating a wooden house. It is well known that the porous and "breathable" structure of wood does not tolerate long-term contact with any moisture-proof polymers and gradually begins to rot. The interlayer acts as a ventilation duct that removes water vapor.

Now let us analyze separately the thermal insulation of various building structures using Penofol.

Ceiling and roof cladding

Preliminary insulation of the attic roof slopes is proposed to be done according to the following scheme (shown above in the drawing):

- On top of the rafters, waterproofing is laid horizontally - a diffusion membrane, the minimum overlap is 100 mm. The order of attaching the canvases is from bottom to top.

- The membrane is pressed against the beams by counter-lathing bars, the horizontal boards of the main lathing are nailed to them. A roof covering is mounted on top - metal tiles, slate, profiled sheet and so on.

- From the inside, horizontal beams 50-60 mm thick are attached to the rafters, the installation pitch is 60 cm.

- A three-layer "Penofol" type B with two foil surfaces is targeted at the bars. Note that thin insulation bypasses the rafters so that there is a gap on both sides.

- Internal cladding is screwed vertically to the ends of the bars - lining, moisture-resistant gypsum board, chipboard panels or other finishing materials.

Attention! A roll of "Penofol" is rolled vertically on the surface, adjacent canvases are stacked end-to-end, not overlapping. Carefully glue the seams with aluminum tape.

In this case, the insulation reflects heat flows from both sides, which is very useful in the summer, when the metal roof gets very hot. The inner layer remains unventilated, moisture from the outer air is removed through the membrane. Since "Penofol" serves as a barrier to steam, in the attic it is necessary to organize a natural exhaust through a separate ventilation duct.

Please note that an inaccuracy was made in the drawing above - there is no external counter-grill, which creates a ventilation duct above the superdiffusion membrane. In the next version of the diagram, which shows the insulating "pie" of the attic roof, the frame of the lathing is clearly visible. What is the difference between this sheathing method:

- Between the rafters there is a thick layer of the main insulation - 120-200 mm of mineral wool.

- The bottom of the mineral wool is hemmed with a two-layer "Penofol" type A right along the ends of the beams. The aluminum faces into the attic room, the canvases are turned horizontally.

- Between the polyethylene and mineral wool insulation, a gap of 2-3 cm is left, from the side of the foil - about 4 cm.

- Bars for interior decoration are nailed to the ends of the beams directly through the polyethylene layer.

The foil surface faces the inside of the room, a gap is provided between it and the cladding

The section clearly shows that "Penofol" plays the role of an additional insulator and vapor barrier - the traditional film from the inside is not used. The moisture formed in the mineral wool is removed through the upper air and the waterproofing membrane. Vapors from human activity are removed by supply and exhaust ventilation.

Advice. When working with Penofol, it is important to understand the essence: we always leave a layer in front of the foil, lay the polyethylene base close to the building structures. We connect the canvases only end-to-end.

Ceilings are insulated according to a similar principle:

- If from the side of the attic the wooden floor is covered with expanded clay, sawdust or reeds, it is enough to lay 1 layer of "Penofol" type B, making gaps with the help of the lathing.

- Type C material can be glued directly to the concrete ceiling, foil downwards. Next, mount the frame for attaching the gypsum board or other finish.

- When capital insulation of the ceiling is required, use an attic scheme, only without the membrane and outer sheathing. Install a frame made of beams or galvanized profiles, insert the main insulation between them, then hem the bottom with type A polyethylene foam.

If Penofol is the only heat flow insulator (which is not always correct), choose the maximum material thickness - 8 ... 10 mm. In tandem with other heaters, a sheet with a thickness of 3-4 mm works well. For more details about the device of the attic roof, see the video:

Thermal insulation of walls

If you have carefully studied the previous section, you will quickly understand how to insulate walls with Peonofol.Typically, the material is used for interior cladding in 3 ways:

- with one air gap on the frame made of a bar 2-3 cm thick;

- with two vents along the lathing from a bar of 40-50 mm;

- as an internal vapor barrier as part of a full-fledged "pie".

