What is polyurethane foam (hard modification)?

Polyurethane foam Is actually a group of materials belonging to the category of plastics, which are made on the basis of polyurethanes. The structure of the corresponding materials contains a significant proportion of cavities filled with air - pores or bubbles. Polyurethane foam was invented in the 1930s. Soon he began to be actively involved in various areas of economic activity.

Polyurethane foam

The "classic" polyurethane foam is most often understood as its solid variety. This material is actively used as an element of thermal insulation in the construction of residential premises. There are modifications of solid polyurethane foam, which are characterized by an operational speed of hardening and can be effectively used to give stability to individual building structures - we are talking about the so-called polyurethane foam.

Cured polyurethane foam has a high degree of chemical and thermal resistance. It is often possible to remove it from the surface on which it is distributed only mechanically. It is necessary to distinguish rigid polyurethane foam from similar materials such as polystyrene, foam latex or cellulose sponge, which have a completely different chemical composition.

The most interesting questions that mattress buyers ask:

1. Is it possible to make a mattress of non-standard sizes?

Yes. But each mattress factory has its own terms and cost of making mattresses of non-standard sizes. A consultant can tell you more details by phone.

2. Why do mattresses of the Ascona factory have a warranty period of up to 10 years, while other factories have a warranty period of 1.5-2 years?

The extended warranty of the Ascona factory covers only defects in the springs, i.e. if the spring bursts or the spring block breaks. Which, with the correct use of the mattress, happens very rarely. "Natural wear of materials" is not covered by Ascona's warranty. The standard warranty period (1.5 years) is enough to identify a defect. Therefore, most manufacturers do not extend the warranty period.

3. Which mattresses are better: spring or springless?

If you prefer firm mattresses, then we would advise you to first of all pay attention to springless mattresses. Magniflex. They have been produced in Italy for over 50 years and surpass domestic spring or springless mattresses in terms of comfort, orthopedicity and durability. In the event that you prefer soft or medium hard mattresses, it is better to consider spring mattresses.

4. Which economical mattress option would you recommend?

There is a series of inexpensive springless mattresses from the Dream Line factory - Dream Roll Eco. They are delivered vacuum packed (rolled into a roll), i.e. they are conveniently transported in a passenger car. Elastic and comfortable. Made of high density polyurethane foam. Much more comfortable than mattresses on the spring block "bonnel", which cost about the same.

5. What is the difference between a block of independent springs (TFK) and a "bonnel" and which is better?

- The number of springs in the TFK block is 2 times more than in a conventional spring block. This increases the comfort and life of the mattress.

- Springs in TFK do not have fasteners to each other and are placed in separate bags made of non-woven material. Thanks to this, the springs do not creak, do not "climb out" and support the body in the correct position.

6.What is the difference between foam rubber and polyurethane foam (PPU), artificial latex, orthopedic foam Orto Foam and Ormafoam, and which is better?

If you figure it out, then nothing. During the Soviet era, polyurethane foam was supplied by the Scandinavian company Porolon, hence the common name "foam rubber". PU foam has different density, elasticity and wear resistance. High-quality polyurethane foam does not contain allergy-causing substances and does not emit dust. According to numerous studies, it does not affect human physiology, which is confirmed by certificates issued by the FS for supervision in the field of consumer protection and human well-being. The durability of this material depends on its density grade and manufacturer. Such and "Ormatek" and some others prefer to call polyurethane foam - Orto Foam and Ormafoam orthopedic foam.

7. What is the difference between latex and polyurethane foam and artificial latex. What's better?

Latex - foamed sap of the Hevea tree. Thanks to its microporous structure, it is more resilient and resilient than standard polyurethane foam. Also, latex is more wear-resistant and can withstand prolonged stress better. The percentage of natural rubber tree sap in the latex used by mattress manufacturers ranges from 10 to 40%. Accordingly, the higher this percentage, the better the quality of latex. Mattress manufacturers prefer not to publish information on the composition of latex. Artificial latex, as experience shows, is called ordinary polyurethane foam.

8. Which mattress to choose for a child?

The standards for a “right” mattress for a child are the same as for an adult. The mattress must conform to the shape of the body. It shouldn't be too hard or soft. If the child weighs less than 50 kg, then the best option would be a mattress with a TFK block of independent springs, felt and 2-3 centimeters of latex. If the child weighs between 50 and 90 kg, then it is worth considering options with TFK springs, felt, 1 cm of coconut coir and 1-2 cm of latex. You can also consider options where polyurethane foam is used instead of latex.