An important point. To insulate the walls from the inside, it is better to use moisture-proof materials - extruded polystyrene foam or sprayed polyurethane foam. The dew point will surely fall into the thickness of the insulator, but the steam will never escape from the smallest closed pores. By the way, it is better not to buy polystyrene - it is capable of passing moisture.

In lumber, log and frame houses, "Penofol" must be fastened with a stapler to the crate in order to provide a 2-3 cm void on the aluminum side. Fences made of foam blocks and aerated concrete with open pores are sheathed using a similar technology.

User reviews about "Penofol"

It must be admitted that on popular forums there are very diverse responses and opinions of homeowners about reflective polyethylene insulation. We would venture to suggest that the negative or positive in the comments depends on the correct use of the material.

Here are a few examples, discarding deliberately purchased reviews:

Vyacheslav, Donetsk, Ukraine.

Recently, in order to repair it, it was necessary to open the plasterboard wall cladding inside the room. Behind it was a foil-clad Penofol covering a plastered cinder block wall. There was dampness and black mold under the insulation, all the cladding had to be dismantled and the walls dried.

Ivan, Veliky Ustyug, RF.

He lined with "Penofol" 5 mm cold veranda made of wood. I pinned it with a stapler to the walls and ceilings, laying sheets of chipboard. This winter I calmly opened the door to the veranda, not being afraid to cool the house, the temperature outside was minus 40 degrees. Sometimes he drowned the extension with a potbelly stove to dry the walls.

Natalia, Lipetsk, RF

No matter how they insulated the northern wall of my private house, I could not get rid of the mold. We tried cotton wool, polystyrene, all kinds of waterproofing. A father-in-law, a builder, came to visit, he redid everything and reveted it with this brilliant material. The result after opening (after a year) - the wall is dry.

While looking for video material for publication, we came across an interesting moment confirming our assumptions. The installers are well aware of the recommended methods of using Penofol, but in practice the technology is constantly being violated. The reason is clear: the device of a double lathing for the sake of a thin layer of insulation is economically inexpedient. It is better to mount on the subsystem a full-fledged thermal insulation made of basalt wool or "Penoplex" without any frame.

Finally, about other use cases

Domestic craftsmen use polyethylene foam insulation for a wide variety of purposes:

- frost protection of heating pipes and hot water supply;

- interior decoration of the door leaf;

- reflective screen glued to the outer wall behind the heating radiators;

- inexpensive thermal insulation of outbuildings - sheds, workshops, garages;

- exotic - shoe insoles made of thin-sheet insulation 3 mm.

Polymeric insulator "Penofol" is a material that deserves attention. When applied according to the instructions, it will serve as a good insulation. But do not try to save money and solve all thermal insulation problems at the expense of one thin polyethylene, use other effective insulation materials.

Today we will tell you on what principle reflective insulation works and on which side to lay the insulation with foil. These two aspects simply cannot be separated, because if the installation is incorrect, foil insulation simply does not work. In addition, we will tell you about the archival aspects of installation and their effect on heat loss and indoor climate. And of course, we will conduct our educational program separately for each type of insulation with foil.These include polystyrene in sheets, mineral wool in sheets and rolls, foamed polyethylene in rolls, as well as shells for insulating pipes made of expanded polystyrene and mineral wool.

How to properly lay styrofoam with foil

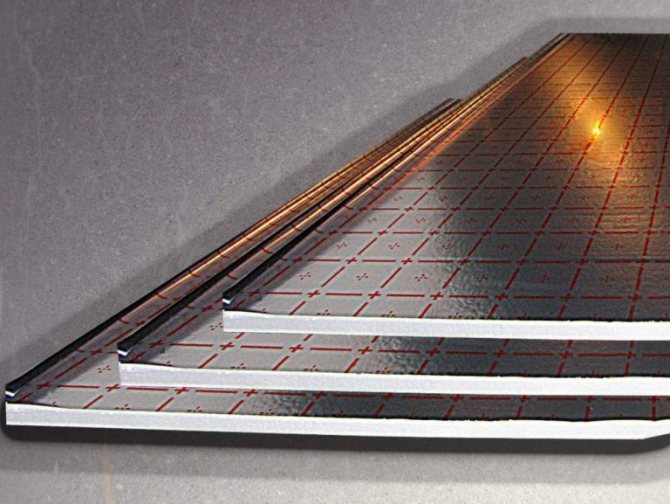

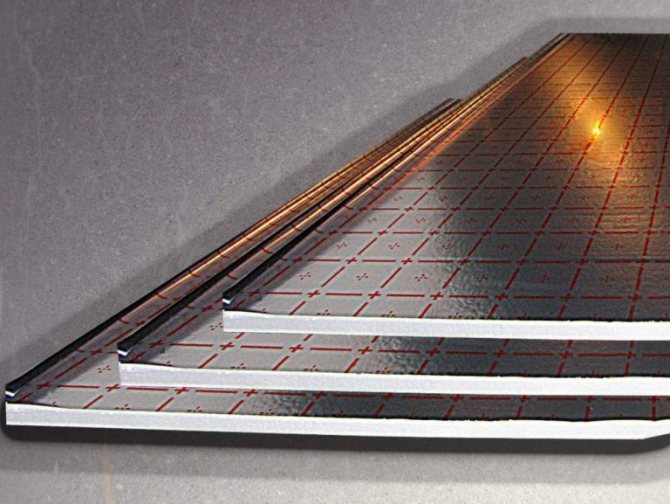

Expanded polystyrene mats for floor insulation and subsequent installation of a low-temperature "warm floor" system.

Consider which side to lay the insulation with foam foil in the narrow direction of installation of low-temperature heating systems, that is, warm floors. Now you can find on sale special foam mats (sheets), which are covered with foil on one side. In addition, markings are applied on the foil for laying polymer pipes or electric cables. As you know, heat sources during the installation of underfloor heating must be at a certain distance from each other for the system to work correctly.

In this case, the most important role is played by insulation with foil, how to fix it correctly is the key point. Reflective insulation works by reflecting infrared rays, that is, heat. It beats off up to 97% of all IR radiation like a mirror. Naturally, the reflected rays must return back to the room, so the logical conclusion on how to lay the foil insulation suggests itself. Of course, the reflective surface is inward.

Technique how to lay insulation with foil for warm floors:

- the sub floor is leveled;

- foiled foam plates are glued to construction glue;

- a cable or pipes are laid according to the marking;

- everything is filled with a screed with a reinforcing mesh.

Another important point on how to properly lay insulation with foil: the plates should fit snugly to the floor. It happens that due to the unevenness of the mats themselves, they lie unevenly on the floor, even if it is perfectly flat. To correct the situation in places where the thermal insulation does not fit snugly, it is simply cut. That is, several smaller ones are made from one sheet, while the operation is carried out already in place, after the mats are laid.

Considering the principle by which foil insulation works, which side to put is easier to figure out. Reflective insulation should reflect infrared radiation into the room, respectively, it fits with the shiny side in the middle.

Such plates are used only for floor insulation, they are not used for walls and ceilings, since there are thermal insulation options specially designed for this. These include:

- mineral wool in mats and rolls with one-sided or double-sided foil;

- foamed polyethylene with foil.

By the way, ordinary foam or its extruded analogue in tandem with foam foam perfectly replaces mats for floor insulation and further installation of a low-temperature floor heating system. The only inconvenience is the lack of markup.

If you have to build a private house, then water heating will be the best option for heating it. There are, of course, air, steam and electric heating, but they cannot compete with a liquid heating circuit.

The two-pipe scheme of water heating of a two-story house can be vertical and horizontal. Drawings with explanations here.