9. Why do you need an orthopedic base, if the mattress is already orthopedic?

The orthopedic base is a metal frame with bent-glued birch lamellas (slats). This design allows you to transfer part of the load from the mattress to the base. This increases the wear resistance of the mattress and improves its orthopedic properties. Plus, when you turn the mattress, the base of the bed ventilates the bottom of the mattress. All mattress manufacturers recommend using either an orthopedic bed base or a rigid base in the form of a sheet of plywood or chipboard, but never place the mattress on a mesh or spring base. Otherwise, your mattress will quickly fail and it cannot be replaced under warranty.

10. What would you recommend an inexpensive orthopedic mattress with a block of independent springs?

Pay attention to the model Classik +15 Hard TFK from the Dream Line factory. This mattress is cheaper than mattresses with similar filling from other factories, while it has all the necessary components: a TFK spring block, thermal felt, polyurethane foam and jacquard fabric.

11. Is coconut coir used in mattresses harmful?

Not. Coconut in children's and adult mattresses is not harmful to health. This fact is confirmed by the sanitary-epidemiological certificate and the conclusion of the German laboratory TUV, indicating the absence of formaldehyde and phenol in coconut.

What is foam rubber?

The material in question is a type of polyurethane foam - in its elastic modification. Significant volumes of foam rubber were imported into our country under the Scandinavian Porolon brand - hence the name of the corresponding product, which is common in the Russian Federation.Foam rubber is a relatively new material. On an industrial scale, it began to be produced in the middle of the 20th century, that is, a little later than the "classic" polyurethane foam.

Foam rubber

The peculiarity of foam rubber is that about 90% of its volume is air. A significant part of this volume can be very quickly replaced by water - if you substitute foam rubber under the stream or immerse it in a container with liquid. The material in question is also characterized by high resistance to deformation.

Elasticity and ability to absorb water make foam rubber one of the most useful materials in everyday life. Sponges are made from it for washing dishes and other purposes. Foam rubber is often used as a filler in the manufacture of furniture. Sometimes it is used as a heater - due to the relatively low through air permeability.

However, the material in question has a number of disadvantages.

First of all, it is worth noting that the production of foam rubber is a very harmful process for the environment, because toxic substances are used within it. Over time, the material in question loses its useful properties - it becomes less elastic, the air layers present in it disappear. Therefore, foam rubber is most often used in those areas where it is not expected to be used too intensively or where frequent replacement of products that are made on the basis of the corresponding material is acceptable.

What are the similarities between orthopedic foam and regular foam rubber

- In the composition. It is polyurethane, which can consist of two or more components, but is ultimately a refined product.

- In the internal structure. Cured polymer foam consists of air cells with elastic walls, similar to soap suds. Bubbles can shrink and expand. Due to this, the product made of polyurethane foam has the ability to push through, change the volume depending on the load.

- Limited service life. All synthetic foams change their properties over time. The polymers of which they are made degrade, and this process cannot be slowed down.

- In the ability to accumulate moisture. The porous structure of the foam leads to the fact that the liquid easily penetrates into the formation and remains in it for a long time. None of the types of modern orthopedic foam is devoid of this disadvantage, although the one produced using the "open cell" technology is better ventilated. A humid environment is an excellent refuge for fungi, dust mites and other unwanted human companions.

- In the release (emission) of toxic substances. Even formulations that have European safety markings emit volatile organic compounds (VOCs) throughout their service life. This is due to the fact that the chemical processes in the finished polyurethane foam do not stop when it leaves the factory. Studies in other countries have shown the emission of VOCs in springless mattresses for children.

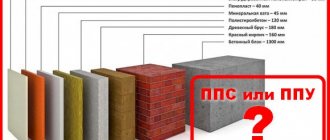

Table

| Polyurethane foam | Foam rubber |

| What do they have in common? | |

| Foam rubber is a soft type of polyurethane foam | |

| What is the difference between them? | |

| Solid, inelastic, has a lower percentage of air pockets in the structure | Soft, elastic, 90% air |

| Used as a building material, insulation | It is used as a material for hygiene items, furniture filler, sometimes as insulation |

Structure

Foam rubber is an elastic polyurethane foam with an open-cell structure. Open cells provide good air and moisture permeability. The elasticity or stiffness of polyurethane foam is achieved by using different types of polyols in the composition. Whether it is polyurethane foam or foam rubber, the general composition of the mixtures for their preparation will be the same, but the specific types of the same component (polyols) provide different characteristics of the stiffness of the material. This is what the flexible polyurethane foam used for upholstery looks like:

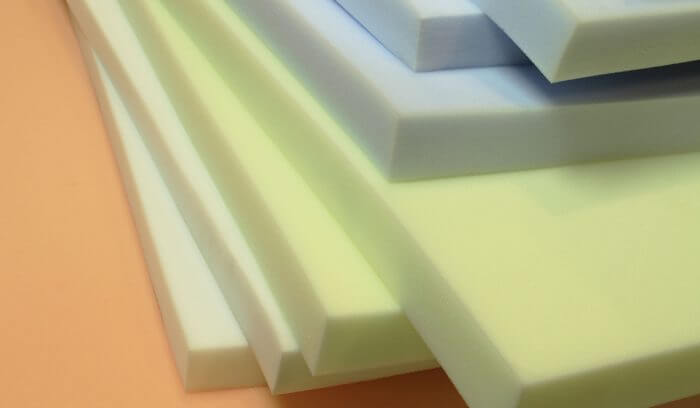

And this is a rigid polyurethane foam, which is used for highly effective thermal insulation:

Advice from a professional In order not to be confused when ordering thermal insulation, remember that polyurethane foam and foam rubber are one and the same thing. It is rigid polyurethane foam that is used for thermal insulation of premises by spraying. Due to the low coefficient of thermal conductivity, PU foam provides the most effective insulation of premises

The conclusion is simple: foam rubber and polyurethane foam are one and the same material, it makes no sense to position them as different heaters and learn how to distinguish polyurethane foam from foam rubber. Rigid polyurethane foam grades with low thermal conductivity are used for insulation, and elastic polyurethane foams have found their application in the furniture industry.

Highly elastic foam brands (HR and HR *).

Highly elastic polyurethane foam differs from the standard one in the form of improved comfort characteristics and high elasticity (the elasticity of some highly elastic polyurethane foam variations is 75%, while standard foam is 60%). Over time, highly elastic foam brands are used more and more in the light industry. They are used to make high-quality orthopedic mattresses, decorative pillows, comfortable furniture (in Europe, the production of highly elastic brands occupies 30% of the total production of polyurethane foam, despite the fact that they are more expensive than other brands). In terms of its quality properties, highly elastic foam rubber can soon completely replace soft and standard polyurethane foam with great success.

Foam mattress or polyurethane foam?

It is no secret that the basis of a polyurethane foam mattress is foam rubber, familiar to everyone. Today, foam rubber remains quite popular, it is often used for the production of furniture and mattresses.

It is interesting, but true: the name "foam rubber" (Porolon) was once a proper name, so was the name of the Scandinavian manufacturing company that supplied this material to the Soviet Union. And the very first samples of polyurethane foam, that is, foam rubber, were obtained in Germany in 1941.

If you have come across negative reviews about the quality of foam rubber for mattresses, then orthopedic products based on polyurethane foam are an excellent confirmation of the implausibility of these facts, because a completely new foam rubber is used for the production of modern mattresses, which is significantly different from what was actively used during the Soviet Union. But I would like to note that even then foam mattresses were famous for their durability and ability to withstand heavy loads.

Separately, it is worth mentioning the production technology of polyurethane foam mattresses. To create the material, a molding method is used: foamed polyurethane foam is poured into molds, and after special processing, cellular material is obtained, which ideally retains its initial shape in almost any conditions and does not lend itself to deformation. In the production of the material, components such as isocyanate, polyol, catalysts and foam stabilizers, and water are used.

Thus, a mattress made of polyurethane foam or polyurethane foam (foam rubber) is a product based on almost uniform thin-walled cells filled with air. It is the number of cells that determines the rigidity of the mattress, as well as its service life, permanent deformation and recoverability.

Today, for the production of orthopedic products, such types of polyurethane foam are used as:

-Soft foam rubber. As a rule, it is the basis for "upholstered" furniture, that is, interior items, sleep and relaxation of increased comfort. As for the density of soft foam rubber, it ranges from 8 to 10 kg / m3. It is used as the sole or additional material for sofas, mattresses, seats.

Soft and super soft foam brands (HS).

The following models are distinguished among the popular brands of soft polyurethane foam: HS 2520, HS 3030, HS 3530. Super soft foam is PU foam with a compression stress below 1.5 kPa. Varieties of soft and super-soft foam rubber are often used to form backs in upholstered furniture and flooring material in anatomical mattresses. And yet, HS 3530 foam rubber is independently used for the manufacture of seats, and super-soft brands are used for the production of covers for polyurethane foam pillows.