What is foil isolon and how does it differ from usual

Important: Since foamed polyethylene has a low melting point, Folgoizolon does not insulate high-temperature objects - gas and solid fuel boilers, chimneys of private houses. The heat-insulating Folgoizolon presented on the construction market has the following characteristics:

Do not confuse Folgoizolon on a polyethylene foam basis and Folgoizol, the technical characteristics of which are regulated by GOST grade FK and FG roofing and waterproofing, its basis is a bitumen-rubber or bitumen-polymer binder, covered with aluminum foil on top.Watch this video on YouTube Installation features One of the main disadvantages of foamed polyethylene is insufficient rigidity, this narrows the scope of its use and imposes certain restrictions on installation work, the basic rules for which are:

One of the best options for using Folgoizol is to lay it first on the inner surface of a wall or roof slope with a foil layer outside, then mineral or glass wool is placed on it.

This provides steam and moisture protection of mineral wool that absorbs water well and significantly reduces heat loss from infrared radiation. Various types of Folgoizolon are sold on the market, the price of which depends on its parameters - the thickness of polyethylene foam, reflective film made of aluminum foil, manufacturing technology, the cost of some brands:

Polyethylene foam insulation Izolon PPE

Watch this video on YouTube Folgoizolon is one of the many brands of polyethylene foam based insulation widely represented in the domestic market, which has earned positive feedback from consumers, its use is advisable as an auxiliary insulation to reflect the infrared spectrum of thermal radiation, as well as in places where the thickness of the layer plays significant role.

Most often, the material is used on floors as a heat-reflecting underlay for laminate, board, hot water pipe or electrical wiring for underfloor heating.

On the modern building materials market, new products are constantly appearing, differing in technical characteristics and scope. If we talk about heaters, then the latest novelty was foil-insolon, that is, foil-clad isolon. It is really irreplaceable in modern mechanical engineering and construction. Folgoizolon is a foamed polyethylene covered with a polypropylene film.

Do you need windows installation? Foil insulation is made on the basis of various porous materials, on which a metal layer is applied to reflect thermal energy.

Types of foil isolon

Such insulation works on the principle of a thermos, reliably retaining heat inside the room. Metal is able to reflect heat and prevent blowing, which is important when using metallized insulation when carrying out work on exterior decoration.

Hello, today I would like to tell you about such a "universal" material as folgoizolon. Let's first figure out what it is in general. Folgoizolon is foamed polyethylene covered with polypropylene film or aluminum foil. Foamed polyethylene itself has a cellular structure, thanks to which it does not absorb moisture, but at the same time it is a vapor barrier. One of the most common myths about this material is that it can be used as an "independent" insulation.

One of the advantages of foil-clad heaters is the thickness, which starts from 1.5 cm. The most common aluminum heaters are 0.5-1 cm, also 5 cm or more.

Even the minimum thickness of the material is sufficient to reliably protect the room from unnecessary heat loss. Let us consider in more detail the general characteristics and advantages of metallized heat-insulating material:

This is interesting: there is an opinion that a foil-coated heat insulator slightly protects against the penetration of radioactive particles into the room. As a result, all the advantages of foil insulation allow you to save money during the construction and further operation of the premises, since heating costs will decrease.

There are a lot of heaters with a foil layer.Almost every manufacturer of thermal insulation materials has a foil-coated line, and everyone calls their products differently, respectively, the same material may have a different name. Folgoizol, foiloplast, energoizol, all of these are practically the same material. The most popular foil-coated material is made on the basis of polyethylene foam.

It can be two or three layers.

ABOUT MATERIAL

It is used everywhere, in the construction of houses, baths, saunas. Also used for soundproofing and insulating cars. Can be used as a backing for laminate and other flooring. The thickness of the foil coating rarely exceeds 15 microns. The foil layer can be applied on both sides of the insulation, due to which the material is able to reflect both internal heat and cold penetrating from the outside of the room.

The base made of foamed polyethylene is environmentally friendly, does not rot and resists moisture well.

Which side to attach the foamed polyethylene with foil

When the question arises of how to fix the foil insulation to the wall, then most often we are talking about penofol. This is an insulation that consists of two layers. The first layer is polyethylene foam and the second layer is foil. In addition, there are products in which the foil is on both sides. The reflective surface can be glossy, like a mirror, or wrinkled (embossed). It is believed that the relief allows you to slightly increase the reflection area, but not critical, so there is not much difference.

Unlike mats for floor insulation, regarding penofol, the answer to the question: "Which side to fasten the insulation with foil?" sounds like this: the base (foamed polyethylene) to the wall or other insulation.

The thing is that this material is used for both internal and external insulation. It turns out that during the thermal insulation of the facade, it will not work to put the penofol with the shiny side inward, it will look outward. What will it give us:

- such insulation will not reflect heat from the room, since there is no ventilation gap between the foil and polyethylene;

- the insulation will not let the summer heat into the house.

Two-layer reflective insulation, where polyethylene foam acts as a damper and reinforcement.

It is because of the absence of any significant displacements in the direction of increasing the thermal insulation qualities of the room that experts do not use penofol for external insulation. How to properly lay foil insulation penofol:

- you need to put it from the inside of the room with the shiny side to the heat source;

- there must be an air buffer zone (ventilated gap) between the foil and the trim;

- the material is stacked end-to-end;

- fastened with either studs or staples;

- the joints are glued with aluminum (not ordinary, namely aluminum) tape.

These manipulations are performed in order to create a sealed reflective screen, which additionally acts as a vapor barrier, since it does not allow steam or moisture to pass through. Why, answering the question of how to properly lay insulation with foil, do we emphasize the ventilation gap? The fact is that without it, the material will not perform its functions. The air space allows the foil to repel exactly the infrared radiation from the front standing structures (drywall, lining, siding, whatever).

If there is no air gap, then the heat will be transferred to the foil not by means of infrared rays, but by direct contact of materials. The thermal conductivity of aluminum is extremely high, therefore, the process of heat removal outside the premises in this case will even accelerate. A thin layer of foamed polyethylene does not create a special barrier to heat loss, and its main function is different: it acts as a damper and reinforcement for foil, everything else is indirect.

This will create an undesirable side effect - condensation. The foil does not allow steam to pass through, and it settles on it in the form of condensation. If there is a ventilation gap, then the micro droplets of moisture simply evaporate. In the absence of an air buffer zone, moisture collects and absorbs into the finish, causing fungus to appear. This is what ignorance of which side to put the insulation with foil can lead to.

Despite the fact that there is plenty of information about heating a house from vulture panels, many can still decide on the method of heating a home from this material. Although there are many approaches that have a lot of advantages and benefits.

You can find all the necessary information about convector heating at home with photos and videos on our website by clicking on this link.

Varieties of foil insulation

At the present time, there are several types of this material. They differ among themselves not only in the density of the upper layer, but also in the type of heat insulator.

The main types of foil-based insulation:

- Polyethylene foam (isolon, penofol, fogoizol)... This type is produced in rolls. The material is distinguished by a low price. Foamed polyethylene is used to create insulation. It can be either stitched or not stitched. The thickness of the canvas ranges from 3 to 10 mm. A distinctive feature is the presence of a self-adhesive surface. Some types of foamed polyethylene foam have a reinforced layer that is made of fiberglass mesh. As for the foil layer, it can be either on one or on both sides.

- Mineral wool... The material is distinguished by high rates of moisture resistance. Foil mineral wool is sold not only in rolls, but also in the form of slabs. Basalt is often used for its production. Thanks to him, the service life of the canvas increases significantly. The material is used everywhere. This is due to good thermal conductivity and fire safety.

- Styrofoam... Such foil insulation is intended for the "warm floor" system. Its density ranges from 30-50 kg / m. It is produced in the form of rolls with a width of 50 cm. The thickness of the canvas is in the range from 3-5 mm.

Foil polystyrene with markings

Important! Any type of material acts as an excellent sound insulator.

With proper use, each type of foil-clad insulation will perform its functions as much as possible. To get what you want, you just need to follow simple rules.

What to glue mineral wool with foil

Foiled mineral wool is produced in rolls and sheets. It is attached with a universal construction adhesive.

Mineral wool with one-sided and double-sided foil is produced in rolls and sheets of different thickness. Mineral wool means all its varieties: from glass wool to basalt wool. It, like polystyrene, is glued to the wall and additionally reinforced with dowels. What to glue insulation with mineral wool foil on? For work, a universal plaster-adhesive mixture is used, which is suitable for both cotton wool and expanded polystyrene.

When choosing how to glue foil insulation, you need to consider only high-quality mixtures from leading manufacturers:

If the surface on which the insulation is heated is even, then the glue is applied with a layer of 3 cm with a notched trowel around the entire perimeter of the insulation sheets. If the cotton wool is glued to an uneven surface, then the glue is applied 4 cm thick with flat cakes, the diameter of which is at least 10 cm.

In addition, before laying the insulation with foil, you need to clean and prime the work surface for better adhesion. Again, we remind you about the ventilation gap and that the reflective foil should look inside the room. For external insulation, such material is not used, since it is impractical.Mineral wool with foil is suitable for baths, as it is resistant to high temperatures, but it is afraid of moisture, so it must be protected with a vapor barrier. This does not apply to stone wool, as it practically does not absorb moisture.

Which is better - foil foam or basalt insulation?

The building materials market is full of types of insulation. They have their own characteristics, positive, negative sides.

General parameters of thermal insulation:

- Weight. The insulation should not weigh much, because when mounting it on the structure there should be no weighting.

- Thickness. The thinner the material, the more space is left in the room.

- Low thermal conductivity.

- Moisture permeability. The material should absorb moisture as little as possible.

- Noise isolation. Does not pass sounds from the street.

- Environmentally friendly material. Should not emit harmful substances.

- Easy to install.

Comparing basalt insulation and foil foam, you need to compare their characteristics.

Basalt wool

Produced from rocks of volcanic origin. It does not burn, has good sound insulation performance, and does not lose its qualities over time. It is completely safe for health.

Penofol - application

Produced from polyethylene foam with a porous structure. A layer of foil is glued on top as a heat reflector. This heat-insulating material is several times thinner than basalt wool. In addition, it reflects heat and practically does not absorb it.

Which insulation to choose depends on the budget for the insulation, as well as personal preferences.

How to install insulation with foil for pipes

Shells for insulation of communications are made of foam and mineral wool.

In addition to thermal insulation for floors, horizontal ceilings and walls, there is also insulation with a reflective layer for insulating pipes. These are shells made of expanded polystyrene or mineral wool. The former are lighter and are not afraid of moisture, while the latter can withstand high temperatures, which is appropriate when insulating chimneys. Given the fact that the material is already produced in the form of a pipe, the question of whether to put the insulation with foil outside or inside is not worth it. There is a shell that you put on the pipe and that's it, you won't be able to turn it inside out.

At the same time, there is always a choice when buying, since they are also produced with one (outer) or two (outer and inner) foil layers. Such shells are used for:

- laying of highways through the air;

- laying highways underground;

- laying of highways in unheated rooms;

- insulation of chimneys.

In some cases, they are used for thermal insulation of pipes so that the coolant does not lose its temperature even in heated rooms. For example, in industries where the first and last heat exchangers of one circulation ring are installed at a great distance from each other.

Folgoizol for heat-hydro-sound insulation of various construction objects

It has internal pores filled with air, due to which it has good thermal insulation characteristics. Such insulation is most often used for thermal insulation of bath rooms and bathrooms. The insulation is laid with an overlap of no more than 10 cm, the joints are glued with metallized tape and pressed with a rail, or fixed with staples.

Foil mineral wool Another type of insulation with a metal coating is mineral wool.

It is mainly used for external insulation or for thermal insulation of attic rooms. Glass wool mineral wool, even without a metal layer, has good thermal insulation qualities. The presence of a metal layer on the surface only enhances its effectiveness.